If you're running a business in Queensland, the main piece of legislation you need to know is the Work Health and Safety Act 2011 (QLD). This is the big one. It sets out the core legal duties for everyone, but it doesn't work alone. It's backed up by the more detailed Work Health and Safety Regulation 2011 and a set of practical Codes of Practice.

Think of these three parts working together as a complete system for workplace safety in Queensland.

Decoding QLD’s WHS Legal Framework

Getting your head around Queensland's WHS legislation doesn't have to be a headache. It's best to see it as a three-tiered structure, moving from broad principles down to specific, on-the-ground actions. Each layer has a clear job, creating a full picture of what's required to manage safety.

This system makes sure that everyone from a director in the boardroom to a new apprentice on a construction site understands their role in keeping the workplace safe. For businesses in high-risk sectors like manufacturing or construction, getting this structure right is the first and most critical step towards meeting your legal duties.

Here’s a quick breakdown of how the key pieces fit together:

QLD WHS Legislation at a Glance

| Component | What It Is | Practical Purpose |

|---|---|---|

| WHS Act 2011 | The primary law. | Sets out the fundamental, legally binding duties for everyone in the workplace. It's the "what" you must do. |

| WHS Regulation 2011 | The detailed rules. | Provides specific, mandatory requirements for managing particular high-risk activities and hazards (e.g., asbestos, confined spaces). This is the "how" for known dangers. |

| Codes of Practice | The practical guides. | Offers step-by-step advice on how to meet your duties under the Act and Regulation. Not law, but highly influential in court. |

This table gives you a bird's-eye view, but let's drill down into what each part means for your day-to-day operations.

The Foundation: The Work Health and Safety Act 2011

The Work Health and Safety Act 2011 (the Act) is the cornerstone of the whole system. It establishes the broad responsibilities and duties that apply to everyone involved in a workplace. At its heart is the foundational principle that a Person Conducting a Business or Undertaking (PCBU) must ensure the health and safety of their workers and others, so far as is reasonably practicable.

The Act is the 'what' of WHS law. It tells you what your fundamental duties are, but it's not overly prescriptive about how you have to meet them. It's focused on the outcome a safe workplace not the exact methods you use to get there.

The Details: The Work Health and Safety Regulation 2011

If the Act is the foundation, think of the Work Health and Safety Regulation 2011 (the Regulation) as the detailed blueprint. It supports the Act by spelling out mandatory requirements for managing specific hazards and risks. For any high-risk work, this is your rulebook.

The Regulation gets into the nitty-gritty for things like:

- Managing risks from hazardous chemicals or asbestos.

- Mandatory licensing for high-risk work, like operating a crane or erecting scaffolding.

- Specific procedures you must follow when working in confined spaces or at heights.

It takes the general duties from the Act and turns them into concrete, legally binding actions for well-known and serious workplace dangers.

Practical Guidance: Codes of Practice

Codes of Practice are essentially the "how-to" manuals for workplace safety. They provide practical, step-by-step guidance on how to comply with the duties laid out in the Act and Regulation. While they aren't law themselves, they carry serious weight. In court, a Code of Practice can be used as evidence of what’s known about a hazard and the accepted ways to manage it.

Following an approved Code of Practice is often the most straightforward way to show you’ve met your legal duties. If you choose a different path, the onus is on you to prove your method provides an equal or better level of safety.

These documents translate your legal obligations into everyday actions, covering everything from managing noise in a factory to electrical safety on a construction site. They are an indispensable tool in your safety kit.

It's worth noting that Queensland adopted the national model WHS laws on 2 January 2012. This was a major shift, expanding duties to cover all health risks and placing a positive duty on company officers to exercise due diligence. Penalties also saw a steep increase, now reaching up to $3 million for corporations. You can learn more about the history of model WHS laws to get the full context behind these changes.

Who Is Responsible? A Practical Breakdown of Duties

Under Queensland's work health and safety laws, everyone has a role to play in keeping the workplace safe. But it’s not a one-size-fits-all situation. The law is very specific about who is responsible for what, assigning legally binding duties to different roles within a business.

Whether you're the business owner, a senior manager, or the person operating the machinery, you have specific obligations. Understanding these duties is the first step toward a compliant and safe work environment. The three key players here are the PCBU, the Officers, and the Workers. Let's break down what that actually means in practice.

The PCBU: The Primary Duty of Care

The buck really starts and stops with the Person Conducting a Business or Undertaking (PCBU). Don't let the clunky legal term fool you; this is simply the entity running the show. It could be a large corporation, a small family company, a sole trader, or a partnership. If you're running the business, you're almost certainly the PCBU.

The PCBU has the main responsibility what the law calls the 'primary duty of care' to ensure the health and safety of everyone affected by the business. This isn't just about your direct employees; it includes contractors, visitors, and the public.

This duty requires you to eliminate or minimise risks so far as is reasonably practicable.

"Reasonably practicable" is the legal measuring stick for your safety efforts. It means you must do everything you reasonably can to manage a risk. This involves weighing up the likelihood and severity of potential harm against the available solutions, what's known about the hazard, and the cost and effort of fixing it.

For a PCBU, this isn't a passive role. It means you must be actively:

- Providing and maintaining a work environment that is safe and free from health risks.

- Making sure machinery, equipment, and substances are used, handled, and stored safely.

- Supplying clean, accessible, and adequate facilities for your team's welfare.

- Giving workers the right information, training, instruction, and supervision to do their jobs safely.

Officers and the Duty of Due Diligence

Next up are the Officers. An Officer isn't just a job title; it refers to anyone who makes or helps make decisions that affect a big chunk of the business. Think company directors, CEOs, and other senior leaders who have real influence over the company's direction.

Officers have a personal duty to exercise due diligence. This is a separate and distinct responsibility from the PCBU's primary duty. It means they can't just delegate safety and forget about it. They must personally take reasonable steps to ensure the business is meeting its WHS obligations.

A Safety and Compliance Officer often plays a huge part in helping executives meet this duty, but the legal responsibility remains with the Officer.

To satisfy their due diligence duty, an Officer must actively:

- Stay on top of current work health and safety matters.

- Have a solid grasp of the business's operations and the specific hazards involved.

- Ensure the business has the right resources (time, money, people) and processes in place to manage risks.

- Confirm the business has effective processes for reporting and responding to incidents, hazards, and risks.

- Check that these resources and processes are actually being used and are working as intended.

Workers and Other Persons at the Workplace

Finally, workers themselves have duties under work health and safety legislation in QLD. And the term 'worker' is broad it covers your direct employees, but also contractors, subcontractors, apprentices, trainees, and even volunteers.

At its core, a worker's responsibility is to look after themselves and others. Their duties include:

- Taking reasonable care for their own health and safety.

- Making sure their actions (or inaction) don't put others at risk.

- Following any reasonable instruction given by the PCBU to ensure safety.

- Cooperating with any reasonable safety policies or procedures.

A classic example is a welder on a construction site. They have a duty to follow the safe work method statement (SWMS), use the correct welding screens, and wear all their required personal protective equipment (PPE). If they don't, they're not just risking their own safety, but breaching their legal duty of care.

Even visitors or customers on-site have a basic duty to take reasonable care for their own safety and follow any safety directions they're given. And while this guide is focused on QLD, many principles of managing a safe environment are universal; you can find related insights in this guide to managing building compliance in NSW.

To make it clearer, let's look at how these roles and duties play out in a typical work setting.

Key WHS Duties Who Does What

This table breaks down the core responsibilities for each role with a practical example you might see on a construction site or in a factory.

| Role | Primary Duty | Example Action (Construction/Manufacturing) |

|---|---|---|

| PCBU | Ensure health and safety so far as is reasonably practicable. | Installing guardrails on elevated platforms or machinery to prevent falls and entanglement. |

| Officer | Exercise due diligence to ensure the PCBU complies with its duties. | Allocating budget for a new ventilation system after reviewing reports of air quality issues in a factory. |

| Worker | Take reasonable care for their own safety and the safety of others. | Correctly using a safety harness when working at heights as instructed by their supervisor. |

As you can see, safety is a team effort where each person has a distinct and important part to play. Understanding your specific duties is non-negotiable for keeping people safe and staying on the right side of the law.

Managing Risks The Four-Step Process

Complying with Queensland's WHS laws isn't about memorizing the Act cover-to-cover; it's about getting good at actively managing risks in your workplace. It all comes down to a straightforward, repeatable four-step process. This is a practical loop you can use on a construction site, in a factory, or in an office today to meet your legal duties.

This structured approach takes you from simply spotting a potential problem all the way through to confirming your fix actually works. Think of it as a continuous cycle, not a one-and-done task.

Step 1 Identify The Hazards

You can't manage a risk you don't know exists. The first step is to systematically find anything in your workplace that has the potential to cause harm. This means looking beyond the obvious dangers and thinking about all aspects of your work.

Get out on the floor and open your eyes. A great tool to get you started is a comprehensive construction risk assessment template, which helps you methodically walk through and evaluate potential issues.

Here are a few practical ways to hunt for hazards:

- Workplace Inspections: Do a walk-through with a critical eye. Look for things like unguarded machinery, trip hazards from trailing cables, or materials stacked unsafely.

- Consulting Your Team: Your workers are on the front line. They often know the hidden dangers of their tasks better than anyone. Just ask them what they think is unsafe.

- Reviewing Information: Dig into manufacturer's instructions for equipment, check safety data sheets for chemicals, and look at old incident reports. History often tells you where the problems are.

Step 2 Assess The Risks

Once you've identified a hazard, you need to figure out how big a deal it is. This is the risk assessment part. You're trying to determine how likely it is that the hazard will actually hurt someone and how severe that harm could be. This is all about prioritisation.

For example, an unguarded saw blade in a timber yard is a hazard that presents a very high risk of a severe injury that’s an urgent priority. On the other hand, a slightly uneven patch of concrete in a low-traffic area is still a risk, but it’s probably less urgent to fix.

To do this properly, you need to consider the nature of the harm, how serious it could be, and the likelihood of it happening. For a deeper dive, our guide on how to do a risk assessment breaks down the specifics. This step is about making informed decisions, not just guessing.

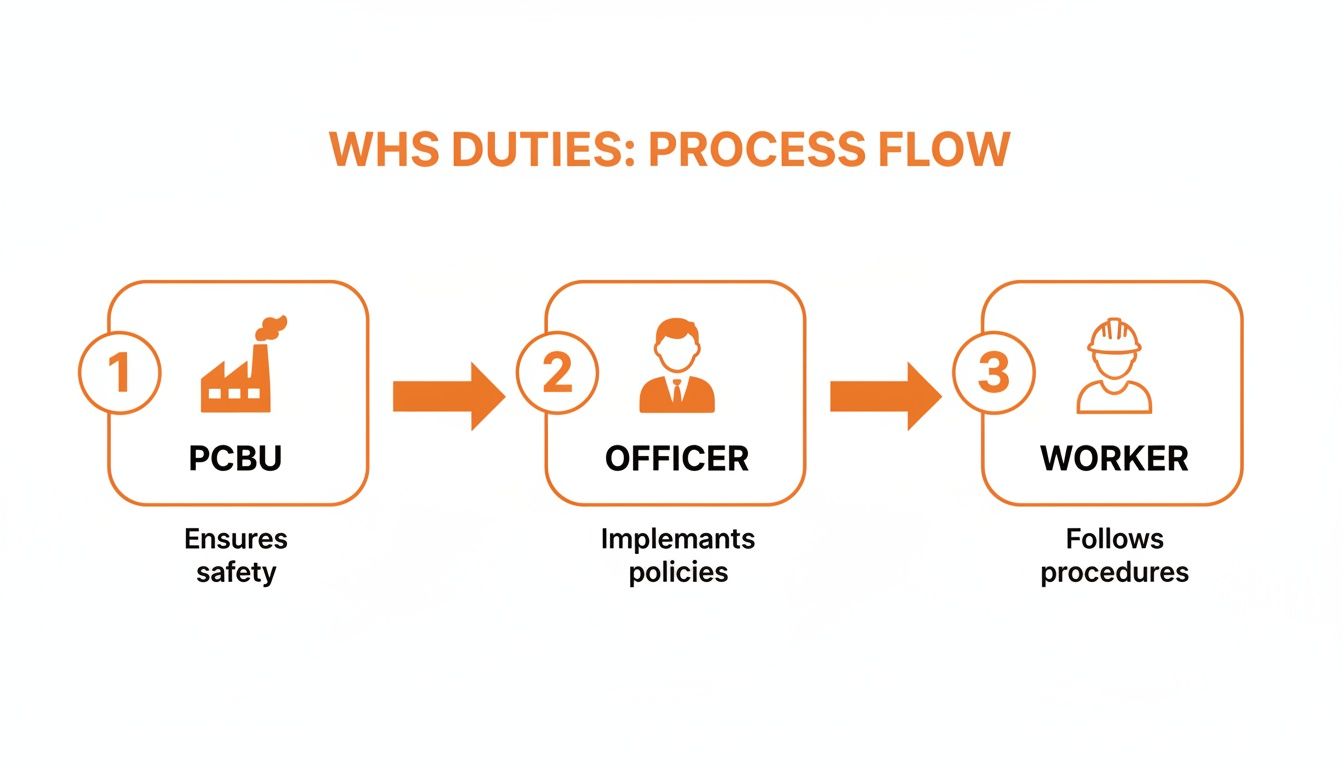

This visual shows how WHS duties flow, from the PCBU's overall responsibility down to the Officer's diligence and the Worker's on-the-ground actions.

It clarifies how responsibility is shared, ensuring that risk management is embedded at every level of the business.

Step 3 Control The Risks

After assessing your risks, it's time to do something about them. The law is very clear here: you must use the hierarchy of controls. This is a system that ranks risk controls from most effective to least effective. Your job is to always aim for the highest level of protection that is reasonably practicable.

The hierarchy, from best to worst, is:

- Elimination: The gold standard. Get rid of the hazard completely. For instance, can you assemble structures on the ground instead of working at heights?

- Substitution: Replace the hazard with something safer. Think swapping a toxic chemical for a non-toxic one or using a quieter piece of equipment.

- Isolation: Physically separate people from the hazard. A classic example is putting noisy machinery inside a soundproof enclosure.

- Engineering Controls: Make physical changes to the workplace itself. This could be installing guardrails on machinery or a ventilation system to remove fumes.

- Administrative Controls: Change the way people work. This includes things like safe work procedures, job rotation to limit exposure, or putting up warning signs.

- Personal Protective Equipment (PPE): This is your last line of defence. Providing hard hats, safety glasses, or gloves only protects the individual and does nothing to the hazard itself.

Relying only on PPE is one of the most common compliance mistakes we see. The QLD WHS legislation demands you work your way down from the top of the hierarchy, not start at the bottom.

Step 4 Review Your Controls

Your job isn’t finished once a control measure is in place. The final step which is really just the start of the next cycle is to regularly review your controls. You need to make sure they are actually working as intended and haven't accidentally created new problems.

Your controls should be reviewed:

- When you realise a control measure isn't working effectively.

- Before a big change happens, like bringing in new machinery or processes.

- If a new hazard or risk is identified.

- After a workplace incident or even a near-miss occurs.

- At regular, scheduled intervals as part of your ongoing safety checks.

This four-step process creates a continuous loop of improvement. It ensures your approach to safety stays relevant and effective, which is how you keep your team safe and your business compliant.

What Happens When Things Go Wrong: Incident Notification and Investigations

Let's be realistic even with the best safety plans, things can still go wrong on site. Knowing exactly what to do in the moments after an incident is just as critical as all the prevention work you do.

How you respond isn't up for debate. Your actions are dictated by the work health and safety legislation qld, which lays out clear, non-negotiable steps for reporting serious incidents. Get it wrong, and you could be facing significant penalties on top of dealing with the incident itself.

Here’s a practical breakdown of what the law calls a 'notifiable incident', the immediate steps you must take, and what to expect if Workplace Health and Safety Queensland (WHSQ) gets involved.

What is a Notifiable Incident?

First things first, the law doesn't expect you to report every single scrape or near-miss. A notifiable incident is a specific, serious event that has to be reported to the regulator immediately. Getting this definition right is the first crucial step.

These incidents are broken down into three main categories:

- The death of a person: This is straightforward and applies whether the person is a worker, contractor, or just a member of the public.

- A serious injury or illness: This isn't just any injury. We're talking about injuries that require immediate hospital admission, an amputation, serious head or eye injuries, or exposure to a substance that could cause lasting harm.

- A dangerous incident: Think of this as a major "close call" with the potential to have caused serious harm. This includes things like the collapse of a structure, an uncontrolled explosion, or the failure of major gear like a crane.

If an event ticks any of these boxes, you have an immediate legal duty to act.

Immediate Steps After an Incident

When a notifiable incident happens, you have to follow a two-part process without delay. Time is of the essence, and every action you take will be scrutinised.

First, preserve the incident site. This is non-negotiable. You can't disturb anything until an inspector arrives or gives you the all-clear. This is so investigators can see exactly what happened, as it happened. The only exceptions are to rescue an injured person or to make the site safe from any further immediate risk.

Do not move equipment, clean up spills, or alter the scene in any way unless it's to prevent another immediate injury. Preserving the site is a legal requirement, and tampering with it can be a serious offence.

Second, notify WHSQ immediately. This means picking up the phone as soon as you are aware of the incident. You can’t put it off until the end of the day or the next morning. After that initial call, you’ll also need to submit a written notification form within 48 hours. Using a structured incident report template for QLD is a smart move here, as it helps ensure you capture all the necessary details accurately for your own records and for the official report.

What to Expect From a WHSQ Investigation

If WHSQ decides to investigate, an inspector will show up at your workplace. It's important to understand that these inspectors have significant legal powers to figure out what happened and why.

An inspector can legally:

- Enter any workplace without giving you prior notice.

- Take measurements, photos, and samples.

- Seize equipment or documents that are relevant to their investigation.

- Interview anyone at the workplace, and these interviews are often recorded.

The main goal of the investigation isn't to play the blame game. It's to understand the root cause of the incident to prevent it from ever happening again. However, if they find breaches of the WHS Act, the inspector can take enforcement action.

Enforcement Actions and Notices

Based on what they find, a WHSQ inspector can issue several types of notices. These are legally binding documents that require you to take specific actions.

- Improvement Notice: This is issued when an inspector believes there's a breach of the WHS Act. It will spell out the breach and give you a specific deadline to fix it.

- Prohibition Notice: This one is more serious. It's handed out if an inspector believes an activity poses an immediate or imminent risk to someone's health and safety. It legally forces you to stop that activity right away until the risk has been dealt with.

In the most serious cases, particularly where there's been a reckless or grossly negligent breach of duty, WHSQ may recommend prosecution. It's worth remembering that these enforcement measures are part of a system that's always being reviewed. The 2017 Best Practice Review of WHSQ, for instance, led to key changes like mandatory reviews of Codes of Practice to keep the law responsive to modern workplace risks. You can read more about the key findings from the WHSQ review on the official government site.

Common Compliance Mistakes and How to Avoid Them

Even businesses with the best intentions can fall into the same old compliance traps. Spotting these common mistakes in your own systems is the first step to closing the gaps before they turn into a real problem. Let’s be clear: staying on top of work health and safety legislation in QLD isn't just about dodging fines it's about making sure every single person on your team gets home safe at the end of the day.

A lot of these errors come from a "set and forget" mentality. A business will put a safety system in place, tick the box, and then just let it gather dust. But safety isn't a one-off task; it needs to be actively managed, reviewed, and adapted as your workplace evolves.

Let's break down the most common pitfalls and what you can do to steer clear of them.

Assuming a Risk Assessment Is a One-Time Job

This is a big one. It's incredibly common to see risk assessments treated as a box-ticking exercise. Once it's done, it gets filed away, never to be seen again. A manufacturing business might do a brilliant, thorough assessment when they install a new press brake, but then completely fail to look at it again for years.

The thing is, workplaces are living, breathing environments. They are never static. New people start, equipment gets older, and the pressures of production change how work gets done. A risk assessment that was perfectly fine six months ago could be dangerously out of date today, missing a brand-new hazard like a worn-out emergency stop button or a new shortcut workers have started taking to save time.

How to avoid this:

- Schedule regular reviews: Lock in reviews for your risk assessments in the calendar. Do it at least once a year, or even more frequently for your high-risk activities.

- Let change be your trigger: Make it company policy to immediately review a risk assessment whenever you bring in new gear, change a work process, or after any incident or near-miss.

Failing to Genuinely Consult with Workers

The law is black and white on this: you must consult with your workers on safety matters. But so often, this "consultation" is just a one-way information dump. A manager holds a toolbox talk, reads out a new procedure, and ticks the "consultation" box without anyone else saying a word. That’s not consultation. It's a briefing.

Real consultation is a two-way street. Your team on the factory floor or out on the construction site are the ones at the coalface. They have the best understanding of the real-world risks they deal with every single day. If you ignore their input, you're missing out on the most valuable safety intelligence you can get.

A better way to do it? Actively ask for their feedback. Before you roll out a new traffic management plan on a busy site, walk the route with the truck drivers and machine operators who actually have to use it. They’ll point out blind spots or logistical nightmares in about five minutes things you’d never see on a piece of paper.

Providing Inadequate Training and Supervision

Handing a new starter a 100-page safety manual and telling them to sign a piece of paper is not training. It's a classic case of "paperwork over practice," and it's a massive compliance gap. You simply can't learn how to safely operate a complex piece of machinery by reading a book.

Training has to be practical and hands-on, and you need to verify that the person actually gets it. For a new welding machine, for example, your training needs to include a proper demonstration, supervised practice runs, and a final competency check to make sure the worker can truly use it safely on their own.

Supervision is the other half of the equation. This is especially critical for new and young workers, who we know are statistically at a much higher risk of getting hurt. A supervisor’s job is to make sure the safe work procedures cooked up in the office are actually being followed out on site.

Incorrectly Reporting or Ignoring Incidents

A lot of businesses just don't understand their incident reporting obligations. They might think they only need to report something if a worker takes a week off, completely missing the legal definition of a 'notifiable incident'. A really dangerous event, like a scaffolding collapse that luckily didn't injure anyone, is still a notifiable incident and must be reported to WHSQ immediately.

Failing to report or even just delaying a report is a serious breach. To get this right, you need to make sure all your managers and supervisors are trained on exactly what a notifiable incident is. You need a dead-simple procedure for immediate reporting that everyone knows by heart, including who to call and the critical importance of preserving the incident scene.

Key Resources and Where to Find Help

Let's be honest, you're not expected to memorise every last clause of Queensland's WHS laws. That would be impossible. The real skill is knowing exactly where to look when you need a straight answer.

Think of this section as your compliance cheat sheet. These are the official sources, the ones that hold the most weight. Bookmark them, get familiar with them, and you'll always have the authoritative answer right at your fingertips.

Official Government and Legal Sources

When you need the definitive word on a safety issue, always go straight to the source. These links will take you to the full text of the legislation and the main government portal for everything WHS in Queensland.

- Workplace Health and Safety Queensland (WHSQ): This is your number one stop. WHSQ is the government body in charge, and their website is packed with practical guidance, official forms (like for incident notifications), and advice tailored to specific industries.

- Work Health and Safety Act 2011: Want to see the law for yourself? This link takes you straight to the primary legislation on the official Queensland Government website. No second-guessing, just the text of the Act itself.

- Work Health and Safety Regulation 2011: Here's where the finer details live. This regulation spells out the specific requirements for things like high-risk work, hazardous chemicals, and other particular workplace risks.

- Codes of Practice: These are your practical guides. WHSQ provides a full list of approved Codes, which give you clear, actionable advice on how to meet your duties for specific hazards and tasks, from manual handling to managing asbestos.

It's crucial to remember these laws didn't just appear out of thin air; they were forged in the wake of tragedy. Major industrial disasters like the Collinsville and Moura mine explosions tragically exposed just how weak older regulations were. These events directly pushed legislators to create the stronger, more proactive framework we see in the WHS Act 2011 today. To get the full picture, you can learn more about how Queensland work accidents shaped safety laws and understand why these rules are so critical.

FAQ

Getting your head around work health and safety rules in Queensland can throw up a lot of questions. Here are some straight, practical answers to the most common queries we hear from business owners and managers.

WHS Act vs WHS Regulation

What’s the main difference between the WHS Act and the WHS Regulation?

Think of the WHS Act 2011 as the main rulebook. It lays out the big-picture principles and the legally binding duties for everyone in a workplace. It basically tells you what you have to do, like providing a safe work environment.

The WHS Regulation 2011, on the other hand, is the detailed instruction manual. It gets into the nitty-gritty, giving you the specific how-to for managing high-risk work things like working from heights, handling asbestos, or using certain types of machinery. You need to follow both to be fully compliant.

The Role of Codes of Practice

Do I actually have to follow a Code of Practice?

While Codes of Practice aren't law, you absolutely should treat them as if they are. If an incident ends up in court, a relevant Code can be used as evidence to show what's known about a hazard and the standard, accepted ways to control its risks.

If you follow an approved Code for a specific task, you’re generally considered to have done your bit and met your legal duties for that issue. If you decide to go a different route, the burden of proof is on you to show your method provides a level of safety that's equal to or even better than what the Code recommends.

Following a Code is the most straightforward path to compliance. If you deviate, be prepared to justify and prove your alternative safety measures can stand up to scrutiny.

Application to Small Businesses

As a small business owner, do all these rules really apply to me?

Yes, they do. The WHS Act applies to every single business in Queensland, no matter how big or small. The guiding principle is what is ‘reasonably practicable’ for you to do to keep people safe.

This crucial term considers things like how severe a risk is, what solutions are available to control it, and the cost involved. A small fabrication workshop won't have the same resources as a massive manufacturing plant, but the fundamental duty to protect your workers’ health and safety is exactly the same.

Running a safe and compliant workplace doesn't have to be a constant battle with paperwork and spreadsheets. Safety Space brings everything into one simple platform, replacing outdated systems and cutting down your admin time. You get real-time oversight, so you can stop chasing paper and start focusing on protecting your people and your business.

Book your free demo and consultation today.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.