Near-miss reporting is the simple act of documenting unplanned moments that could have caused injury or damage, but thankfully didn't. Think of them as the "close calls" or "lucky breaks" that happen on any worksite, from a factory floor to a busy construction project.

By tracking these events, you get a clear warning, a heads-up about hidden dangers before they turn into actual accidents.

What Is a Near Miss in the Workplace?

A near miss is a free lesson. It's an unplanned event that points out a weakness in your system, process, or environment without the pain and cost of an injury or property damage. Recognising and reporting these is the first step in moving from reacting to problems to preventing them.

Imagine a hammer falling from a scaffold. If it hits a worker, it's a serious incident. If it lands on the empty ground below, it's a near miss. The potential for injury was identical in both scenarios; only luck changed the outcome. Ignoring that fallen hammer just means you're waiting for luck to run out.

The Smoke Detector Analogy

Think of your near-miss reporting process like a smoke detector for your safety program. A smoke detector doesn't wait for the building to be on fire; it alerts you at the first sign of smoke, giving you that critical window to act.

A near-miss report does the same thing. It’s an early warning about underlying hazards that could easily lead to a significant incident. One report might not seem like a big deal, but when you start tracking them, patterns emerge. If you're looking for guidance on how to structure these reports, you can find some great templates in these incident reports samples.

Practical Examples of Near Misses

These kinds of events happen every day in industrial and construction settings. The real trick is to train your team to see them not as minor events to be ignored, but as valuable opportunities for improvement.

Here are a few common examples:

- Slips and Trips: A worker nearly slips on an unreported oil spill but catches their balance just in time. The spill is the hazard, and that near-slip is the crucial warning.

- Falling Objects: A box tumbles from a high shelf in a warehouse, landing just metres away from an employee. This immediately points to issues with storage procedures or racking stability.

- Equipment Malfunctions: A piece of machinery unexpectedly shuts down or fails to operate correctly, luckily without causing an injury. This is a clear indicator that maintenance is overdue.

A near miss is a warning shot. It provides all the information of an accident report, but without the cost of an injury, downtime, or damage. Reporting it turns bad luck into good data.

By documenting these close calls, you gather the information needed to fix problems before they get worse. It’s never about assigning blame; it’s about identifying the weak spots in your operations and making practical fixes to prevent future harm.

Why Tracking Near Misses Is Non-Negotiable

Ignoring a near miss is like seeing a puddle on the factory floor and just walking around it. Sure, you might avoid slipping this time, but you haven't fixed the leaky pipe that’s causing the problem. Tracking these events isn’t about creating more paperwork; it’s about gathering operational information to prevent costly downtime and serious injuries.

This data is one of the most powerful leading indicators you can have. While incident reports tell you what went wrong yesterday, near misses reporting gives you a clear window into what could go wrong tomorrow. It's the difference between reacting to a catastrophic breakdown and performing preventative maintenance that stops it from happening.

Uncovering Hidden Workplace Hazards

Think of every near miss report as a clue. Each one points to a hidden hazard in your workflows, your equipment, or the worksite itself. A single report might seem minor, but when you start collecting them, patterns emerge. And that’s where the real value is.

For instance, one report of a near slip in a specific area is easy to brush off. But three reports in the same location over two weeks? That tells a much bigger story. It might lead you to discover a slow, recurring leak from overhead machinery that only becomes a hazard during certain shifts, a problem you’d never find during a standard inspection.

This proactive approach is much more effective than just reacting to accidents. This has been proven in other fields, too. For example, an analysis of accident blackspots in Sydney found that clusters of near misses often occurred in locations with low historical crash data. These insights allowed authorities to fix risky intersections before serious accidents happened.

Tracking near misses turns random "close calls" into a predictable roadmap of your biggest risks. It allows you to invest your time and money where they will have the greatest impact on preventing actual incidents.

From Data Point to Decisive Action

Ultimately, the whole point of near misses reporting is to drive practical actions that make the workplace safer and more efficient. By catching these issues early, you can take simple, low-cost steps to head off major consequences.

Just think about these tangible outcomes:

- Preventing Injuries: Fixing that recurring leak prevents a serious fall, saving an employee from harm and the company from a costly WorkCover claim.

- Reducing Downtime: A near miss report noting a forklift's brakes felt "soft" can trigger a maintenance check. This simple action can prevent a major equipment failure and the production halt that would have followed.

- Improving Processes: Multiple reports of workers nearly tripping over improperly stored materials can highlight a flaw in your site's organisation, leading to a simple process change that improves workflow for everyone.

At the end of the day, tracking this information is a non-negotiable part of running a smart, safe, and productive operation.

Overcoming Common Barriers to Reporting

Even the best-designed near miss reporting system is useless if your team doesn't use it. Figuring out why people might hesitate to file a report is the first step toward fixing the problem. The reasons are usually straightforward. They often boil down to fear, frustration, or a belief that it’s just not worth the effort.

Tackling these barriers head-on is the only way you'll get the data you need to stop incidents before they happen. Luckily, the solutions are just as practical as the problems.

Barrier 1: The Fear of Blame

Let's be honest, the number one reason people stay quiet about a near miss is the fear of getting in trouble. Workers worry they’ll be blamed for what happened, especially if their own actions played a part. If people think they will get in trouble for reporting, they won't.

- Solution: Establish a strict no-blame reporting policy and mean it. Make it clear that the goal isn't to find out who was at fault, but to understand what went wrong with the system or process. Investigations should focus on root causes like inadequate training or faulty equipment instead of pointing fingers. This is how you build trust and get honest feedback.

Barrier 2: The Process Is Too Complicated

Nobody wants to interrupt their day to wrestle with a long, confusing form. If reporting a near miss takes 15 minutes and involves hunting down paperwork, most people won't do it. The reporting process needs to be quicker and easier than the event itself.

- Solution: Keep it simple. Use accessible reporting tools, like a mobile-friendly digital form that can be filled out on a phone in less than two minutes. All you really need is the essential info: what happened, where, and when. Reducing friction is everything.

When a worker sees their report is taken seriously and leads to a tangible fix, they understand its value. This feedback loop is the single most powerful motivator for continued reporting.

Getting people to give feedback is a challenge in any field, not just safety. To make sure your system works, you need to actively encourage people to take part. It’s worth looking into some proven strategies to increase reporting rates, many of which can be adapted from general survey best practices.

Barrier 3: The Belief That Nothing Will Change

This one is perhaps the most damaging barrier of all: the feeling that reports just disappear into a black hole. If your team thinks their efforts are being ignored and nothing ever changes, they'll stop contributing. Why bother reporting a hazard if it’s still there a month later?

- Solution: Create a visible feedback loop. When a report comes in, acknowledge it immediately. More importantly, once you’ve investigated and taken corrective action, communicate the outcome, not just to the person who reported it, but to the wider team. This proves that their input directly makes the workplace safer.

Underreporting is a massive issue in Australia. It’s estimated that around 31% of all safety incidents, including near misses, go unreported. This is a critical gap, especially when you consider that nearly 500,000 work-related injuries happen every year. Closing that gap starts with making reporting easy, safe, and worthwhile.

How to Set Up a Near Miss Reporting System That Actually Works

Setting up a solid near miss reporting system doesn’t need to be a bureaucratic nightmare. Forget the complex paperwork and endless meetings. A good system is built on clarity, simplicity, and a commitment to actually doing something with the information you gather.

The goal is to create a simple path from spotting a close call to putting a solution in place. It's a blueprint any supervisor on a construction site or manager on a factory floor can follow. The whole process boils down to a few key actions that everyone on the team can get behind.

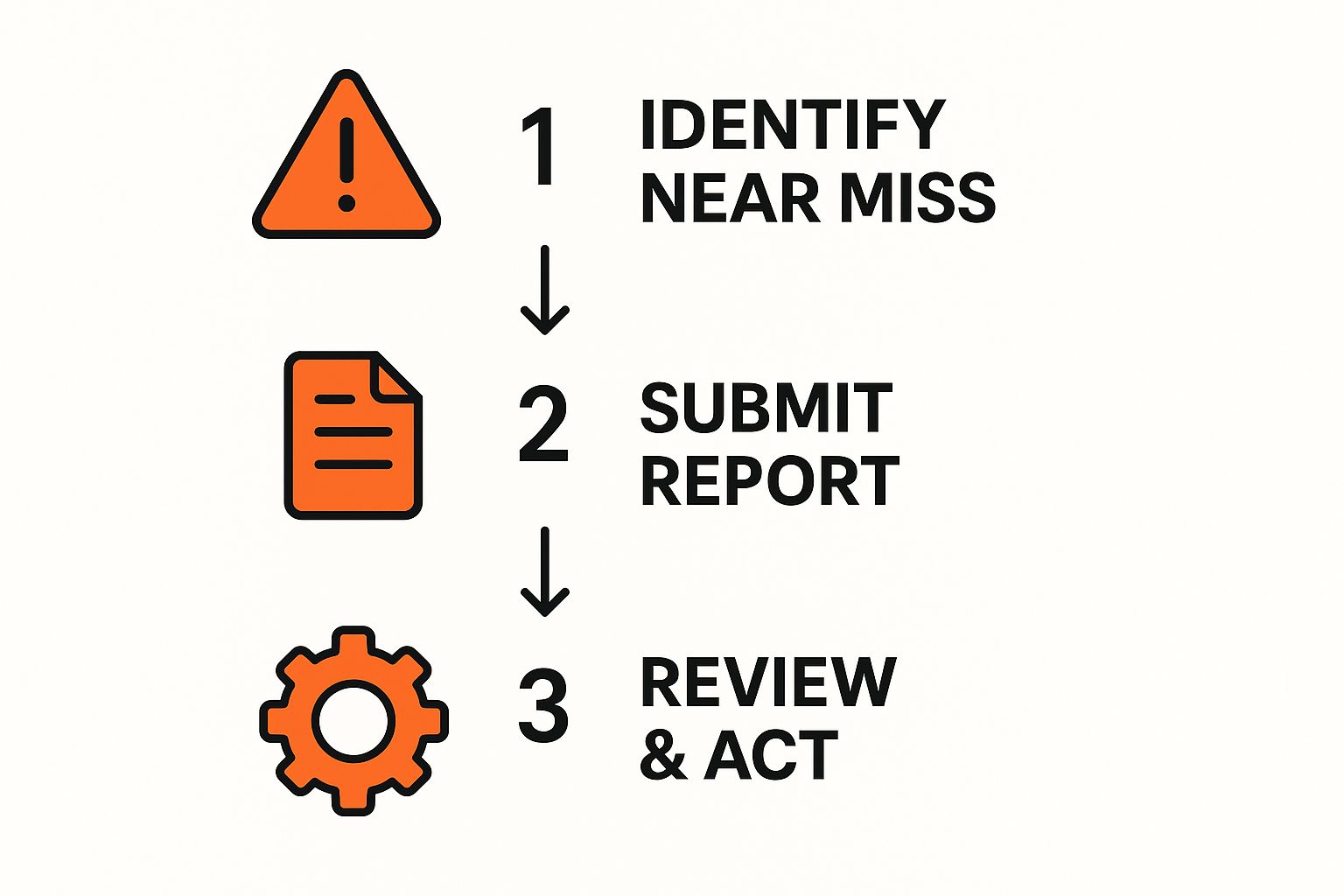

This visual breaks down the basic flow, from the moment a near miss is identified right through to taking corrective action.

As you can see, it’s a simple loop: see something, say something, and then do something about it. Let's break down how to make that happen.

Step 1: Get Everyone on the Same Page About What a Near Miss Is

First things first, you need to make sure everyone on your team has the same understanding of what a near miss looks like in your specific workplace. Generic definitions are useless here. You need real-world examples that people can relate to.

For a construction crew, a near miss isn't an abstract concept. It's things like:

- A piece of rebar falling from the third storey and landing exactly where a worker was standing just a moment before.

- An electrician almost taking a serious tumble over an unsecured extension cord across a busy walkway.

In a manufacturing setting, it could be:

- A pallet jack with a dodgy brake suddenly rolling away on its own, only stopping inches from a critical piece of machinery.

- An operator hearing a weird grinding noise from a press just before a component snaps off, thankfully without hurting anyone.

When people know exactly what to look for, they’re far more likely to report it. Clarity at this stage is non-negotiable.

Step 2: Make Reporting Ridiculously Easy

The reporting process needs to be as friction-free as possible. If it’s a pain, people just won't do it. Simple as that.

Luckily, you have options, from old-school methods to digital solutions. A physical drop-box with simple, one-page forms can still work. Or, you could set up a dedicated email address or a digital form people can access instantly with a QR code on their phone.

Modern tools, like a dedicated incident management system, make this even easier. They allow workers to log a report right from their phone in a couple of minutes, attach a photo, and get back to their job.

Step 3: Explain the 'Why' Behind the 'What'

Once you've got the system built, you need to roll it out to the team. This isn't just about sending a memo; it's about explaining why you're doing this. You have to drive home the point that near miss reporting is about finding and fixing problems, not pointing fingers.

This is your moment to hammer home the no-blame approach. Make it clear that reporting a close call is seen as a massive contribution to keeping everyone safe. It's an act of looking out for your mates.

The success of any reporting system hinges on trust. Workers must believe that their reports will be used for improvement, not punishment. This trust is built through consistent action and transparent communication.

Step 4: Follow Through with a Clear Review Process

Every single report has to be reviewed. No exceptions. This is how you show the team you’re serious and that their effort wasn't wasted. A crucial first step here is understanding what workflow automation is so you can design a process that runs smoothly without manual chasing.

Your procedure should clearly outline who reviews the reports, the timeframe for that review, and how you’ll find the root cause. The focus must always be on "what" went wrong and "why," never on "who" messed up.

Finally, a system is only as good as the action it inspires. You have to assign corrective actions, track them until they're done, and communicate the results back to the team. Closing that loop is what proves their reporting leads to real, tangible change on the ground.

A quality report is the foundation of this whole process. To ensure the information you get is actually useful, it needs to contain a few key details.

Essential Elements of a Good Near Miss Report

This table breaks down the crucial information to include in any near miss report to make it actionable.

| Information Field | Why It's Important | Example |

|---|---|---|

| Date, Time, and Location | Provides context and helps identify patterns related to specific times or areas. | "14 June 2024, approx. 10:15 AM, near the loading bay at the main warehouse." |

| Description of Event | A clear, objective account of what happened, avoiding blame or personal opinion. | "A forklift carrying a full pallet reversed without its warning beeper sounding." |

| Immediate Actions Taken | Shows what was done on the spot to manage the immediate risk. | "The area was cordoned off, and the forklift was taken out of service." |

| Potential Outcome | Helps prioritise the investigation by clarifying the severity of what could have happened. | "If a worker had been in the forklift's path, it could have resulted in a fatality." |

| Suggested Improvements | Gathers valuable insights from the person who witnessed the event. | "Recommend daily checks for all audible warning devices on mobile plant." |

| Witnesses (if any) | Provides additional perspectives for a more thorough investigation. | "John Smith (Site Foreman) also saw the event." |

Making sure your report forms, whether digital or on paper, capture these fields will give your review team the information they need to get to the root cause and prevent a close call from becoming a tragedy.

Turning Near-Miss Data into Predictive Power

Collecting near-miss reports is a great start, but it's only half the battle. The real value comes when you start connecting the dots. Reacting to individual reports is like playing whack-a-mole; you’re fixing isolated problems but missing the bigger picture of why they keep popping up.

The key is to move from one-off fixes to spotting patterns. This is where your data transforms from a simple record into a powerful tool that helps you see what's coming next. By analysing reports collectively, you start to uncover the systemic risks that are invisible when you only look at a single event.

From Raw Data to Actionable Insights

You don't need a fancy system to get going. A simple spreadsheet is often all it takes to start organising your near-miss reporting data and making sense of it. The whole point is to categorise each report so you can look for clusters and recurring themes.

Try sorting your reports using a few key filters:

- Location: Are multiple reports coming from 'Warehouse Bay 3' or near 'Machine B'?

- Time of Day: Do close calls seem to happen more often during the night shift?

- Activity: Is there a spike in reports during a specific task, like 'loading trucks'?

- Equipment Involved: Does a certain forklift or piece of machinery keep showing up?

This kind of analysis tells you exactly where to focus your attention and resources. A cluster of reports in one area might point to a localised environmental hazard, while a pattern tied to a specific task could signal a flawed procedure or a gap in training.

Making Trends Obvious

Once you've categorised the data, simple charts can make these patterns leap off the page. A basic bar chart showing near misses by location can instantly highlight problem zones on your worksite. Putting the data into a visual format makes it much easier to communicate the risks to your team and get their buy-in for making changes.

For those looking to take it a step further, understanding more advanced predictive analytics techniques can turn raw reports into genuine foresight. Our guide on predictive safety analytics also offers practical steps to get you started.

It's also worth remembering that how you define and collect data massively affects the trends you see. For instance, the Victorian heavy rail network recorded thousands of "near hits" over several years. But when the definition of near-miss reporting was updated in 2022, the numbers dropped dramatically. This shows how critical consistent definitions are for accurate analysis.

The ultimate goal here is to make smarter, evidence-based decisions. It shifts you from guessing where the next incident might happen to knowing exactly where your biggest risks lie.

By treating every near-miss report as a valuable piece of the puzzle, you build a clearer picture of your operational risks. This gives you the insight needed to make smart, targeted improvements that stop incidents before they happen.

Common Questions About Near Misses Reporting

Even with a solid system in place, questions always pop up about the practical side of near miss reporting. Getting these answers right is what makes the process work on the ground, not just on paper.

Let's break down some of the most common queries we hear from managers and supervisors. These are the small but critical details that can make or break whether your team gets on board.

How Do We Get Employees to Actually Report Near Misses?

This is the big one. It's the question we get asked more than any other, and the answer comes down to two things: make it dead simple, and make it completely safe.

First, your reporting tool has to be incredibly easy to use. Think a mobile app or a simple online form that takes less than two minutes to fill out. The less friction, the better.

More importantly, you need an iron-clad no-blame policy. You have to publicly and repeatedly state that no one will ever be penalised for reporting a near miss. When people genuinely trust the system won't be used against them, they’ll use it.

Always close the loop. Acknowledge every report quickly and, crucially, communicate the changes you’ve made. When your team sees their reports lead to real, visible improvements, they understand it’s not just another box-ticking exercise.

What's the Difference Between a Near Miss and a Minor First Aid Incident?

The line in the sand here is the outcome. Did someone get hurt or not?

A near miss is an event where no injury occurred, but it very easily could have. Picture a heavy box falling from a high shelf and landing right next to someone. The potential for serious harm was there, but luck saved the day. That’s a near miss.

A minor first aid incident, on the other hand, is when a minor injury did happen and needed basic medical attention. If that same box had grazed the person's arm on the way down, causing a cut that needed a bandage, it becomes a first aid incident. Both events are valuable learning opportunities and should be reported, but they fall into different buckets for investigation and tracking.

Do We Have to Investigate Every Single Near Miss Report?

While every single report needs to be reviewed, the level of investigation can and should vary. It just isn't practical to treat every report the same. The smart move is to categorise near misses based on their potential severity.

This allows you to focus your limited time and resources where they matter most: on the risks with the highest potential for serious harm.

A report about a slightly wet floor might just need a quick clean-up and a check for the source. But a report about a forklift's brakes failing or a piece of scaffolding coming loose? That needs to trigger a much deeper investigation to find the root cause. This tiered approach keeps the system both effective and manageable.

Ready to move beyond messy spreadsheets and piles of paperwork? Safety Space provides a simple, all-in-one platform to manage near miss reporting, incident investigations, and all your H&S compliance needs.

See how you can protect your team and your business by booking a free demo.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.