Work Health and Safety (WHS) policies and procedures are the core of a practical safety system. They state your company's commitment to safety and define the exact steps your team needs to take to work safely.

Think of it like this: the policy is your destination—a safe workplace with zero incidents. The procedures are the turn-by-turn directions that guide your team on how to get there safely, every single time.

What Exactly Are WHS Policies and Procedures?

Let's cut through the jargon. WHS policies and procedures are not just about ticking a legal box; they are the operational backbone of a predictable and safe work environment. This is especially true in high-risk sectors like construction and manufacturing, where guesswork is not an option.

A WHS policy is the high-level statement from the top. It is a formal declaration of the organisation's commitment to keeping everyone—employees, contractors, and visitors—safe and healthy. It sets the direction and communicates the company's safety goals.

WHS procedures, on the other hand, get down to the details. They are the practical, step-by-step instructions that show how to perform specific tasks safely. They turn the broad statements in the policy into concrete, repeatable actions on the ground.

For example, if a policy states a commitment to preventing falls from height, a procedure will detail exactly how to inspect a harness, correctly set up scaffolding, or operate a mobile elevated work platform.

The Role of Each Document

It is important to understand how these two documents work hand-in-hand. The policy gives you the "what" and the "why," while the procedures provide the "how."

- Policy (The What): Declares the company's objective to manage risks associated with hazardous manual tasks.

- Procedure (The How): Provides a checklist for assessing lifting risks and step-by-step instructions for using a forklift to move heavy materials.

This distinction is everything. A policy without clear procedures is just a set of good intentions with no real plan. Procedures without a guiding policy are just a jumble of instructions with no overarching goal. Together, they create a complete, functioning system for managing workplace safety.

A well-defined set of WHS policies and procedures acts as an operational guide. It gives your team clear, consistent instructions, which reduces confusion and the likelihood of incidents caused by guesswork.

Why They Are Different But Connected

Understanding the difference helps clarify who is responsible for what. Senior leadership typically signs off on the WHS policy, showing that commitment comes right from the top. But it is the supervisors and workers on the floor who are most involved in creating and following the specific procedures. They are the ones with the hands-on expertise.

This structure helps make sure safety is not just a top-down mandate. It becomes a practical system built with input from the very people doing the work. It is a framework designed to protect your people and your operations, not just generate a pile of paperwork.

Policy vs Procedure at a Glance

This table breaks down the key differences between a WHS policy and a procedure, showing how they work together to create a safe system of work.

| Element | WHS Policy | WHS Procedure |

|---|---|---|

| Purpose | States the company's overall safety commitment and goals. | Details the specific steps to safely perform a task. |

| Scope | Broad and applies to the entire organisation. | Narrow and focused on a specific task or process. |

| Content | General principles, objectives, and responsibilities. | Step-by-step instructions, checklists, and safety checks. |

| Audience | All employees, management, contractors, and stakeholders. | Workers and supervisors performing the specific task. |

Ultimately, policies set the standard, and procedures make sure everyone can meet it consistently. When both are clear, well-communicated, and actively used, you have the foundation of a solid safety system.

Why Your Business Cannot Afford to Ignore WHS

It is easy to see WHS policies and procedures as just another compliance box to tick. But treating them that way is one of the biggest risks any business can take. The consequences of getting safety wrong are not hypothetical. They are real, expensive problems that hit everything from your bottom line to your project deadlines.

Ignoring WHS is not just a safety lapse; it is a direct threat to your company’s stability and future.

The most obvious and painful consequences are legal and financial. Regulators are watching closely, and they are not afraid to act. We are not talking about minor slaps on the wrist anymore; the penalties can be severe enough to seriously damage a company's financial health.

The data backs this up. Work Health and Safety prosecutions in Australia are on the rise. Since just one recent year, Safe Work Australia has chased penalties totalling a staggering $164 million for WHS breaches.

The Financial Drain of an Incident

Beyond the initial shock of a regulatory fine, the financial cost of a workplace incident sends ripples through the entire business. These are the expenses that often get overlooked until it is far too late.

- Increased Insurance Premiums: A poor safety record means you'll pay more for workers' compensation insurance. It is a recurring cost that chips away at your profits, year after year.

- Legal Fees: Defending your business against a WHS prosecution or a personal injury claim is a long, costly fight. It drains funds that should be fuelling growth and innovation.

- Equipment and Property Damage: Incidents often leave behind broken machinery, ruined materials, or damaged facilities. These unbudgeted repairs and replacements can be incredibly expensive.

And those are just the direct costs. The knock-on effects on your day-to-day operations can be even more damaging in the long run, disrupting the very core of how your business runs.

A single serious incident can bring a project to a grinding halt, tarnish your reputation with clients, and kick off a formal investigation. The cost is never just the fine; it is the cascade of operational chaos that follows.

Operational Setbacks and Hidden Costs

When a safety incident happens, it is not business as usual. The disruption spreads fast, hitting productivity, timelines, and your most important asset: your people. Ignoring WHS is, in effect, ignoring the stability of your entire operation.

The operational fallout looks like this:

- Project Delays and Downtime: Work stops. An incident triggers investigations, site clean-ups, and the need for corrective actions. These delays lead to missed deadlines and can even trigger penalty clauses in your client contracts.

- Loss of Skilled Workers: An unsafe workplace is a place people do not want to be. High staff turnover means you are constantly bleeding money on recruitment and training, all while productivity suffers.

- Damaged Reputation: Word gets around. A serious incident can wreck your reputation with customers, potential hires, and the industry at large, making it harder to win contracts and attract top talent.

Ultimately, strong WHS policies are a fundamental business safeguard. They also tie directly into creating a positive workplace, which is a key part of effective employee health and well-being strategies. This is a smart, practical investment in protecting your people, your profitability, and your company's future.

Building the Core of Your WHS Policy

A strong WHS policy is the foundation of your entire safety system. It is much more than just a document filed away in a drawer; it is your public commitment that sets the direction for every single safety-related action in your business. Without it, your safety efforts are just guesswork, lacking any real focus or authority.

Think of your policy as the constitution for your company's safety. It establishes the fundamental principles and laws that everyone, from the CEO down to the newest apprentice on site, must follow. A vague or poorly written policy just creates confusion, leading to inconsistent and unsafe practices on the workshop floor.

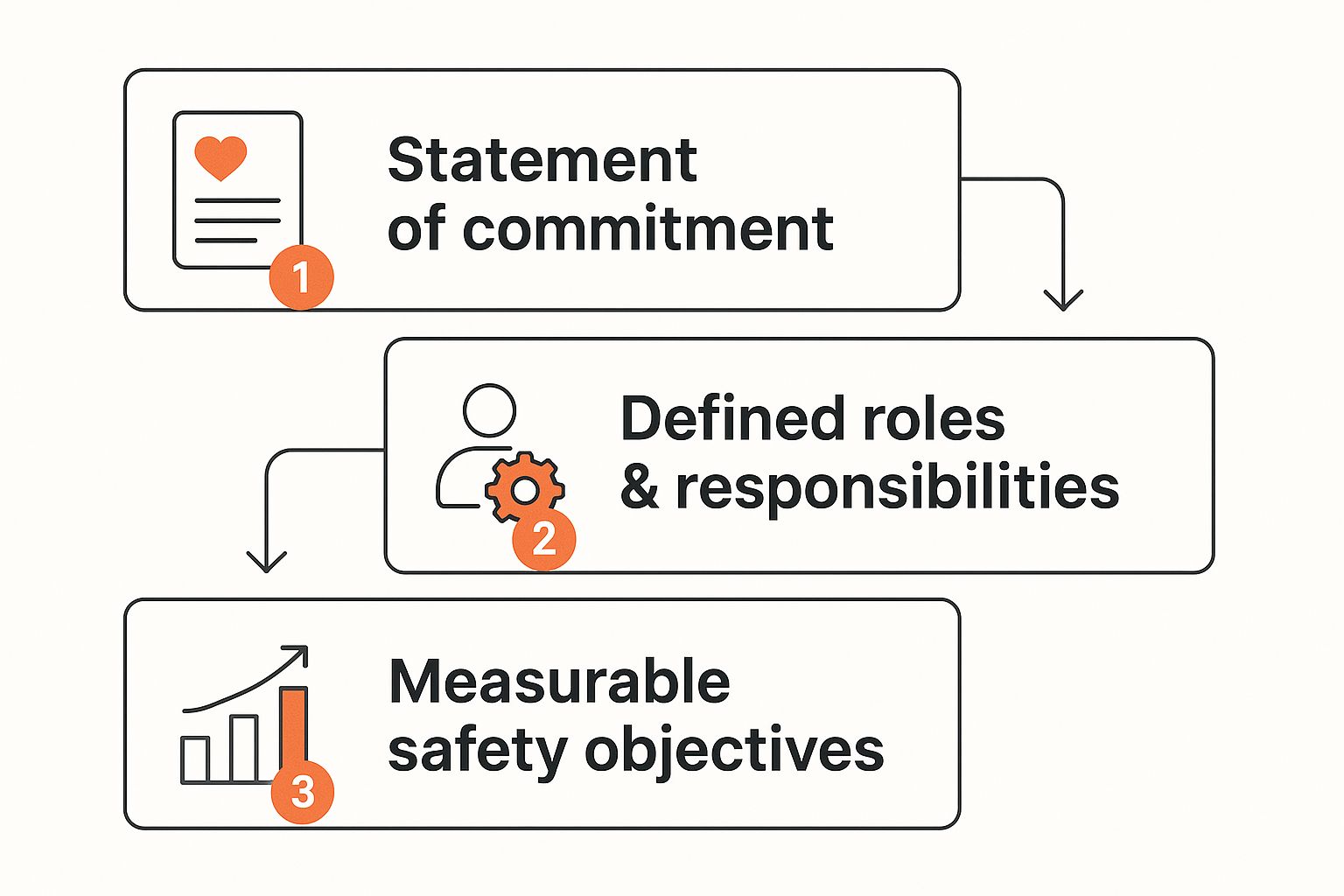

To be worth the paper it is written on, your WHS policy needs to be built on three critical pillars: a clear statement of commitment, well-defined roles and responsibilities, and specific safety objectives.

This process flow shows how these core components lock together to form a solid policy.

As you can see, it all starts with a clear commitment. That commitment then dictates who is responsible for what, which in turn leads to concrete, trackable goals.

Defining Roles and Responsibilities

One of the most common failure points in safety systems is ambiguity. When people are not 100% sure what they are supposed to do, critical tasks get missed. Simple as that. Your WHS policy has to spell out exactly who is accountable for what.

This is not about setting people up to take the blame; it is about providing absolute clarity so everyone can play their part effectively. Getting specific is the only way to avoid the classic "I thought someone else was handling it" problem.

Your policy should detail responsibilities for three main groups:

- Management: This group is on the hook for providing resources (like proper training and PPE), setting the safety objectives, and making sure the policy is regularly reviewed and kept up to date.

- Supervisors: They are the ones on the ground responsible for day-to-day implementation. This means running toolbox talks, making sure procedures are followed, and dealing with hazards on the spot.

- Workers: Their duties are clear: follow all safety procedures, report any hazards or incidents immediately, and use equipment the way they were trained to.

By clearly separating these duties, you create a system where everyone understands their specific contribution to keeping the workplace safe. It also builds a rock-solid framework for accountability.

A policy that just says "everyone is responsible for safety" without defining individual duties is effectively making no one responsible. Real accountability comes from clear, documented expectations for each and every role.

Setting Clear and Measurable Objectives

A statement of commitment is a great start, but it needs to be backed up by tangible goals. Your WHS policy must include specific, measurable objectives that prove you are actively working towards a safer workplace.

These objectives are what turn your good intentions into a real action plan. They give you a way to track your progress and show everyone that your policy is more than just words on a page. In high-risk industries, these objectives are non-negotiable.

Here are a few examples of practical safety objectives you might set:

- Reduce manual handling injuries by 15% within the next 12 months.

- Achieve 100% completion of competency training for all new machine operators before they work unsupervised.

- Conduct quarterly site safety inspections and close out 95% of identified actions within 14 days.

Of course, a fundamental part of crafting a robust WHS policy is understanding the legal goalposts. For instance, businesses must comply with the latest UK hazardous waste disposal regulations when setting objectives around chemical safety. These foundational elements ensure your WHS policies and procedures are not only compliant but genuinely practical and effective.

Writing WHS Procedures for High-Risk Work

Think of your WHS policy as the destination on a map. The procedures? They are the turn-by-turn directions your team uses to get there safely. This is where safety theory hits the ground and becomes real action.

For high-risk work, like operating heavy machinery or working on a multi-storey construction site, a vague or confusing procedure is a direct path to an incident. The goal is not just to have a document, but to create instructions so clear they become second nature.

These are not meant to be binders gathering dust on a shelf. They are active, daily-use tools for the workshop floor or construction site. The best ones are always practical, easy to follow, and built with input from the people who actually do the work.

Start with the Task, Not the Paperwork

Before you write a single word, you need to understand the task inside and out. The only way to do that properly is through a task-based risk assessment. Forget generic templates for a moment and get out into the real world.

Go to the work area. Watch the job being done. Most importantly, talk to the workers and supervisors who live it every day. They know the unofficial shortcuts, the recurring frustrations, and the exact moments where things feel a bit sketchy.

Your job is to break the entire task down into small, logical steps. For each one, ask three simple questions:

- What could go wrong here? (The hazard)

- How likely is it, and how bad could it be? (The risk)

- What can we do to stop it? (The control measure)

This process gives you the raw material for a procedure that actually works. It makes sure the steps you write are grounded in reality, tackling the real hazards your team faces, not just the ones you can imagine from behind a desk.

Keep It Simple and Visual

Once you have your steps and controls figured out, the next challenge is writing them in a way people will actually use. The single biggest mistake is loading up your procedures with technical jargon and dense paragraphs of text.

The person climbing scaffolding or operating a lathe needs instructions they can understand in a split second. Use simple, direct language.

Write in short sentences with an active voice. Instead of, "The safety guard must be engaged prior to operation," just say, "Engage the safety guard before you start." It is clearer, more direct, and far easier to remember under pressure.

The real test of a good procedure is whether a new worker, with basic training, could follow it and do the job safely without having to ask a bunch of questions. If they cannot, it is not finished.

Visuals are your best friend. A few well-placed photos or simple diagrams can explain a complex step far better than a hundred words. Show a picture of the correct way to attach a harness or point out the emergency stop button. This breaks up the text and makes the whole document much easier to digest.

To show you what this looks like in practice, here is a simplified breakdown for a common high-risk task.

Example Procedure Breakdown for Working at Heights

| Step | Action | Key Safety Check |

|---|---|---|

| 1. Pre-Start Inspection | Inspect harness, lanyards, and anchor points for wear or damage. | Check that inspection tags are in-date. Do not use damaged equipment. |

| 2. Don Harness | Put on the full-body harness, ensuring all straps are snug and untwisted. | Perform a buddy check to confirm D-ring is correctly positioned between shoulder blades. |

| 3. Secure to Anchor | Attach lanyard to a certified anchor point rated for fall arrest. | Confirm the anchor point is structurally sound and not on a handrail. |

| 4. Commence Work | Move to the work area, keeping the lanyard taut and avoiding slack. | Always maintain 100% tie-off when moving between anchor points. |

This table format makes the critical actions and safety checks immediately clear, stripping away any unnecessary fluff.

Involve the Experts: Your Workers

You simply cannot write a practical procedure in isolation. The people doing the job every single day are your subject matter experts. Getting them involved is not just a "nice-to-have," it is essential.

When workers help create the procedures, they take ownership of them. They are far more likely to follow the steps because they know they are based on reality, not theory. This collaboration also highlights practical problems you might have missed.

For instance, your draft procedure might call for a specific tool, but the team on the ground knows that tool is often unavailable or just does not work for that particular job. Their feedback helps you build a procedure that is both safe and practical. Using a customisable safe work procedures template can give your team a solid starting point to build from.

The need for this level of detail is clear in the data. Vehicle incidents are a leading cause of worker fatalities, accounting for 42% of deaths in a recent year. At the same time, falls from height have jumped by a shocking 71%, highlighting a critical area where clear, actionable procedures can save lives.

How to Implement and Review Your WHS System

Creating a folder full of WHS policies and procedures is a start, but it is definitely not the finish line. Those documents cannot prevent incidents on their own. Their real value comes from how well they are put into practice on the factory floor or construction site, and how consistently they are kept up to date.

An effective WHS system is a living part of your business. It needs to be rolled out properly, understood by everyone, and regularly checked to make sure it is still doing its job. Without that active management, even the best-written documents become useless.

From Paper to Practice: Implementation Steps

Putting your WHS system into action is not about sending a company-wide email and hoping for the best. Real implementation means making sure every single person understands their role in keeping themselves and their teammates safe.

It all starts with clear communication. You need to formally introduce the new or updated policies and procedures to the whole team. Use every channel you have: team meetings, toolbox talks, and direct conversations from supervisors.

Next up is training. This is absolutely non-negotiable, especially when it comes to high-risk procedures.

- Induction for New Starters: Every new employee must get trained on the core WHS policies from day one. This sets crystal-clear safety expectations before they even touch their first task.

- Task-Specific Training: Anyone performing a job covered by a new procedure, like operating a specific piece of machinery, needs hands-on training to make sure they know the steps inside and out.

- Refresher Training: Regular refreshers are crucial for keeping safety knowledge front-of-mind. They are also the perfect opportunity to introduce any updates to existing procedures.

By investing in a solid rollout, you build a foundation where everyone knows what is expected of them. A well-implemented system should also be part of a broader safety management system, which you can explore in our detailed guide.

The WHS System Review Cycle

Your workplace is not static. New machinery gets installed, projects change, and your team evolves. Your WHS system has to keep up, which is why a regular review cycle is so important.

Think of it like servicing your car. You do not wait for it to break down on the motorway; you perform regular checks to keep it running safely. The same logic applies to your WHS policies and procedures.

A scheduled review process turns your safety system from a reactive, "fix-it-when-it-breaks" model into a proactive one. It is how you find and fix small issues before they have the chance to become major incidents.

So, when should you pull out the documents and give them a once-over? There are a few key triggers that should prompt you to take a closer look.

A simple yet effective review schedule hits these key milestones:

- Annual Review: At a bare minimum, all core policies and procedures should be reviewed once a year. This is your chance to check for any legislative updates and make sure they still match what is actually happening on the ground.

- Post-Incident Review: After any workplace incident or near-miss, the first step (after making sure everyone is safe) should be to review the relevant procedures. This is how you find out what went wrong and what needs to change to stop it from happening again.

- When Changes Occur: Bringing in new equipment, changing a work process, or moving to a new site? You have to review and update your WHS system to address any new hazards that come with those changes.

- Following Consultation: Feedback from your team during safety meetings or site walks is gold. If workers raise a concern that a procedure is impractical or outdated, that is a clear signal it is time for a review.

This continuous loop of implementation and review is what keeps your safety system relevant and effective. While Australian work-related injury rates are relatively low, the fact that serious injury claims still exceed 139,000 annually shows there is absolutely no room for complacency. Your commitment to this cycle is critical for protecting your team.

Common Questions We Get About WHS

Even when you have a decent handle on WHS, practical questions always pop up. Here are some straight answers to the things we hear most often from business owners, managers, and safety officers on the ground in construction and manufacturing. The goal is simple: give you clear, usable info you can act on today.

Are WHS Policies Actually a Legal Requirement?

Yes, they absolutely are. Under Australia's model WHS laws, every business (or PCBU, in legal terms) has a primary duty of care to keep its workers safe. While the legislation does not have a line item saying, "you must have a written policy," trying to prove you are meeting your duty of care without one is next to impossible.

Think of it this way: a documented WHS policy is your proof. It is the clearest possible evidence that you have thought about your risks and have a formal system in place to manage them. If an incident ever happens, that policy is the foundation of your legal defence.

What's the Difference Between a Policy and a SWMS?

This one trips a lot of people up, but it is pretty straightforward. Your WHS policy is the big picture, while a Safe Work Method Statement (SWMS) is a close-up for a specific, high-risk job.

- Your WHS Policy is the overarching document for the whole business. It lays out your company's commitment to safety, setting the goals and outlining who is responsible for what.

- A SWMS is laser-focused on a single task. It is a mandatory document for high-risk construction work (like demolition or working at heights) that breaks down the specific hazards and the exact control measures you will use.

So, your WHS policy will state that you are committed to managing high-risk work safely. The SWMS is the nitty-gritty plan showing how you will do it for that specific job.

How Often Should We Be Reviewing Our WHS Policies?

Your WHS documents should never gather dust on a shelf. They need to be living documents that reflect how your business actually operates. A regular review cycle is not just best practice; it is essential for keeping them effective.

As a rule of thumb, plan to give your core WHS policies and procedures a thorough review at least once every 12 months.

But some situations demand an immediate review. You will need to pull them out and update them straight away if:

- You have a workplace incident or a serious near-miss.

- You bring in new machinery, new chemicals, or change a major work process.

- Your team gives feedback that a policy or procedure just is not working in practice.

- There is a change to WHS legislation or an updated Code of Practice.

Think of your WHS system like it is part of your operational toolkit. It has to adapt when your work changes. An outdated procedure is a dangerous one.

Can We Just Download a WHS Template and Use That?

A template is a fantastic starting point. It gives you a solid structure and makes sure you have covered the key legal bases. But, and this is a big but, you cannot just slap your logo on it and call it a day.

A template is the beginning of the process, not the end.

For your WHS policies and procedures to be worth the paper they are written on, they must be customised. You have to work through the document and tailor it to the specific hazards, equipment, and day-to-day realities of your workplace. If you do not, it becomes a useless piece of paper that will not hold up to scrutiny from a regulator.

Do Small Businesses Really Need WHS Policies?

Yep, they sure do. WHS laws do not care if you have five employees or 500. A small metal fabrication shop has the same fundamental duty of care as a massive construction firm.

The scale might be different. Your WHS system can be simpler and more direct, but the legal obligation is exactly the same. For a small business, these documents are vital for protecting your most important asset: your people.

Running a safe, compliant, and efficient workplace should not be a constant struggle with paperwork. At Safety Space, we built a platform to replace spreadsheets and outdated software, giving you a single source of truth for your entire health and safety system. From real-time monitoring to AI-powered form completion, we make managing WHS straightforward. See how you can protect your people and your profits by booking a free demo.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.