If you’ve heard the acronyms OHS or WHS used, you might be wondering what the difference is. The short answer is not much. They both point to the same goal: having a formal system to keep people safe at work.

Work Health and Safety (WHS) is simply the modern, national term for what was traditionally known as Occupational Health and Safety (OHS). Think of it as the set of rules for preventing injuries and illness on your worksite.

What Do OHS and WHS Look Like in Practice?

At its core, a good WHS framework is about being proactive. It's not about filling out paperwork after an accident. It’s about identifying and managing risks before anyone gets hurt. It’s a structured approach to make sure every worker, contractor, and visitor gets home in one piece at the end of the day.

Imagine your worksite is a busy highway. You wouldn’t let cars drive without road rules, speed limits, and traffic lights, right? WHS provides those same rules for your workplace. These are legally required systems designed to control hazards and protect everyone involved.

This is especially important in high-risk industries like construction and manufacturing, where the potential for serious harm is a daily reality. The numbers from Safe Work Australia tell a sobering story. Over the past decade, more than 1,850 Australian workers have died from work-related injuries, and over 1.14 million serious workers' compensation claims were lodged. You can learn more about the latest WHS statistics and their impact to understand what's at stake.

OHS vs WHS At a Glance

So, what's the practical difference between the two terms? It really just comes down to which state or territory you’re in. The shift from "Occupational" to "Work" was part of a national push to standardise safety laws and make the language more inclusive of modern working arrangements.

The term 'work' is broader than 'occupation' and is intended to cover all types of workers, including contractors, volunteers, and labour-hire employees, not just those in traditional employment relationships.

This simple table breaks down where each term is used.

| Term | Meaning | Where It Is Used |

|---|---|---|

| WHS | Work Health and Safety | Most Australian states and territories (NSW, QLD, SA, TAS, ACT, NT) |

| OHS | Occupational Health and Safety | Victoria and historically across Australia |

For business owners and site managers, the key takeaway is that both acronyms refer to your legal duty of care. Whether your state calls it OHS or WHS, the goal is identical: create a safe working environment through deliberate, consistent action.

Navigating Australian Workplace Safety Laws

When it comes to workplace safety in Australia, the law tries to keep things simple. The rules are laid out in plain language, defining who's responsible for what and the penalties for getting it wrong.

At the national level, Safe Work Australia is the body that creates the model Work Health and Safety (WHS) laws. Think of this as the master template that guides every state and territory.

This model is made up of the Act, Regulations, and various Codes of Practice. Together, they explain your duties in detail.

- The Act is the national framework. It sets out the core duties for businesses and the basic steps for managing risk.

- The Regulations get more specific, detailing obligations like mandatory training or how to control certain hazards.

From there, each state and territory regulator takes these national laws and makes them official in their own jurisdiction. This is why you have bodies like WorkSafe Victoria inspecting sites across the state to make sure everyone is following the rules.

Understanding Your Duty as a PCBU

You’ll hear the term PCBU a lot. It stands for a ‘person conducting a business or undertaking’, which is a broad way of capturing anyone with management control. This isn't just the CEO; it includes site managers, contractors, and heads of organisations.

A PCBU's primary duty of care is all about being proactive. You can't wait for an accident to happen. You're expected to:

- Actively look for hazards and keep a record of what you find.

- Put controls in place to manage those risks, like installing machine guards or putting up safety signs.

- Constantly review those controls to make sure they're working and adjust them based on feedback from your team.

The legal test here is what’s considered ‘reasonably practicable’. This simply means you must take every step you realistically can to keep people safe on site.

How the Rules Are Enforced

Regulators like WorkSafe turn these national standards into real-world action through site inspections and audits.

When an inspector shows up, they’ll examine your documents, chat with your workers, and issue improvement notices if they find something that isn't up to scratch. And if the breach is serious, the penalties can be severe. Fines can reach as high as $1.89 million.

A PCBU must meet their duties 'so far as is reasonably practicable' to avoid serious legal and financial risk.

Failing to comply isn't just about fines. It can lead to court proceedings and even make individual directors personally liable. In recent years, companies have been hit with penalties well over $300,000 for serious safety failures.

For a closer look at how this works in a specific state, check out our guide on Western Australia WHS laws.

Really getting your head around what WHS means in a legal sense makes your duties crystal clear. Site managers should be documenting every risk assessment and safety plan as a matter of habit. It’s this paper trail that proves you're meeting your duty of care if a regulator ever comes knocking.

A good starting point is to:

- Review your company policies against the WHS Act.

- Train your staff, especially supervisors, on their PCBU responsibilities.

- Schedule regular site audits and, most importantly, record the outcomes.

Taking these steps doesn't just reduce risk, it demonstrates to regulators that you take safety seriously. With penalties this heavy, compliance is simply non-negotiable.

Duty in Action

Let’s make this real. Imagine a construction site where an excavator starts digging without a traffic management plan in place.

The PCBU has a clear duty to assess how vehicles and people will interact and to mark out clear exclusion zones. In a real case in WA, failing to do just that resulted in a $120,000 fine. It's a classic example of not taking a 'reasonably practicable' step.

| Jurisdiction | Regulator | Penalty Example |

|---|---|---|

| National | Safe Work Australia | Develops the model laws |

| Victoria | WorkSafe Victoria | Fines up to $1.89M |

| WA | WorkSafe WA | Fines up to $500k |

Laws and regulations change, so it's vital to regularly review and update your WHS procedures to stay current.

This is where a tool like Safety Space can make a huge difference. It helps you track your compliance obligations and document your audits in real time, making sure you’re always meeting your legal requirements and, more importantly, protecting your team from harm.

Compliance protects your people, your profits, and your reputation. It’s everyone’s responsibility.

The Building Blocks of an Effective WHS System

Knowing the laws is one thing, but putting them into practice on a busy worksite is another challenge. A functional Work Health and Safety (WHS) system isn't just a binder of policies gathering dust on a shelf. It’s a living part of your daily operations, built on practical actions that protect your team.

To get a grip on what WHS looks like in action, you can break it down into four core pillars. Think of these as the non-negotiables for any system that actually keeps people safe.

Practical Risk Management

At its heart, safety is all about managing risk. It boils down to a simple, repeatable three-step process you can apply to any task, on any worksite.

- Spot the Hazard: First, you have to identify what could actually cause harm. For example, on a construction site, an unguarded edge on a second-storey platform is a clear-cut hazard.

- Assess the Risk: Next, figure out how likely it is that the hazard will hurt someone and how serious that injury could be. With the unguarded edge, the risk of a fall is high, and the potential outcome is catastrophic.

- Apply Controls: Finally, put practical measures in place to eliminate or minimise the risk. This means getting temporary guardrails installed (an engineering control) before anyone is allowed to work near that edge.

It's crucial that this process is documented. A simple risk assessment record is your proof that you’ve met your duty of care.

Meaningful Worker Consultation

You are legally required to talk to your team about safety matters that affect them directly. This isn't just a courtesy; it's a fundamental part of the WHS framework. Your workers are the ones on the tools, so they often have the best insights into what the real risks are day-to-day.

Consultation means more than just telling your team what to do. It’s about actively seeking their input on spotting hazards, assessing risks, and making changes to work procedures.

This could be as simple as a toolbox talk before a shift starts, or it could be more formal, like setting up a dedicated health and safety committee. When workers are involved in the process, they are far more likely to buy into the procedures because they helped create them.

Thorough Incident Reporting

Too many businesses only focus on reporting injuries, but that’s a reactive approach. A strong WHS system tracks near misses with the same level of seriousness. A near miss isn't a lucky break; it's a warning sign that a control has failed.

For instance, if a pallet of bricks slips from a crane but doesn't hit anyone, reporting it allows you to investigate why it slipped. Was the rigging incorrect? Was the equipment faulty? Finding the root cause prevents a future incident where someone might not be so lucky.

The sheer volume of workplace incidents shows why this is so critical. In 2021-22 alone, approximately 497,300 people in Australia experienced a work-related injury or illness. You can discover more insights about workplace safety statistics in Australia to understand the full scope of the problem.

Effective Training and Induction

No worker should ever start a task without understanding the safety rules that apply to it. A thorough induction is your first line of defence.

This process makes sure every single person on site, including contractors, knows:

- The specific hazards of that particular site.

- The emergency procedures and evacuation points.

- How to report an incident or a hazard.

- Who the first aid officers and safety representatives are.

Ongoing training is just as important. If you bring in new machinery or a different chemical, workers need specific training on how to handle it safely. Documenting all of this is your proof of compliance. For a deeper dive into what a complete system looks like, check out our guide on the 9 Key Elements of a Health and Safety Management System.

Managing the Most Common Workplace Hazards

Knowing what OHS/WHS means is one thing, but the real test is applying that knowledge to your worksite. An effective WHS system focuses on the hazards most likely to cause serious harm or death, especially in high-risk sectors like construction and manufacturing.

The recent stats paint a sobering picture. Data from Safe Work Australia shows a spike in workplace fatalities, with 200 deaths reported in a single year. Vehicle incidents were the biggest culprit, causing 42% of all fatalities. Even more alarming, deaths from falls from height shot up by 71% in just one year. You can dig into the latest findings from Safe Work Australia to see the full story.

Let's break down some of these critical risk areas.

Falls From Height

Working at height is a daily reality on most building sites, and it remains one of the biggest killers. A fall from just two metres can be fatal, which is why controlling this risk has to be a priority.

The hierarchy of controls gives us a clear roadmap here. You always start at the top by trying to eliminate the hazard completely. If that's not possible, you work your way down.

- Engineering Controls: Think scaffolding with complete guardrails or using elevated work platforms (EWPs). These are far better options than relying on individual fall protection because they protect everyone in the area, not just one worker.

- Personal Protective Equipment (PPE): A harness and lanyard system should always be the last resort. It only protects one person and its effectiveness is entirely dependent on correct setup, training, and use. It’s the final safety net, not the primary plan.

Being Hit by Moving Objects or Vehicles

Busy worksites are a constant flow of moving parts, like forklifts in warehouses, excavators on civil sites, and trucks making deliveries. Managing the interaction between people and plant is a non-negotiable part of your WHS duty of care.

A few practical controls can make all the difference:

- Separation: Create clearly marked exclusion zones where pedestrians are not allowed to go. Physical barriers like bollards or temporary fencing are far more effective than just a painted line on the ground.

- Traffic Management Plans: Designate specific routes for vehicles and separate walkways for people. Good signage and adequate lighting are essential to making these plans work.

- Communication: Always use spotters for reversing vehicles and make sure every operator is trained, competent, and authorised for the equipment they’re using.

Manual Handling Injuries

Injuries from lifting, pushing, pulling, and carrying are incredibly common and costly. They are a massive driver of workers' compensation claims, causing long-term pain for employees and serious downtime for the business. If you need a refresher on spotting these risks, check out our guide on what is hazard identification.

Proactive WHS isn't about avoiding the work; it's about making the work safer. Using a mechanical aid to lift a heavy object is a prime example of a simple, effective control that prevents serious injury.

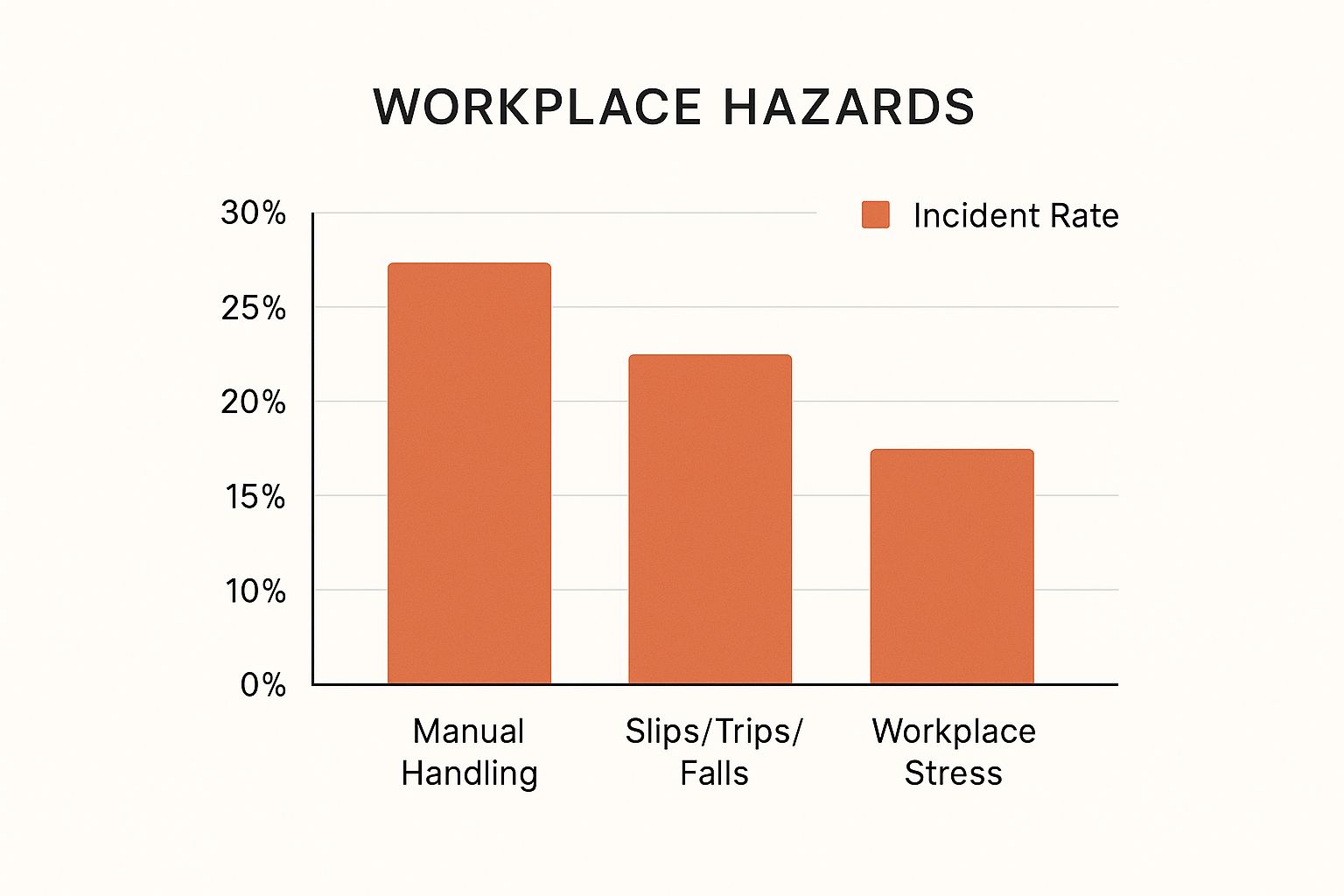

This chart drives home where the biggest risks lie, showing you exactly where to focus your safety efforts.

As the data clearly shows, manual tasks and falls are right at the top of the list for causing injuries, making them critical areas to get right in your risk management plan.

Top Workplace Hazards and Practical Controls

To help you put this into practice, here's a quick reference table outlining some common hazards in high-risk industries and the best ways to control them, following the hierarchy of controls.

| Hazard | High-Risk Industry | Practical Control Example |

|---|---|---|

| Working at Height | Construction | Elimination: Design the structure so maintenance can be done from the ground. Engineering: Install permanent guardrails on rooftops or use scissor lifts instead of ladders. |

| Moving Vehicles | Manufacturing, Warehousing | Separation: Create dedicated, barrier-protected walkways for pedestrians. Admin: Implement a site-specific traffic management plan with speed limits and one-way systems. |

| Manual Handling | All | Substitution: Use lighter-weight building materials. Engineering: Install mechanical aids like vacuum lifters, cranes, or pallet jacks to handle heavy loads. |

| Hazardous Chemicals | Manufacturing | Substitution: Replace a solvent-based chemical with a safer, water-based alternative. PPE: Provide chemically-resistant gloves and eye protection (as a last resort). |

| Unguarded Machinery | Manufacturing, Workshops | Engineering: Retrofit fixed physical guards to prevent access to moving parts. Admin: Implement a 'lockout-tagout' procedure for all maintenance work. |

This isn't an exhaustive list, but it highlights a crucial point: the most effective controls are the ones that are designed into the work process, rather than relying on people to remember to do the right thing every time.

How Good Safety Practices Benefit Your Business

Investing in a solid Work Health and Safety (WHS) system is one of the smartest commercial decisions you can make, going far beyond just ticking a legal box. It delivers real returns that directly impact your bottom line and operational stability.

Let's be clear: a practical approach to safety isn't an expense. It's an investment in a more resilient and profitable business.

When you get proactive about managing workplace risks, you’re doing more than just preventing injuries, you’re protecting your financial health. Fewer incidents mean fewer workers’ compensation claims, which can lead to a significant drop in your insurance premiums over time. It’s a direct financial reward for running a safer operation.

Plus, think about what happens after a serious incident. Work grinds to a halt for investigations, equipment might be impounded, and the entire team's workflow gets thrown into chaos. Preventing these events means your projects stay on schedule and on budget, helping you avoid the hidden financial drain that comes with every shutdown.

Avoiding Penalties and Gaining a Competitive Edge

The financial argument for good WHS gets even more compelling when you look at the penalties for getting it wrong. Regulators can hit you with on-the-spot fines for minor breaches, while serious failures can lead to prosecutions and penalties climbing into the hundreds of thousands of dollars.

Those six-figure fines can be crippling for any business, making proactive safety management a non-negotiable financial defence.

A strong safety record is more than just proof of compliance; it’s a powerful commercial asset that demonstrates reliability and professionalism to potential clients.

This track record gives you a massive competitive advantage. Many large clients, especially in construction and manufacturing, won't even consider hiring a contractor without a proven and documented safety system. They audit their partners' safety performance before awarding tenders. Having your WHS documentation in order can be the very thing that helps you win those lucrative contracts over your competitors.

Boosting Productivity and Team Stability

Beyond the money, good safety practices have a direct and positive impact on your team's performance.

When workers feel secure and know their wellbeing is a genuine priority, they can focus better on the task at hand. This naturally leads to higher-quality work and greater productivity right across the board.

A safe workplace also helps with team morale and reduces staff turnover. Experienced, skilled workers are far more likely to stick with a company that protects them, saving you the huge costs that come with constantly recruiting and training new people.

Ultimately, a safe worksite is a stable and efficient worksite. By investing in WHS, you're building a more dependable, productive, and successful business from the ground up.

Your Top WHS Questions Answered

When you're running a business, figuring out the nuts and bolts of Work Health and Safety can feel like one more thing on an already-full plate. We get it. Here are some no-nonsense answers to the questions we hear most often from people on the ground.

Where Do I Even Start with Improving WHS?

The best first step is always the simplest: go for a walk.

Grab a notepad, leave your desk, and walk through your entire workplace. Your only goal is to spot things that could hurt someone. You don't need a fancy system to begin.

Look for the obvious stuff like trip hazards, poorly stacked boxes, machines with missing guards, or workstations that force people into awkward positions. The most important part? Talk to your team. Ask them what worries them. They're the ones doing the work, and they usually know exactly where the real risks are hiding.

Jot down what you find, figure out what's most likely to cause serious harm, and start fixing those things first.

Do I Really Need to Hire a WHS Consultant?

Probably not. While the law says you must manage safety, it doesn't say you have to pay a consultant to do it for you. For most small and medium-sized businesses with fairly standard risks, bringing in a consultant is often an unnecessary expense.

Before you spend a cent, check out the free resources from your state's WorkSafe authority. They have a goldmine of practical checklists, document templates, and codes of practice that cover the vast majority of workplace situations.

A consultant might make sense if you’re in a really high-risk or complex industry, like major construction sites or facilities handling dangerous chemicals. But for everyone else, you can absolutely build a solid WHS system in-house.

Your legal duty is to ensure safety, not to outsource it. Using freely available official resources is often the most effective way for smaller businesses to build a compliant WHS system from the ground up.

How Much Paperwork Is Actually Necessary?

The goal here isn't to create a mountain of paper; it's to have proof that you’re actively managing safety. The amount of documentation you need should be directly proportional to the risks in your business.

Try thinking of it as ‘record-keeping’ instead of ‘paperwork’. A few key documents are non-negotiable:

- A simple WHS policy that shows your commitment to keeping people safe.

- Records of your risk assessments and what you did to control the hazards you found.

- A register of any hazardous chemicals you have on site.

- Notes from worker training sessions and consultation meetings.

That’s it. These records are your evidence that you're meeting your legal duties. Using a digital tool can make managing this stuff a lot less painful than wrestling with binders and filing cabinets.

Are Near Misses Really That Important to Report?

Yes. One hundred percent. A near miss is a free lesson on what could have gone horribly wrong. It’s an alarm bell telling you that one of your safety controls failed, and you just got lucky that nobody was hurt this time.

Think about it. If a heavy tool drops from a scaffold and lands a metre away from a worker, that's a critical near miss. Reporting it forces you to figure out why it fell. Was the scaffolding set up incorrectly? Was the equipment faulty? Was the procedure wrong?

Finding and fixing that root cause is what stops the exact same thing from happening again next week, potentially with a fatal outcome. Ignoring your near misses is like ignoring the flashing warning lights on your dashboard. Sooner or later, you're going to break down.

Juggling all these moving parts, from risk assessments to incident reports, is a real challenge. Safety Space brings everything together in one place, giving you an organised WHS system that makes it easier to stay compliant and protect your team. See how it works by requesting a free demo today.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.