A risk management matrix is one of the most practical tools in a safety professional's kit. At its core, it's a simple visual grid that helps you prioritise workplace hazards by weighing up how likely a risk is to occur against how severe its consequences would be.

This simple chart moves you away from gut feelings and guesswork, giving you a structured and defensible way to make safety decisions.

Understanding the Risk Management Matrix

Think of a risk management matrix like a weather forecast for your site. A forecast for a light shower (low likelihood, low impact) means you might grab a light jacket, but that’s about it. A cyclone warning (very low likelihood, catastrophic impact), on the other hand, demands immediate and serious action.

The matrix works in the exact same way. It helps you categorise hazards so you can focus your time, money, and energy where they're genuinely needed most. It turns abstract feelings about danger into a concrete, visual plan, creating a shared language to talk about risk that everyone from management to the new apprentice can understand.

Let's break down the essential building blocks that make up a typical risk matrix. While the exact labels might change from company to company, these core ideas remain the same.

Key Components of a Risk Management Matrix

| Component | What It Is | Practical Example (Manufacturing) |

|---|---|---|

| Hazard Identification | The specific thing or situation with the potential to cause harm. | A piece of machinery (e.g., a press) with an unguarded moving part. |

| Likelihood Scale | A rating of how probable it is that an incident will occur. | Rare: Has never happened. Possible: Might happen once a year. Likely: Happens several times a year. |

| Consequence Scale | A rating of the severity of potential harm if an incident occurs. | Minor: First aid injury. Moderate: Lost time injury. Catastrophic: Fatality or permanent disability. |

| Risk Rating | The final score, calculated by combining likelihood and consequence. | A "Likely" event with "Moderate" consequences might be rated as a "High" risk. |

| Control Measures | Actions taken to eliminate or reduce the risk to an acceptable level. | Installing a physical guard on the machine and implementing a lock-out/tag-out procedure. |

These components come together to create a simple, yet powerful, grid for evaluating and managing workplace safety.

A Tool for Practical Decision-Making

Let's be clear: a risk matrix isn't just an academic exercise. It's a functional tool designed to answer one critical question: "What do we need to fix first?"

By plotting each hazard you’ve identified onto the grid, you get an instant visual snapshot of your risk profile. Hazards that land in the top-right corner, high likelihood and high consequence, are your screaming priorities. Those in the bottom-left, the low-likelihood and low-consequence stuff, can be managed with less urgent controls.

A risk management matrix gives you a systematic way to justify your safety decisions. Instead of just saying a hazard is "bad," you can show exactly where it falls in terms of probability and impact, making it far easier to get budget and time for corrective actions.

Core Functions of the Matrix

In a day-to-day setting, a well-used risk matrix helps you do several key things consistently:

- Prioritise Hazards: It visually separates the trivial risks from the critical ones, so you know you’re tackling the biggest threats first.

- Standardise Assessments: It gives everyone, from supervisors to new starters, the same framework for evaluating potential dangers. No more guesswork.

- Justify Resource Allocation: The matrix provides clear data to back up requests for new safety gear, process changes, or extra training.

- Track Risk Reduction: After you implement new controls, you can reassess the hazard. Seeing its position on the matrix shift to a lower-threat area is a simple, powerful way to measure your progress.

This structured approach is a fundamental part of any solid health and safety management system. It’s the backbone of how Australian organisations evaluate and prioritise their operational risks, which is one of the 9 key elements of a health and safety management system.

Defining The Two Axes: Likelihood and Consequence

A risk management matrix is built on two simple, practical ideas: how likely a problem is to happen, and how bad it will be if it does. Getting these two axes right is the most critical part of building a matrix that actually works for your operation.

If your definitions are vague or subjective, your risk ratings will be meaningless guesswork. The goal is to get away from words like ‘sometimes’ or ‘bad’ and create clear, operational definitions that anyone on your team can understand and apply consistently. This means tying your ratings to real-world, observable events on your site or factory floor.

Pinning Down Likelihood

Likelihood, or probability, is all about how often you realistically expect a hazardous event to occur. To make this useful, you have to tie your rating scale to timeframes or frequencies that make sense for your projects or production cycles. A generic scale is useless; a custom-built one is a powerful tool.

A common approach is a 1-to-5 scale, but the labels you attach to these numbers are what give them real meaning.

Example Likelihood Scale (Construction Project Focus):

- 1 (Rare): Unlikely to ever occur during the project's lifecycle.

- 2 (Unlikely): Could happen, but probably won't. Maybe once in several years.

- 3 (Possible): Might occur once during the project's lifecycle.

- 4 (Likely): Expected to occur at least once on this project.

- 5 (Almost Certain): Occurs multiple times per month on this project.

See how using a descriptor like "on this project" grounds the assessment in a concrete reality? This helps your team make consistent judgements, whether they’re assessing risks on a six-month high-rise build or a two-year infrastructure project.

Quantifying Consequence

Consequence, or impact, measures the severity of the outcome if the hazardous event happens. Just like with likelihood, abstract terms are your enemy. The best way to define consequence is to link it directly to tangible outcomes your business understands, things that affect people, equipment, the environment, or your operations.

For a health and safety focus, linking consequences directly to injury types is an incredibly effective method.

A practical consequence scale removes emotion from the assessment. It turns a fuzzy discussion about a 'nasty accident' into a specific evaluation: are we talking about a first-aid case, a trip to the hospital, or something that stops work for a week?

For instance, a scale focused squarely on worker health and safety might look like this:

Example Consequence Scale (H&S Focus):

- 1 (Insignificant): A minor incident requiring no treatment or first aid only. No time is lost.

- 2 (Minor): Requires first aid treatment. The person can return to their normal duties immediately.

- 3 (Moderate): Results in a lost time injury (LTI) where the worker needs medical treatment and cannot return to normal duties.

- 4 (Major): Causes a serious, irreversible injury or illness, resulting in permanent disability.

- 5 (Catastrophic): Results in a fatality.

This approach provides absolute clarity. A supervisor assessing the risk of a fall from a low platform can immediately tell the difference between a "Minor" outcome (a sprained ankle, first aid applied) and a "Major" one (a fall from a greater height causing permanent injury). This distinction is vital for assigning the correct risk level and deciding how urgent the controls are.

The real value of a risk management matrix emerges when these two custom-built axes come together. By defining likelihood and consequence in terms that reflect the reality of your specific workplace, you create a reliable tool for prioritising hazards and making defensible safety decisions.

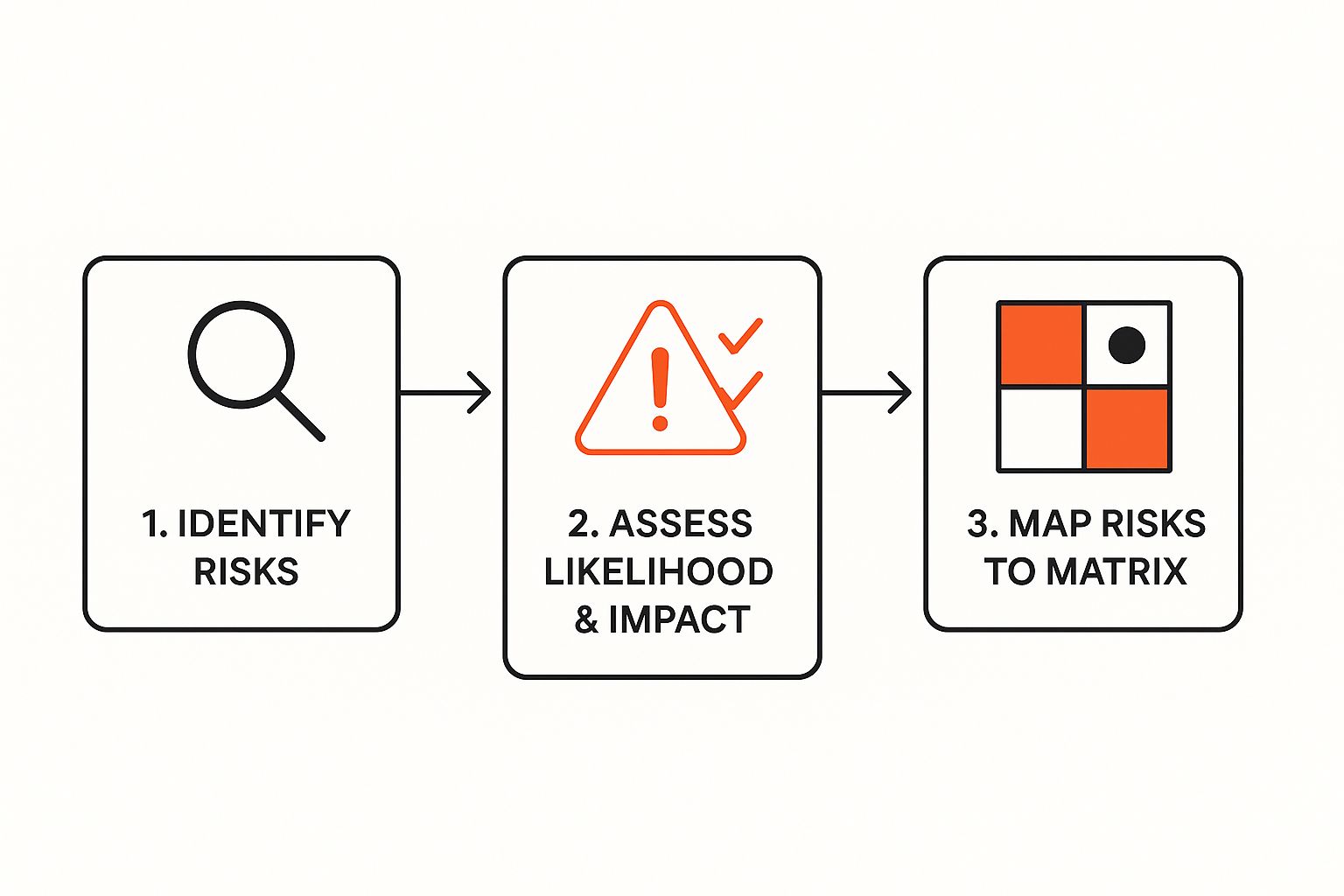

Building Your Risk Matrix Step by Step

Creating a practical risk management matrix isn't just an academic box-ticking exercise. It’s about building a functional, real-world tool for your specific workplace. Sure, you can grab a generic template, but a matrix you build yourself delivers genuine clarity on the hazards your team actually faces day-to-day.

This guide walks you through building one from the ground up. It’s a direct and actionable process. By the end, you'll have a visual tool that helps you make consistent, defensible decisions about where to focus your safety efforts.

Step 1: Define Your Custom Scales

Before you even think about drawing a grid, you need to define what the axes actually mean. As we've covered, these are likelihood (how often something could happen) and consequence (how bad it would be if it did).

The trick here is to ditch vague terms. "Unlikely" is useless. Instead, define it with a specific frequency that makes sense for your work, like "May occur once in a 12-month project." This customisation is what gives your matrix its power. Your team needs to agree on what each rating means in the context of their daily work, whether that's on a factory floor or a construction site.

To get started, here is a practical example of how you can define your scales. Feel free to adapt these definitions to better reflect the realities of your own operations.

Sample Likelihood and Consequence Scales

| Rating | Likelihood Definition | Consequence Definition (H&S Focus) |

|---|---|---|

| 5 (Almost Certain) | Expected to occur in most circumstances. Happens frequently. | Catastrophic: Fatality or permanent total disability. |

| 4 (Likely) | Will probably occur in most circumstances. Happens several times a year. | Major: Permanent partial disability, serious irreversible illness. |

| 3 (Possible) | Might occur at some time. Happens once every 1-2 years. | Moderate: Medical treatment injury (MTI), lost time injury (LTI). |

| 2 (Unlikely) | Could occur at some time. Hasn't happened yet but is conceivable. | Minor: First aid treatment required, no lost time. |

| 1 (Rare) | May occur only in exceptional circumstances. | Insignificant: Near miss with no injury or property damage. |

Having these clear, agreed-upon definitions is the foundation for a consistent and objective risk assessment process.

Step 2: Design the Grid Layout

With your scales defined, it's time to build the grid itself. For most construction and manufacturing settings, the 5x5 risk matrix is the sweet spot. It offers enough detail to distinguish between different risk levels without getting bogged down in complexity.

You'll have five levels for likelihood running down one axis (usually the vertical Y-axis) and five levels for consequence along the other (the horizontal X-axis). This creates a simple grid with 25 squares, each one representing a unique combination of probability and potential harm. A basic spreadsheet is all you need to get this started.

The core of a good risk matrix is its visual simplicity. It’s designed to give you an at-a-glance understanding of your risk landscape, turning complex data into a clear map for action.

Step 3: Create and Colour-Code Your Risk Zones

Now for the fun part: bringing the grid to life by assigning risk levels to the squares. This is almost always done with a simple, universally understood three-tiered colour system.

- Green (Low Risk): These are acceptable risks that just need standard procedures and minimal oversight.

- Yellow (Medium/Moderate Risk): These risks demand management attention and mitigation measures to bring them down to a lower, more acceptable level.

- Red (High Risk): These are your showstoppers. Unacceptable risks that demand immediate, decisive action to control the hazard.

You'll colour the squares on your 5x5 grid based on their combined score. A rare event with insignificant consequences (bottom-left corner) will be green. An almost certain event with catastrophic consequences (top-right corner) will be bright red. Everything in between will typically be yellow, forming a diagonal pattern across your matrix.

This visual flow makes it incredibly fast to identify, assess, and map your risks.

This process shows exactly how raw hazard identification gets transformed into a prioritised action plan, all thanks to the matrix.

Step 4: Plot Your Identified Hazards

This is where the rubber meets the road and the tool becomes genuinely useful. Grab your list of known workplace hazards, from operating specific machinery in a factory to working at heights on a construction site, and start plotting each one on the matrix.

For every hazard, you just need to ask two simple questions:

- Based on our agreed scale, what's the likelihood of this event happening?

- If it does happen, what's the most probable consequence?

For example, you might decide a trip hazard from a trailing power lead has a "Likely" (4) chance of causing an incident, but the outcome would probably be a "Minor" (2) injury. You'd find the square where row 4 and column 2 intersect and place that hazard right there. Involving your frontline workers in this step is non-negotiable; their hands-on experience provides the most accurate read on how often things really happen.

Step 5: Set Clear Action Rules for Each Zone

The final, and most critical, step is deciding what each colour actually means in practice. A risk matrix is completely useless if it doesn't drive action. You have to create clear, non-negotiable rules for each risk zone.

These rules tell your supervisors and workers exactly what to do when a risk falls into a certain category. No guesswork, no ambiguity.

Example Action Rules:

- Red (High Risk): Work stops immediately. The hazard must be controlled before anyone resumes work. Senior management must be notified.

- Yellow (Medium Risk): The hazard must be mitigated within a set timeframe (e.g., 24 hours). Temporary controls might be used, but a permanent fix is required.

- Green (Low Risk): The risk is acceptable. Manage it with routine procedures and standard monitoring. No immediate special action is needed.

By setting these hard rules, you take the guesswork out of safety. Everyone on site knows that a "red" risk isn't a suggestion, it's a hard stop that demands immediate and serious attention. This is how your matrix becomes a central, living part of your daily safety management.

Right, so you've put in the hard yards to build your risk management matrix. It's populated, colour-coded, and ready to go. What now? Now, it becomes your most powerful visual tool for getting things done.

The matrix's real job is to shift you from simply identifying risks to actively treating them. It’s not just a collection of problems; it’s a clear, prioritised roadmap for taking action. This transforms risk management from a reactive scramble into a structured, proactive process.

The beauty of the matrix is its simplicity. Your eyes are immediately drawn to the top-right corner, the red zone. Any hazard you've plotted there is your top priority, no questions asked. These are the risks with a nasty combination of high likelihood and high consequence, and they demand immediate attention. The ones in the yellow and green zones can be handled with less urgency, but they still need a plan.

Introducing The Hierarchy Of Controls

Once you've decided to treat a risk, you need a systematic way to solve the problem. For this, we turn to the hierarchy of controls. It’s the industry-standard framework for finding the most effective and reliable way to reduce or eliminate a hazard.

Think of it as a ladder. You always start at the top rung and work your way down, because the highest controls are the most effective. Why? Because they're designed to remove the hazard entirely or physically change the work environment, taking human error out of the equation as much as possible.

Applying The Hierarchy Step By Step

Let's walk through a real-world manufacturing example to see how this plays out.

The Hazard: A worker is manually lifting heavy castings, each weighing 20kg, from a crate on the floor. They then have to carry them over to a grinding machine.

The Matrix Rating: You plot this on your risk matrix. The repetitive nature of the task makes the Likelihood a ‘4’ (Likely), and the potential for a serious back injury (a lost time injury) makes the Consequence a ‘3’ (Moderate). This lands the risk squarely in the Red Zone.

Because it's a high-priority risk, we immediately apply the hierarchy of controls.

Elimination (Most Effective): Can we get rid of this hazardous task completely? What if we automated the process? A robotic arm could be installed to transfer the castings from the crate to the machine, meaning no manual lifting is needed. The risk of a manual handling injury is now completely eliminated. This is always the best-case scenario.

Substitution: If automation isn't practical right now, can we replace the hazard with something safer? Perhaps we could use smaller, lighter castings that only weigh 5kg each. This substitutes the heavy, high-risk load with a much lighter one, significantly dropping the injury risk.

Engineering Controls: If we can't eliminate or substitute, can we physically isolate people from the hazard? This is where engineered solutions shine. We could install a mechanical lift-assist device, like a small jib crane or a vacuum lifter. The worker still guides the casting, but the machine does all the heavy work. This is a very reliable control because it doesn't depend on a worker's behavior or technique.

Using a risk management matrix to pinpoint high-risk tasks and then applying the hierarchy of controls is a core part of modern risk governance. It gives you a structured, defensible process for every decision you make.

In the Australian public sector, for instance, these formal frameworks are non-negotiable. Surveys show that 70-80% of government entities rely on tools like a risk matrix to embed this kind of structured thinking into their daily operations. It ensures decisions are based on systematic analysis, not just gut feelings. You can dig deeper into these frameworks in the Comcover Risk Management Benchmarking survey.

What About The Lower-Level Controls?

The hierarchy doesn't stop there. The next levels are considered less effective because they rely more on people doing the right thing, every time.

Administrative Controls: This is about changing how people work. We could introduce job rotation, so one person isn't lifting heavy items all day. We could also implement a mandatory two-person lift rule for heavy items, or roll out comprehensive training on safe manual handling techniques.

Personal Protective Equipment (PPE) (Least Effective): Finally, can we give the worker equipment to protect them? For this particular hazard, steel-toed boots would protect their feet if a casting were dropped. But PPE does absolutely nothing to prevent the primary risk, the back strain injury. This is precisely why PPE is always the last line of defence.

By methodically working down the hierarchy, you ensure you've considered the most robust solutions first. You don't just jump to training (an administrative control) when an engineering fix like a lift-assist device would be far more effective at actually preventing the injury.

The matrix tells you where to focus your efforts, and the hierarchy shows you how to fix it.

Common Mistakes to Avoid With Your Risk Matrix

A risk management matrix is an incredibly powerful tool, but its value completely collapses if it’s built on shaky foundations or just left to gather dust. Let's be honest, a matrix is only useful if it's actually used, correctly and consistently. Falling into a few common traps can quickly turn this practical safety tool into a useless document, creating a lot of frustration and, even worse, a false sense of security.

Knowing these pitfalls ahead of time is the secret to building a risk matrix that genuinely helps you make better safety decisions on your site. Here are the most common mistakes people make, and more importantly, how you can steer clear of them.

Using Vague or Generic Terms

This is probably the single most destructive mistake you can make. When your scales for likelihood and consequence use fuzzy words like ‘unlikely’ or ‘moderate’ without crystal-clear definitions, every risk assessment becomes a subjective guessing game. One supervisor's 'rare' might be another's 'possible', which makes your entire risk matrix inconsistent and unreliable.

The fix is simple but absolutely essential: customise your scales. As we covered earlier, you must define each rating with specific, measurable criteria that make sense for your specific work environment.

Bad Likelihood: "Might happen."

Good Likelihood: "Expected to occur once during a 6-month project."

Bad Consequence: "A bad injury."

Good Consequence: "Results in a Lost Time Injury (LTI) requiring medical treatment."

That kind of precision gets rid of the guesswork and ensures that two different people looking at the same hazard will land on a very similar, if not identical, conclusion.

The ‘Set It and Forget It’ Approach

A risk matrix isn't a static document you create once during a project kickoff and then file away forever. Workplaces are living, breathing things. Conditions change, new machinery gets introduced, processes get updated, and new workers come on board. A matrix that’s six months old might as well be a historical artefact, it probably doesn’t reflect the reality of your site today.

A risk management matrix should be a living document, not a museum piece. Its purpose is to reflect current operational risks, not historical ones. If it’s not updated, it's not useful.

To avoid this trap, build reviews directly into your regular safety schedule.

When to Update Your Risk Matrix:

- After any incident or near-miss: This is a huge red flag that your previous assessment might have missed something.

- When introducing new equipment or substances: A new machine brings new, unassessed risks with it.

- When changing a work process or procedure: Altering how a task is done can create new, unforeseen hazards.

- At scheduled intervals: Plan a full review at least once a year, or at the start of any major new project phase.

These periodic check-ins are a core part of effective safety management. This is exactly why the importance of regular safety audits for your business can't be overstated; they force you to constantly reassess your controls and make sure your documentation actually matches reality.

Ignoring the People Who Do the Work

Want to know the quickest way to create an inaccurate risk assessment? Do it in isolation from an office. While managers and supervisors have a crucial high-level perspective, they don't always have the same hands-on, ground-level understanding as the workers performing a task day in and day out. They’re the ones who know the unofficial workarounds, the frustrating parts of a process, and how often a so-called "rare" event actually happens.

When a small group assesses risks without any frontline input, it often leads to groupthink, where assumptions go completely unchallenged and the final assessment doesn't match what’s really happening on the ground.

The solution? Make consultation a non-negotiable step in your risk assessment process. When you’re plotting hazards on the matrix, bring in the workers and supervisors who are directly involved. Ask them simple, direct questions like, "Honestly, how often does this machine really jam up?" or "What's the worst injury you could realistically see happening from this task?"

Their input isn't just valuable; it's absolutely essential for getting your likelihood and consequence ratings right. This collaborative approach also builds a sense of ownership and shows your team that their expertise is respected, which makes them far more likely to buy into and follow the controls you ultimately put in place.

Weaving The Matrix Into Your Daily Work

Let's be honest. A risk management matrix isn't a document you create just to tick a box for an audit and then let it gather dust. If you want to get any real value out of it, it has to become a living, breathing part of your day-to-day operations. This means embedding it into the routines and decisions made right there on the site or factory floor.

The goal is to shift your team's thinking. Stop treating risk assessment as a one-off project and start seeing it as a practical, ongoing tool. It should guide conversations, justify spending, and be the first thing your team looks at when planning new work.

Make it a Topic of Conversation

One of the easiest ways to bring the matrix to life is to make it a regular feature in your team catch-ups. Don't let it stay hidden on a server somewhere. Print it out, stick it on the wall in the site office or break room, and make it visible.

During weekly toolbox talks, pick one or two risks straight from the matrix to discuss. Talk about the controls you have in place and, this is the important part, ask your team if they're still working effectively. This keeps the information fresh and constantly reinforces that safety is a shared responsibility.

Use the Matrix to Justify Spending

A well-maintained risk matrix is one of your most powerful allies for getting budget approval for safety improvements. When you need to request funds for new equipment, training, or engineering controls, the matrix provides the hard data to back you up.

Instead of just saying, "We need new machine guarding," you can build a much stronger case:

"This unguarded machine is currently rated as a 'High' risk on our matrix due to its 'Likely' probability of causing a 'Major' injury. By investing $5,000 in engineered guards, we can reduce that risk down to 'Low', which is within our acceptable tolerance level."

See the difference? It turns a subjective request into a clear, data-driven business decision. You're no longer just spending money; you're actively buying down risk and demonstrating a tangible return on investment.

Link it to Project Planning and SWMS

Your risk matrix should be the foundation for all new work. Before starting any new project or non-routine task, make consulting the matrix a non-negotiable step in your standard operating procedure.

For instance, when you're putting together a Safe Work Method Statement (SWMS), the matrix can directly inform the "principal hazards" section. Any tasks that fall into the red or yellow zones on your matrix automatically demand detailed, robust control measures to be outlined in the SWMS. This creates a direct, practical link between your high-level risk assessment and your on-the-ground safety procedures.

This sharper focus on risk management is a huge driver of market growth. In Australia, the risk management market is projected to shoot up from USD 270 million in 2024 to over USD 782 million by 2033. Organisations are already spending over AUD 7.3 billion on related services this year alone. You can dig into more of these figures in the latest Australian risk management market report.

Digital Tools vs Whiteboards

How you maintain your matrix is less important than the principles behind it. Whether you use a slick digital platform, a detailed spreadsheet, or a big whiteboard on the wall, the core function is the same. Digital tools can certainly make updates and sharing easier, but a visible, well-used whiteboard can be just as effective for many teams.

Choose the method that works best for your crew and your workplace. The key is that the risk matrix is accessible, understood, and consistently used to drive real safety improvements across your entire operation.

Frequently Asked Questions About Risk Matrices

Got a few questions? You’re not alone. When it comes to risk matrices, a few common queries pop up time and time again. Let’s tackle some of the most frequent ones we hear from Health & Safety managers on the ground.

How Often Should We Update Our Risk Matrix?

Think of your risk matrix as a living document, not a set-and-forget exercise. As a bare minimum, you should be reviewing and updating it at least once a year.

But the real answer is: you update it whenever something significant changes. This could be bringing in new machinery, overhauling a work process, or starting a completely new type of project. Crucially, you should always revisit it after a near-miss or an incident. An outdated matrix isn’t just useless, it gives a false and dangerous sense of security.

Can a 3x3 Matrix Work Instead of a 5x5?

Absolutely. For smaller, less complex operations with a handful of clear-cut hazards, a 3x3 risk matrix can be perfectly fine. It gives you a quick, high-level snapshot of your risk landscape.

However, for more complex environments like construction, large-scale manufacturing, or sites with lots of moving parts, a 5x5 grid is almost always better. It provides more detail and nuance, helping you make more precise decisions. The best choice is always the one your team finds clear, practical, and easy to use consistently.

Who Should Be Involved in Creating the Risk Matrix?

This is a big one. The most effective matrices are a team effort, period. You need the H&S managers and project supervisors, of course. But the most critical voices are the frontline workers who actually do the job day in and day out.

Their hands-on experience is gold when it comes to assigning realistic likelihood and consequence ratings. Leaving them out is one of the most common mistakes we see, and it almost guarantees an inaccurate and ineffective risk assessment.

For more answers to common questions, you can review our full FAQ page.

Stop chasing paperwork and start preventing incidents. Safety Space is the all-in-one platform that makes managing your risk matrix, audits, and compliance straightforward. See how you can get real-time oversight and protect your team by booking a free demo at https://safetyspace.co.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.