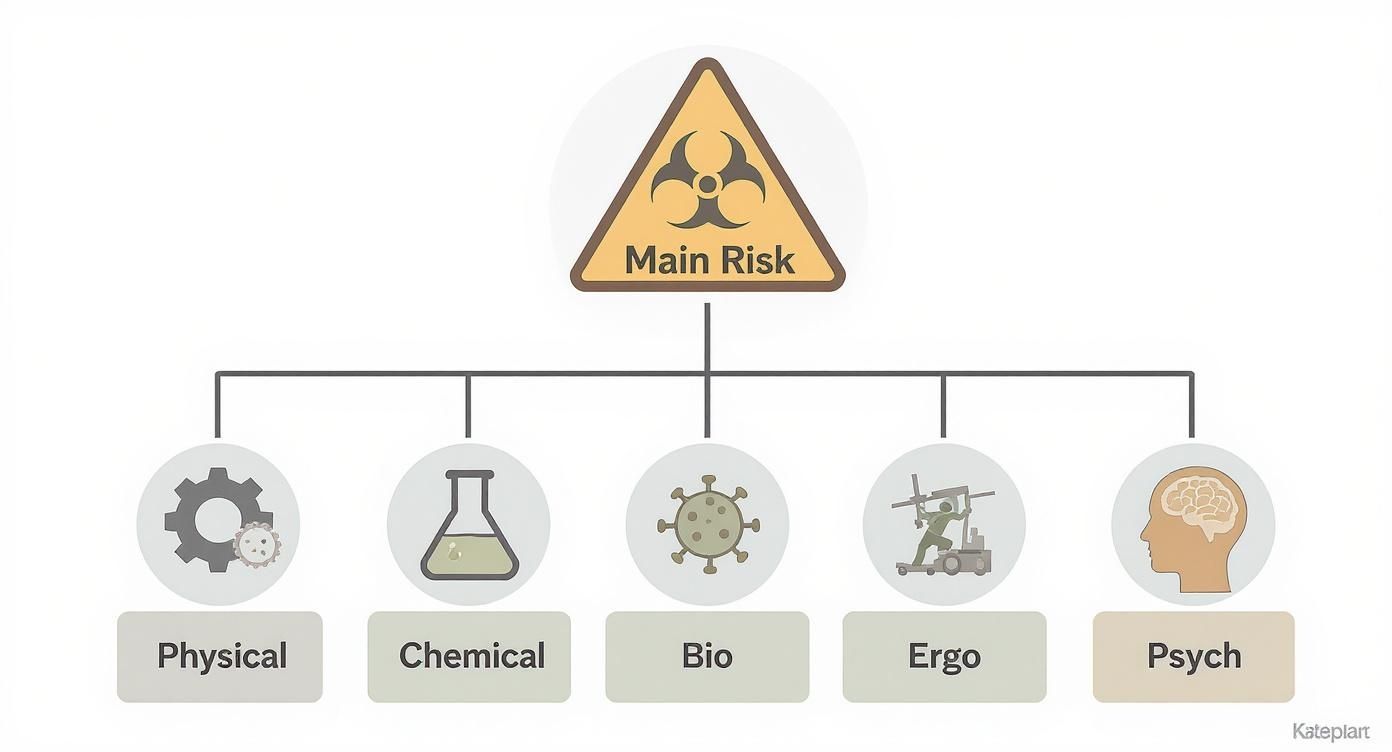

When you're trying to get a handle on workplace safety, it's easy to feel overwhelmed by all the different things that could go wrong. The trick is to break it down. Think of it less as one giant problem and more as a few distinct categories of challenges. Most workplace hazards fall into one of five main groups: physical, chemical, biological, ergonomic, and psychosocial risks.

Understanding these categories is the first step toward building a safety system that actually works. It helps you move from just reacting to incidents to proactively spotting trouble before it starts.

A Practical Guide to Workplace Risk Categories

So, what are these five types of risk? Think of them as a mental checklist you can run through when you walk onto any job site. Some dangers are obvious, like a noisy piece of machinery, but others are much more subtle, like the long-term strain a repetitive task puts on someone's body.

By sorting potential hazards into these groups, you make sure nothing gets missed. It’s a simple but effective way to organise your approach and build a solid safety plan.

The Five Core Types of Risks

Let's break down each of the five main risk groups. Each one represents a different source of potential harm, covering everything from tangible objects right through to the work environment itself.

- Physical Risks: These are usually the easiest to spot. We're talking about anything in the environment that can cause harm through force or energy. Common examples include unguarded machinery, excessive noise, electrical hazards, working at heights, or a slippery floor.

- Chemical Risks: This group covers any hazardous substance that can cause harm, whether it's liquid, solid, or gas. Think of things like industrial cleaning agents, solvents, welding fumes, or fine dusts like silica.

- Biological Risks: These are hazards that come from living organisms. This is a major one in healthcare and agriculture, but it can pop up anywhere. We're talking about viruses, bacteria, mould growing in a damp area, or even insect bites in outdoor work.

- Ergonomic Risks: This is all about the fit between a person and their job. It’s the physical strain that a task puts on the body over time. Poorly designed workstations, repetitive movements, awkward postures, and heavy lifting are all classic ergonomic risks that lead to sprains, strains, and long-term injuries.

- Psychosocial Risks: These are the hazards that affect a person's mental health and wellbeing. They're often invisible but can be just as damaging as a physical injury. This category includes things like excessive workload and stress, workplace bullying, poor communication, and a lack of support from managers.

Seeing them laid out like this shows that a good safety plan needs to cover all the bases. This structured thinking is the foundation of good hazard identification. If you want to get more details on that initial process, check out our guide on what is hazard identification.

To make this even clearer, here’s a quick summary table.

Quick Guide to Workplace Risk Categories

| Risk Type | Description | Example in a Construction Setting |

|---|---|---|

| Physical | Hazards from environmental factors or energy that can cause direct physical harm. | An unguarded saw or excessive noise from a generator. |

| Chemical | Harmful substances that can be inhaled, ingested, or absorbed through the skin. | Inhaling silica dust from cutting concrete or spilling an industrial solvent. |

| Biological | Threats from living organisms or organic matter. | Exposure to mould in a damp, poorly ventilated area. |

| Ergonomic | Strain on the body from poorly designed tasks, equipment, or workspaces. | Developing a back injury from repeatedly lifting heavy materials. |

| Psychosocial | Factors in the work environment that affect mental and emotional wellbeing. | High stress levels due to unrealistic project deadlines. |

This table is a great starting point for training your team to spot different kinds of risks in their own work areas.

The key takeaway is that risk isn't just one thing. A truly safe worksite requires looking at potential harm from multiple angles, from the machines people use to the stress they might be under. Addressing only one category leaves big gaps.

Spotting Physical and Chemical Dangers

When you're on site, physical and chemical risks are two of the most immediate dangers you'll come across. They're tangible hazards that can cause serious harm in an instant if they aren't properly managed. Knowing how to spot and control them is the foundation of keeping your worksite safe and productive.

Physical risks are usually the most obvious ones. Just think of any source of energy or force that has the potential to hurt someone. This could be moving parts on machinery, objects falling from scaffolding, or the deafening noise from industrial equipment. On a busy construction site, it might be an unsecured ladder waiting to slip or an exposed electrical wire. In a factory, it could be a forklift zipping through a tight space or an unguarded conveyor belt.

But these dangers aren't just about sudden accidents. Constant exposure to high noise levels, for instance, can cause permanent hearing loss over time. The key is to walk through the work environment and constantly ask yourself, "What here can move, fall, crush, or shock someone?"

Identifying Common Physical Hazards

To make spotting these risks more practical, it helps to break them down. Thinking in categories helps you systematically scan a work area and find potential problems before they turn into incidents.

Some of the most common physical risks you’ll see include:

- Moving Machinery: This is a big one. It covers any equipment with moving parts, like presses, saws, or robotic arms, that could easily trap or injure a worker.

- Working at Heights: Any work done on ladders, scaffolding, or rooftops carries a significant fall risk. This is consistently a leading cause of serious injuries in the construction industry.

- Electrical Hazards: Frayed cords, overloaded circuits, and equipment that isn't properly grounded can lead to severe shocks or even fires.

- Noise and Vibration: It's easy to overlook, but long-term exposure to loud machinery or vibrating tools can cause serious, long-term health issues.

Managing Chemical Risks on Site

Chemical risks are just as serious, covering any substance that could cause harm if it's inhaled, touched, or swallowed. And we're not just talking about big barrels of corrosive acid here. This includes everyday materials like industrial solvents, cleaning agents, welding fumes, and the fine dust from cutting concrete.

The first step in managing these is simply knowing exactly what you're dealing with. Every hazardous chemical on your site must have a corresponding Safety Data Sheet (SDS). Think of this document as your practical guide. It gives you the crucial info on storage, handling, and what to do if things go wrong.

Keeping an organised and accessible library of Safety Data Sheets isn't just a compliance task. It's a critical tool that gives your team the practical information they need to handle materials safely every single day.

Proper management comes down to clear, actionable steps. This means storing chemicals in designated, well-ventilated areas, making sure every container is correctly labelled, and providing the right Personal Protective Equipment (PPE) like gloves or respirators. Training is essential; your team has to understand the specific risks of the chemicals they use and the right procedures for handling them.

Figuring out exposure levels is also a big piece of the puzzle. For tricky situations, you can use our chemical exposure calculator to get a better grip on potential risks. When you combine solid handling procedures with good awareness, you can dramatically cut down the threat posed by hazardous substances in your workplace.

Uncovering the Hidden Dangers: Biological and Ergonomic Risks

Not all workplace dangers are loud, obvious, or immediate. Some of the most serious threats are the quiet ones. These are the risks that build up over time, almost unnoticed, until they cause significant, long-term harm.

Biological and ergonomic risks fall squarely into this category. They often fly under the radar in day-to-day operations, making them easy to miss until it’s too late. Spotting these hidden threats is a crucial part of any solid safety management plan.

When we talk about biological risks, we’re talking about hazards from living organisms. And no, this isn't just a concern for scientists in a lab. These risks can pop up in any industrial setting. Think about mould growing in a damp, poorly-ventilated corner of a workshop, bacteria breeding in unclean facilities, or contaminated water sources on a sprawling construction site. Pinpointing these issues, like knowing the signs of mold in air ducts, is the first step to tackling the invisible dangers that can compromise your team's health.

The Slow Burn of Ergonomic Risks

Ergonomic risks are all about the physical toll a job takes on the human body. Unlike a sudden fall, this kind of damage is a slow burn, accumulating from repetitive movements, awkward body positions, or using too much force. It’s essentially a slow-motion injury caused by a mismatch between a person and their work.

These problems are common in industries like manufacturing and construction. On an assembly line, making the same tiny movement hundreds of times a day can easily lead to painful conditions like carpal tunnel syndrome. For a construction worker, years of heavy lifting or working hunched over in tight spaces can result in back and shoulder injuries that are completely debilitating.

The core principle of ergonomics is simple: fit the job to the person, not the person to the job. A minor adjustment to a workstation’s height can be the difference between a healthy employee and one facing a lifetime of chronic pain.

Managing these risks effectively starts with just watching how the work gets done. Keep an eye out for tasks that involve:

- Repetitive Motions: Actions performed over and over again, like twisting, turning components, or packing boxes.

- Awkward Postures: Working with hands above the shoulders, bending at the waist for extended periods, or kneeling on concrete.

- Heavy Lifting: Manually handling materials or tools, especially when it involves twisting the torso.

Practical Fixes to Reduce Physical Strain

Once you start spotting these patterns, you’ll find that many of the solutions are surprisingly straightforward. For instance, raising a workbench can stop a worker from slouching all day, which does wonders for preventing back strain. Providing anti-fatigue mats is a simple fix that eases the stress on workers who are on their feet for long shifts.

Training is just as crucial. Teaching your team proper lifting techniques, like bending at the knees and not the waist, is a basic but incredibly effective preventative measure. For jobs with repetitive hand movements, scheduling short, regular breaks for stretching can make a world of difference.

By paying attention to these subtle yet significant risks, you’re not just ticking a compliance box. You’re actively protecting your people from injuries that can seriously impact their wellbeing, both on and off the job.

The Impact of Psychosocial Risks

Not every risk on a worksite leaves a physical mark. Some of the most disruptive hazards are the ones that affect your team's mental and emotional wellbeing.

These are known as psychosocial risks, and they usually grow out of poor work design, disorganised processes, or ineffective management.

We're talking about more than just feeling stressed. These are real workplace hazards that can lead to burnout, high staff turnover, and a measurable drop in productivity. In high-pressure environments like manufacturing or construction, the impact can be even more pronounced.

Imagine a factory floor where production targets are constantly unrealistic. The team feels perpetually behind, which leads to chronic stress and exhaustion. Or picture a construction site with vague instructions and patchy communication, where the crew has no real say over how they tackle their tasks. In these situations, burnout isn't just a possibility; it's almost inevitable.

Common Sources of Psychosocial Harm

To get a handle on these risks, you first need to recognise what they look like on the ground. They often show up in the way work is structured and how people interact day-to-day.

Here are a few key examples to watch for:

- High Job Demands: This isn’t just about being busy. It’s when the workload is consistently excessive, with tight deadlines creating a constant feeling of pressure.

- Low Job Control: When your team has little say in how or when their work gets done, it can breed feelings of helplessness and frustration.

- Poor Support: This is what happens when help from supervisors and colleagues is missing, leaving people feeling isolated when they run into problems.

- Workplace Conflict: Unresolved disagreements, bullying, or harassment can create a toxic atmosphere that directly damages mental health.

Think of it this way: if a machine is poorly designed or maintained, it will eventually break down. In the same way, if a job is poorly designed, it puts unsustainable strain on the person doing it, leading to burnout and poor performance.

Practical Steps for Managing These Risks

Tackling psychosocial risks isn’t about big gestures. It’s about making deliberate, practical changes to the work environment to reduce stressors at their source.

For example, promoting clear and open communication is a simple but incredibly effective fix. When everyone understands what’s expected and feels they have a voice, it cuts down on uncertainty and conflict.

Another critical step is ensuring workloads are fair and manageable. This might mean reviewing project schedules, reallocating resources, or bringing on extra hands during peak periods.

Finally, creating clear channels for support is essential. This means making sure supervisors are approachable and properly trained to help their teams navigate pressure. By focusing on these practical management strategies, you can build a more resilient and productive team, addressing one of the most significant types of risks in the modern workplace.

The Rise of Digital Risks in Modern Industry

As industrial sites become more connected, a new breed of risk has moved from the server room to the factory floor. Digital threats are no longer just an IT headache; they're a serious operational hazard for every manufacturing, construction, and industrial business.

The line that once separated the operational technology (OT) running your machinery from the information technology (IT) managing your data has become incredibly blurry. While this connectivity makes us more efficient, it also creates new problems. A cyberattack isn't just about stolen data anymore. It can physically shut down a production line or hijack the control systems for heavy equipment.

These aren't just hypothetical scenarios. A ransomware attack could freeze your entire plant, halting production for days and costing you a fortune. A simple data breach could expose sensitive project plans or employee details, leading to massive financial and reputational damage.

Securing Your Connected Worksite

Tackling these modern types of risks means we need to think beyond standard IT security. The game has changed. The real focus now has to be on protecting the critical systems that keep your doors open and your operations running.

The national data backs this up. Cybersecurity threats have become one of the most dominant risk categories in Australia. The Office of the Australian Information Commissioner (OAIC) reported that a staggering 1,113 data breaches were notified during 2024. That’s a huge 25% jump from the 893 reported in 2023 and the highest annual total since mandatory reporting started. You can dig deeper into these findings on Australian data breaches to see just how fast this problem is growing.

Given this reality, protecting your industrial control systems is completely non-negotiable. These are the brains behind the brawn, the systems directly managing physical processes, and they need to be shielded from anyone who shouldn’t have access.

Here's the key shift in thinking: your digital security plan is now a core part of your operational safety plan. A vulnerability in your network can be just as dangerous as an unguarded machine on the factory floor.

Building a Practical Defence

So, what can you actually do about it? The good news is that you don't need to become a cybersecurity guru overnight. Practical, effective measures are well within reach for any organisation. It all comes down to putting sensible controls in place.

Start with these fundamental steps:

- Secure Your Industrial Control Systems: A great first move is to separate your OT network (the one running the machines) from your general business IT network (the one for emails and admin). This simple step, often called network segmentation, makes it much harder for a threat that gets into your email system to cross over and cause physical chaos.

- Train Your People: Many breaches begin with a simple phishing email that an employee clicks on. Regular, practical training helps your team spot suspicious messages and think twice before clicking dangerous links. This is one of the highest-impact, lowest-cost things you can do.

- Have an Incident Response Plan: Don't wait for an attack to happen to figure out your game plan. Create a clear, simple plan that outlines who to call and what steps to take to isolate the problem and get back up and running. When the pressure is on, a plan is everything.

By treating digital threats with the same seriousness as any other workplace hazard, you can shield your operations from this disruptive and rapidly growing risk. This isn't just about protecting data anymore; it's about protecting your entire business.

A Simple Plan for Managing Workplace Risks

Knowing the different types of risks is a great start, but the real value comes from what you do with that knowledge. You need a straightforward plan to systematically find, understand, and deal with workplace hazards. This isn’t about creating complex documents just for compliance; it's about a practical process that actually keeps people safe.

A simple, four-step framework works for any hazard, from a slippery floor to a complex chemical exposure. Let’s walk through it with a running example from a construction site to see how it works in the real world.

Step 1: Identify the Hazards

First, you need to find what could cause harm. Walk through your worksite with a fresh pair of eyes and look for potential problems. Even better, talk to your team. They’re on the ground and often know the risks better than anyone.

- Construction Example: During a site walk, you notice a generator running in a poorly ventilated basement. This immediately flags a clear physical risk (noise) and a chemical risk (carbon monoxide fumes).

Step 2: Assess the Risks

Once you've spotted a hazard, you need to figure out how serious it is. This comes down to two simple questions: How likely is it that someone will be harmed? And how severe would that harm be?

- Construction Example: The generator is loud, but the bigger issue is the fumes. The likelihood of carbon monoxide poisoning is high because the space is enclosed, and the potential harm is severe, even fatal. This immediately makes it a high-priority risk that needs urgent attention.

Step 3: Control the Risks

Now it's time to take action. The goal here is to eliminate the risk if you can, or at the very least, reduce it as much as practically possible. You should always aim for the most effective solution first, which usually means getting rid of the hazard entirely.

For a deeper dive into this crucial step, you can explore our detailed article on effective control measures for risks.

The best control is always elimination. Moving the generator outside completely removes the fume hazard from the enclosed space, which is far more effective than just giving workers masks.

Here are some options you might consider, from most to least effective:

- Elimination: Can you get rid of the hazard? (Move the generator outside.)

- Substitution: Can you replace it with something safer? (Use an electric generator.)

- Engineering Controls: Can you physically isolate people from it? (Install a powerful ventilation system.)

- Administrative Controls: Can you change how people work? (Limit time spent in the basement.)

- Personal Protective Equipment (PPE): Can you protect the worker with gear? (Provide carbon monoxide detectors and respirators.)

Step 4: Review Your Controls

Your job isn't done once a control is in place. You have to circle back and regularly check that it's working as intended. Are people following the new procedure? Is the equipment still effective? Is the fix still in place?

- Construction Example: After moving the generator outside, you check back to ensure it stays there. You also confirm that the extension cords now in use don't create a new trip hazard, ensuring your solution hasn't accidentally introduced a different type of risk.

This four-step cycle, Identify, Assess, Control, Review, is a simple but effective way to manage all the different types of risks we've discussed. For a more expansive view, consider guides on building a resilient risk management strategy that protects your entire business.

Managing these steps with paper and spreadsheets can be a real headache. Safety Space gives you a central platform to identify, track, and review risks in real-time, making sure nothing falls through the cracks. Simplify your safety management by visiting https://safetyspace.co to book a free demo.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.