Ever heard of a Fatigue Risk Management System (FRMS)? It’s a structured way for companies to find, track, and tackle the risks that pop up when workers are tired. This isn't about just telling people to get more sleep; it's a practical, operational tool that plugs directly into your business.

In high-stakes industries like construction and manufacturing, an FRMS gets to the root of the problem. It helps you identify and manage the real causes of fatigue, things like tough shift schedules, heavy workloads, and even the work environment itself.

What Exactly Is a Fatigue Risk Management System?

A proper FRMS goes way beyond just counting the hours someone has worked. Instead, it gives you a data-driven framework to actively monitor, assess, and control fatigue-related hazards before they cause trouble. Think of it as a proactive system designed to stop incidents before they happen, keeping your crew alert and operations running smoothly.

It’s a bit like preventative maintenance for your workforce. You service your machinery to prevent breakdowns, right? An FRMS does the same for human performance, helping you avoid costly errors and accidents. It treats fatigue not as an individual’s personal problem, but as a predictable and manageable business risk.

This kind of system is built on the understanding that fatigue isn't simple. It’s influenced by a whole group of factors, including:

- Work Schedules: The timing, length, and sequence of shifts.

- Workload: The physical and mental demands of the job.

- Commute Times: How long it takes for your workers to get to and from the site.

- Environmental Conditions: Things like extreme heat, constant noise, or poor lighting.

By looking at all these pieces together, you get a much clearer picture of your company's fatigue risks and can start taking targeted, effective action.

Moving Beyond Old-School Methods

Traditionally, managing workplace tiredness was all about sticking to prescribed hours-of-service rules. While those rules are a decent starting point, they just don't capture the messy reality of human fatigue. A modern FRMS is different. It’s performance-based, meaning it focuses on actual alertness levels rather than just the hours logged on a timesheet.

This table breaks down the key differences between the old way and the new.

FRMS vs Traditional Approaches to Fatigue

| Aspect | Traditional Approach (Prescriptive) | FRMS Approach (Performance-Based) |

|---|---|---|

| Focus | Compliance with rigid hours-of-service rules. | Managing actual fatigue levels and performance. |

| Approach | Reactive, often responds after an incident occurs. | Proactive, aims to prevent incidents from happening. |

| Flexibility | "One-size-fits-all" rules for everyone. | Tailored to specific operational risks and individual needs. |

| Data Use | Primarily tracks hours worked. | Uses data on schedules, workload, and performance to predict risk. |

| Responsibility | Seen mainly as an individual worker's responsibility. | Shared responsibility between the organisation and the individual. |

As you can see, an FRMS is a far more sophisticated and effective tool for keeping people safe and productive.

A true fatigue risk management system is about ensuring fatigue is managed in the same structured, evidence-driven way as any other safety hazard. It’s a shift from simply reacting to incidents to proactively preventing them.

A Systemic Approach to a Complex Problem

Fatigue is a massive issue in Australian workplaces, impacting both health and safety. Research from Safe Work Australia shows that the most effective strategies for managing fatigue are organisational. It’s about fixing the system, not just focusing on the individual.

The review actually identified 28 different strategies that work at this level, which really drives home the point: a comprehensive, system-wide approach is essential.

This means a successful FRMS works fatigue considerations into daily operations, from project planning and scheduling all the way to incident investigations and reviews. It stops being a separate "safety thing" and becomes part of how the business runs, protecting both your people and your bottom line.

Why a Fatigue Risk Management System Is Good for Business

Thinking of a fatigue risk management system as just another compliance box to tick is a massive missed opportunity. The truth is, a solid FRMS is a powerful business tool that directly supports your operational efficiency and protects your bottom line. It’s about moving beyond just preventing major accidents to tackling the quiet, everyday costs of a tired workforce.

When workers are fatigued, they don’t just become safety risks; their whole performance takes a hit. Picture a heavy machinery operator on a construction site. A tired operator moves slower, their actions are less precise, and they’re far more likely to make a mistake that leads to expensive rework, damaged equipment, or wasted materials.

These little inefficiencies snowball. A single miscalculation on a factory floor can spoil an entire batch of product. One delayed task on a building site can throw the whole project schedule out of whack. An FRMS helps you get a handle on these operational risks by treating fatigue as a predictable, and controllable, factor in your business.

The Real Costs of Unmanaged Fatigue

The financial sting of fatigue isn't always obvious. It often hides in plain sight, buried in your operational metrics. But when you start looking, you’ll see both direct and indirect costs piling up.

Here’s where it really hurts:

- Productivity Takes a Nosedive: Studies have shown that working while fatigued can impair someone's performance just as much as working while intoxicated. That translates directly to slower work, fewer units produced, and less progress per shift.

- Errors and Rework Skyrocket: Tired workers make more mistakes. In manufacturing, that could mean defects that force you to scrap an entire run. On a construction project, it might be an incorrectly measured cut that holds up the next phase.

- Projects Get Delayed: When small errors and productivity dips happen across a whole team, the combined effect can lead to major project delays, and that can trigger some painful contractual penalties.

- Good People Leave: A constantly exhausted workforce is a stressed and unhappy one. This is a fast track to burnout and higher staff turnover, which saddles you with the hefty costs of recruiting, hiring, and training new people.

By putting a fatigue risk management system in place, you’re making a direct investment in operational stability. It’s all about building a more resilient, predictable, and productive team.

A fatigue risk management system isn't just about managing safety; it's about managing performance. When you address the root causes of fatigue, you create a far more efficient and reliable operation.

Protecting Your Most Valuable Asset

Beyond the numbers and schedules, managing fatigue is simply crucial for the long-term health and wellbeing of your employees. When your team is well-rested and alert, they're more engaged, more focused, and better able to handle the daily grind. This has a direct impact on the quality of their work and their loyalty to the company.

Ignoring fatigue has consequences that stretch well beyond the worksite. According to Safe Work Australia, persistent fatigue seriously increases the risk of mental and physical health problems. For instance, consistently working long hours (over 35-40 hours a week) can raise the risk of stroke by 35% and death from ischemic heart disease by 17%. You can learn more about these findings by reading the full research about fatigue risks.

This just goes to show that being proactive about fatigue isn’t just good for business; it's essential for keeping your workforce healthy and sustainable. A proper FRMS helps you meet your duty of care to your people while also protecting your operational performance. It’s a non-negotiable part of modern business management.

The Core Components of an Effective FRMS

A fatigue risk management system isn’t just a single document or a piece of software you can buy off the shelf. Think of it as a complete operational framework with several interconnected parts, all working together to manage the risk of tiredness in your workplace. If you picture it as a machine, each component is a vital gear that keeps the entire system running smoothly.

If one part is missing or poorly designed, the whole system grinds to a halt or becomes dangerously ineffective. Let's break down these core components into practical, understandable pieces.

A Clear Fatigue Management Policy

This is the foundation of your entire system. A fatigue management policy is a formal document that states your organisation's commitment to managing fatigue. But it’s not just a piece of paper to be filed away; it’s a clear signal to everyone, from the CEO to the newest apprentice, that you take this issue seriously.

This policy should clearly outline the shared responsibilities. It spells out what the company will do, like providing fair schedules and a safe work environment, and what is expected of workers, such as reporting fatigue concerns without fear of blame. It sets the ground rules for everything that follows.

Your fatigue policy acts as the blueprint for your FRMS. It defines the goals, assigns responsibilities, and provides the authority needed to put controls in place and make them stick.

Identifying Fatigue Hazards

You can't manage a risk you haven't seen. This component is all about actively looking for the workplace conditions and factors that are likely to cause fatigue. Think of it like a pre-start check on a piece of heavy equipment; you’re systematically searching for potential problems before they cause a breakdown.

In construction and manufacturing, you'll find common fatigue hazards everywhere, including:

- Work Scheduling: Long shifts (over 10 hours), ridiculously early starts, night work, and unpredictable overtime all take their toll.

- Workload: Physically demanding tasks, mind-numbingly repetitive work, or jobs requiring high levels of concentration for long periods are classic culprits.

- Environmental Factors: Working in extreme temperatures (both hot and cold), constant loud noise, and poor lighting can drain energy fast.

- Commuting: Long travel times to and from remote sites chip away at potential rest periods, creating a risk before the shift even begins.

This process isn't a desk job. It involves actually talking to your workers, reviewing shift rosters, and walking the floor to see the work in action.

Risk Assessment and Control Measures

Once you’ve got your list of hazards, the next step is to figure out how risky they actually are. A mentally draining task might be a low risk at the start of a day shift but becomes a high-risk gamble ten hours into a night shift. The whole point is to prioritise your efforts on the biggest problems first.

Following the assessment, you must implement control measures. These are the practical, real-world actions you take to reduce the risk. This isn't about eliminating every single hazard, which is often impossible, but about putting sensible controls in place to manage them. To get a better grasp of this, you can learn more about how to select and apply different types of control measures for risks in our detailed guide.

This could include things like:

- Smarter Scheduling: Designing rosters that actually allow for adequate rest and recovery between shifts.

- Workload Management: Ensuring tasks are distributed fairly and that high-stress jobs are rotated among team members to give people a break.

- Improved Work Environment: Providing designated rest areas or improving lighting on night shifts to reduce strain.

Training and Education

An FRMS is useless if people don't understand it or, even worse, don't know it exists. This part of the system is all about training everyone. Managers and supervisors need to know how to spot the signs of fatigue, understand the company’s policy, and effectively implement the control measures.

Workers need training to understand what fatigue is, how it affects their performance, and what their responsibilities are. A key part of this is making sure they know how to report when they feel unfit for duty due to tiredness, and that they can do so safely.

Incident Investigation and Continuous Review

Even with the best system in the world, incidents can still happen. When they do, it's crucial to have a process for investigating whether fatigue was a contributing factor. This isn't about blaming the individual; it's about digging deep to find out if a weakness in the system allowed the incident to occur.

Finally, a fatigue risk management system is not a "set and forget" solution. It requires continuous review. You need to regularly check if your controls are working, gather honest feedback from your team, and analyse data from incident reports and fatigue assessments. This allows you to make adjustments and improve the system over time, ensuring it remains effective as your operations change.

How to Build Your Fatigue Risk Management System

Creating a fatigue risk management system from scratch can feel like a massive undertaking, but it doesn’t have to be. The trick is to start small, focus on practical steps you can take right now, and build momentum. Think of it less like building a skyscraper overnight and more like laying a solid foundation, one brick at a time. The goal here is progress, not perfection on day one.

This section breaks down the process into a straightforward, step-by-step action plan to get your FRMS off the ground. It’s designed for the real world, especially for busy construction and manufacturing environments.

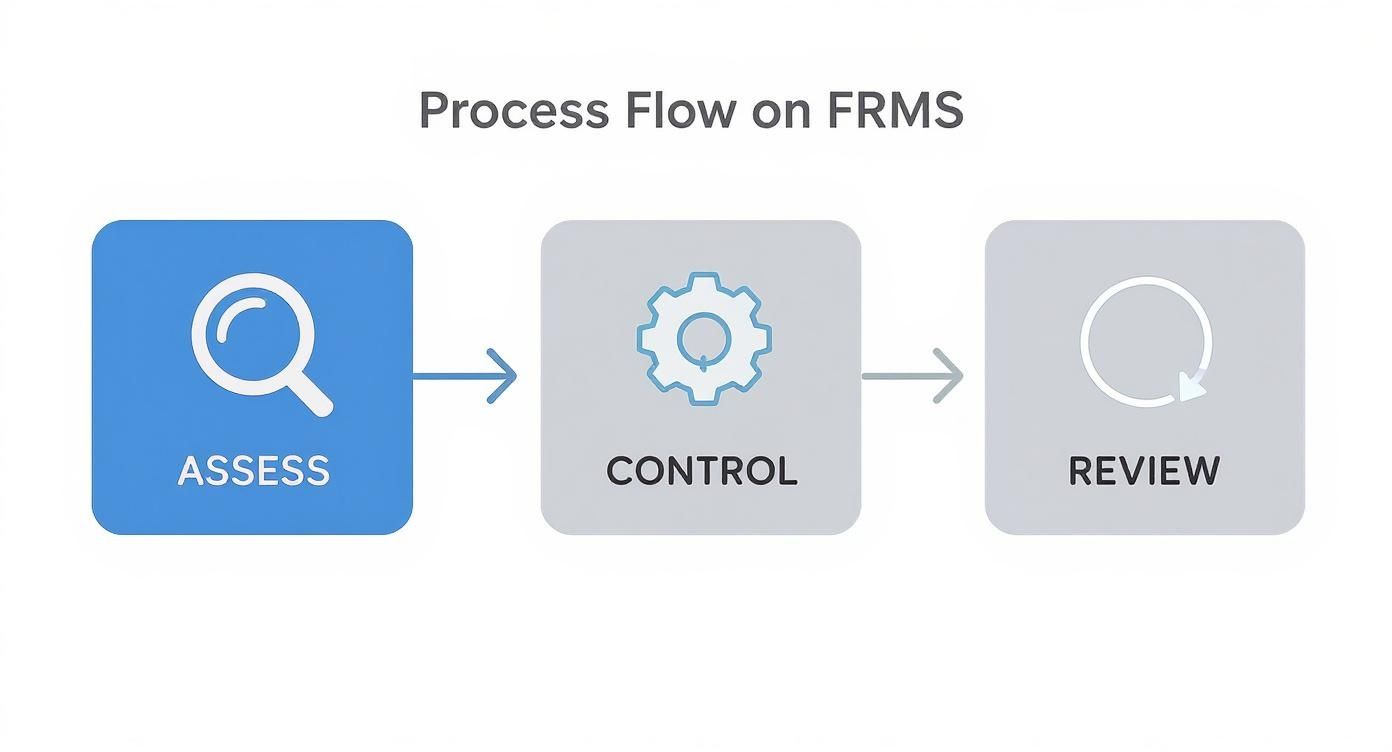

This simple process flow shows the core cycle of any good fatigue risk management system.

As you can see, managing fatigue isn't a "set and forget" task. It's a continuous loop of assessing risks, putting controls in place, and then checking to see if they’re actually working.

Step 1: Get Leadership Commitment

Before you even think about policies or procedures, you need the people in charge on your side. An effective FRMS needs resources, time, and a clear, top-down message that managing fatigue is a non-negotiable priority.

Go to your leadership with a simple business case. Explain how fatigue isn't just a safety issue, it hits productivity, quality, and project timelines hard. When they understand that an FRMS protects the bottom line, you'll get the backing you need to make a real difference. Without it, you're just creating a paper-based system that will gather dust.

Step 2: Form a Small Implementation Team

You don't need a huge committee for this. Just pull together a small, focused team to spearhead the effort. A good mix would be a manager or supervisor, a representative from the workforce (like a trusted leading hand or machine operator), and someone from your H&S team.

This blend gives you both operational oversight and crucial on-the-ground insights. Let's be honest, the people doing the work usually have the best feel for where the real fatigue risks are hiding.

Step 3: Identify Your Biggest Fatigue Risks

Okay, now it's time to find your hotspots. Don't try to solve every problem at once. Just focus on the top two or three issues causing the most grief.

Start by asking some practical questions:

- Which shifts are the absolute toughest? (Think night shifts or those quick turnaround rosters).

- What specific jobs are the most draining, either mentally or physically?

- Are long commutes to remote sites eating into your workers' rest time?

- Is overtime getting out of hand for certain roles or teams?

Dig into your shift rosters, have a chat with the crew during toolbox talks, and review any incident reports where tiredness might have been a factor. The goal is to pinpoint your highest-priority hazards so you can tackle them first.

Step 4: Implement Basic Controls

Once you know your biggest risks, pick a few simple, practical controls to put in place. Again, start small and aim for quick wins.

For example, if you realise that back-to-back long shifts are a major problem, your first control could be a simple rule guaranteeing at least 10 hours of rest between shifts. If high-concentration tasks are the issue, maybe you could introduce a job rotation system to give people a mental break.

The key is that the controls should be straightforward, easy to explain, and directly linked to the specific risks you found. This is an approach that has proven effective in Australian industries for decades. In fact, the development of the FRMS concept in Australia was heavily influenced by early trials like the Queensland Fatigue Management Programme, which began back in 1994. It showed that these systems could genuinely reduce driver fatigue and improve scheduling. You can read more about these foundational fatigue management programs to see how far back this goes.

A fatigue risk management system is not a one-off project; it’s an ongoing part of your operational management. Just like any other aspect of your business, it needs regular attention to stay effective.

Step 5: Train Your People

A new system is useless if no one understands their part in it. Run short, sharp training sessions for both managers and workers.

- For Managers & Supervisors: Train them on how to spot the signs of fatigue, how to have a supportive chat with a worker who's struggling, and exactly how the new controls work.

- For Workers: Explain the real-world risks of fatigue, what the new rules are, and how they can report any concerns. Make it crystal clear that reporting fatigue is about preventing accidents, not about getting anyone in trouble.

Step 6: Set Up a Simple Reporting Process

Your team needs a dead-simple way to raise concerns about fatigue, whether it's for themselves or a mate. This could be as easy as speaking directly to their supervisor or using an existing hazard reporting channel you already have.

The process absolutely must be confidential and non-punitive. If people are worried they'll be blamed or lose a shift for speaking up, they’ll stay quiet, and your entire system will fall apart. This reporting process is a critical part of a broader health and safety management system that depends on open and honest communication.

Step 7: Review and Adjust

After a few months, get your implementation team back together to see how things are tracking. Are the controls actually working? Has anything improved? What’s the feedback from the crew on the floor?

Use that feedback to make smart adjustments. Maybe one control isn't as practical as you thought, or perhaps a new risk has popped up. An FRMS should be a living system that you constantly adapt and refine over time.

Practical Tools and Controls to Manage Fatigue

Once you've got the structure of your FRMS sorted, it's time to bring it to life with practical, real-world tools and controls. This is where the theory hits the factory floor.

Effective controls aren't about reinventing the wheel. They are simple, direct measures that tackle the specific fatigue hazards you’ve already identified. It's about moving from knowing there's a problem to actively fixing it with straightforward actions your team can get behind immediately.

Optimising Shift Schedules and Workload

Your shift roster is probably the single most powerful tool you have for managing fatigue. A poorly designed schedule is a guaranteed recipe for burnout, but a few thoughtful tweaks can turn it into your best defence. This isn't just about limiting hours; it’s about building rosters that give people a genuine chance to recover.

Here are a few things to consider:

- Implement Minimum Rest Periods: Make a hard rule of at least 10-12 hours off between shifts. No exceptions. This gives workers a proper opportunity to rest and recharge.

- Limit Consecutive Night Shifts: Nobody can work nights indefinitely. Cap consecutive night shifts at three or four before scheduling a proper break.

- Rotate Demanding Tasks: For those mentally taxing or physically draining jobs, rotate people through them. Don't let one person carry that load for an entire shift.

- Plan for Overtime: Overtime happens, but it shouldn't be a constant scramble. Plan for it where you can and make sure it’s shared around fairly, not dumped on the same few people every time.

Using Environmental and Administrative Controls

The environment your team works in makes a huge difference to their fatigue levels. Simple, low-cost changes to the workplace can seriously reduce the physical and mental strain, helping everyone stay alert.

At the same time, administrative controls, basically, the rules and procedures you put in place, create clear guidelines for managing fatigue risk. These are especially critical for improving operational safety in environments with heavy machinery, where an operator's alertness is non-negotiable.

Here’s what that looks like in practice:

- Improve Lighting: For night shifts or dim indoor areas, switch to bright, cool-toned lighting. It’s a simple trick that helps stave off drowsiness.

- Create Designated Rest Areas: Give your team a quiet, comfortable space away from the noise where they can actually switch off during their breaks.

- Implement a Two-Person Rule: For critical tasks late in a shift, get two people to do it together. It’s an easy way to have a second set of eyes for cross-checking.

- Encourage Self-Assessment: Give your crew the tools to check in with themselves. A confidential fatigue self-assessment tool lets them make smart decisions about their own fitness for work.

A Quick-Reference Hazard Checklist

To tie this all together, here's a simple table matching common fatigue hazards with practical controls you can put in place. Think of it as a handy cheat sheet for supervisors to use during pre-start meetings or safety walks.

Common Fatigue Hazards and Practical Controls

| Fatigue Hazard | Example Control Measure 1 | Example Control Measure 2 |

|---|---|---|

| Long Commute Times | Offer flexible start/finish times where possible to avoid peak traffic. | Encourage carpooling to allow passengers to rest during the journey. |

| High Physical Workload | Provide mechanical aids (e.g., hoists, trolleys) to reduce manual handling. | Schedule the most physically demanding tasks for the start of the shift. |

| Monotonous, Repetitive Tasks | Introduce short, frequent "micro-breaks" to break up the monotony. | Rotate staff through different tasks to keep them more engaged. |

| Extreme Heat or Cold | Provide climate-controlled break areas for recovery. | Adjust work schedules to avoid the hottest or coldest parts of the day. |

This isn't an exhaustive list, but it's a solid starting point you can adapt for your own workplace.

The best controls are often the simplest ones. An effective fatigue risk management system relies on practical, consistent actions, not on complex, expensive technology that nobody uses.

Ultimately, the goal is to choose tools and controls that fit your operation. By focusing on tangible actions around schedules, workload, and the work environment, you can build a robust system that genuinely reduces risk and supports a safer, more productive team.

Common FRMS Mistakes and How to Avoid Them

Implementing a fatigue risk management system is a solid move, but it's easy to get tripped up by some common mistakes that can make it completely ineffective. Knowing these pitfalls ahead of time helps you build a system that actually works in the real world, instead of just looking good on paper.

The biggest mistake? Creating a system that exists only in a binder on a shelf. This "paper-only" FRMS has all the detailed policies you could ask for, but nobody on the floor knows about them or uses them. It's just a compliance exercise that does nothing to actually manage fatigue.

Another classic failure is turning fatigue into a blame game. When an incident happens, the focus immediately snaps to the individual worker's choices, like their bedtime or diet. This approach completely misses the point of a system, which is to identify and fix organisational issues, like poor scheduling or excessive workloads, that set people up to fail in the first place.

Creating a Paper-Only System

A fatigue risk management system that isn't worked into daily operations is basically useless. It just becomes another administrative burden instead of a practical tool for keeping people safe and productive.

The solution is to embed fatigue checks into the routines you already have. Don't create new meetings; just piggyback on the ones you've already got.

- Toolbox Talks: Kick off the day with a quick, two-minute chat about fatigue. Ask simple questions like, "Anyone dealing with a long commute?" or "How are the night shift guys feeling after that run of hot weather?"

- Pre-Start Checklists: Add a simple fatigue check-in to your existing pre-start equipment checklists. It normalises the conversation and makes it a routine part of getting the job done.

- Shift Handovers: Make fatigue a standard point of discussion during shift handovers. The outgoing supervisor can flag any concerns for the incoming team, so there are no surprises.

By working these small actions into your existing workflows, the FRMS becomes a living, breathing part of your operation, not just a document gathering dust.

Blaming Individuals Instead of the System

When a worker makes a fatigue-related error, the easy route is to point the finger at them for being tired. But a genuine FRMS looks deeper. It asks why the worker was tired. Was it because of a last-minute roster change, sustained overtime, or a physically draining task with no breaks?

To sidestep this mistake, you need to shift the focus from individual fault to a proper systemic analysis.

When investigating an incident, your first question shouldn't be "What was the worker doing wrong?" It should be "What part of our system allowed this to happen?" This simple change in perspective is the key to building a system that actually prevents future incidents.

This approach is also critical from a regulatory standpoint. Authorities expect businesses to manage systemic risks, not just discipline individuals. For example, between October 2020 and January 2023, WorkSafe ACT issued four improvement notices for failures in managing fatigue risks. This shows that regulators are focused on the system, not just the individual. You can read more about these regulatory actions and data on fatigue.

Misunderstanding Technology and Data

Plenty of companies invest in fatigue-monitoring software or wearable devices, expecting a silver-bullet solution. But these tools are only as good as the system they support. A common mistake is to collect mountains of data without a clue how to interpret it or what actions to take based on the results.

The fix is to treat technology as a support tool, not the entire system. Before you invest in any tech, ask yourself:

- What specific problem are we actually trying to solve with this tool?

- Who is going to be responsible for analysing the data?

- What specific actions will we take based on the alerts or reports?

Technology can be great at helping to identify risks, but it can't fix a bad roster or an unrealistic workload. The human element of management and decision-making is still the most important part of any effective fatigue risk management system.

Your FRMS Questions, Answered

Even with the best intentions, rolling out a fatigue risk management system can bring up a few questions. Let's tackle some of the most common ones that come up for managers and business owners.

Is an FRMS a legal requirement in Australia?

While you might not find a law that explicitly says "you must have a system called an FRMS" for every single industry, the legal responsibility is crystal clear. Under Australia's Work Health and Safety (WHS) laws, every employer has a primary duty of care to manage risks. Fatigue is absolutely one of those risks.

Think of it this way: a documented FRMS is the most straightforward way to prove you’re taking that duty of care seriously. And for certain high-risk industries, like heavy vehicle transport, the rules around managing fatigue are much more specific and prescriptive.

Can’t we just get our workers to tell us when they’re tired?

It’s a common approach, but it’s one of the biggest mistakes a business can make. Encouraging your team to speak up about fatigue is a vital piece of the puzzle, but relying on it alone is a recipe for disaster. Why? Because severe fatigue clouds your judgement.

Often, the person who is dangerously tired is the last one to recognise it. A proper fatigue risk management system doesn't wait for someone to put their hand up. It proactively looks at schedules, workloads, and other factors to get ahead of the risk before someone is already past their limit.

An effective FRMS doesn't just ask, "Are you tired?" It asks, "Are our work arrangements creating a situation where fatigue is inevitable?" This shifts the focus from individual feelings to organisational responsibility.

How is an FRMS different from just managing work hours?

Tracking hours is a start, but it’s like trying to understand a whole movie by only looking at one scene. It misses the bigger picture. An FRMS goes so much deeper. It’s not just about the quantity of work, but the quality of the rest in between.

A real FRMS looks at the whole context:

- When is the work happening? A night shift is always going to be more draining than a day shift.

- What kind of work is it? A mentally demanding task is different from a physically repetitive one.

- What about breaks? It considers the small pauses within a shift, not just the time off between them.

Ultimately, an FRMS is a complete framework for managing the total risk. It’s a world away from simply checking a timesheet.

Ready to stop managing fatigue with spreadsheets and paperwork? Safety Space gives you a single, easy-to-use platform to track hazards, manage schedules, and keep your team safe and productive. See how it works with a free demo and H&S consultation.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.