Let's be honest, trying to manage workplace health and safety with a jumble of scattered documents, verbal instructions, or a messy spreadsheet is a recipe for disaster. A formal, written set of policies and procedures is your single source of truth. It's the official guide that everyone from senior management down to the newest hire or subcontractor can actually follow.

This isn't just about ticking a box for the regulators. It's about setting clear expectations for how work gets done safely on your site, every single day.

Why A Template Is Your Most Practical Starting Point

Starting from a blank page is a massive time sink and risks leaving critical gaps. That's where a solid policies and procedures template comes in. It gives you a structured framework to build upon, so you can adapt a proven system to your specific worksite instead of reinventing the wheel. You save a huge amount of time while making sure all your key safety areas are covered right from the get-go.

The Immediate Pay-Offs of a Structured Document

Using a well-designed policies and procedures template gives you practical advantages straight away. It shifts your H&S management from being reactive, only dealing with problems after they happen, to being proactive and preventative.

Here are the key benefits you'll see almost immediately:

- Consistency Across the Board: It guarantees every team member and subcontractor gets the exact same instructions for high-risk tasks. This drastically reduces the temptation for anyone to take dangerous shortcuts.

- Clear Accountability: When roles and responsibilities are written down, there’s no confusion. Everyone knows what they’re responsible for, from daily equipment checks to emergency response actions.

- Simplified Onboarding: New starters can get up to speed much faster with a clear document to refer back to, rather than trying to remember everything from word-of-mouth training.

- A Defensible Position: If an incident ever occurs, having a comprehensive, implemented policy demonstrates your due diligence. It provides a clear, official record of your safety protocols.

A strong set of policies provides the backbone for your entire safety system. It's the reference point for training, the guide for daily operations, and the evidence of your commitment during an audit or investigation.

Moving Beyond Just Ticking Boxes

While meeting your legal requirements is non-negotiable, the real value of a good policy document is how it's used every day. Think of it as the instruction manual for your worksite.

For those running complex sites, this clarity is absolutely critical. If you’re looking to build out your entire safety framework, a great next step is to review a comprehensive occupational health and safety management plan template to see how it all fits together.

Ultimately, a template is a powerful tool. It helps you build a clear, documented system that turns abstract safety goals into concrete, actionable steps that protect both your people and your business.

Building Your Foundation with Essential Policy Sections

A policies and procedures template is only as good as the information you put into it. A document with gaps isn't just unhelpful, it's a massive liability. It creates confusion on the ground and leaves dangerous holes in your safety system.

To build a manual that’s genuinely useful, you need a rock-solid structure covering all the non-negotiable elements. Think of these sections as the framework of a building. If one support is weak or missing, the whole thing becomes unstable. Your goal is a document that's both compliant and actually makes sense to the team on the tools.

This means writing in plain English. Cut the corporate jargon that makes sense in an office but means nothing to a worker on a factory floor or up on a scaffold. Let’s break down the essential sections your template absolutely must include.

Your Health and Safety Policy Statement

This is your starting point: a short, clear declaration of your company’s commitment to keeping people safe. It’s not the place for fine print or long procedures. Instead, think of it as a high-level statement signed by senior management that sets the tone for everything else.

Your policy statement should briefly outline your aims, like preventing injuries and meeting your legal obligations. It’s the public face of your safety commitment and the first thing any auditor or inspector will ask to see.

Roles and Responsibilities

Here’s where you get specific about who does what. Vague responsibilities are a recipe for disaster because crucial tasks get missed. You need to clearly outline the safety duties for every single role in your organisation, from the top down. Don't just list job titles; detail the actual safety-related tasks they own.

For instance, your breakdown might look something like this:

- Site Supervisors: Responsible for running daily pre-start talks, checking all team members have the correct PPE, and having the authority to stop any job deemed unsafe.

- Machine Operators: Required to complete pre-use checklists on their equipment, report any faults immediately, and follow all lockout-tagout procedures without fail.

- All Workers: Have a duty to report hazards, follow established safety procedures, and actively participate in safety training.

When you clearly define these roles, you kill the "I thought someone else was doing that" problem, a phrase that shows up far too often in incident reports. If you want to dive deeper, you can learn more about the specifics of writing effective health and safety policies in our detailed guide.

Risk Management Procedures

This is the real engine room of your manual. It details how your company identifies hazards, assesses risks, and puts controls in place. The procedures here can't be theoretical; they need to be practical and easy for your team to follow.

This section must cover:

- Hazard Identification: Your methods for finding potential problems, whether it's through site inspections, worker reports, or incident investigations.

- Risk Assessment: The system you use to figure out how likely a hazard is to cause harm and how bad that harm could be.

- Control Measures: Your process for applying the hierarchy of controls (elimination, substitution, engineering controls, admin, and PPE) to manage those risks.

This section shouldn't just be theory. It needs to include the actual forms you use, like your risk assessment matrix or your Safe Work Method Statement (SWMS) template, so everything is in one place.

Emergency Preparedness and Response

When an emergency hits, the last thing you want is people guessing what to do next. This part of your template lays out the exact steps for different emergency scenarios relevant to your site. No ambiguity.

Be sure to cover the critical situations:

- Medical emergencies and first aid response.

- Fire evacuation plans, including assembly points and warden duties.

- Chemical spills and containment procedures.

- What to do in case of a structural failure or equipment collapse.

For high-risk environments, you really need to flesh this out. It’s worth looking at detailed disaster recovery plan examples and integrating that level of detail into your own plans. Having clear, well-drilled procedures is what separates controlled chaos from a genuine disaster.

Incident Reporting and Investigation

Finally, you need a bulletproof procedure for when things go wrong. This section details how your team should report incidents, injuries, and, just as importantly, near misses. The process must be simple and encourage reporting, otherwise people just won't report things.

Your procedure needs to specify:

- The immediate steps to take after an incident to secure the area and give aid.

- Who to report to and the timeframe for reporting.

- The exact forms that need to be filled out.

- The process for investigating the incident to find the root cause, not just to point fingers.

A strong reporting system is one of your best tools for preventing the next incident. It helps you spot trends and fix the underlying issues before they lead to something far more serious.

How to Customise the Template for Your Worksite

Let's be blunt: a generic policies and procedures template is just a starting point. Using one straight out of the box is like giving every worker the same size boots. It might tick a compliance box, but it’s completely useless on the ground. The real value comes when you mould that document to fit the specific risks, machinery, and roles unique to your worksite.

Whether you're running a busy manufacturing plant or coordinating trades on a sprawling construction site, your policies have to mirror your reality. A document talking about generic hazards won't help anyone. It needs to address that unguarded conveyor belt in your factory or the very real fall risks on level three of your current build.

This isn't about rewriting the whole thing from scratch. It’s about making targeted, practical adjustments that turn a standard template into a tool your team will actually use because it speaks their language and solves the problems they face every single day.

Start with a Site-Specific Hazard Assessment

Before you touch a single word in the template, you have to know what you’re customising it for. Walk your site with a critical eye, specifically looking for the things that generic safety language just doesn't cover. This isn’t a formal audit; it's a practical walkthrough to ground your document in the real world.

Zero in on what makes your operation unique:

- Specialised Equipment: What machinery do you have that’s out of the ordinary? Think about custom-fabricated presses, specific models of cranes, or automated systems with their own quirks and risks.

- Work Environment: Are there tight spaces, overhead power lines, significant dust, or constant vehicle traffic that define your work area? These environmental factors create unique hazards.

- Specific Tasks: Pinpoint the high-risk jobs. This could be anything from confined space entry in a manufacturing vessel to rigging and lifting precast concrete panels on a construction site.

- People and Roles: A maintenance fitter has a completely different risk profile than a forklift operator or a new apprentice. Your policies need to reflect that.

This quick assessment gives you a concrete list of what needs to be specifically addressed in your template, ensuring it’s immediately relevant to the people doing the work.

Tailor Language for Different Roles and Tasks

Once you have your list of hazards, it’s time to adapt the template. The key here is to swap out vague, corporate jargon for direct, actionable instructions. Your team needs to know precisely what to do, not just read about the company’s "commitment to safety."

A generic policy might say: "Personnel must operate machinery safely."

That’s meaningless. A properly customised procedure gives clear, direct instructions.

- For a Press Operator: "You must verify the light curtain is active and complete the two-hand control check before starting each cycle. Do not bypass any guards, even for a minor jam."

- For a Crane Operator: "You must conduct a pre-lift inspection using form HS-04 and confirm the exclusion zone is clear of all personnel before lifting any load over 500kg."

This level of detail cuts through the ambiguity and turns the procedure into a useful job aid rather than a document that just gathers dust.

The goal is to write for the person performing the task, not for a safety committee. Use simple language, short sentences, and focus on the actions they need to take to stay safe.

The need for this kind of customisation is thrown into sharp relief by the latest workplace safety statistics. Recently, Australia recorded 188 work-related fatalities, a tragic reminder of the risks involved in high-risk industries. With a national fatality rate of 1.3 per 100,000 workers, sectors like construction and manufacturing are still major contributors.

For Health and Safety Managers, especially in states like Western Australia where the rate is higher, this is a call to action. Using a platform like Safety Space to deploy and manage tailored WHS policies can directly address the site-specific risks that lead to these incidents. You can explore more insights from the Safe Work Australia 2025 report on workplace safety statistics at ldn.com.au.

Template Customization Checklist Manufacturing vs Construction

How you adapt your policies and procedures template will vary hugely depending on your industry. A manufacturing plant and a construction site might both be high-risk, but their primary hazards are worlds apart.

Here’s a practical, side-by-side look at how you might customise key sections for each environment.

| Policy Section | Example for a Manufacturing Plant | Example for a Construction Site |

|---|---|---|

| Emergency Response | Procedure for chemical spills from stored drums, including location of spill kits, containment steps, and contact info for the hazardous materials team. | Plan for structural collapse or trench failure, detailing rescue protocols, assembly points away from unstable ground, and communication with emergency services. |

| Equipment Safety | Lockout-Tagout (LOTO) procedure for a specific conveyor belt system, including energy isolation points and verification steps before maintenance begins. | Procedure for safe use of mobile elevating work platforms (MEWPs), specifying ground condition checks, wind speed limits, and mandatory harness attachment points. |

| Hazardous Materials | Rules for handling and storing industrial solvents, specifying required ventilation, PPE (e.g., nitrile gloves, respirators), and decanting procedures. | Procedure for managing silica dust from concrete cutting, requiring on-tool water suppression, designated cutting zones, and fit-tested P2/N95 respiratory protection. |

| Site Access | Policy for visitor and contractor sign-in, requiring a site-specific induction video on machine guarding and pedestrian exclusion zones before they can enter the factory floor. | Rules for site entry, including mandatory completion of a general induction, hard hat and steel-toed boot requirements, and a daily pre-start briefing on the day’s hazards. |

Taking the time to make these specific adjustments does more than just tick a box. It creates a document that is a genuinely useful tool for preventing incidents in your unique, real-world work environment.

A Practical Checklist for Rolling Out Your New Policies

So you’ve crafted a solid policies and procedures document. That’s a huge step, but honestly, it’s only the beginning. A perfect template sitting unread on a shared drive doesn’t protect anyone on site. The real work starts now: getting those policies out of the folder and into daily practice.

The goal is to make sure everyone, from the site supervisor to the newest apprentice and every subbie, understands and follows the updated procedures. This isn’t about just firing off a PDF and hoping for the best. A successful rollout takes clear communication, hands-on training, and getting your key people on board from day one.

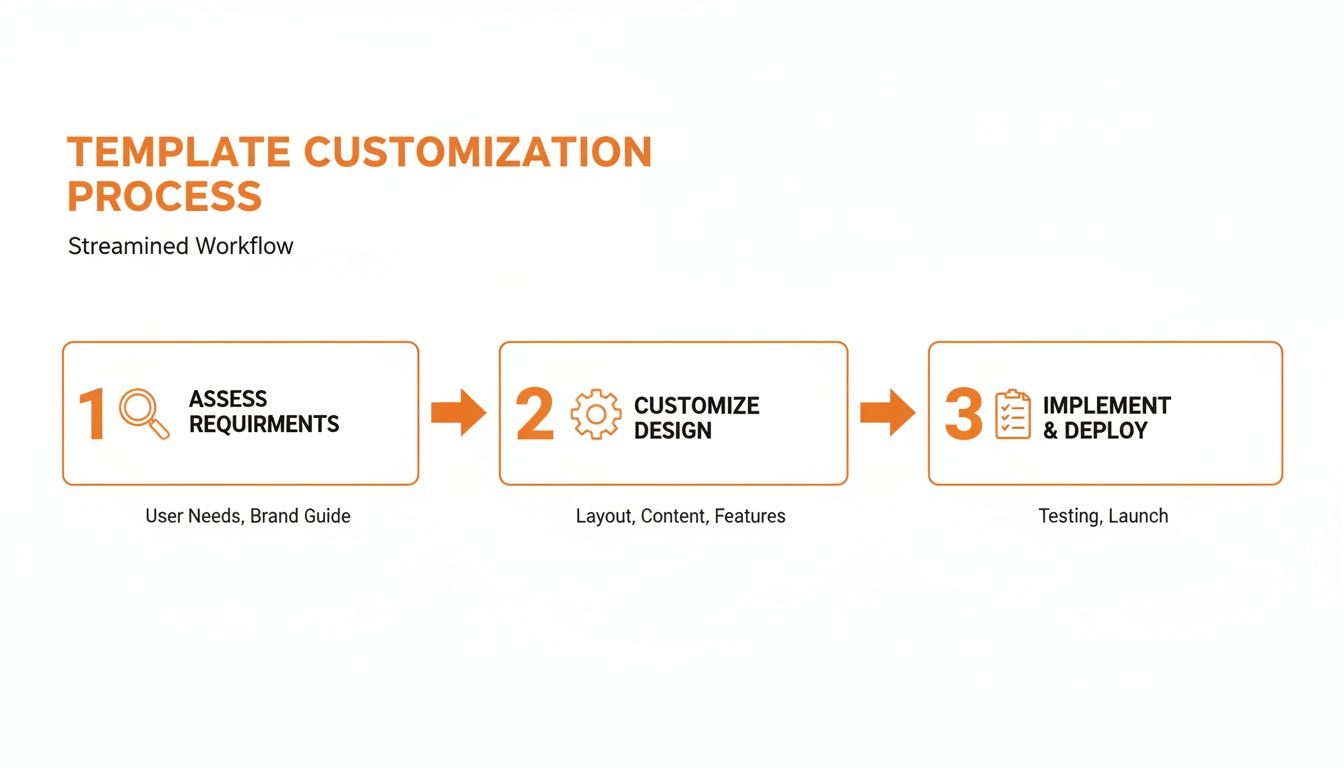

This is the basic flow for turning a template into a living, breathing part of your worksite safety system.

Moving from assessment to customisation and finally to implementation is the logical path to making your H&S policies genuinely effective.

Get Your Supervisors Onboard First

Before you breathe a word to the wider team, you need to get your supervisors and team leaders in your corner. They're the ones who have to enforce these rules every single day. If they don't get the 'why' behind a change or feel a new rule is impractical, your rollout is dead in the water.

Schedule a proper session with them. Walk them through the customised policies and procedures template, explaining the key changes and, more importantly, the reasons behind them. Then, listen to their feedback. They’re on the front line and will spot practical issues you might have missed, like a procedure that clashes with the site layout or a tool they don't have.

Getting buy-in from your leaders is the single most important step. They are your champions on the floor; if they support the new policies, your team is far more likely to follow their lead.

Plan Training That Actually Works

Nobody learns anything from Death by PowerPoint. Your training has to be active, practical, and directly relevant to the jobs your team actually does. Generic safety talks are forgotten the second they end, so focus your sessions on the "how-to" of your new procedures.

Instead of just reading from the document, build your training around real-world situations:

- Role-Specific Sessions: Don't lump your welders and forklift drivers into the same room. Group people by their roles and focus only on the procedures that directly affect their work.

- Hands-On Demonstrations: For anything involving equipment, get the team out to the machine. Physically walk them through the new lockout-tagout steps or the pre-start checks. Muscle memory is a powerful thing.

- "What If" Scenarios: Throw practical problems at them. "What do you do if you spot a frayed electrical lead?" or "Show me the steps to report a near miss with the new form." This tests their understanding, not just their ability to sit quietly.

Communicate Clearly and Consistently

Now it’s time to loop everyone else in, including contractors and temp staff. Your communication needs to be simple, direct, and repeated across different channels.

Use a mix of methods to make sure the message lands:

- Official Announcement: Send out a company-wide email or memo to officially launch the new manual. Make it crystal clear where everyone can find the document at all times.

- Toolbox Talks: Use your daily or weekly pre-starts to cover one new procedure at a time. Breaking it down into small, digestible chunks over a few weeks is far more effective than trying to cram it all in at once.

- Visible Reminders: Stick up posters or notices in common areas like the lunchroom or near relevant workstations. Think a simple poster with new emergency contacts by the first aid station or a visual guide for a new chemical handling procedure in the storeroom.

Repetition is everything. People need to hear a message multiple times before it truly sinks in, especially when you’re changing old habits. Be ready to answer the same questions over and over, and patiently explain the practical reasons for the changes.

Keeping Your Policies Current with Version Control

An outdated policy is a dangerous policy. Let’s be blunt about it. A document that still references old equipment, lists incorrect emergency contacts, or points to retired legislation isn’t just useless, it actively creates a false sense of security and a massive compliance risk. This is exactly why version control isn't a "nice-to-have"; it's a non-negotiable part of your safety management system.

Without a simple way to track changes, you're inviting chaos. It's easy to end up with multiple versions of a procedure floating around the worksite. One supervisor might be using the new protocol for a piece of machinery, while another team is working off a two-year-old document they found buried on a shared drive. That kind of inconsistency is a direct path to confusion, incidents, and injuries.

Establishing a Simple Version Control System

You really don't need complicated software to get this right. The secret is consistency. All it takes to get started is a straightforward naming convention and a single, central location for the master document.

Your system should include a few basic elements right on the cover page of your policies and procedures template:

- Version Number: Keep it simple. Something like V1.0, V1.1, or V2.0 works perfectly. A small tweak, like fixing a typo, might bump it to V1.1. A major process overhaul? That’s V2.0.

- Review Date: The date the document was last officially reviewed and approved.

- Next Review Date: The date the next scheduled review is due.

- Summary of Changes: A quick, bullet-pointed list of what’s new. For example, "Updated LOTO procedure for the new CNC machine" or "Revised emergency contacts for Site B."

This simple header information tells anyone, at a glance, whether they have the current, correct version in their hands.

Setting a Practical Review Schedule

A policy manual should be a living document, not something you write once and then shove in a drawer to gather dust. You need a regular, scheduled review cadence, but just as importantly, you need to be ready to update it whenever certain events pop up.

Think of your policy document like a service manual for your worksite. It needs to be updated whenever you add a new part or discover a fault. An out-of-date manual is worse than no manual at all.

Your review schedule should really be triggered by two things: time and events.

- Scheduled Annual Review: At a bare minimum, you should conduct a full review of all policies and procedures once a year. This is your chance to catch outdated information, make sure everything aligns with new business goals, and ensure nothing has slipped through the cracks.

- Event-Driven Reviews: Certain events must trigger an immediate review of any relevant policies. These include things like:

- After any significant incident or near miss.

- When new plant, machinery, or equipment is introduced.

- If there are changes to relevant WHS legislation or codes of practice.

- When a new hazard is identified during a risk assessment.

A system like Safety Space can automate this entire process. Instead of relying on calendar reminders and manual tracking, the platform provides a central, single source of truth for all your documents. You can learn more about how a dedicated document management program can automatically flag documents for review, which helps maintain compliance without the administrative headache. This approach makes keeping your policies current a systematic process, not just another task on your to-do list.

Bringing Your Policies to Life with Digital Tools

Let’s be honest, static documents stuffed in a filing cabinet or lost on a shared drive have their limits. To make your policies a real, living part of your daily operations, you have to move beyond a paper-based system. Integrating your new policies and procedures template into a digital platform is what connects your documentation to the actual work happening on site.

This move is a game-changer. It allows you to link specific procedures directly to their corresponding risk assessments or Safe Work Method Statements (SWMS). Suddenly, your manual isn't just a reference document, it's an interactive tool that guides daily tasks.

This kind of dashboard view gives managers a clear line of sight into how policies are being followed across different sites and teams, which is something paper could never do.

Get Real-Time Monitoring and Better Data

A digital system gives you something paper can't: real-time information. You can actually see if procedures are being followed by tracking the completion of linked forms, checklists, and inspections. This data is gold because it helps you spot where people might be taking shortcuts or where a process is consistently failing.

Modern platforms also use tools like AI-powered form completion to make reporting faster and more accurate for your team on the ground. For them, it means less time spent on paperwork. For you, it means the data you collect is actually useful for spotting trends and preventing incidents.

A Clear View for Multi-Site Operations

For managers overseeing multiple sites, a centralised digital platform is essential. It provides a single, clear view of compliance across every project or factory floor. You can instantly see which sites are up-to-date with their procedures and which ones are lagging behind, helping you direct your attention where it's needed most.

This level of oversight is critical when you look at the scale of workplace incidents. Serious workers' compensation claims in Australia recently hit 146,700, with construction (12%) and manufacturing (10.1%) being major contributors. A digital platform helps enforce standardised incident reporting and corrective action templates across all sites, reducing the administrative chaos that so often leads to compliance gaps. You can find out more in the latest workers’ compensation report from sbs.com.au.

Moving your policies to a digital platform isn't just about storage. It's about accountability, visibility, and turning your documents into active tools that help you spot problems before they lead to an injury.

Common Questions Answered

Look, I get it. When you're knee-deep in trying to get your health and safety documents sorted, a lot of practical questions pop up. Here are some of the most common ones I hear from managers on the ground, with straight-up answers to help you get moving.

What’s the Real Difference Between a Policy and a Procedure?

Think of it like this: a policy is the 'what' and the 'why.' It’s your high-level promise. It sets the direction, like a mission statement for safety. For example: “We are committed to maintaining a safe work environment for all employees and contractors.” It's the stake in the ground.

A procedure is the 'how.' It’s the nuts and bolts, the specific, step-by-step playbook for actually doing something safely. A great example is the detailed sequence of actions for a lockout-tagout on a piece of machinery. One single policy can, and often should, be supported by dozens of detailed procedures.

How Often Should We Be Reviewing Our H&S Policies?

As a hard and fast rule, you need to review absolutely everything annually. No exceptions.

But that’s just the baseline. You’ve got to do an immediate review whenever the game changes. That means:

- After a serious incident or a near-miss that made everyone’s heart stop.

- When you bring in new gear, substances, or change the way you do things.

- If the health and safety laws or codes of practice get an update.

- When an inspection or risk assessment uncovers a new hazard you hadn't accounted for.

Your policy manual has to be a living document that reflects what’s happening on your site today. It’s not a dusty file you tick off and forget about. An outdated policy is a dangerous one.

Can We Just Download a Generic Template and Call It a Day?

Absolutely not. This is one of the most common, and riskiest, shortcuts I see people take. A generic policies and procedures template is just a starting point, a foundation to build on. It has no idea about the specific hazards, the exact machinery, the unique site layout, or the different roles within your operation.

When a regulator walks onto your site, they’re looking for proof that your policies are real and relevant to your workplace. Using a template as-is leaves massive safety gaps, doesn't protect your crew from the risks they actually face, and can leave you seriously non-compliant.

Ready to stop guessing and start building a safety system that actually works? With Safety Space, you can upload, customise, and manage all your H&S documents from one simple platform. Book your free demo today and see how it works.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.