A Safe Work Procedure (or SWP) is a detailed set of instructions that spells out exactly how to do a job safely, from beginning to end. It's not just more paperwork; it’s a practical tool used on construction sites and in manufacturing plants to stop injuries before they happen by identifying hazards and spelling out the controls.

What Are Safe Work Procedures Really?

Let's get straight to it. A Safe Work Procedure (SWP) is your team's playbook for getting a job done without anyone getting hurt.

It takes you past vague warnings like "be careful" and gives you clear, step-by-step instructions for tasks where the stakes are high. For example, instead of just telling someone to "use the grinder safely," a solid SWP will detail the exact PPE needed, how to inspect the disc before you start, and what to do if the tool kicks back.

These documents are critical in industries like construction and manufacturing, where a simple mistake can lead to a serious injury. The hard truth is that most incidents are preventable. Data shows that workplace fatalities in Australia climbed to 200 worker deaths in 2023. Over 75% of these tragedies happened in just six industries, including construction and manufacturing. The findings from Safe Work Australia really highlight why clear, usable procedures are so vital.

A well-written SWP is a key part of your bigger safety framework. It works hand-in-hand with your entire safety system to build a safer workplace. You can see how this fits into the bigger picture by exploring the 9 key elements of a health and safety management system in our other guide.

Core Parts of a Procedure That Works

For an SWP to be worth the paper it’s written on, it needs specific, practical information. It has to be something the person doing the job can read and understand quickly, right there on the floor or on-site. Generic templates from the internet often fall flat because they don't account for the unique conditions and risks of your site.

Here's a quick look at the essential parts that make a safe work procedure a useful tool on the ground, not just another file collecting dust in a cabinet.

| Component | What It Covers | Why It's Necessary |

|---|---|---|

| Task Description | A clear title and brief summary of the job. | Immediately tells the worker what the procedure is for, avoiding confusion. |

| Identified Hazards | A list of all potential dangers associated with the task. | Raises awareness of what could go wrong, from electrical shock to slips and falls. |

| Control Measures | Specific actions to eliminate or reduce each hazard. | Provides clear instructions on how to work safely (e.g., "isolate power supply before starting"). |

| Required PPE | The exact Personal Protective Equipment needed for the job. | Ensures workers are properly protected before the task begins. No guesswork. |

| Emergency Actions | Steps to take if something goes wrong. | Prepares workers for emergencies, reducing panic and improving outcomes. |

A good SWP is about clarity and action. It needs to give your crew the exact information they need to recognize the risks and follow the right steps to stay safe. If it’s too complicated or too generic, it simply won't get used.

How to Spot Real-World Site Risks

You can't write a useful safe work procedure without first knowing the actual dangers on a worksite. A generic checklist from a template won't protect anyone from the specific hazards your team faces every day. The real skill is looking at the work with a critical eye and breaking it down to see the risks hiding in plain sight.

It helps to use a common construction task as an example. Let’s take erecting mobile scaffolding for a two-storey building project. If you just write "set up scaffolding safely" on a procedure, you've missed the point. The real risks live in the details of the job.

Breaking Down the Task

To find the hazards, you first need to break the overall job into smaller, sequential steps. Thinking about that scaffolding task, the major parts aren't just one single action but a series of them.

- Transporting Materials: This is the first step, moving all the scaffolding components from the storage container to the work area.

- Site Preparation: Next, you need to inspect and prepare the ground where the scaffold will be built.

- Assembling the Base: This involves locking the wheels and putting together that crucial first level.

- Building Upwards: From there, you're adding the subsequent levels, platforms, and handrails.

- Final Inspection: The last step is performing all the necessary checks before anyone is authorized to use it.

By splitting the job into these distinct parts, you can analyze each one for its own specific dangers. This approach to breaking down work is a fundamental part of managing risk in project management, and it's what ensures you don’t overlook critical safety steps.

Identifying Hazards at Each Stage

Now, let's hunt for the hazards in each of those steps. This is where you shift from theory to practical, on-the-ground risk identification.

For transporting materials, the risks might include manual handling injuries from lifting heavy frames or workers tripping while carrying long poles. When it comes to site preparation, the dangers could be an unstable base from soft or uneven ground, or the risk of getting too close to overhead powerlines. These are the details that make a safe work procedure effective.

The goal is to get specific. A hazard isn't just "the scaffold might fall." It's "the scaffold could become unstable because the locking castors are not engaged on the slightly sloped concrete." That's the level of detail that actually prevents incidents.

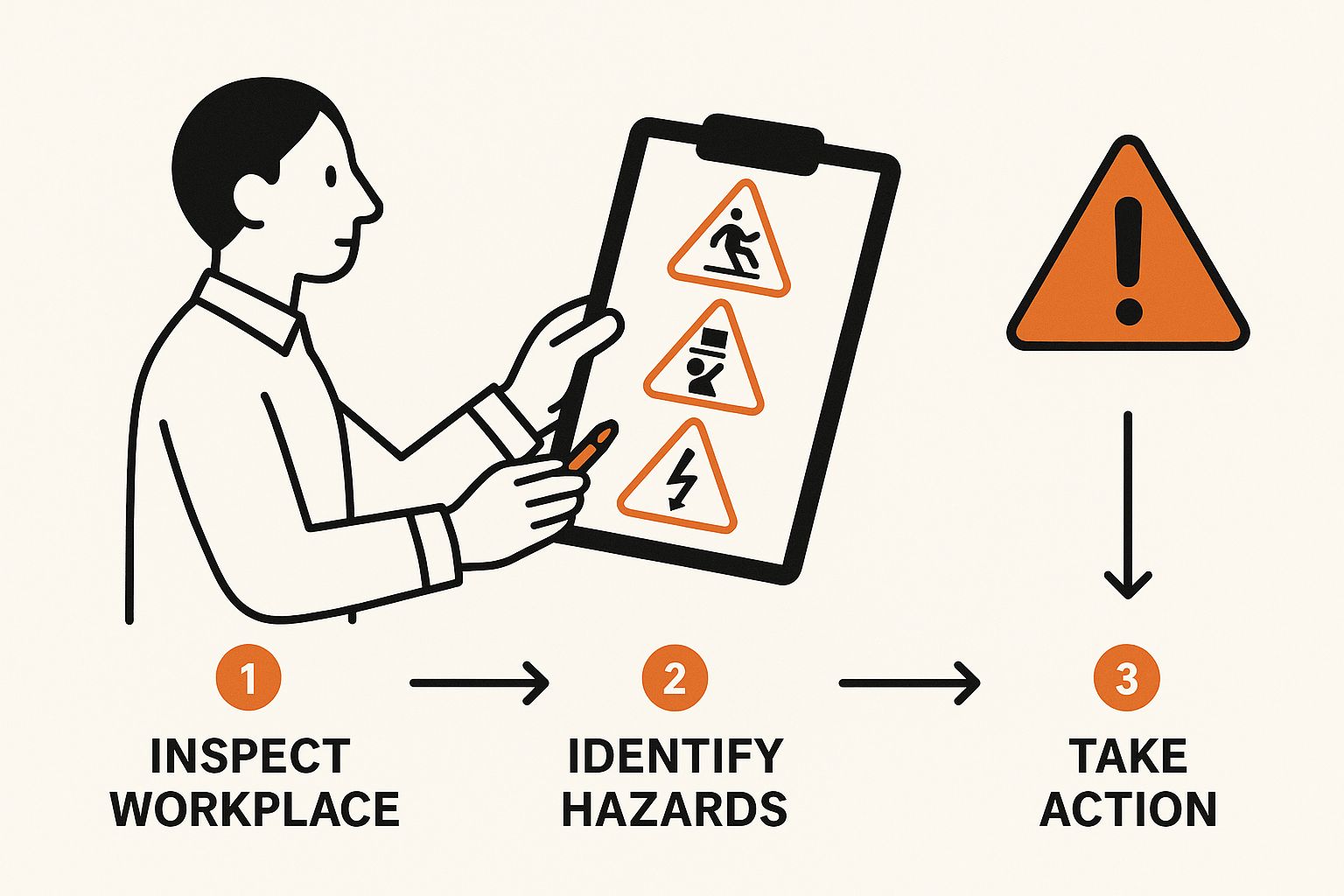

This infographic gives a simple view of how an inspector scans for different types of hazards in a work area.

It highlights the need to actively look at the environment for multiple risk categories, not just the obvious ones.

Assembling the scaffold introduces its own set of risks, like dropped tools or components hitting people below, or pinch points when connecting frames. As you build higher, the risk of falls becomes the number one concern, alongside the danger of the structure tipping if it's not assembled correctly.

By analyzing each stage like this, you create a complete picture of what could go wrong. That picture is the solid foundation for writing a procedure that people can actually use to stay safe.

Writing Procedures People Will Actually Follow

A safe work procedure is useless if it’s just a box-ticking exercise. If it’s confusing, long, or packed with jargon nobody understands, it will end up gathering dust on a shelf instead of keeping people safe.

The goal is to create a practical tool for the person doing the job. It needs to make immediate sense on a noisy worksite, not just satisfy a compliance audit.

Think about the difference between these two instructions for using a metal lathe:

- The confusing way: "The operator must ensure the workpiece is securely affixed within the chuck prior to machine activation, verifying guards are correctly positioned to mitigate ejected materials."

- The clear way: "Before you start: Firmly clamp the part in the chuck. Check the safety guard is down."

The second one is direct, uses plain English, and tells the worker exactly what to do. That's the point of a safe work procedure.

Use Simple Language and Formatting

Complex language doesn't make a procedure safer. It just makes it harder to follow. Stick to simple words and short sentences. Your crew on the ground doesn't have time to decipher a technical manual when they're about to start a high-risk task.

Use formatting to your advantage. Breaking up text with bullet points, numbered lists, and bold text makes the whole thing scannable and easier to digest.

A good procedure boils down to a few simple writing rules:

- Use active voice. Say "Isolate the power source" instead of "The power source should be isolated." It’s direct and tells people what to do.

- Keep sentences short. One main idea per sentence is a solid rule.

- Use lists for steps or gear. Bullet points are perfect for listing required PPE, while numbered lists are great for sequential actions.

Your procedure should be written for the worker, not for the safety manager or a lawyer. If the person doing the job can’t understand it quickly, it has failed.

This isn't just theory; it has real-world consequences. The Australian construction industry recorded the second-highest number of workplace fatalities in 2023. This prompted SafeWork SA to conduct 213 audits, leading to 674 statutory notices, including 195 prohibition notices that stopped work on the spot.

These numbers show that regulators are looking past the paperwork. They’re focused on whether your procedures are actually being followed. You can read more about these regulatory actions on the SafeWork SA website.

Show, Don’t Just Tell

Sometimes, words just aren't enough. One of the most effective ways to improve a procedure is to include photos or simple diagrams from your actual worksite. A picture showing the correct way to attach a safety harness is far more powerful than a paragraph describing it.

For example, this template for a Safe Work Method Statement (SWMS) from SafeWork NSW is a great illustration of clarity.

Notice how it breaks the task down into logical steps and forces you to list controls for each hazard. This makes the information clear and actionable.

Visuals are brilliant for demonstrating things like:

- Correct setup for equipment

- How to wear specific types of PPE

- "No-go" zones or other danger areas

- The location of emergency shut-off buttons

Get out on site and take photos using your own people and your own gear. It makes the procedure instantly relatable and removes any guesswork. A clear photo showing the right way to brace a trench is better than a page of complicated text.

Training That Actually Sticks

A well-written safe work procedure is a great start, but it’s useless if it just sits in a folder. Handing a worker a document and getting a signature isn't training; it's a paper-shuffling exercise. For a procedure to protect people, the information needs to move from the page into practice on the worksite.

Real training is about communication that works. It means getting people actively involved, not just ticking a box. This is important because memory fades fast. One study found that only about half of employees could accurately recall their safety training a week later. That number dropped to 10% after six months. You can read the full research about safety training recall yourself, but the takeaway is clear: one-off sessions just don't work. Ongoing reinforcement is needed.

Methods for Practical Training

To make training stick, you have to make it interactive and tie it directly to the job at hand. People learn best by doing and discussing, not by passively listening to someone in a site shed.

Here are a few practical methods that get real results:

- Toolbox Talks: These short site meetings are perfect for zeroing in on a specific safe work procedure before a shift starts. You can run through the procedure for a task happening that day, highlight the key risks, and answer questions.

- On-the-Spot Demonstrations: For anything involving specific gear or techniques, show, don't just tell. Walk them through the critical steps of the procedure, like how to correctly set up a mobile scaffold or follow the lockout-tagout process. Get them to do it with you.

- 'What-If' Scenarios: Throw realistic problems at the crew. Ask them, "What would you do if the e-stop on this machine failed?" or "What's the first thing you do if you see your mate get a chemical splash?" This kind of thinking cements their understanding of what to do when things go wrong.

The real test of good training isn't whether they can sign a form. It's whether they can explain the procedure back to you. Ask a worker to show you a critical safety check or talk you through the steps. If they stumble, the training hasn't worked.

Making Procedures Accessible on Site

Even with the best training, procedures need to be easy to find when it matters most. No one is going to walk back to the site office to rifle through a binder. The information needs to live where the work is happening.

Think about these simple but effective ways to make procedures instantly available:

- QR Codes: Put a weather-resistant QR code sticker directly on a piece of machinery. Anyone can scan it with their phone and instantly pull up the relevant SWP.

- Laminated Copies: For key work areas, keep laminated, durable copies of procedures at the point of use. This could be in a plastic sleeve at a workstation or attached near the equipment.

By making safe work procedures both easy to understand through hands-on training and simple to access on-site, you’re giving your team the tools they need to follow the rules and stay safe.

Keeping Your Procedures Up to Date

A safe work procedure isn't a "set and forget" document. A procedure gets filed away and never looked at again. Meanwhile, the worksite changes daily. New equipment arrives, staff come and go, and job requirements shift.

A procedure written just six months ago could be dangerously out of date today. It has to be a living document that adapts to the reality of your operations.

The review process can't be random. You need clear triggers that automatically prompt you to take another look and make sure it's still fit for purpose. If you wait for an incident to happen, you're too late.

When to Review a Safe Work Procedure

Certain events on-site should act as immediate red flags, signalling that a review is needed. These are moments when the risk profile of a task has most likely changed, making the old instructions obsolete.

Think of these as your review triggers:

- After any incident or near-miss. This is the most critical trigger. The event itself is proof that the existing controls weren't effective enough.

- When new equipment is introduced. A new machine, tool, or vehicle comes with its own hazards and operating rules that need to be captured.

- If the task itself changes. Even a minor change in a process can introduce new risks that weren't there before.

- When new people join the team. A review is a good way to reinforce procedures and check that everyone, new and old, is on the same page.

- At scheduled intervals. Even if nothing obvious changes, a regular check-in (annually, for example) is just good practice. It keeps safety front of mind.

This is especially true as technology changes how we work. By 2025, the growing use of automation and robotics in Australia is creating new kinds of risks around how people interact with machines. This means safe work procedures must be updated frequently to manage these emerging challenges. You can find more insights on how HSE trends are reshaping workplace safety on thesafestep.com.au.

Get the Right People Involved

A supervisor reviewing a procedure in an office is a good start, but it's not enough. Your most valuable feedback will always come from the people who perform the task every day.

They know the shortcuts people are tempted to take, the frustrations with the current process, and what actually works on the floor.

Involving your crew in the review process isn't just about being inclusive; it's about getting accurate, ground-truth information. They will spot problems and offer practical solutions that a manager, sitting in an office, might never see.

This process is a key part of maintaining workplace safety and is closely related to more formal assessments. You can learn more about the importance of regular safety audits for your business in our related guide.

When you sit down with the team, ask direct questions. Does this step still make sense? Is this PPE really the best option we have? Is there a safer or simply a better way to get this done?

This collaborative approach is what makes your procedures practical, effective, and respected by the people who use them.

Even with a solid system for your safe work procedures, questions are bound to come up. When they do, you need straight answers to keep things moving.

Here are a few of the most common queries we hear from site managers and business owners, along with our practical take.

Are Safe Work Procedures Legally Required?

Yes, but the official language can be murky. Under Australia's WHS Act, a Person Conducting a Business or Undertaking (PCBU) has a primary duty of care. A large part of that duty is providing and maintaining safe systems of work for your crew.

The legislation won't spell out "you must have a document titled 'Safe Work Procedure' for every single task." But it does require that you manage risks. A documented SWP is the most practical and widely accepted way to prove you have a system in place to control known hazards.

For any task that's routine or carries a higher risk, a written procedure isn't just best practice, it's the industry standard for meeting your legal obligations.

What’s the Difference Between an SWP and a SWMS?

This is a massive point of confusion, especially on construction sites. The real difference is a legal one, and it all comes down to the type of work being done.

A Safe Work Procedure (SWP) is a general term for any documented process for doing a job safely. You might have an SWP for changing a tyre on a ute or for the daily maintenance checks on a piece of machinery.

A Safe Work Method Statement (SWMS) is a specific legal requirement for what’s defined as "high-risk construction work" under WHS Regulations. We're talking about jobs like working at heights over two metres, demolition, or anything near live electrical lines.

The easiest way to think about it is this: all SWMS are a type of SWP, but not all SWPs are a SWMS. A SWMS is a high-stakes, legally mandated document for a specific list of dangerous jobs that must be done before work starts.

What Do I Do if a Worker Ignores a Procedure?

This is a serious situation that needs to be handled immediately, but also fairly. When someone ignores a safe work procedure, they're putting themselves and their workmates at risk.

Your first move is always to stop the work. Find out why the procedure wasn't followed.

Sometimes, it's an honest mistake. Maybe the training wasn't clear, or there's a flaw in the procedure that makes it impractical in the real world. If that's the case, it’s a good chance to get feedback and fix the process.

However, if it was a deliberate breach, you have to follow your company’s disciplinary process. This needs to be a clear, documented procedure that might lead to a formal warning or being removed from the site, depending on how severe the risk was. The key here is consistency.

Trying to manage safety documents, training records, and reviews across multiple sites can be an uphill battle. Safety Space replaces scattered paperwork and clunky spreadsheets with a single platform that works.

See how you can simplify your compliance, get a real-time view of your sites, and build a safer workplace. Book a free demo and consultation to see how it works.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.