A near miss is an unplanned event that almost resulted in injury, illness, or damage, but didn't. Think of it as a free warning sign from your workplace. It’s a clear signal that a hazard exists, and the only thing that prevented a serious outcome was luck or timing.

So, What's a Near Miss in Simple Terms?

Imagine a heavy box topples from a high shelf in a warehouse. It lands with a thud exactly where a worker was standing just seconds before. No one got hurt and nothing was damaged, but the potential for a severe injury was clear.

That close call is a near miss. It’s easy to breathe a sigh of relief and move on, but that’s a missed opportunity. Instead, it's far more valuable to see it as a leading indicator. It points directly to a real problem in your work processes, equipment, or environment that needs to be fixed before that luck runs out.

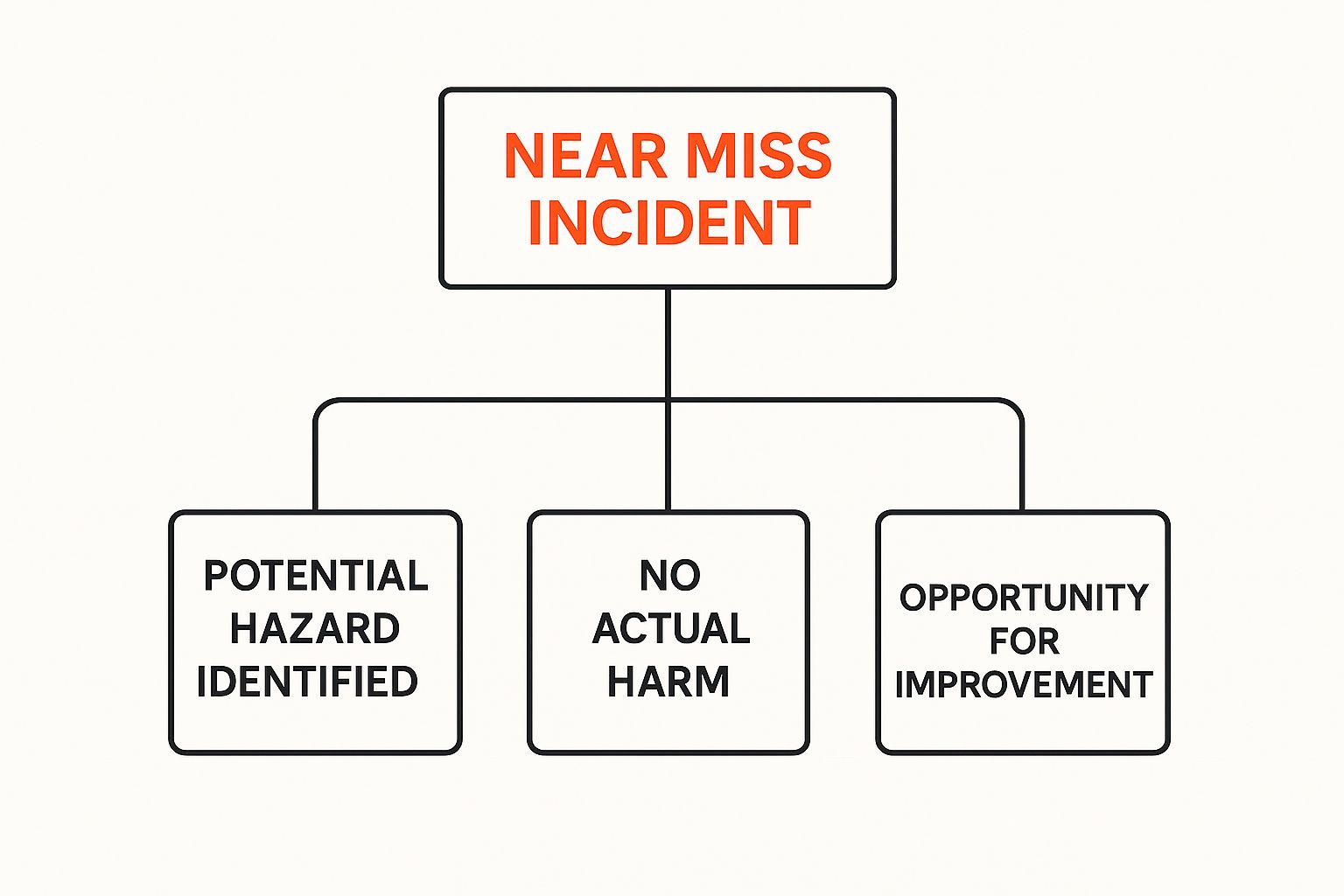

The infographic below shows what a near miss is and why it matters.

As you can see, every near miss is a chance to spot a hazard where no harm occurred, creating an opportunity to make things safer for everyone.

Getting the Lingo Right: Key Workplace Safety Terms

To talk about safety well, we all need to be on the same page with the language we use. It’s common for people to use "near miss," "incident," and "accident" in the same way, but in health and safety, they have specific meanings.

Getting these terms right isn’t just about being picky; it helps make clear exactly what happened and what level of response is needed. This simple table breaks down the differences.

Near Miss vs Incident vs Accident

| Term | Definition | Example (Construction Site) |

|---|---|---|

| Near Miss | An event that had the potential to cause harm, but didn't. | A hammer falls from scaffolding and lands on the empty ground below. |

| Incident | An unplanned event that results in property damage but no injury. | A forklift backs into a wall, causing damage to the wall but not injuring the operator. |

| Accident | An unplanned event that results in injury or illness to a person. | A worker trips over a loose cable and sprains their ankle. |

Understanding these differences helps everyone in the team report issues with more clarity, making sure that the right follow-up actions are taken every time.

Why Investigating Near Misses Is Essential

Ignoring a near miss is like deleting a free lesson on how to prevent a future disaster. These "close calls" aren't just moments of good luck; they're critical warnings that show hidden flaws in your work processes, equipment, or environment before they cause a recordable injury.

When you investigate what is a near miss, you shift from being reactive to proactive. Instead of waiting for an accident to happen and then trying to fix the fallout, you get ahead of the problem. This approach saves time, protects your team, and reduces costs associated with downtime and potential injury claims.

Think of it this way: a near miss is a direct preview of a future accident. Investigating it is your opportunity to change the ending of that story.

The Link Between Near Misses and Serious Incidents

The connection between minor close calls and major accidents is clearer than you might think. Many serious injuries, and even fatalities, are preceded by a series of smaller, unaddressed near misses. Each one is a clue pointing to a bigger, systemic risk that's just waiting to cause harm.

Data from Safe Work Australia shows just how common the events leading to these incidents are. In 2023, vehicle incidents and being struck by moving objects accounted for over half of the 202 worker fatalities.

On top of that, issues like body stressing (45,500 claims) and falls, slips, and trips (30,300 claims) were leading causes of serious injury claims. It's no surprise that these incidents often start out as near misses that were overlooked. By tracking and acting on these warnings, you can systematically remove the hazards that lead to such bad outcomes.

Building a Stronger System

Every near miss investigation provides practical, real-world data you can use to make your workplace safer. It’s not about pointing fingers or assigning blame; it's about digging to find the root cause.

Was it a faulty piece of equipment? A gap in training? Or an unsafe shortcut that has quietly become common practice?

Answering these questions allows you to put in place specific, corrective actions that actually work. This process strengthens your entire safety program, making it more resilient and effective. Properly managing this flow of information is one of the 9 key elements of a health and safety management system, as it turns potential disasters into practical, life-saving improvements.

Real-World Near Miss Examples

The idea of a near miss can feel a bit abstract. So, let's make it real. We'll look at a couple of practical examples from high-risk work environments that show just how fine the line is between a close call and a catastrophe.

These stories aren't just what-ifs; they show how a routine task can turn dangerous in a split second. They stick in your memory and help drive the message home on site.

Example 1: Construction Site

Picture a busy construction site. A team is working on the ground floor, right below another crew assembling scaffolding two levels up. A strong gust of wind catches a plank that wasn't properly secured. It tumbles end over end, hitting the concrete with a loud crack, just centimetres from a worker's head.

In this case, the worker was very lucky. A few steps to the left or a slightly different angle of the fall, and this would have been a serious injury, or worse. This near miss is a massive, flashing warning sign that the procedure for securing materials aloft is failing.

This is a textbook example of what is a near miss in a building environment. It’s a free lesson, delivered by the real world, on why double-checking tools and materials is required, especially when working at height.

Example 2: Manufacturing Plant

Now, let's head inside a manufacturing plant. An experienced machine operator is trying to clear a minor jam. Under pressure to keep the production line moving, he decides to bypass a safety guard for what he thinks will be just a second. As he reaches into the machine, it unexpectedly cycles.

He yanks his hand back in a flash, feeling the whoosh of air on his fingertips as the press slams down. No harm done. But the potential for a life-changing hand injury was sky-high.

This incident reveals a dangerous gap between the official, written procedure and how the work actually gets done on the floor. This "close call" is a critical signal that people are taking shortcuts. It tells you the safety guards might be too clunky or the process too slow, pushing workers to find a workaround. Addressing this head-on is how you prevent the real accident from ever happening.

How to Report a Near Miss

Knowing what a near miss is only gets you halfway there. It’s what you do next that really counts.

Reporting a close call shouldn’t be a complex or intimidating process. At its heart, it’s a straightforward activity focused on fixing problems, not pointing fingers. When someone experiences or witnesses a near miss, the real goal is to capture what happened quickly and clearly so the root cause can be uncovered and fixed for good.

A clear, simple reporting process removes fear and confusion. It makes it easier for everyone on site to contribute to making the workplace safer.

A Simple 3-Step Reporting Process

If you find yourself in a near miss situation, these three steps are all you need to remember. Following them ensures the event is handled correctly and actually leads to positive change.

Stop and Secure the Area: Your first priority is simple: prevent an actual accident from happening. Stop what you’re doing immediately and make sure the area is safe for everyone. This could be as simple as cordoning off a spill, shutting down a piece of equipment, or just warning others about the immediate hazard.

Tell Your Supervisor Immediately: Let your direct supervisor or safety rep know what happened as soon as you can. A quick verbal report is the fastest way to get the ball rolling and make sure leadership is aware of the risk. Don’t wait until the end of your shift, timing is everything.

Document the Facts: While the details are still fresh in your mind, write down what happened. Stick to the facts. The aim is to create a clear picture of the event, not to assign blame.

What Information to Record

When you're documenting the event, try to capture these key details. This information is vital for the investigation that follows.

- What happened? Describe the event from start to finish.

- Where did it happen? Be specific about the location.

- When did it happen? Note the date and time.

- Who was involved or who was nearby?

- What factors did you notice that might have contributed? Think about things like a wet floor, faulty gear, or poor lighting.

The importance of a simple, no-blame reporting process can't be overstated. A major Australian survey found that while 54% of workers know about serious hazards at their workplace, many feel there aren’t enough consequences for employers to truly prioritize safety. This perception can kill any motivation to report issues. You can read the full findings on Australian worker safety perceptions to learn more.

Ultimately, a simple, blame-free system is what encourages people to report these crucial warnings before they turn into something much worse.

Turning Reports into Corrective Actions

A near miss report is only as good as the action it starts. Once you've logged the details of a close call, the real work begins: a practical investigation process designed to turn that "what if" moment into a lasting safety improvement.

Let's be clear: this process isn't about finding someone to blame. It’s all about digging into the "why" behind what happened. The final goal is to pinpoint the root cause so it can be fixed properly, preventing the exact same thing from happening again, only next time, with a much worse outcome.

A near miss report isn't just a piece of paper. It's the starting point for a process that directly protects you and your workmates by making the job tangibly safer.

From Report to Solution

The investigation isn't just a formality; it's the bridge from gathering facts to developing a concrete fix. This usually involves a few key steps:

- Gather Information: The safety team or supervisor will look at your report, chat with anyone who saw what happened, and check out the area where the near miss occurred.

- Find the Root Cause: This is where they dig deeper than the obvious issue. Was it a faulty piece of equipment, a missing machine guard, a confusing procedure, or just poor lighting?

- Develop Corrective Actions: Based on the true root cause, a practical and lasting solution is created. We're talking about a permanent fix, not a temporary patch-up job.

For example, a report about a slippery floor near a machine shouldn't just result in a one-time cleanup. A proper investigation might find the machine has a slow, persistent leak. In that case, the corrective actions would be to repair the machine, install permanent non-slip matting, and add the area to a daily cleaning schedule. You can find out more about how to prioritise fixes like these with a good risk management matrix.

This practical approach shows exactly how your report leads directly to a safer workplace for everyone. And it's not just a theory; the data backs it up. Analyses show that worksites with high numbers of near misses often overlap with the sites of actual accidents, including serious injuries. This proves that tracking what is a near miss helps us find and fix dangerous blind spots before anyone gets hurt.

Common Questions About Near Misses

Even with a clear process in place, people are often hesitant to report a near miss. It's only natural. Getting straight answers to common worries helps everyone feel more confident in doing the right thing.

Let's tackle some of the most frequent questions we hear.

Will I Get in Trouble for Reporting a Near Miss?

No. A good reporting system is designed to fix the problem, not find someone to blame. The whole point of tracking near misses is to get ahead of hazards before they cause real harm. When you report something, you’re being helpful and proactive, not causing trouble.

What If the Near Miss Seems Minor?

Report it anyway. Seriously. It’s the small things that often lead to the big accidents.

A slightly frayed cord or a small puddle on the floor might seem insignificant. But think about it, under slightly different circumstances, that tiny issue could have led to a serious injury. A pattern of seemingly "minor" reports is often the loudest signal that a much bigger risk is hiding in plain sight.

Every single report, no matter how small, adds a valuable piece to the safety puzzle. This data helps your safety team spot dangerous patterns and fix systemic risks that just aren't visible from a single incident.

Who Is Responsible for Fixing the Problem?

Your main job is just to report what you saw, clearly and honestly. From there, it’s typically up to your supervisor or a dedicated safety manager to take the lead.

They'll investigate what happened to get to the root cause and figure out the best way to make sure it doesn't happen again. This could mean:

- Repairing a piece of faulty equipment

- Updating a work procedure that's no longer safe

- Organising extra training for the team

It’s always a good idea to circle back with your supervisor to see what action was taken. This kind of follow-through is exactly what makes things like regular safety audits for your business so effective.

At Safety Space, we provide a simple, all-in-one platform to manage near miss reporting, investigations, and corrective actions, helping you build a safer, more compliant workplace. Get your free demo today.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.