What exactly is health safety software?

It’s a digital toolkit built to handle all your workplace safety jobs in one place. Forget the mountains of paperwork, the endless binders, and those spreadsheets that crash every time you try to sort them. This software acts as a central command centre for everything from incident reports and site inspections to tracking compliance.

What Health Safety Software Actually Does

This image shows how it works in the real world. A supervisor on a construction site, tablet in hand, isn't just looking busy. They're logging safety data instantly. No more trekking back to the office with a messy clipboard. Information is captured and shared on the spot, making the whole process quicker and far more accurate.

Moving Past Paper and Spreadsheets

For too long, industries like construction and manufacturing have been bogged down by paper forms and convoluted spreadsheets. We've all been there. It's slow, mistakes are common, and spotting a worrying trend is next to impossible. A single lost inspection form or a misfiled incident report can have massive consequences.

Health safety software fixes this by digitising the entire workflow. Suddenly, all that critical safety information lives in one organised, accessible hub. Everyone from the site supervisor to the CEO can see what’s going on. This isn't just a tech upgrade; it’s about making safety management more reliable and proactive.

The shift is happening fast. The Australian digital health software market is predicted to hit USD 28.6 billion by 2033, largely because cloud-based platforms are making it so much easier for businesses to keep up with their regulatory obligations.

From Paperwork to Platform: A Quick Comparison

To really grasp the difference, it helps to see a side-by-side comparison. The table below breaks down a few common safety tasks, showing just how much things change when you ditch the old manual methods.

| Safety Task | Traditional Method (Paper & Spreadsheets) | Health Safety Software Method |

|---|---|---|

| Incident Reporting | A worker fills out a paper form, which someone then has to manually type into a spreadsheet. | A worker reports the incident directly from a mobile app, instantly notifying managers. |

| Site Inspections | A supervisor walks the site with a clipboard, ticking boxes and taking separate photos to match up later. | A supervisor completes a digital checklist on a tablet, attaching photos directly to specific items. |

| Corrective Actions | A manager emails a task to a team member, with no easy way to track if or when it gets done. | A corrective action is assigned right in the system, complete with deadlines and automatic reminders. |

| Compliance Tracking | Someone manually checks a master spreadsheet to see if training certificates are still valid. | The system automatically tracks expiry dates and sends out alerts when renewals are due. |

As you can see, moving to a digital system doesn't just organise your safety info. It makes it actionable.

This principle holds true even in highly specialised fields. For example, looking at how drone compliance software can simplify regulations and ensure safety by automating complex checks shows the power of a centralised system. By having all your data in one place, you can immediately spot recurring issues or see which sites have overdue actions, letting you get ahead of problems before they escalate.

Core Features Every Business Really Needs

When you first start exploring health and safety software, the long lists of features can be pretty overwhelming. Platform after platform will throw dozens of functions at you, but only a handful are truly essential for the day-to-day work in industries like construction and manufacturing.

Let's cut through the sales pitches and focus on the non-negotiable tools you'll actually rely on. These core features are the workhorses that replace the most time-consuming, error-prone parts of your current safety process. Think of them as the foundation for a more organised, responsive safety system.

It's no surprise that adoption is growing so quickly across Australia. In high-risk sectors, more than 80% of companies with OHS software are using incident reporting modules to get on top of hazards. Cloud-based platforms are dominant, making up over 60% of deployments because they give teams real-time access from anywhere. By automating compliance, Australian manufacturers have managed to cut incident rates by up to 30%. You can look into the data on the Australian OHS software market to see these trends for yourself.

Instant Incident and Hazard Reporting

If there’s one feature that’s absolutely critical, it’s the ability to capture incidents and hazards the moment they happen. The old way of filling out a paper form back in the site office hours later is just too slow. Crucial details get forgotten.

With a modern system, that power is in the hands of your workers on the ground. A factory floor worker spots an oil spill, pulls out their phone, opens an app, and logs the hazard in less than a minute. They can even snap a photo for proof. This instantly notifies the right supervisor, who can assign a cleanup task without ever leaving their desk.

This isn't just about being faster; it's about being more accurate. The details are fresh, the evidence is visual, and nothing gets lost in a stack of paperwork. You get a clean, time-stamped record of what happened, who was told, and what was done about it.

Digital Risk Assessments and Method Statements

Managing risk is the core of workplace safety, but creating, distributing, and updating Safe Work Method Statements (SWMS) or other risk assessments can be a logistical nightmare. Health and safety software solves this by giving you a central library for all these crucial documents.

Imagine you need to update a risk assessment for a piece of machinery. Instead of printing and handing out new copies to everyone, you just update the master document in the software. The system then automatically notifies all relevant team members that a new version is live and can even require them to sign off digitally, confirming they’ve read it.

This digital approach ensures everyone is always working from the most current information. It removes the risk of someone using an old, outdated procedure on-site, which is a common cause of incidents.

Mobile Safety Inspections and Audits

Regular inspections are fundamental to keeping a worksite safe, but clipboards and paper checklists are slow and clunky. Digital inspections completely change this process.

A site supervisor can walk through a construction zone with a tablet, tapping through a pre-built digital checklist for a pre-start check. When they spot an issue, like a damaged guardrail, they can:

- Flag the item right there in the checklist.

- Take a photo of the damage and attach it instantly.

- Assign a corrective action to the maintenance team with a clear deadline.

This isn’t just about replacing paper. It’s about creating a live, actionable record of your site’s condition that you can track from start to finish. The consistency and clarity you get from a simple, mobile-friendly form means data is captured properly, every single time.

Automated Compliance and Training Management

Finally, keeping track of compliance from equipment maintenance schedules to employee training certificates is a massive administrative headache. Good health safety software automates it all.

The system can store every employee's certifications and automatically send alerts to both the worker and their manager 60, 30, and 7 days before a ticket or qualification is due to expire. This proactive nudge prevents those heart-stopping moments when you realise someone is operating machinery with an expired licence, protecting both the individual and the business from serious risk.

How AI Is Changing Safety Management

Let's cut through the hype around Artificial Intelligence (AI). When it comes to safety management, it’s not about robots taking over the worksite. It's much more practical. It’s about using smart software to finally make sense of all the safety data your business already has piled up.

Think of it as having a super-powered data analyst who never sleeps. AI can go through years of incident reports, inspection notes, and near-miss logs to spot subtle patterns that even a seasoned pro might miss. This is the key to shifting from reacting to incidents to actually getting ahead of them.

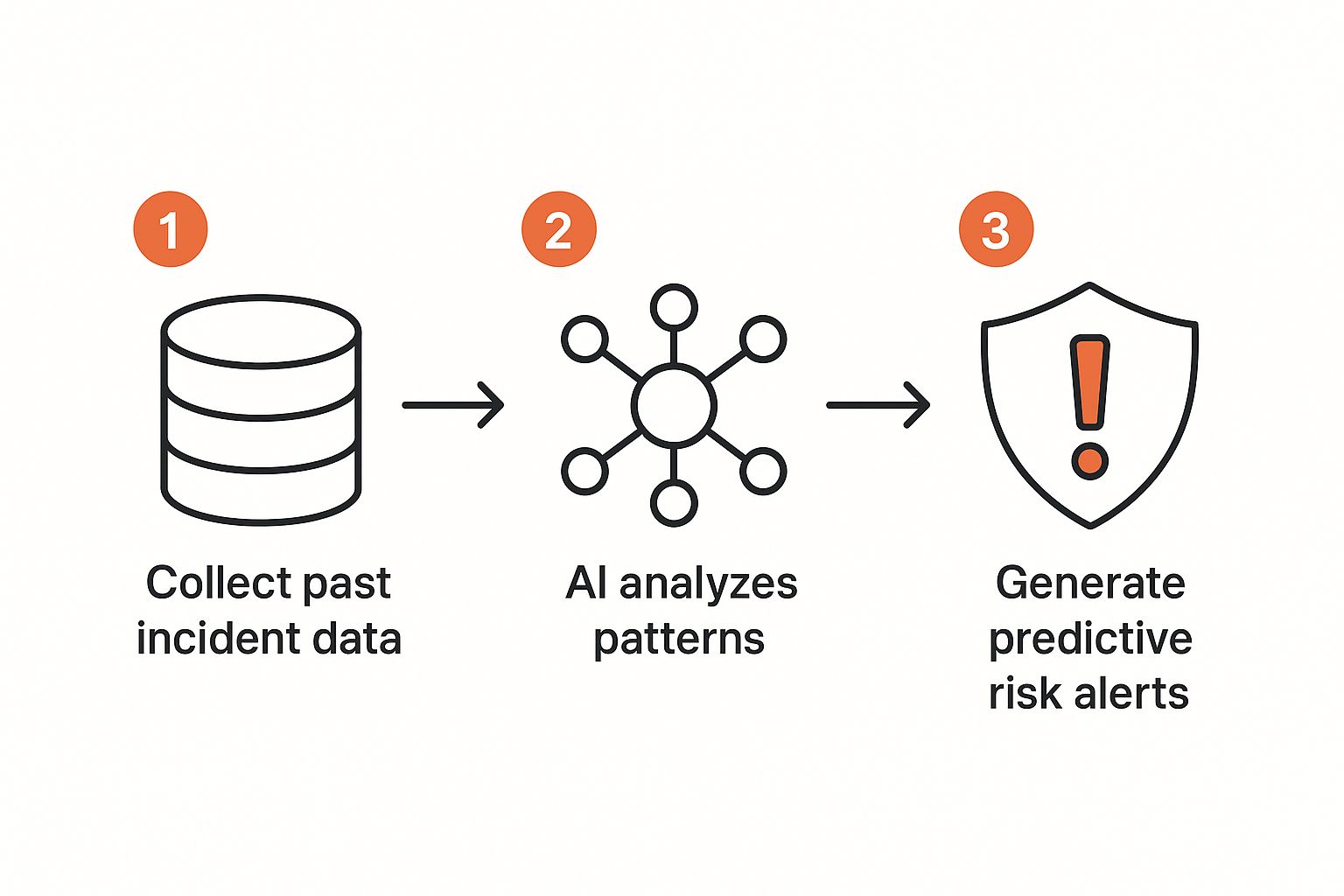

Finding Risks Before They Become Incidents

One of the biggest game-changers AI brings to health safety software is its ability to predict where risks are hiding. By analysing all your historical data, the software can forecast where your next incident is most likely to happen. This isn’t guesswork; it’s a data-driven heads-up.

For instance, an AI might go through your records and flag that a specific machine on the night shift is involved in a high number of near misses, but only during the winter months. That’s a highly specific insight you can act on immediately.

Armed with that knowledge, you could:

- Schedule extra maintenance for that machine before winter kicks in.

- Run refresher training for the night shift team, focusing on cold-weather operations.

- Update your risk assessment with new controls for that specific scenario.

This kind of targeted action is much more effective than sending out another generic safety memo. It helps you focus your time, money, and energy on the areas with the highest measurable risk, preventing incidents before they have a chance to occur.

Automating the Burden of Reporting

Any safety manager will tell you how much time gets eaten up by paperwork and admin. Compiling monthly reports, prepping for audits, or pulling together compliance data often means hours spent wrestling with different spreadsheets and documents. It's a grind.

AI-powered tools can take most of that work off your plate. You can tell the AI to generate a monthly incident summary, complete with trend analysis and charts, and have it ready in seconds. It can also boil down complex safety data into a simple, visual dashboard that’s perfect for management meetings.

This gives your leadership team a clear, immediate view of where attention needs to go, without anyone having to dig through raw data.

The real win here is time. By automating routine reporting, AI frees up your safety professionals to do what they do best: being out on the floor, coaching teams, and actively improving workplace safety.

As AI gets further integrated into workplace safety, these capabilities will become the norm. To see where this is all heading, you can learn more about how AI is revolutionising workplace safety in our detailed guide. The focus will always be on tangible results that make a real difference, like driving down incident rates and giving your team back their most valuable resource, time.

A Plan for Choosing and Implementing Your Software

Picking the right health safety software is a big decision. But how you roll it out is where the rubber really meets the road. A rushed or clunky implementation can kill adoption rates, leaving your team frustrated and your investment wasted. A clear, practical plan is the difference between success and a very expensive headache.

Breaking the process down into four distinct stages keeps things manageable and makes sure you don't miss anything critical. This isn't just about buying a new program; it's about weaving a new tool into the fabric of your daily operations. The real goal is getting your team on board from day one by making the whole process feel logical and straightforward.

Stage 1: Define Your Specific Needs

Before you even think about watching a single demo, you need to be honest about the problems you're trying to solve. What are the biggest safety admin headaches causing you grief right now? Is it the endless chase for incident reports, wrestling with SWMS, or just trying to keep track of who’s trained in what?

Go and talk to the people on the ground, the ones who will actually be using this thing. Ask your site supervisors, team leaders, and frontline crew what drives them crazy about the current paper-based mess. Their feedback is gold.

From there, create a simple checklist. Split it into "must-have" features and "nice-to-have" extras. This list becomes your guide as you evaluate different providers and stops you from getting distracted by shiny features you don't actually need.

Stage 2: Vet Vendors and Ask the Right Questions

With your needs clearly defined, you can start exploring your options. It's easy to be wowed by flashy features during a demo, but you have to stay focused. Stick to your checklist and drill down with questions that matter to your business.

This is a crucial step. You're not just buying software; you're choosing a partner. Getting the team involved in these early conversations is key to making sure the chosen system works for everyone.

When you're talking to potential vendors, you need to get past the sales pitch and find out what really makes them tick. A great way to do this is with a vendor vetting checklist.

Vendor Vetting Checklist

Asking the right questions upfront can save you a world of pain later. Use this table as a starting point to compare providers and see who really understands your world.

| Category | Key Question to Ask | Why It Matters |

|---|---|---|

| Functionality | "Can you show me exactly how your software handles [your specific problem, e.g., SWMS management] for a business like mine?" | A generic demo is useless. You need to see if it solves your real-world problems in a way that makes sense for your industry. |

| Offline Capability | "How does the system work when there's no internet? Can my team complete forms and sync them later?" | Many work sites have patchy reception. If the app is dead without Wi-Fi, it's not fit for purpose. |

| Support | "What does your support look like? Are your team based in Australia? What are your hours?" | When something goes wrong, you need fast, local support from people who understand AU regulations, not a chatbot in another time zone. |

| Implementation | "What's your process for getting us set up, and what support do you provide during the rollout?" | A good partner will have a clear, supportive onboarding process. A bad one will sell you the software and disappear. |

Don't be afraid to push for a trial period. The only way to truly know if a system will work for your crew is to let them get their hands on it in a real-world setting for a couple of weeks.

Stage 3: Plan a Phased Rollout

Whatever you do, don't try to launch the new software to the entire company at once. That's a classic recipe for chaos. A phased rollout, starting with a small, motivated pilot group, is a much smarter and safer approach.

Pick one team or a single worksite to be your guinea pig. This small group can learn the system inside and out, give you priceless feedback, and help you iron out any kinks before you go company-wide. These early adopters often become your biggest champions, helping to train and win over their colleagues when it's time to expand.

Your rollout plan should be simple and clear:

- Select a Pilot Team: Choose a crew that's generally open to new tech and will give you honest, constructive feedback.

- Set Clear Goals: Define what success looks like for the pilot. Something like, "Complete 100% of pre-start checks using the app for two weeks straight."

- Gather Feedback: Schedule regular, informal check-ins with the pilot team. Find out what’s working, what’s clunky, and what needs to change.

- Refine and Expand: Use that real-world feedback to make adjustments before you roll the software out to the next group.

Stage 4: Focus on Practical Training

Finally, forget long slide presentations. Your training has to be practical and hands-on. People learn by doing, not by sitting in a stuffy room for two hours.

Organise short, role-specific training sessions. Show your supervisors how to build a digital inspection form. Walk your frontline workers through submitting a hazard report on their phones. Keep every session focused on the handful of tasks they’ll actually perform every day.

Give them simple, one-page guides they can refer to later, and make sure they know who to call with questions after the initial training is done. The goal is to build their confidence until using the new health safety software becomes second nature.

For more in-depth guidance on choosing the right system, you can explore our detailed guide to health and safety management software. Following these steps will help you not only select the right platform but also ensure it becomes a valued tool that makes everyone's job safer and easier.

Calculating the Real Return on Investment

Investing in health and safety software isn't just a safety decision; it's a solid financial one. But to get the leadership team on board, you need to speak their language. That means moving beyond safety metrics and talking about the bottom line. Calculating the return on investment (ROI) makes the business case crystal clear, showing exactly how the software pays for itself through savings you can see and some you might not expect.

This isn't just about ticking boxes or preventing incidents. It’s about building a more efficient and financially sound operation. A strong business case shifts the conversation from "it's the right thing to do" to "it's the smart thing to do for our finances."

Breaking Down the Direct Cost Savings

Direct savings are the most obvious wins and the easiest to track. These are the tangible costs that you'll see shrinking on your balance sheet once the software is up and running. Think of them as immediate financial victories.

The main areas where you'll see these savings are:

- Reduced Insurance Premiums: Insurers like proactive risk management. When you can show them clear, auditable digital records of your safety efforts, they often reward you with lower premiums.

- Fewer Compliance Fines: Keeping track of training renewals and regulatory submissions is a pain. The software’s automated tracking and reminders make it much harder to miss a deadline, helping you dodge costly penalties.

- Lower Workers' Compensation Claims: By preventing incidents in the first place, you naturally reduce the number and severity of claims. A single serious claim can easily cost tens of thousands in direct payments and send your future premiums soaring.

The market reflects these financial drivers. In Australia, the patient safety and risk management software market is tipped to grow at nearly 14% annually from 2025 to 2030. In 2024, risk management solutions already made up almost 75% of the market. This trend shows a clear shift towards using software to manage financial risks right alongside safety ones. You can explore more insights into the Australian market growth for a deeper dive.

Uncovering the Indirect Financial Gains

This is where things get really interesting. Indirect savings are often overlooked but can have an even bigger impact on your business. These are the benefits that flow from better operational efficiency and fewer disruptions. They might be harder to put a precise dollar figure on, but their effect on your business's health is enormous.

Here’s where you’ll find these hidden gains:

- Increased Productivity: Less downtime from incidents means your teams can keep working. Plus, swapping paper forms for digital ones and automating reports frees up hours of admin work every single week.

- Lower Administrative Costs: Just think about the money you spend on paper, printing, filing cabinets, and storage for all those old records. Going digital cuts these costs and saves countless hours that were once wasted hunting for a misplaced document.

- A Stronger Position for Bids: Many large contracts and tenders now demand detailed proof of a company's safety management system. A professional, organised digital system can give you the competitive edge you need to win the job.

The chart below shows how a company's safety-related costs can drop over time after bringing in a dedicated software solution.

As you can see, the initial investment is quickly balanced out by a major drop in costs from incidents, fines, and administrative headaches, leading to a healthy ROI.

A simple way to get started is to add up the annual cost of your insurance premiums, any fines you paid last year, and the direct cost of your workers' compensation claims. That number alone often builds a powerful case for the software's cost.

For a more detailed analysis, you can use our accident frequency rate calculator to put a real number on your current incident trends. When you combine that data with your direct and indirect cost savings, you'll have a compelling business case that's hard to ignore.

Got Questions? We've Got Answers.

When you're looking into safety software for your business, a few practical questions always come up. Here are some straight answers to the most common ones we hear.

How Much Does Health Safety Software Cost in Australia?

The price can swing a bit, but most Aussie providers stick to a couple of standard models. You'll often see per-user-per-month fees, which are perfect for smaller crews, or per-site fees that usually work out better for bigger companies with multiple locations.

To give you a real-world idea of what to expect:

- Small Businesses (under 50 employees): You're probably looking at around $300 to $800 per month.

- Medium Businesses (50-250 employees): Expect to budget somewhere in the $800 to $2,500 per month range.

- Large Enterprises (250+ employees): Pricing is nearly always customised, but it generally starts from $2,500 and scales up from there depending on what you need.

These numbers are almost always tied to the features you choose and the support you get. Always ask for a clear breakdown so you don't get hit with hidden setup fees.

Is This Software Actually Easy for Non-Tech Staff to Use?

Yes. The days of clunky, confusing systems are long gone. Modern health safety software is built for the people who actually use it, like frontline workers on construction sites and in factories, not IT gurus. The entire focus is on simple, intuitive mobile apps that make daily tasks feel effortless.

Think of it like any other app on your phone. If your team can use their banking app or scroll through social media, they can easily fill out a digital inspection or report a hazard. Good software is all about big buttons, clear instructions, and logical steps, which means you’ll need very little training to get everyone up and running.

How Long Does It Take to Get a New System Running?

Getting a new system rolled out and fully adopted by your team is a process, but it's much quicker than it used to be. You need a solid implementation plan to set realistic expectations, moving from the day you sign up to the day it's just part of how you work.

A well-planned rollout is everything. Don't try to rush it. Starting with a small pilot team and then expanding almost always guarantees better long-term success and gets more of your crew on board.

A smart timeline usually looks something like this:

- Initial Setup & Configuration (1-2 weeks): This is where your provider helps you tailor forms, workflows, and settings to match how you operate.

- Pilot Team Training & Testing (2-4 weeks): A small, select group puts the software through its paces in the real world and gives crucial feedback.

- Company-Wide Rollout & Training (4-8 weeks): You then expand it to everyone else, backed by hands-on training sessions to build confidence.

All up, you should plan for about 2 to 4 months from purchase to full team adoption.

Ready to see how a straightforward, user-friendly system could change your business? Book a free demo with Safety Space. We’ll show you just how simple safety management can be. Visit us at https://safetyspace.co to learn more.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.