If you're looking for a SWMS template for WA, you're in the right place. A Safe Work Method Statement (SWMS) is a required document for any high-risk construction work in Western Australia. It's your plan for managing serious safety risks before the job starts.

Understanding Your SWMS Duties in Western Australia

A SWMS is more than a pre-start checklist. It's a key part of the state's work health and safety laws. Getting it right starts with knowing who is responsible for what. In WA, these duties are clearly set out so everyone knows their role in managing high-risk tasks.

The responsibility sits with the Person Conducting a Business or Undertaking (PCBU), usually the main contractor or business owner. The PCBU must make sure a SWMS is prepared before any high-risk construction work begins. They’re also responsible for making sure it’s followed on-site and updated when things change.

Who Does What on Site

When roles are clear, a SWMS becomes a useful tool instead of a document in a folder. Here’s a quick breakdown:

- PCBU (Principal Contractor): Their job is to get the SWMS created by talking with the workers doing the job. They are legally responsible for its use and for keeping it available on-site for anyone to review.

- Supervisors: They are on the ground, making sure the work follows the plan. It's their responsibility to check that the control measures listed in the SWMS are being used by the crew.

- Workers: The team doing the work, along with their health and safety reps, must be part of the conversation when the SWMS is drafted. They also have a duty to follow the safe work methods agreed upon in the document.

A compliant SWMS is about communicating the plan clearly so that everyone, from the site manager to the newest apprentice, knows exactly how to get the job done without anyone getting hurt.

The Rise of SWMS in WA

While SWMS are not new, the focus on them has grown. The number of high-risk construction projects needing a SWMS jumped by 34% between 2015 and 2020. This reflects tougher enforcement since the Work Health and Safety (General) Regulations 2022 came into effect, which set the SWMS requirement for all high-risk construction.

You can find the official rules on the WorkSafe WA website.

Ultimately, a good SWMS template for your WA project helps you create a practical, site-specific plan. It needs to reflect the actual job, the real-world hazards, and the control measures your team can and will use. Getting a handle on WHS legislation in Western Australia is the best first step to making sure your documents are compliant. This is how you move beyond box-ticking and make safety a functional part of your daily site management.

Adapting Your Template for Real WA Work Sites

Downloading a generic SWMS template is the easy part. The real work is tailoring it to the specific job you’re doing right now, on a real WA work site.

A template filled with vague hazards is just a box-ticking exercise. A properly adapted SWMS is a useful tool for your crew on the ground.

The whole point is to move from general statements to concrete, site-specific details. You need to look at the unique conditions of your location, whether that's a windswept high-rise project in the Perth CBD or a dusty civil works site up in the Pilbara. Each location has its own challenges that a one-size-fits-all document will miss.

For instance, simply writing "working at heights" doesn't help. It tells your team nothing. You need to describe the actual situation they're walking into.

From Generic Hazard to Site-Specific Risk

Let’s break down how to make a SWMS useful for a common construction task in WA. It’s about adding layers of detail that reflect reality.

- Generic Hazard: Working at heights.

- Site-Specific Risk: Installing cladding on the 15th floor of a Perth CBD building, where strong afternoon sea breezes (the Fremantle Doctor) create a risk of workers losing balance or materials being blown off the structure.

That small change in wording completely shifts the focus. It makes you think beyond just fall protection and start considering wind loading, material tethering, and maybe even scheduling the work for calmer parts of the day. The control measures instantly become more targeted and effective.

Here’s another classic WA example: excavation. The coastal plain is known for sandy, unstable soil, which behaves very differently from clay.

- Generic Hazard: Trench collapse.

- Site-Specific Risk: Excavating a 2-metre-deep trench for plumbing in sandy soil near Mandurah, which is prone to collapsing without warning.

The control here isn't just "shoring." It’s specifying the exact type of shoring or trench box needed for that specific soil condition.

A SWMS template for WA is only as good as the site-specific information you put into it. The difference between a compliant document and a useful safety tool is how accurately you describe the environment your team is actually working in.

Tailoring Controls for Manufacturing Environments

This isn't just a construction site problem. A busy warehouse or manufacturing plant in an industrial hub like Welshpool or Kewdale has its own dynamics. A generic "forklift operation" SWMS often fails to capture the real-world interactions that lead to incidents.

Think about this scenario:

- The Task: Moving pallets from the receiving dock to the main storage racks.

- The Generic SWMS: Lists "collision with pedestrians" as a hazard, with a vague control like "use horn at intersections."

- The Site-Specific SWMS: Identifies that the main forklift path crosses a high-traffic walkway between the lunchroom and the factory floor, especially around 10 AM. The control becomes much sharper: "Install physical barriers and a stop sign at the pedestrian crossing. Forklift operators must stop and make eye contact with pedestrians before proceeding. Prohibit non-essential foot traffic in this zone during peak delivery times."

By looking at the when and where of the risk, the control measure changes from a suggestion into a clear, direct instruction that tackles the problem.

Writing Controls Your Team Can Actually Follow

The final, crucial piece is writing control measures that are practical and simple to understand. Ditch the jargon and vague instructions that leave room for interpretation.

Here’s how to turn weak controls into practical instructions for a common manufacturing task:

| Poor Control Measure (Vague) | Practical Control Measure (Specific) |

|---|---|

| "Wear appropriate PPE" | "Wear cut-resistant Level 5 gloves, safety glasses, and steel-capped boots when operating the sheet metal press." |

| "Be careful around machinery" | "Maintain a 2-metre exclusion zone around the CNC machine while it is in operation, marked with yellow floor tape." |

| "Ensure good housekeeping" | "All offcuts and waste materials must be cleared from the work area and placed in the designated yellow bin every hour." |

Specificity is key. It removes doubt and gives your workers clear instructions they can follow without any guesswork. When you adapt your swms template wa with this level of detail, it stops being another piece of paper to sign and forget, and starts being a tool that helps get the job done safely.

Common Mistakes That Make a SWMS Useless

A Safe Work Method Statement can be a powerful tool, but it's worthless if it’s just treated as a box-ticking exercise. Too often, a SWMS gets filled out, signed, and then put in a folder in the site office, never to be seen again.

WorkSafe inspectors see the same critical errors repeatedly. These mistakes create compliance risks and fail to protect your workers. It's easy to fall into the trap of creating a document that looks good on paper but has no practical value.

Avoiding these common problems is what separates a useful SWMS from a useless one. A solid swms template wa is your starting point, but how you fill it in makes all the difference.

Writing Vague and Useless Controls

This is probably the biggest mistake. Control measures like "be careful," "use common sense," or "wear PPE" are meaningless without specifics.

These phrases offer no real guidance. They leave everything open to individual interpretation, which is what a good SWMS is meant to prevent.

Put yourself in a worker's shoes. If they're about to use a concrete saw and the SWMS just says "be aware of surroundings," what does that actually tell them to do? Nothing. A useful control is a direct, measurable instruction.

Here’s what that looks like in the real world:

- Useless Control: "Use correct PPE when cutting concrete."

- Practical Control: "Wear P2-rated respiratory mask, safety glasses, Class 5 hearing protection, and steel-capped boots during all concrete cutting. An exclusion zone of 5 metres must be taped off with barrier mesh."

The second version is a clear instruction. It names the specific gear required and adds a measurable action (the 5-metre exclusion zone). There's no room for guesswork.

Failing to Consult with the Team

Another classic error is creating the SWMS in an office, far from the actual work. A site manager filling out a template without talking to the people on the tools is guaranteed to miss critical details.

The workers doing the job have hands-on knowledge. They know the quirks of the equipment, the tricky parts of a task, and the shortcuts people might take. Leaving them out of the conversation means you’re ignoring your best source of safety information.

Consultation isn't just a nice-to-have; it's a legal requirement under WA WHS laws. A SWMS developed without talking to the relevant workers is non-compliant.

Involving your team also creates ownership. A worker who helps write the safety plan is more likely to follow it than one who is just handed a document and told to sign.

Treating the SWMS as a "Set and Forget" Document

Work sites are constantly changing. The weather shifts, new hazards appear, and unexpected problems arise. A SWMS written at the start of a project might be irrelevant a week later.

A common failure is not reviewing and updating the document when things change. A SWMS is a living document, not a static one.

It must be reviewed if:

- The scope of work changes: Even a small tweak to a task can introduce new risks.

- Site conditions are altered: A heavy downpour could make an excavation site unstable, or a new delivery could block an escape route.

- An incident or near-miss occurs: This is a huge sign that your controls aren't working and need an immediate rethink.

For example, a SWMS for trenching created during a dry spell is no longer good enough after a significant downpour. The risk of collapse is now much higher. The review process isn't just paperwork; it’s a critical check to make sure your plan still matches the reality on the ground.

Putting Your SWMS into Action on Site

Having a perfectly customised SWMS template for your WA project is a great start, but it’s useless if it just sits in a folder. The real test is turning that document into a practical, on-the-ground tool that your team uses every day. This is where you move from a compliance exercise to an active safety process that prevents incidents.

The bridge between the written plan and the physical work is the pre-start meeting. This daily huddle is the perfect time to make the SWMS the central point of discussion. Instead of a quick, generic "be safe out there," use the SWMS to walk the team through the day's high-risk tasks.

This process ensures everyone, from your most experienced operator to the newest apprentice, is on the same page. They need to hear the specific hazards and the exact control measures they are expected to follow.

The Pre-Start SWMS Walkthrough

Running a pre-start meeting with the SWMS as your guide is both simple and effective. It’s not about reading the document word for word. Think of it as a focused conversation that reinforces the plan.

A good walkthrough covers these key points:

- Confirm the Task: "Right, today we're installing the roof trusses on Level 2. Does everyone understand the sequence we've outlined in the SWMS?"

- Highlight Key Risks: "Remember, the main risks are falls from height and dropped materials. The wind is forecast to pick up after midday, so we need to be extra careful with securing tools."

- Reinforce Controls: "Full-body harnesses are mandatory, and all tools must be tethered. We've established a 5-metre exclusion zone below the work area, marked with barrier tape."

- Check for Understanding: "Any questions about the harness inspection or the tethering points? Does anyone see any other hazards we haven't covered?"

This kind of conversation makes the SWMS feel relevant. It also gives workers a chance to provide input based on what they're seeing on-site, which is valuable.

A SWMS sign-off isn't just about collecting signatures. It’s a formal acknowledgment that each worker has participated in the discussion, understands the risks, and agrees to follow the agreed-upon control measures. This documented understanding is critical for accountability.

From Paper to Practice: The Supervisor's Role

Once the work starts, the supervisor’s job is to make sure the plan is being followed. This is about active monitoring. A supervisor should be able to walk through the work area and see the control measures from the SWMS in action.

If the SWMS says an exclusion zone is required, is it in place and being respected? If specific PPE is listed, is everyone wearing it correctly? This daily oversight turns the SWMS from a theoretical plan into a set of observable actions. It's also vital for covering specific high-risk tasks like excavation; for instance, understanding safe potholing practices in construction is necessary before breaking ground.

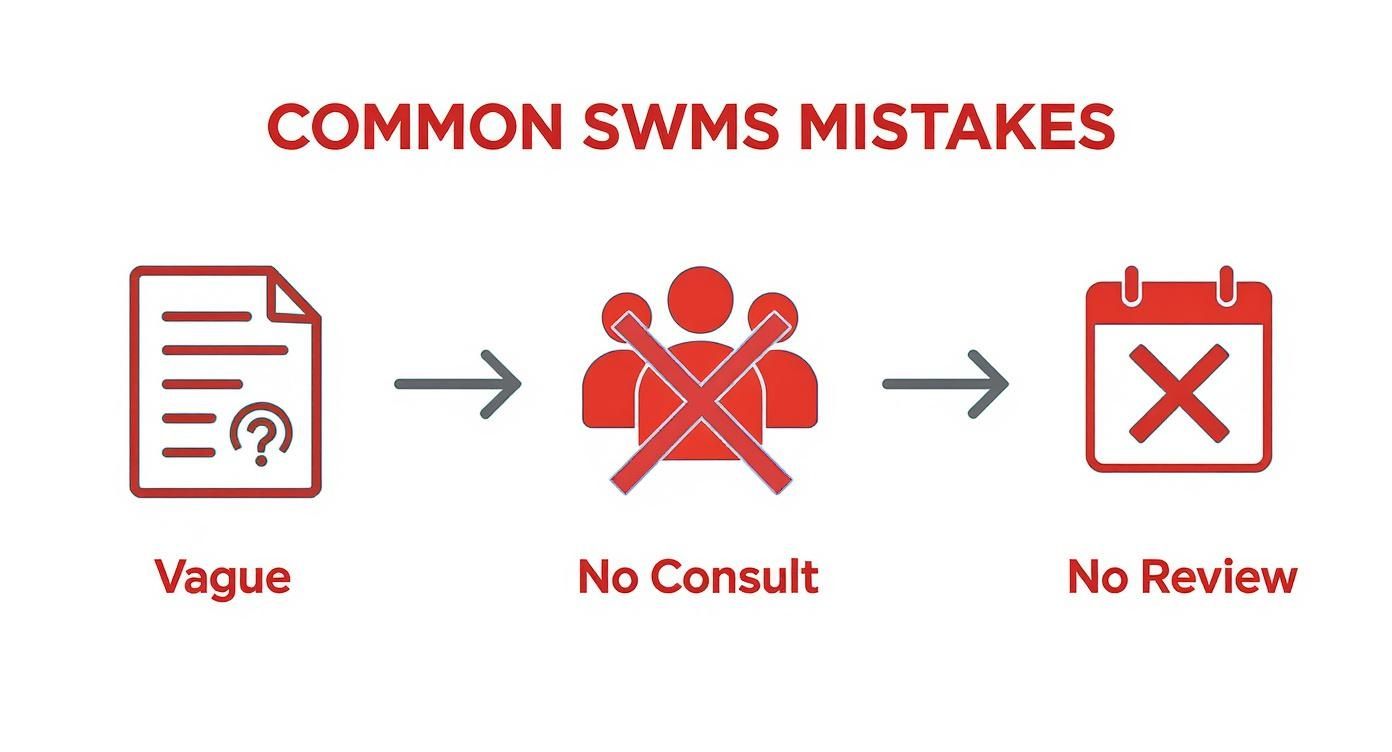

This infographic shows some of the most common ways a SWMS can fail before it even gets to the implementation stage.

These failures, vague controls, no worker consultation, and a lack of review, make it nearly impossible to implement the document effectively on site.

Documenting Understanding, Not Just Attendance

Getting workers to sign the SWMS is a crucial step, but it has to be done right. It's more than just an attendance sheet.

The sign-off is a record that each person has been informed about the risks and controls. It must happen after the pre-start discussion, never before.

This documented step is often checked during site inspections. It connects the planning phase with the practical work, showing that you’ve communicated the safety plan to the people most at risk. This also ties directly into a thorough site induction process, where general site rules are reinforced by task-specific safety plans like the SWMS. You can learn more about building a solid process with a good site induction template that complements your SWMS.

By making the SWMS a central part of daily site conversations and supervisory checks, it becomes a dynamic and useful tool, not just another piece of paper. It helps make sure the safety measures planned in the office are the same ones being used on the tools.

Managing SWMS for Subcontractors and Multiple Sites

The paperwork can start to pile up when you bring subcontractors onto a project or manage work across different WA locations. Juggling all those parts needs a clear process, not just a bigger folder. Your responsibilities as the principal contractor extend to every person on site, including those working for other companies.

When you engage a subcontractor for high-risk construction work, you have a legal duty to collect, review, and approve their SWMS before they start. This is a critical check to make sure they’ve thought through the risks and have a compliant plan.

Reviewing Subcontractor SWMS

You don't have to write their SWMS for them, but you are responsible for making sure it’s up to standard. When a subcontractor gives you their SWMS, you're looking for a few key things to confirm it’s not just a generic, recycled document.

A proper review means checking for:

- Site-Specificity: Does it mention your project by name and address? Or is it a generic template that could apply to any job?

- Task Relevance: Does the SWMS accurately describe the exact high-risk work they’ll be doing on your site?

- Clear Controls: Are the control measures specific and actionable? Vague statements like "work safely" are a major red flag.

- Worker Consultation: Is there evidence that they’ve talked it through with their own workers?

You're checking that they've done their homework. If their SWMS is not good enough, you have to send it back for revision before they can begin. This is a non-negotiable part of your duty. Keeping track of these interactions and approvals can be a challenge, which is why many businesses use a dedicated contractor management system to keep all the documentation and communication in one place.

Adapting a Master SWMS for Multiple WA Sites

For businesses operating across different regions, like a project in the Pilbara and another in the South West, creating a brand-new SWMS for every site is a waste of time. The better approach is to develop a solid master SWMS template for your high-risk tasks and then adapt it for each location's unique conditions.

Think of your master SWMS as the main recipe. For each new site, you're not starting from scratch; you're just adjusting the ingredients based on the local environment.

For instance, your master SWMS for operating a crane will cover universal hazards like dropped loads and equipment failure. But the site-specific version needs that extra layer of detail.

- For the Pilbara site: You might add controls for managing the effects of extreme heat on machinery and operators, plus procedures for securing the crane during cyclonic wind warnings.

- For the South West site: The focus might shift to controlling risks related to working on softer ground after heavy winter rains or managing interactions with the public in a built-up area.

This method allows you to maintain a high standard of safety planning across all your operations. By starting with a strong master document, your site teams can focus their energy on identifying and controlling specific local risks, which makes the whole process more practical.

Getting Your SWMS Ready for an Audit

The thought of a WorkSafe WA visit, or even an internal review, can be stressful. This isn't about reciting regulations; it's a practical checklist to help you self-assess your SWMS documents and your process.

Think of it as a quick health check. It’s designed to help you spot and fix small gaps before they turn into a major headache during an inspection.

Is It Actually for This Site and This Task?

First things first, an inspector can spot a generic, copy-pasted SWMS from a mile away. It's an immediate red flag.

- Does your SWMS clearly name the project, list the specific site address, and define the exact high-risk work it covers?

- Have you identified hazards unique to this specific WA site? Think about local soil conditions, coastal wind, extreme heat, or tricky site access points.

- Are the control measures you’ve listed practical for the job, using the gear and people you actually have on-site?

Was the Right Team Involved?

Next is proving that your SWMS is a collaborative document, not just instructions handed down from an office.

Remember, consultation is a non-negotiable legal requirement. You must have proof that you've involved the people doing the work.

Have the workers who will be on the tools been consulted while the SWMS was being developed? Is there a clear sign-off sheet showing they've read it, understood it, and had the chance to ask questions?

Is It Being Used on Site?

Finally, and most critically: is the SWMS actually being put into practice? A perfectly written document that gathers dust in the site office is useless.

- Are the control measures detailed in the SWMS physically in place and being used correctly on the worksite?

- Do your supervisors and foremen regularly check that the work matches what's written in the SWMS?

- Do you have a clear process for reviewing and updating the document if site conditions change, a new hazard appears, or you have a near-miss?

Before any formal audit, running through these simple questions gives you a clear, honest picture of where you stand. Use this quick checklist to see how your SWMS stacks up.

Pre-Audit SWMS Checklist

| Check Point | Status (Yes/No) | Action Needed |

|---|---|---|

| Is the project name and address clearly stated? | ||

| Does it cover a specific high-risk construction task? | ||

| Are site-specific hazards (e.g., local weather) included? | ||

| Is there a record of worker consultation? | ||

| Is the worker sign-off section complete? | ||

| Are the specified controls physically present on site? | ||

| Is there a process for reviewing/updating the SWMS? |

This simple table can be a real help. If you've got a "No" anywhere, that's your starting point. Fixing these items now will put you in a much stronger position when an inspector arrives.

Got Questions About WA SWMS Templates?

We hear these a lot when talking to businesses across Western Australia. Here are some quick, direct answers to the most common questions about SWMS.

Does My Small Business in WA Really Need a SWMS?

Yes, if you're doing 'high risk construction work'. It doesn't matter if you're a sole trader with a Ute or a large company.

If the work falls into that high-risk category, like working at heights over two metres, any kind of demolition, or digging near pressurised gas lines, a SWMS is required. It has to be done before anyone picks up a tool.

How Often Should I Review a SWMS?

A SWMS is a living document, not a set-and-forget piece of paper. You must review it if the job changes, even slightly, or you realize a control measure isn't working in the real world.

An incident on site? That's an automatic trigger for a review. But it's good practice to give it a quick look before every shift. A quick pre-start chat is the perfect time to confirm nothing's changed and everyone's still on the same page.

Your SWMS has to reflect the reality on the ground right now. An outdated SWMS offers no protection if conditions have changed and your controls are no longer effective.

Can I Use a Generic SWMS Template from Another State?

You can, but it's not recommended. It's safer and simpler to start with a template that’s already aligned with WA's specific WHS legislation.

If you grab a generic one, the responsibility is on you to make sure it meets every requirement of WA law. You'll also need to heavily customize it for the specific work, the site, and all the local hazards. It often creates more work than it saves.

Stop chasing paperwork and start getting safety right. Safety Space brings all your SWMS, subcontractor compliance, and site monitoring into one simple platform. Book a free demo and see how much easier H&S management can be.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.