For any business in Western Australia, the Work Health and Safety Act 2020 (WHS Act) is the key piece of workplace safety law. It replaced the old Occupational Safety and Health Act 1984, bringing WA's legislation in line with the national model WHS laws used by most other states.

This wasn't just a name change. The WHS Act created a different way of handling safety, moving from a system that often reacted after an incident to one that demands proactive risk management from everyone in the workplace.

What the WHS Act Means for Your WA Business

The purpose of the WHS Act is simple: to create a consistent, modern framework that keeps workers safe. The main thing to understand is that its protections cover more than just direct employees. It includes contractors, volunteers, and even visitors who could be harmed by your business operations.

For many WA businesses, this has meant rethinking their safety systems. It's no longer enough to have a safety folder gathering dust on a shelf.

From the Old OSH Act to the New WHS Act

The old OSH Act 1984 was in place for decades, but the modern workplace is different. When the new WHS Act started in March 2022, it brought significant updates that reflect today’s work arrangements and place clearer duties on senior leaders.

This alignment with other states also makes things easier for companies that operate across Australia.

Some of the most important changes introduced include:

- A new duty for company officers to exercise ‘due diligence’, making senior leaders personally responsible for making sure the business meets its safety obligations.

- The introduction of industrial manslaughter as a criminal offence, with severe penalties for businesses whose safety failures result in a death.

- A ban on insurance policies covering WHS penalties. Fines now come directly from the business or individual responsible.

These changes were part of a major legislative overhaul passed by Parliament on 3 November 2020. For a more detailed look, the Government has a helpful overview of WA's WHS Act that breaks down the framework.

A Practical Comparison

Understanding the core differences between the old and new laws is the best way to get a handle on your current responsibilities. The language has changed, but more importantly, so have the expectations. These laws are supported by specific regulations, and our guide on the Workplace Health and Safety Regulation 2011 provides more context on how the Act is applied.

To make it simple, let's compare the old OSH Act with the current WHS Act. The table below highlights the biggest shifts that WA businesses need to know.

Key Changes from the Old OSH Act to the Current WHS Act

| Aspect | Old OSH Act (Pre-2022) | Current WHS Act (Post-2022) |

|---|---|---|

| Primary Duty Holder | "Employer" | "Person Conducting a Business or Undertaking" (PCBU), a much broader term. |

| Protected Individuals | "Employees" | "Workers", which includes contractors, volunteers, trainees, and apprentices. |

| Officer Duties | Less specific, implied duties. | Explicit duty of "due diligence," requiring proactive safety management from senior leadership. |

| Highest Offence | Gross negligence offences. | Industrial Manslaughter, with penalties up to $10 million for a body corporate and 20 years imprisonment for individuals. |

| Consultation | Required, but with less defined processes. | Stronger, mandatory requirements for consulting with workers and other duty holders. |

As you can see, the scope of responsibility has grown. The shift from "employer" to "PCBU" and "employee" to "worker" means you have a duty of care to a much wider group of people. This is a critical change that catches many businesses out.

Who Holds Responsibility Under the WHS Act

When it comes to the WHS Act in WA, the old idea of responsibility stopping with the "employer" is gone. The Act uses a much wider net, introducing broader categories of 'duty holders'. This makes sure everyone, from the boardroom to the workshop floor, has a clear part to play in keeping the workplace safe.

Understanding these roles is the first real step toward compliance.

For example, on a busy construction site, you have the main building company, project managers, crane operators, subcontractors, and delivery drivers. The WHS Act doesn't just point a finger at the head company; it creates a web of shared responsibility, giving each of these groups specific legal duties.

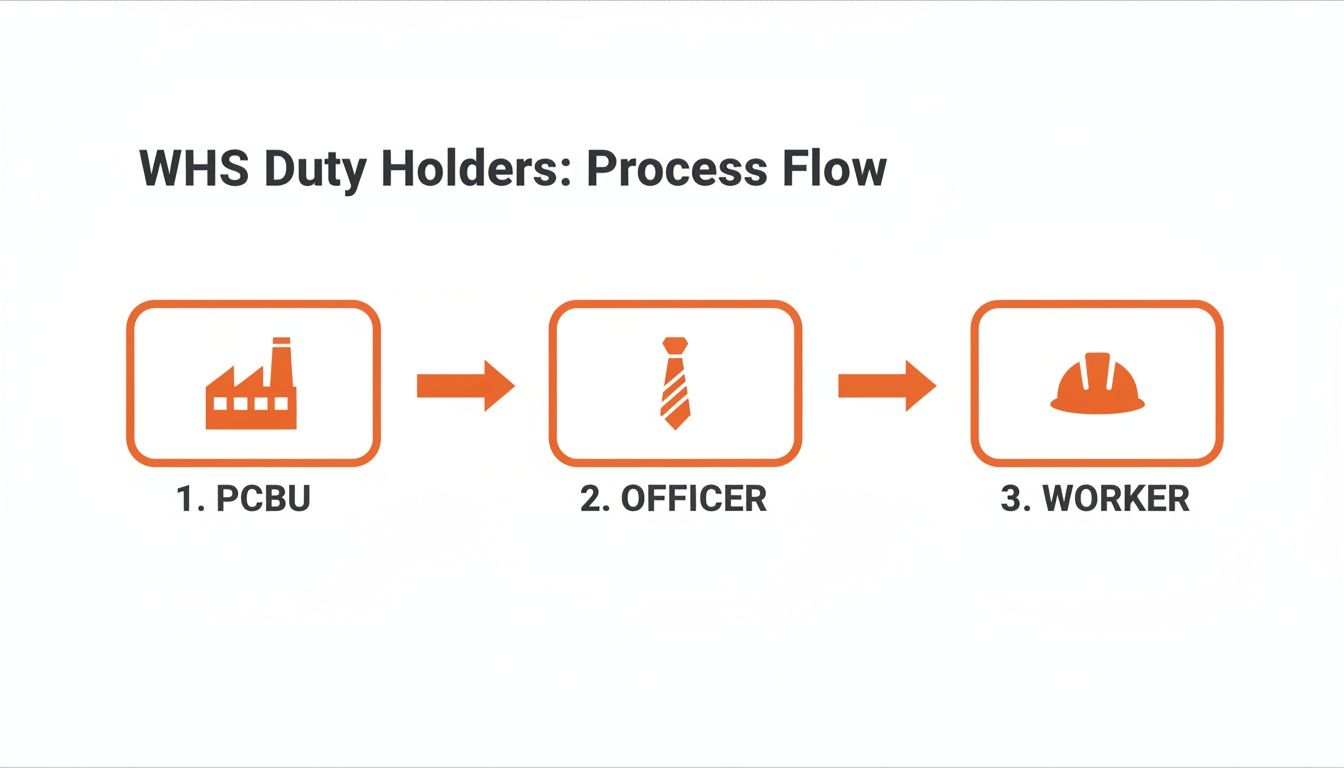

The three main players you need to know are the PCBU, Officers, and Workers. Each has their own set of obligations, and they all overlap to form a solid safety net.

The Person Conducting a Business or Undertaking (PCBU)

This is the most important one. The Person Conducting a Business or Undertaking (or PCBU) is the broadest and most significant duty holder. This term replaces the old "employer" label and covers a wider spectrum of work arrangements. A PCBU isn't just a large corporation; it can be a partnership, a sole trader, or an unincorporated association.

Your construction company is a PCBU. Its primary duty of care is to ensure, as far as is reasonably practicable, the health and safety of its workers. But it doesn’t stop there. This duty extends to anyone else who could be affected by its work, like subcontractors, visitors, or members of the public walking past the site.

This primary duty breaks down into a few key actions:

- Providing and maintaining a work environment that's free of health and safety risks.

- Making sure any plant, structures, and substances are used, handled, and stored safely.

- Giving people the right information, training, instruction, or supervision they need to stay safe.

- Monitoring workers' health and the conditions at the workplace to prevent injuries or illnesses.

For that construction site, this means more than just buying hard hats. It’s about training everyone on when and how to use them, having a system to check for damage, and enforcing a clear rule for what happens if someone isn't wearing one. It’s a complete system, not just a one-off purchase.

The switch from 'employer' to 'PCBU' is a major change. It reflects how businesses operate today and makes it clear: the entity controlling the work has the primary responsibility for safety, no matter what the employment contract says.

Officers and Their Duty of Due Diligence

The WHS Act also puts a spotlight directly on the people at the top. An Officer is anyone who makes, or helps make, decisions that affect a large part of the business. This isn't just the CEO; it includes company directors, secretaries, and any senior leader with the power to influence the company’s direction.

Officers have a personal duty to exercise due diligence. This is a proactive job. It’s not about them personally checking every safety harness, but about making sure the business has the right systems in place to manage safety, and that those systems are actually working.

Due diligence means an Officer must take reasonable steps to:

- Get and keep their knowledge of WHS matters up-to-date.

- Understand the business, including its specific hazards and risks.

- Ensure the PCBU has and uses the right resources and processes to manage those risks.

- Ensure the PCBU has a solid process for hearing about incidents and hazards, and responding to them properly.

Back on our construction site, a company director needs to ensure there's a proper budget for safety equipment and training. They should be the one reviewing incident reports and asking tough questions to confirm that real changes have been made. Their role is about strategic oversight, not day-to-day management, which aligns with the responsibilities of a dedicated health and safety officer whose job is to support this leadership function.

The Duties of Workers

Finally, Workers have their own duties under the Act. And just like the other terms, "worker" is defined broadly. It covers not just your direct employees but also contractors, subcontractors, apprentices, and volunteers.

A worker's fundamental duty is to take reasonable care of their own health and safety. Just as importantly, they have to make sure their actions (or inaction) don't put anyone else at risk.

More specifically, a worker must:

- Follow any reasonable instruction given by the PCBU.

- Cooperate with any reasonable health and safety policy or procedure.

On the ground, this means a scaffolder has a duty to follow the safe work method statement they were trained on. If they spot a damaged ladder, they have a responsibility to report it. They can't just walk past thinking it’s someone else’s problem. This concept of shared responsibility is the foundation of the work health and safety act WA.

Managing Risk and Consulting With Your Team

Knowing your duties under the Work Health and Safety Act WA is one thing, but putting them into practice is where safety really happens. It’s not about ticking boxes; it’s about actively managing safety on the ground. This comes down to two connected activities: managing risks and consulting with your team.

Think of risk management as your plan for preventing things from going wrong. It’s a structured, four-step loop that you need to follow to meet your primary duty of care. For any business, especially in fields like construction or manufacturing, this isn't a one-time task. It's a constant process of adapting to new projects, equipment, and people.

The Four Steps of Risk Management

The WHS Act requires a systematic approach to finding and fixing hazards. This isn’t about a one-off audit but a continuous cycle.

- Identify Hazards: First, you have to find what could hurt someone. This means getting out on the floor, walking the site, and talking to the people doing the work. A hazard could be anything from an unguarded saw and a slippery floor to the strain of repetitive manual tasks.

- Assess Risks: Once you've spotted a hazard, you need to figure out how serious it is. How likely is someone to get hurt, and how bad could the injury be? A frayed power cord across a busy walkway is a much higher risk than a misplaced box in a quiet storage room. To get this right, a structured approach is best. Our guide on how to do a risk assessment walks you through a clear method.

- Control Risks: This is the action step. The law is very specific here: you must use the hierarchy of controls. This is a ranked system for choosing the most effective safety measures first.

- Review Controls: Finally, you have to check that your solutions are actually working. Are people using them? Have they accidentally created a new problem? This review keeps your safety measures effective over time.

For more on this business process, check out this a complete guide to risk management from Escrow Consulting Group. It provides insights that go beyond just WHS.

The goal of risk management isn't to create a workplace with zero risk, that’s often impossible. The legal standard is to eliminate or minimise risks 'so far as is reasonably practicable'. This simply means doing what you are reasonably able to do in your circumstances to keep people safe.

The Power of Consultation

Consultation is a mandatory legal duty under the WHS Act, and it’s more than a quick chat. It’s a formal, two-way conversation between the business (the PCBU) and its workers. After all, the people on the tools every day have the clearest view of the real risks and the most practical ideas for how to fix them.

You have a legal duty to consult your workers on things that directly impact their health and safety. This includes:

- Spotting hazards and assessing risks.

- Deciding on the best ways to control those risks.

- Making changes that could affect workplace health and safety.

- Deciding on the procedures for consultation itself.

This flow of duties shows how safety responsibilities move through an organisation.

While the PCBU has the ultimate responsibility, this visual makes it clear that Officers and Workers have their own important roles to play. Good consultation is what holds it all together.

Putting the Hierarchy of Controls to Work

The hierarchy of controls is a framework that prioritises risk control measures from most to least reliable. You must always aim for the highest level of protection that is reasonably practicable.

Here’s what that looks like in a real-world setting:

| Control Level | Description | Practical Example |

|---|---|---|

| Elimination | Physically remove the hazard completely. | Instead of workers using ladders, design the work so it can be done from ground level. |

| Substitution | Replace the hazard with a safer alternative. | Use a water-based paint instead of a toxic, solvent-based one. |

| Isolation | Separate people from the hazard. | Place noisy machinery in a soundproofed enclosure. |

| Engineering | Use physical changes to reduce the risk. | Install guard rails on a machine or a local exhaust ventilation system to remove fumes. |

| Administration | Change the way people work. | Implement safe work procedures, job rotation to reduce repetitive strain, or warning signs. |

| PPE | Protect the worker with Personal Protective Equipment. | Provide hard hats, safety glasses, gloves, and high-visibility vests. |

Administrative controls and PPE are considered the least effective because they depend on people to work correctly. They should only be used as a last resort or to support higher-level controls.

Setting Up Formal Consultation

The WHS Act gives you a few options for structuring your consultation process. The key is to set up a system that fits your business and genuinely gives your workers a voice.

Common arrangements include:

- Health and Safety Representatives (HSRs): These are workers elected by their peers to represent them on WHS matters. HSRs can be an effective channel for communication.

- Health and Safety Committees (HSCs): These formal committees bring management and worker representatives together to discuss and resolve safety issues.

- Other Agreed Arrangements: For smaller businesses, a less formal system can work perfectly well, as long as it's documented and meets the Act's core requirements for effective consultation.

No matter which path you choose, the obligation is the same: share relevant information, give people a real opportunity to share their views, and genuinely consider that feedback when you make decisions. Keeping good records of these meetings and outcomes is essential for showing you're meeting your duties under the Work Health and Safety Act WA.

Enforcement and Penalties Under the Act

Let's break down what happens when the rules aren't followed. The duties laid out in the Work Health and Safety Act WA aren’t just guidelines; they have real consequences. When a business fails on safety, WorkSafe WA is expected to step in. For any business owner, knowing how this works is critical.

These enforcement actions aren’t about punishing businesses for minor slip-ups. They’re a structured process for regulators to address safety breaches, make sure problems get fixed, and hold people accountable when they fail to keep workers safe. The consequences are serious and can escalate fast if they're ignored.

The Role of WorkSafe WA Inspectors

WorkSafe WA inspectors are the on-the-ground referees for the WHS Act. They have significant legal powers, which includes arriving at any workplace, at any reasonable time, without giving you notice.

Once they’re on your site, their authority is broad. An inspector can:

- Walk through and examine the workplace, equipment, substances, or structures.

- Take measurements, run tests, and collect samples.

- Seize items that might be needed as evidence.

- Talk to anyone on site and require them to answer questions.

- Ask for and make copies of any safety-related documents.

Getting in their way or hindering an inspection is a serious offence. Their job is to verify you’re meeting your legal duties, and the law demands full cooperation.

Types of Enforcement Notices

If an inspector finds a breach of the WHS Act, they have a few tools they can use. The most common are formal notices that legally require a business to act. It's important to understand the difference between them.

An Improvement Notice is issued when an inspector finds a current or past breach of the law. It will clearly state what’s wrong and give you a deadline to fix it. For example, if a machine is missing a safety guard, the notice will require you to install one by a specific date.

A Prohibition Notice is much more serious. This is issued when an inspector believes an activity poses an immediate risk of serious injury or death. This notice forces you to stop the risky activity immediately. You can't restart until the inspector is satisfied the danger has been removed. If scaffolding is unstable, a Prohibition Notice will shut down all work on it until it's properly secured.

A notice from WorkSafe is a legal direction, not a tip. Failing to comply with an Improvement or Prohibition Notice is a separate offence. You can be hit with significant fines for ignoring the notice, on top of any penalties for the original safety breach.

Penalties for Non-Compliance

The consequences for failing your duties under the WHS Act are deliberately severe to reflect the seriousness of putting people's lives at risk. Penalties are tiered based on how badly you failed and how serious the outcome was, ranging from fines for basic breaches to jail time for the worst offences.

Your insurance policy won't help you. It is illegal to be insured against WHS fines in Western Australia. Any financial penalty comes straight from the business or the individual officer.

The penalty structure is broken down into three main categories:

- Category 3: Failing to comply with a health and safety duty.

- Category 2: A failure that exposes someone to a risk of death or serious injury.

- Category 1: Recklessly engaging in conduct that exposes someone to a risk of death or serious injury.

The most serious offence is industrial manslaughter. This applies when a business or officer's conduct causes the death of a worker, and they knew their actions were likely to cause death or serious harm. The penalties are huge: up to $10 million for a company and up to 20 years in prison for an individual. These are the real-world consequences for decision-makers responsible for fatal safety failures.

Using Codes of Practice to Guide Compliance

The Work Health and Safety Act in WA lays out your legal duties, but it doesn't always tell you how to meet them on a practical level. That’s where Codes of Practice come in. These documents are guides, giving you clear, actionable steps for managing specific hazards in your workplace.

The WHS Act tells you what you need to do, and the Codes of Practice show you how to do it. They translate broad legal duties into specific instructions for high-risk industries like construction and manufacturing. Following an approved Code is the most direct way to show you’re meeting your legal obligations.

While a Code of Practice isn't a law itself, it carries a lot of weight. If an incident ends up in court, a relevant Code can be used as evidence of what’s considered best practice for controlling a hazard. If you haven't followed the Code, the burden is on you to prove that your method was just as safe, or safer. That's a tough argument to win after something has gone wrong.

How Codes of Practice Work in WA

These codes are developed by the government in consultation with industry experts to make sure they are practical and reflect what works on the ground. They are designed to be a step-by-step manual for anyone from a site supervisor to a business owner trying to manage common but serious risks.

For example, a business using heavy machinery doesn't have to guess what "safe operation" means. The Code of Practice for managing the risks of plant in the workplace gives you detailed guidance on everything from pre-start checks to maintenance schedules and operator training. It takes the guesswork out of compliance.

Following an approved Code of Practice means you are considered to be compliant with your health and safety duties for that specific risk. It gives you a clear path for meeting your obligations under the Work Health and Safety Act WA.

Key Codes for High-Risk Industries

For businesses in construction and manufacturing, some codes are essential reading. Getting familiar with these will directly improve your safety systems and reduce your risk profile.

Some of the most critical Codes of Practice you should know are:

- Managing the risk of falls at workplaces: A must-read for any construction work involving heights. It covers everything from scaffolding and edge protection to fall-arrest systems.

- Hazardous manual tasks: This Code helps you identify, assess, and control risks from lifting, pushing, and repetitive movements that lead to sprains and strains.

- Managing risks of hazardous chemicals in the workplace: This outlines the requirements for labelling, storing, and handling dangerous substances, including the need for up-to-date Safety Data Sheets (SDS).

- Confined spaces: This provides life-saving procedures for safely entering and working in areas like tanks, pits, or pipes where there's a high risk of atmospheric hazards.

It's also important to remember that the WHS Act doesn't operate in a vacuum. If your work involves electrical equipment, for instance, you also have to comply with WA's specific electrical safety laws. Codes of Practice often reference these other laws, helping you build a complete picture of your compliance needs.

These frameworks are always evolving. The government continuously reviews them, and the 2024–25 statutory review for WA’s WHS Act is already discussing new enforcement tools like on-the-spot infringement notices for lower-level breaches. You can see how regulators are using data to shape these changes in their WHS Act statutory review discussion paper.

Your Action Plan for WHS Act Compliance

Knowing your legal duties is one thing, but making them a reality on the factory floor or construction site is another. Compliance with the Work Health and Safety Act WA isn’t about ticking boxes; it’s about building a practical system. You can start laying that foundation today with a few direct steps.

This doesn't need to be a bureaucratic nightmare. The goal is simple: create a process that spots problems early, controls risks effectively, and gets your entire team involved.

Your Initial Compliance Checklist

Let's start with the basics. A simple checklist can guide you through the most critical tasks to get your WHS systems in order.

Conduct a Gap Analysis: First, take a hard look at what you’re already doing for safety. Compare it directly against the WHS Act’s requirements. Are your risk assessments documented? Is consultation happening the way it should be? This exercise will immediately show you where the gaps are.

Develop a WHS Policy: This is your public commitment to safety. Draft a clear, simple document that outlines your business's promise and spells out responsibilities for everyone, from the directors to the newest worker.

Create a Risk Register: This is the core of your safety system. It's a live document that lists all identified hazards, assesses their risk level, and details the control measures you have in place. It's your proof that you are actively managing safety, not just reacting to incidents.

Set Up a Consultation Process: How will you talk to your team about safety? You need to formalise it. Decide whether you’ll use Health and Safety Representatives (HSRs), a committee, or another agreed-upon method, and make sure it’s documented.

A classic mistake is treating safety as a one-off project. It's not. It’s an ongoing process. Your risk register should be a living document, updated every time a new machine arrives or a new type of job begins.

Using Modern Tools to Support Compliance

Piles of paperwork and endless spreadsheets can quickly sink even the best intentions. This is where modern safety management software like Safety Space comes in, helping you keep everything organised and accessible. These platforms give you a central hub to manage risk assessments, track incidents, and store all your compliance documents.

This approach makes it much easier to show you’re meeting your obligations under the Work Health and Safety Act WA. Instead of digging through filing cabinets for an old report, you can instantly pull up records, show consultation minutes, and prove that your control measures are actually being reviewed. It turns your legal duties into a manageable, documented, and effective system.

Your Top WHS Act Questions Answered

Getting to grips with the Work Health and Safety Act WA often brings up a few common questions. Let's tackle some of the most frequent queries from business owners and managers across Western Australia.

What Does 'Reasonably Practicable' Actually Mean?

'Reasonably practicable' is probably the most important phrase in the Act, but it can feel a bit vague. Think of it as a balancing act. It’s about doing what you are reasonably able to do to keep people safe, after weighing up all the factors.

You need to consider how likely it is for a hazard to hurt someone and how serious that harm could be. Then, you balance that against the options you have to fix it, how suitable they are, and what they cost. If a control measure is wildly expensive but the risk is tiny and unlikely, it might not be reasonably practicable. It’s a judgement call, but one that has to be informed and justifiable.

I Only Have a Few Workers. Do I Still Need a Proper Safety Plan?

Yes, absolutely. This is a common trip-up. The WHS Act doesn't care if you have three workers or three hundred; the core duties apply to everyone.

Now, that doesn't mean a small workshop needs the same safety system as a major mining company. It’s all about scale. Your safety plan just needs to fit your business. For a small team, that could look like:

- A straightforward risk register covering your main tasks.

- Simple, documented safe work procedures for your riskiest jobs.

- Regular toolbox talks to chat about safety issues and get feedback.

The point is to have a system that addresses the risks your people face, whatever the size of your crew.

A common mistake is thinking the WHS Act WA is only for large corporations. The primary duty of care applies to every PCBU, from a sole trader with a single contractor to a company with hundreds of employees.

Are Volunteers Covered by the Act?

They sure are. The Act defines a ‘worker’ in very broad terms, and that definition explicitly includes volunteers. This means you owe a volunteer the exact same duty of care as you do a paid employee.

If your organisation relies on volunteers, you have to provide them with the right information, training, and supervision to do their work safely. They need to be part of your safety conversations and have a clear way to report any hazards they spot, all without worrying about any backlash. Forgetting your volunteers’ safety isn’t just bad practice—it’s a direct breach of the law.

Keeping on top of your duties under the Work Health and Safety Act WA requires a smart, organised system. Safety Space gives you a single platform to handle risk assessments, incident reports, and compliance docs, turning your legal obligations into a straightforward, manageable process. See how you can simplify your safety management with a free demo and consultation.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.