A safe operating procedure (SOP) template is your blueprint for getting a job done safely and consistently. It’s more than just another piece of paperwork; it’s a critical tool for any high-risk task, especially in industries like construction and manufacturing. Think of it as a structured guide that clearly spells out the job's hazards, the control measures required, and the exact steps to follow.

What's The Point Of A Safe Operating Procedure Template?

At its core, a safe operating procedure template provides the structure for documenting how to complete a task correctly, every single time. Its main job is to take the guesswork and inconsistency out of high-risk activities. This ensures every worker, whether they're new to the site or have been on the tools for years, has a reliable reference to fall back on. In environments where one small deviation can lead to a serious incident, that consistency is everything.

But it's more than a simple checklist. A well-designed template forces you to systematically think through every part of a job, from the specific personal protective equipment (PPE) needed, right down to the final shutdown and clean-up steps. Using a standard template means you’re less likely to accidentally overlook a critical piece of safety information.

Why This Structure Is So Important

In high-risk industries, the consequences of not having clear procedures are severe. According to a Safe Work Australia report, traumatic injuries tragically claimed the lives of 188 Australian workers in a recent year. A huge portion of these fatalities came from sectors like construction and manufacturing. The fatality rate for machinery operators and drivers was more than five times the national average, which really drives home how vital well-structured SOPs are for these roles.

A good SOP template creates a repeatable process for managing risk. It prompts your team to identify the potential hazards tied to each step of a task and then define the specific control measures needed to manage them.

The real value of an SOP template isn't just in the final document, but in the process of creating it. It forces a detailed, practical conversation about how work actually gets done safely on the floor, not just how it's supposed to be done on paper.

This proactive approach is all about preventing incidents before they can happen. You can see similar principles of structure and preparedness in a guide to an emergency response plan template, where a standardised format is key to an effective response. By standardising your approach with a solid template, you build a much more predictable and controlled work environment for everyone on site.

How to Build Your SOP Template

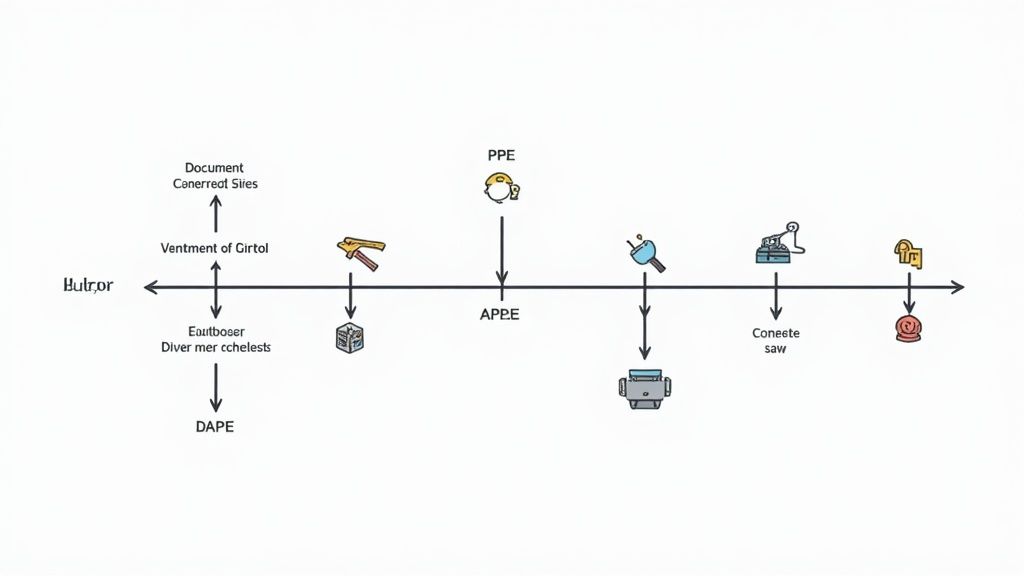

A good safe operating procedure (SOP) template is all about its structure. It’s not about creating complicated forms; it’s about organizing information so anyone can see a task's risks and controls at a glance. Let's build your template from the ground up, starting with the essential fields that create clarity and control.

This isn’t just an administrative exercise. It’s a core part of preventing the kind of incidents that lead to serious injuries. The data from WorkSafe Australia shows just how high the stakes are. In a single year, there were around 146,700 serious workers’ compensation claims lodged, that averages out to about 400 claims every single day. A structured approach is your best defense against becoming one of those statistics.

Start with Document Control

Every SOP template absolutely must begin with a document control block. It’s a small section, usually right at the top, but it’s crucial for preventing confusion and making sure everyone is working from the current version. Without it, you risk outdated procedures lingering on the workshop floor, creating some very real dangers.

Your document control block should have a few key fields:

- Procedure Title: A simple, clear name for the task (e.g., "Operating the Concrete Saw").

- SOP ID Number: A unique code for easy filing and reference (e.g., MAN-CS-001).

- Version Number: To track updates as they happen (e.g., V1.2).

- Effective Date: The day this version of the SOP is officially in use.

- Author/Reviewer: The name or role of who wrote or approved the document.

This information gives you an immediate snapshot of the document's status, which is vital for audits and day-to-day management. It creates a clear history for every procedure you have.

Define the Task and Required PPE

Straight after document control, your template needs a section that sets the scene. Kick it off with a simple field called "Task Description." All you need here is a sentence or two explaining the job this SOP covers. For example: "This procedure outlines the steps for safely cutting concrete slabs using the Model X walk-behind saw."

Next, and just as important, is a dedicated spot for "Personal Protective Equipment (PPE) Required." Don't be vague here. A bulleted list is your best friend because it’s impossible to miss.

Vague instructions like "wear appropriate PPE" are a safety hazard in themselves. Your template needs to force specificity. List the exact items required, like "steel-capped boots, high-impact safety glasses, P2 dust mask, and hearing protection (Class 5)." This removes all guesswork for the operator.

This part of your safe operating procedure template is non-negotiable. It should be one of the first things a worker sees before they even think about starting the task.

Structure the Core Procedure Steps

This section is the heart of your template. The most effective way to structure the actual procedure is with a simple table that clearly links an action to its specific dangers and the controls needed. You can find more on this approach in our detailed guide to a safe work procedure.

A good SOP template moves beyond a simple checklist and becomes a practical tool for managing risk at every stage of a job. Below is a table showing how you can map out hazards and controls for common tasks in manufacturing or construction.

Hazard Identification and Control Measures

| Task Step Example | Potential Hazard | Control Measure |

|---|---|---|

| 3. Secure workpiece in the metal lathe chuck. | Workpiece ejected at high speed. Contact with rotating chuck key. | Confirm power is off. Use correct size chuck key. Tighten all jaws evenly. REMOVE CHUCK KEY before starting. |

| 4. Erecting the first level of scaffolding. | Fall from height. Collapse of the structure. Dropped objects. | Use a harness and lanyard. Ensure all pins and braces are secure. Establish an exclusion zone below the work area. |

| 2. Mixing two-part epoxy resin. | Chemical burns to skin or eyes. Inhalation of toxic vapours. | Wear chemical-resistant gloves and safety goggles. Work in a well-ventilated area or use respiratory protection. |

This layout makes the relationship between an action, its hazard, and the necessary control measure incredibly clear. By building your template with this kind of structure, you create a foundation for actionable and repeatable safety instructions that your team can actually use.

Writing Procedures People Will Actually Follow

A perfectly structured safe operating procedures template is useless if the words inside are confusing, too technical, or just plain ignored. The whole point is to create a document so clear and practical that it becomes the easiest way to do the job right. We’re not writing a technical manual here; we’re giving clear instructions to the person on the tools.

This means you need to get straight to the point. Ditch the corporate jargon and convoluted sentences. Your team on the workshop floor doesn't have time to decode a paragraph of text when they're about to start a high-risk task.

Use Simple Language and Active Voice

This is probably the single most important change you can make. Write in the active voice. It’s direct, it's clear, and it tells people exactly what to do. The passive voice, on the other hand, is often vague and creates confusion about who is responsible for an action.

Just look at the difference:

- Passive: The guard must be checked before operation.

- Active: Check the machine guard before you start.

See? The active version is an instruction, not a suggestion. It's a small tweak in wording that makes a massive difference in clarity. As you write your procedures, go through each step and ask yourself, "Does this tell someone what to do?"

Keep sentences short and use simple, everyday words. If you wouldn't say it in a toolbox talk, don't write it in your SOP. The aim is immediate understanding, not to impress with a big vocabulary.

Bring Procedures to Life with Visuals

Let's be honest, text alone is often not enough, especially when you're dealing with complex machinery or multi-step tasks. People process visual information so much faster than text, so using images to back up your written instructions is a no-brainer.

You don’t need to be a professional photographer, either. Just use your phone to take clear pictures.

Here are a few simple ideas to get you started:

- Label Key Parts: Snap a photo of a machine and use simple arrows to point out the emergency stop, isolation switch, and main controls.

- Show the Correct Sequence: Use a series of photos to show the right order of actions, like how to properly attach a lifting sling.

- Highlight Dangers: A picture of a pinch point with a big warning symbol is way more powerful than a sentence buried in a paragraph.

Visuals break up the text, make the whole document easier to scan, and ensure the critical information really stands out. Of course, beyond just writing, the real challenge is making sure your SOPs are practical; for more on this, check out this guide on how to create SOPs that actually get used.

Involve the People Who Do the Work

You can’t write a practical procedure from behind a desk in an office. It just doesn't work. The most accurate and useful SOPs are always created with input from the experienced workers who perform the task day in, day out.

They know the reality of the job, the hidden quirks of the equipment, and the steps that actually work on the floor.

Schedule time to walk through the task with them. Ask them to explain each step in their own words as they do it. This process not only guarantees your written procedure reflects reality but also makes it much easier to identify hazards and apply effective control measures for risks. Their involvement is the secret ingredient to creating a safe operating procedure that people will actually trust and follow.

Putting Your SOPs Into Action on Site

A safe operating procedures template filled with perfect, clear instructions is a great start, but it doesn't do anything sitting in a folder. The real test is getting those procedures off the page and into the hands of your team in a way that actually sticks.

This is where many businesses stumble. They treat it like a box-ticking exercise instead of a practical, living part of the job.

Simply handing someone a document and telling them to "read it" is not training. Not even close. Effective implementation means showing, not just telling. It demands a hands-on approach that connects the words on the page to the real-world actions on the workshop floor or construction site.

Making Training Practical and Effective

Your goal is to make the SOP the easiest, most natural way to do the job.

One of the best ways to get there is through hands-on demonstrations. Walk the team through the procedure step-by-step, right there with the equipment. Point to the specific guards, switches, and lockout points mentioned in the document. Let them touch the controls and ask questions.

Another powerful tool is the daily or weekly toolbox talk. Instead of a generic safety chat, dedicate a session to a single SOP. You could cover the procedure for a new angle grinder or a recently updated lockout process. This keeps the information relevant and digestible, not overwhelming.

A procedure is only useful if it's understood and accessible. Training isn't a one-time event; it's an ongoing conversation that reinforces the 'why' behind each step, ensuring everyone is on the same page.

Effective workplace safety training integrates these procedures into daily work, making them a familiar reference rather than a forgotten document. It's this consistent reinforcement that makes the procedures become second nature.

Managing Versions and Keeping SOPs Current

Your worksite is not static. Equipment gets updated, processes are improved, and new tools are introduced all the time. Your safe operating procedures must keep up, otherwise, they quickly become irrelevant and, worse, dangerous.

This is where version control becomes absolutely critical.

You don't need a complex system. Every time an SOP is updated, even for a minor change, update the version number (e.g., from V1.2 to V1.3) and the "Effective Date." Simple.

Most importantly, you need a rock-solid process for getting old versions out of circulation. This means:

- Physical Copies: Hunting down and destroying any outdated printed copies that might be laminated to machines or tucked away in binders.

- Digital Files: Ensuring old PDFs are archived and only the current version is available on shared drives or company platforms.

Leaving an old procedure floating around is a recipe for disaster. It can lead to a serious incident if a worker follows outdated instructions for a modified piece of equipment.

Scheduling Regular Reviews

Don’t wait for an incident to review your SOPs. Proactive reviews are essential for keeping them sharp and effective.

A good rule of thumb is to schedule a formal review for every single procedure at least once a year. Pop a reminder in the calendar for each SOP’s anniversary.

When review time comes, get the team involved. Go to the workers who actually use the procedure day in, day out. Ask them directly: "Is this still accurate? Have any steps changed? Is anything here unclear?" Their feedback is pure gold, it’s the most valuable data you can get to ensure your documents actually protect your team.

Common Mistakes That Kill Great SOPs

Even with the best safe operating procedures template, you can fall into a few common traps. I’ve seen it happen time and time again. These mistakes are what turn a practical, life-saving guide into just another piece of ignored paperwork.

Knowing what these pitfalls are upfront means you can steer clear of them and create SOPs that your team will actually use.

The biggest mistake? Making the procedures way too long or complicated. If a worker has to wade through a ten-page document just to figure out how to use a simple tool, they won’t. It’s that simple. The SOP will end up collecting dust on a shelf while people fall back on memory or old habits, which completely defeats the purpose.

Writing in Isolation

Another massive error is trying to write an SOP from behind a desk, without involving the people who actually do the job. You just can’t write a practical, effective procedure from an office.

The workers who perform the task every single day are your true subject matter experts. They’re the ones who know the machine’s quirks, the specific challenges of the environment, and the little tricks that actually keep them safe.

When you write procedures without their input, you almost always miss critical details or, worse, include steps that are completely impractical on the workshop floor. This instantly destroys the document's credibility.

Involving your team isn’t just about getting their feedback; it’s about making them co-authors. A document written with them is far more likely to be a document used by them.

The fix is straightforward: make it a collaboration. Get out on the floor, watch the task being done, and write the steps down with the operator right there. This one simple act builds a sense of ownership and guarantees the final SOP reflects the reality of the job.

Being Too Generic

A "one-size-fits-all" safe operating procedure template is a great starting point, but the content inside can't afford to be generic. An SOP for a drill press in one workshop might be completely wrong for a different model in another location. This is especially true if the environment has its own unique hazards, like nearby pedestrian traffic or overhead obstacles.

Each procedure has to be tailored to the specific:

- Machine or Tool: That means noting its make, model, and any custom modifications.

- Work Environment: You need to consider lighting, ventilation, and what else is happening around the task area.

- Specific Task: A procedure for changing a blade is going to look very different from one for routine daily operation.

Failing to account for these variables creates dangerous gaps in your safety instructions. For instance, a generic SOP might not mention a nasty pinch point on a newer machine or the need for extra ventilation when using a certain chemical in a confined space.

Always walk the job. Write for the exact conditions you see, not for a general idea of the task. Your team's safety literally depends on that level of detail.

Your Top SOP Questions, Answered

If you’re wrestling with how to create a good safe operating procedure, you’re not alone. We get a lot of questions about the practical side of things. Here are a few of the most common ones we hear, with answers straight from our experience.

How Long Should a Safe Operating Procedure Be?

Honestly? It should be as long as it needs to be, but not a single word longer.

For a simple task, like using a bench grinder, you might only need one or two pages. But for a complex piece of machinery that needs a specific setup sequence, it could easily run to several pages.

The real test is usability. If you hand someone a dense, text-heavy document, they’re just not going to read it. That's a fact. You need to break it down with bullet points, use short, punchy sentences, and throw in photos or diagrams wherever you can.

Look, your goal isn't to write a technical manual. It’s to give your team clear, immediate instructions that stop someone from getting hurt. If a step doesn't directly contribute to that, get rid of it.

What's the Difference Between an SOP and a SWMS?

This is a big point of confusion, especially here in Australia. Think of it this way: a Safe Work Method Statement (SWMS) is a specific legal document. It's mandatory for any task that falls under the banner of "high-risk construction work." Its sole focus is identifying the major hazards of that specific job and detailing the controls you'll put in place.

An SOP, on the other hand, is a much broader tool. It’s simply a step-by-step guide on how to do any task safely and to the right standard.

So, while a SWMS is a legal must-have for certain high-risk jobs, you can, and absolutely should, develop an SOP for any task where you need a consistent, safe process.

How Often Should We Review Our Safe Operating Procedures?

At a minimum, you should be reviewing your SOPs on a set schedule. Most businesses find that an annual review works well. But here’s the critical part: a calendar reminder isn't enough.

You must review a procedure immediately any time something changes.

That means pulling it out and updating it when:

- New machinery or equipment shows up on site.

- You modify a process or change the workflow.

- There's an incident or even just a near-miss related to the task.

- The crew on the ground gives you feedback that a procedure is confusing, out of date, or just doesn't work in the real world.

Keeping your SOPs current isn't just a compliance task you tick off a list. It's a fundamental part of running a safe worksite. An outdated SOP can actually be more dangerous than having none at all, because it creates a false sense of security.

Ready to move beyond paper and spreadsheets? Safety Space is a fully customisable Health and Safety platform that simplifies compliance and helps you manage your SOPs effectively. Get a free demo and expert consultation.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.