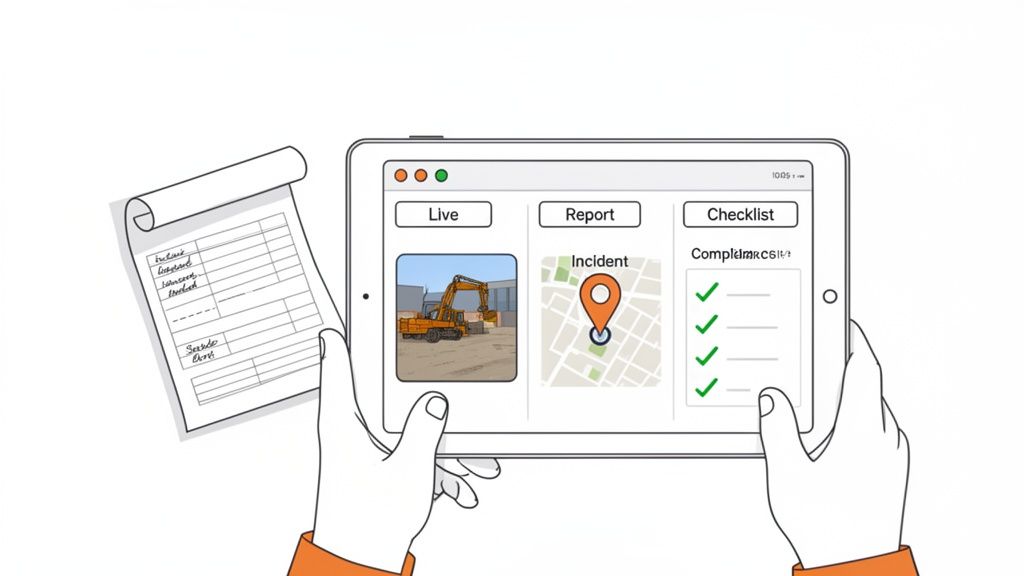

A work safety app is your single source of truth for managing health and safety, replacing the mountain of paper forms and disconnected spreadsheets. It gives you a live, real-time view of what’s happening on your sites, from incident reports to compliance checks, all from a phone or tablet. This is the crucial shift from slow, reactive data entry to proactively getting ahead of workplace risks.

From Clunky Spreadsheets to Real-Time Safety Management

Let's be honest. Managing safety with paper forms and complex spreadsheets is a constant headache. It’s a system built on information trickling in at the end of the day, getting manually punched into a log, and then filed away in a cabinet. The whole process is slow, full of human error, and makes it nearly impossible to get a clear, immediate picture of what’s really happening on site.

Think about a construction site manager juggling subcontractor paperwork, daily toolbox talks, and hazard inspections. In the old world, a critical hazard report might not be seen by the right person for hours, or even days. That piece of paper sits in a ute until it can be handed over, scanned, and emailed. By then, it’s old news.

A work safety app completely flips this on its head. It becomes the central hub for all your H&S tasks, turning every team member's phone into a useful safety tool.

A Practical Shift in Daily Operations

Instead of waiting for yesterday's news, a work safety app delivers a live feed of site activities. You can see incident reports, inspection results, and compliance gaps across all your projects the moment they’re logged. This means you can spot worrying trends and jump on issues before they lead to a serious incident or a costly work stoppage.

It’s about making safety part of the workflow, not an afterthought.

Take a look at how this changes things on the ground:

- On-the-spot hazard reporting: A worker on a construction site spots an unsecured ladder. They pull out their phone, snap a photo, log the hazard, and assign a corrective action to their supervisor right there and then. The report is instantly time-stamped and geo-tagged, creating an accurate, undeniable record in seconds.

- Frictionless subcontractor onboarding: A new electrical subcontractor arrives on site. The site manager uses the app to instantly verify their licences and inductions, assign them the relevant Safe Work Method Statements (SWMS), and get digital sign-off before they even touch a tool.

- Simplified compliance checks: During a site walk, a manager can pull up a custom digital checklist on their tablet and complete a safety audit. The results are automatically saved and available for anyone with clearance to review, building a digital audit trail that is always up-to-date and ready for scrutiny.

To see just how this digital trail strengthens your compliance, you can learn more about using health and safety compliance software to organise and maintain your records.

This image nails the core benefit: safety tasks get done in the field, where the work happens, not back in the site office hours later.

The difference between the old way and the new way is stark. It’s about more than just getting rid of paper; it’s about making safety information immediate and actionable.

Old Methods vs Modern Work Safety App

| Safety Task | Traditional Method (Paper and Spreadsheets) | Work Safety App (Example: Safety Space) |

|---|---|---|

| Hazard Reporting | Worker fills out a paper form, hands it to a supervisor at end-of-shift. Report is manually entered later. | Worker takes a photo and logs the hazard on their phone. Supervisor gets an instant notification. |

| Incident Investigation | Data is collected manually. Reports are typed up and emailed. Tracking corrective actions is a manual process. | All evidence (photos, statements) is captured in the app. Actions are assigned and tracked with automated reminders. |

| Site Inductions | Face-to-face sessions, paper sign-in sheets, manual records filed away. | Workers complete site-specific inductions online before arrival. Records are stored digitally and are easy to verify. |

| Compliance Audits | Manager walks the site with a clipboard and checklist. Results are manually compiled into a report. | Manager uses a tablet with a digital checklist. Results and photos are uploaded in real-time for immediate review. |

| SWMS/JSA Management | Paper copies are collected, often inconsistently. They are stored in a folder and are hard to access or update. | Subcontractors upload SWMS directly to the app. Workers review and sign off digitally before starting work. |

This isn't just a digital version of your old system. It's a fundamental upgrade to how you manage safety.

The real goal is to switch from a system of historical record-keeping to one of active, preventative safety management. It’s about giving your team the tools to identify and fix problems on the spot.

Ultimately, bringing in a work safety app isn't just about "going digital." It’s about making safety information accessible, actionable, and timely for everyone involved, from the person on the tools to the director in the boardroom.

Core Features Your Work Safety App Must Have

Not all safety apps are built the same. When you're choosing a work safety app for a high-risk setting like manufacturing or construction, a basic digital checklist just won't cut it. You need a tool with specific, practical features designed for the realities of your worksite.

Think of these features as non-negotiables. Without them, you're just buying a fancier, more expensive version of the same old problems you had with spreadsheets. The right app moves you from logging incidents to preventing them.

Real-Time Incident Reporting and Management

The most critical feature is the ability for anyone on site to report an incident or hazard the moment it happens. This can't be a feature buried in complex menus; it needs to be fast and intuitive.

Workers should be able to:

- Capture photo and video evidence: A picture is worth a thousand words, especially when documenting an unsafe condition or the scene of a near miss. Visuals provide undeniable context that text alone can't.

- Instantly notify key personnel: When a report is submitted, the right people, such as supervisors, H&S managers, or operations leads, should get an immediate notification so they can act.

- Track corrective actions: Reporting a problem is only half the battle. The app must let you assign corrective actions to specific individuals, set deadlines, and track them through to completion with an automated, auditable trail.

This real-time capability is central to effective incident management software, turning your entire team into an active part of your safety monitoring process. The days of incident reports sitting in a supervisor's truck until the end of the day should be over.

Fully Customisable Digital Forms

Your business has specific safety processes, whether it's for Safe Work Method Statements (SWMS), Job Safety Analyses (JSAs), or daily pre-start checks. A work safety app that forces you into a generic, one-size-fits-all template is a step backwards.

Your chosen app must allow you to build and customise your own digital forms. This makes sure the app adapts to your workflow, not the other way around. Look for AI-assisted form completion, which can pre-fill information like location, date, and user details to reduce admin time and improve the quality of data being collected.

Here’s what a modern dashboard looks like, giving you a live overview of key safety metrics in a manufacturing facility.

This single view gives managers immediate insight into incident trends and compliance status, allowing for quick, data-driven decisions.

Absolute Must-Have Offline Functionality

What happens when your team is working on a remote construction site or in the basement of a large factory with no Wi-Fi? If your app stops working, it’s useless.

Offline functionality is not a "nice-to-have"; it's essential. Workers must be able to complete all their tasks, fill out forms, and log reports without an active internet connection. The app should securely save all data on the device and then automatically sync with the central system as soon as a connection is re-established.

Without reliable offline mode, you create data gaps and discourage workers from using the app in areas with poor reception. This defeats the entire purpose of having a real-time system.

Subcontractor and Multi-Site Management

For operations managers overseeing multiple projects or dealing with a constant flow of subcontractors, visibility is everything. A good work safety app provides a centralised dashboard to monitor compliance across every site and every team.

This means you can see at a glance if a subcontractor has submitted their SWMS, if a specific site has completed its weekly safety audit, or if a high-priority corrective action is overdue. It removes the need to chase down individual supervisors for updates, saving huge amounts of time and providing a single source of truth for your entire operation.

Beyond the functional requirements, the robust security of your work safety app is a non-negotiable core feature, and understanding the key cybersecurity roles for your mobile app is crucial.

A Realistic Plan For Implementing Your New App

Rolling out new software can turn into a massive headache if you don’t have a solid plan. I’ve seen it happen too many times. A successful launch isn’t about flipping a switch and hoping for the best; it’s a careful process of testing, tweaking, and training. A phased approach is always, always better than a "big bang" rollout that just overwhelms everyone.

The real goal is to get your new work safety app adopted smoothly, with as little disruption to your daily operations as possible. That means starting small, getting the setup right, and then expanding in a controlled way. Let's walk through a straightforward plan that actually works in the real world.

Start With a Pilot Program

Before you even think about rolling the app out to every site and every worker, run a pilot program. Pick a single project site or a specific team that’s generally open to new technology. This small-scale test is your golden opportunity to find out what works and what doesn't in a low-risk environment.

The main aims of your pilot program should be to:

- Gather honest feedback: Your pilot group will give you invaluable, unfiltered opinions on the app's usability. Is it easy to report a hazard? Is the daily pre-start form confusing? This is the feedback you need to hear before a full launch.

- Identify internal champions: Look for the supervisors or team leaders who quickly get the app and see its benefits. These people will become your champions, helping to train and encourage their colleagues when you go wider.

- Work out the kinks: You’ll uncover practical issues you hadn't considered. Maybe the app performs poorly in an area with bad mobile reception, or a particular form needs more fields. It's so much easier to fix these issues with a small group of users.

A successful pilot program isn't about proving the app is perfect. It's about finding the imperfections in a controlled setting so you can fix them before they become company-wide problems.

Customise Workflows to Match Your Processes

One of the biggest hurdles to adopting new software is forcing people to abandon familiar processes. A good work safety app should bend to how you already work, not force you into a rigid, one-size-fits-all box. This is where customisation is absolutely critical.

Work closely with your app provider to tailor the platform to your existing safety procedures. If your paper-based incident report has specific fields crucial for your investigations, make sure those are replicated in the digital form. If your Safe Work Method Statements follow a certain structure, the app should support that.

Making the digital process feel familiar is a simple but powerful way to get buy-in from your team. You're not just giving them a new tool; you're giving them a better, faster version of a process they already know. This is a key part of making risk management systems that your team will actually use.

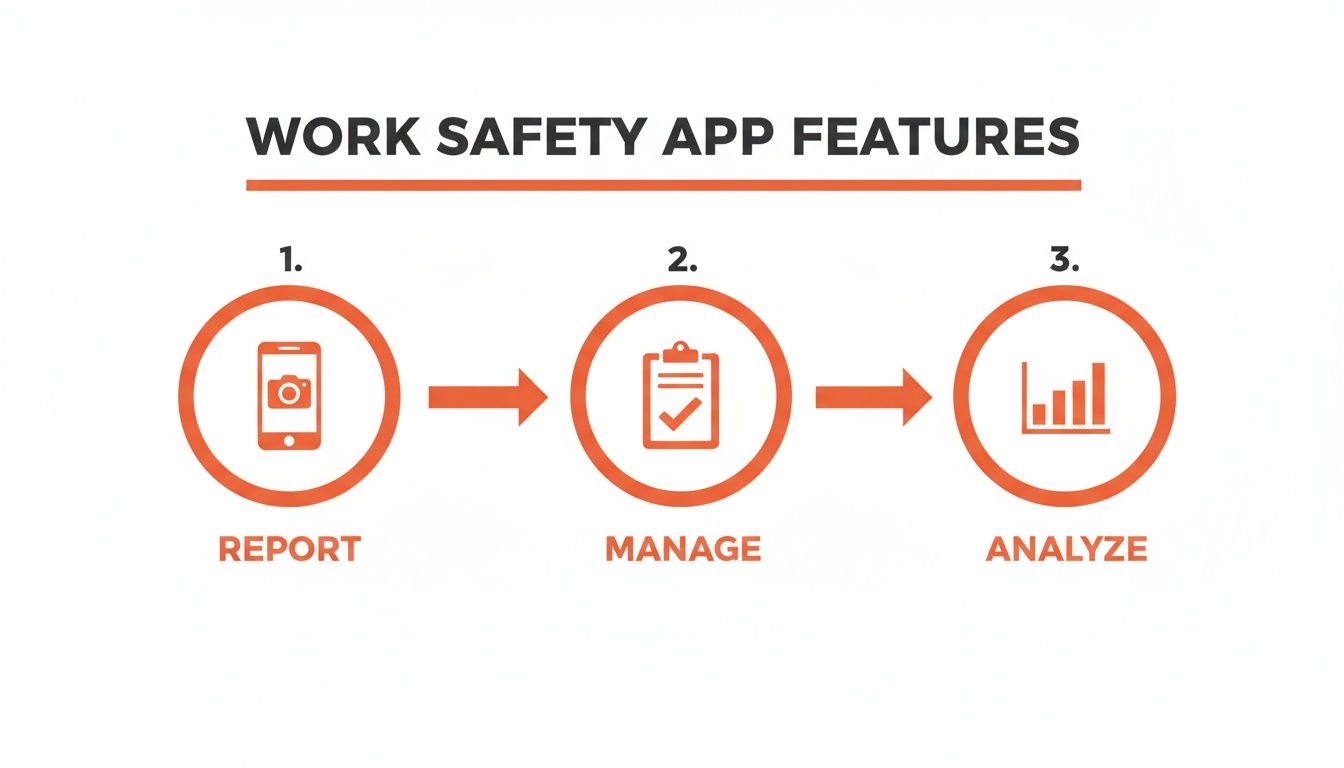

The diagram below shows the simple, three-step process at the heart of most safety app features.

This flow, from reporting an issue, to managing the response and analysing the data, is what replaces slow, clunky paperwork.

Staged Rollout and Role-Specific Training

Once your pilot is done and the app is customised, it's time for the broader rollout. But again, don't do it all at once. A staged rollout, site by site or team by team, is far more manageable.

Your training plan has to be tailored to different roles. Not everyone needs to know every single feature.

- For field workers and subcontractors: Focus on the core tasks they'll do every day. Think practical, hands-on sessions on how to complete a pre-start check, report a hazard with a photo, and sign onto a SWMS. Keep it short, simple, and relevant to their job.

- For site supervisors and managers: Training should cover everything the field team learns, plus how to manage corrective actions, conduct digital audits, and review their team's submissions. They are the frontline managers of the system.

- For operations directors and H&S leaders: This group needs to understand the high-level dashboard and analytics. Their training should be all about how to pull reports, analyse safety trends across multiple sites, and monitor overall compliance.

Practical, group-based training helps build confidence and makes sure no one gets left behind.

Onboarding Subcontractors Effectively

Let’s be honest, subcontractors are a critical part of most operations, but they are often the hardest to get on board with new systems. You have to make the process as frictionless as possible.

Make the app onboarding a standard part of their site induction. Before they can start work, require them to download the app and complete a quick induction module on how to use it for key tasks like SWMS sign-offs and hazard reporting. Provide clear, simple instruction guides they can access anytime.

By making the work safety app a condition of working on your site, you standardise your safety process. You make sure everyone, employee or contractor, is using the same system from day one.

Measuring the Real-World Value and ROI

So, how do you actually prove a work safety app is worth the investment? It’s a perfectly fair question. The value isn't just about feeling safer; it's about seeing real, tangible results that show up on your balance sheet. The good news is, you can measure the return on investment (ROI) using metrics you’re likely already tracking, directly linking the app to protecting both your people and your bottom line.

The most immediate return often comes from slashing wasted time. Just think about the sheer number of hours your supervisors and H&S team spend on safety admin. Chasing signatures, manually punching in incident data from paper forms, and piecing together monthly reports is a massive time sink. A work safety app automates a huge chunk of this, giving your key people back hours every week to focus on proactive safety management out on the floor, not paperwork in the office.

This reduction in the administrative burden is often the easiest ROI to calculate and justify. Just multiply the hours saved per week by your staff's hourly cost, and the financial benefit becomes crystal clear, fast.

From Lagging Indicators to Leading Metrics

For years, safety measurement has been stuck on lagging indicators like Lost Time Injury Frequency Rates (LTIFR). These numbers are important, of course, but they only tell you about failures that have already happened. A work safety app flips the script, giving you powerful leading indicators, data points that help you prevent incidents before they ever occur.

Now, you can start tracking proactive metrics like:

- Average time to close corrective actions: How quickly are identified hazards actually being fixed? A shorter timeframe means less exposure to risk for your team.

- Number of near-miss reports: An increase in near-miss reporting is almost always a positive sign. It shows your team is engaged and actively identifying risks before they cause an injury.

- Safety observation frequency: Are supervisors regularly completing and logging safety walks? This data is a direct measure of engagement with your safety system.

By focusing on these proactive metrics, you shift the conversation from "how many people got hurt last month?" to "what are we doing to stop anyone from getting hurt next month?"

Imagine a manufacturing plant manager noticing a spike in near-miss reports related to a specific machine guard. Using the app's data, they can see it's a recurring issue, dig into the root cause, and implement a permanent engineering fix. This single action prevents a potential serious injury and all the significant costs that come with a workers’ compensation claim.

Reducing the High Cost of Incidents

The direct and indirect costs of a single workplace incident can be staggering, especially in high-risk industries where they pose a constant threat to profitability. Consider the numbers in Australia: construction accounts for 12% of the 146,700 serious workers’ compensation claims. Nationally, just six industries, including construction and manufacturing, account for 80% of traumatic fatalities and 61% of all serious claims. You can dig deeper into these key WHS statistics in Australia.

A single serious incident can trigger a cascade of costs:

- Increased insurance premiums

- Regulatory fines and legal fees

- Project delays and work stoppages

- Equipment damage and replacement costs

- A serious blow to your company's reputation

By speeding up incident reporting and improving the quality of your investigations, a work safety app helps you manage and mitigate these costs far more effectively. Faster incident closure rates mean less operational disruption and a quicker return to business as usual.

Stronger Compliance and a Defensible Audit Trail

Finally, never underestimate the financial value of rock-solid compliance. Proving you are meeting your regulatory obligations with a paper-based system is a nightmare. Records get lost, signatures are missed, and pulling together documentation for an audit becomes a frantic, time-consuming scramble.

A work safety app creates an automatic, time-stamped digital audit trail for everything. Every toolbox talk, every SWMS sign-off, and every safety inspection is recorded, organised, and easily accessible. This digital trail is your best defence during a regulatory inspection, making it simple to demonstrate due diligence and avoid the hefty penalties that come with non-compliance. This isn't just about ticking boxes; it's about building a robust, defensible record that protects your business from the ground up.

Common Mistakes to Avoid When You Roll Out a New Safety App

Even the best work safety app on the market can fall flat if the rollout is fumbled. In my experience, getting your team to actually use new software is the real challenge, and success often comes down to avoiding a few common but critical mistakes.

Spotting these pitfalls early can be the difference between a smooth transition and a failed investment. Let's walk through the most frequent missteps I've seen and, more importantly, how you can steer clear of them.

Forcing a Tool That Breaks Your Workflow

One of the biggest errors is picking a rigid, off-the-shelf app that forces you to abandon safety processes that already work well. Your team has established ways of doing things for a good reason. If new software makes their job harder or forces them to completely relearn a core task, they’ll find a way to avoid it.

The fix? Choose a work safety app that can be customised to fit your existing workflows, not the other way around. Before you sign any contracts, ask the provider to show you exactly how their system can replicate your current JSA, incident report, or pre-start checklist. The goal should always be a better, faster version of what your team already does, not a confusing, foreign system.

Neglecting the People on the Tools

Too often, the decision to buy a safety app is made in a boardroom with zero input from the site supervisors and field workers who will use it every single day. This top-down approach almost guarantees poor adoption because the app doesn't solve the real-world problems your team faces on the ground.

You need to involve your field staff in the selection process. It's that simple.

- Build a small review team: Pull in a couple of your most respected site supervisors and experienced workers.

- Let them test drive the options: Give them demo access to your top 2-3 app choices.

- Get their direct feedback: Ask them which app was easiest for logging a hazard or completing an inspection. Which one felt less like a chore?

When your team helps choose the tool, they have a personal stake in its success. This one move creates a sense of ownership from day one.

Getting buy-in isn't about sending a memo. It's about showing your team that the app is a tool to make their job easier and safer, not just another administrative task handed down from management.

Rolling Out Without Proper Training

Another guaranteed path to failure is providing generic, one-size-fits-all training, or worse, no real training at all. Just sending out a link to a user manual and expecting everyone to figure it out is a recipe for disaster. It leads directly to low usage, frustration, and a whole lot of wasted potential.

Effective training has to be practical and role-specific. Your field workers don't need to know the ins and outs of configuring backend reports; they need a quick, hands-on session showing them exactly how to complete their three most common tasks. Supervisors, on the other hand, will need deeper training on how to manage corrective actions and review their team's data.

Ignoring Post-Launch Support

The work isn't finished once the app goes live. Forgetting to provide ongoing support is a slow-burn mistake that erodes confidence over time. Your team will have questions, run into minor issues, and forget how to use certain features. That's just human nature.

Set up a clear and simple support system right from the start. This could be a designated "super-user" on each site who can handle basic questions, or a direct line to the app provider’s support team. Just checking in with teams a few weeks after the rollout to ask what's working and what isn't shows you’re committed to making the tool a success for them.

Using a Safety App to Manage Mental Health Risks

Physical safety is only one side of the coin. The mental wellbeing of your team is just as crucial, and a modern work safety app can be a useful ally in spotting and managing psychological risks, not just physical ones. This takes you beyond traditional incident management and helps you meet a significant part of your duty of care obligations.

For too long, mental health has been siloed as a separate, HR-led issue. But let's be clear: psychosocial hazards like crushing workloads, impossible deadlines, and workplace conflict are genuine safety risks. They can, and should, be tracked and managed just like any other hazard. The trick is giving people a safe, confidential way to raise these concerns without fear.

Identifying Psychosocial Hazards Early

A good work safety app gives your team tools like confidential reporting channels or simple, customisable wellbeing check-in forms. These features create a direct line of communication for workers who would never feel comfortable speaking up in a toolbox talk or flagging an issue with their direct supervisor.

Think about a construction site manager who starts to see a pattern in the app’s data. Over a few weeks, several confidential reports from a specific crew mention extreme fatigue and stress tied to a project deadline. This isn't gossip; it's a leading indicator. This insight allows the manager to step in early, adjust the workload, and prevent burnout before it leads to a costly mistake or a serious incident.

Using Data to Support Your Team

This isn't about playing Big Brother. It’s about spotting trends in aggregated, anonymised data. A work safety app lets you measure and act on leading indicators for mental health risks with the same rigour you apply to physical hazards.

And this proactive approach is becoming more critical by the day. Recent Australian data shows mental health claims shot up 14.7% in just one year, now making up 12% of all serious workers’ compensation claims. Even more concerning is that the median recovery time for these claims is nearly five times longer than for physical injuries. You can discover more about these work health and safety statistics and see the impact for yourself.

A comprehensive safety app shouldn't just be about hard hats and high-vis. It needs to integrate features for mental wellbeing, including providing guidance on making reasonable adjustments for mental health at work to properly support your employees.

Using an app for wellbeing check-ins or confidential feedback gives you a way to listen at scale. It helps you identify systemic issues, like unrealistic production targets in a manufacturing plant, that could be impacting the entire workforce.

When you equip your team with a tool that supports both their physical and psychological safety, you’re building a far more complete and effective H&S system. This approach finally acknowledges that a truly safe workplace is one where every aspect of an employee's wellbeing is taken seriously.

Got Questions? We’ve Got Answers.

Here are some of the most common questions we hear from H&S and operations leaders when they're exploring a new work safety app. These are the practical, real-world queries that come up time and again.

How Much Training Will My Team Actually Need?

This is a big one. The last thing you want is a tool that creates more work than it saves.

Honestly, the amount of training hinges entirely on the app's design. A well-designed, intuitive app should feel natural to your team on the ground. For core functions like filling out a pre-start or reporting a hazard, field staff should pick it up in less than an hour. The key is a dead-simple user interface that doesn’t require a manual.

Your managers and H&S coordinators, on the other hand, will need a bit more in-depth training. They’re the ones who'll be customising forms, running performance reports, and digging into safety data across different sites, so they need to know how to get the most out of the system.

Can This App Actually Work on Our Remote or Black-Spot Sites?

Yes, it absolutely has to. This isn't a "nice-to-have"; it's a non-negotiable feature for any serious work safety app.

Solid offline functionality is essential. It allows your workers on remote construction sites, in basements, or across large manufacturing plants with patchy Wi-Fi to complete all their reports without a single interruption. The app simply saves the data securely on their device and automatically syncs it back to the main system the moment they get a connection. No lost reports, no excuses.

The ability to work anywhere, anytime, is what makes a digital safety tool genuinely reliable. If an app can't function without a perfect signal, it's not built for the realities of a proper worksite.

How Do I Know My Company’s Data is Secure?

Data security is paramount, especially when you're dealing with sensitive incident reports and employee information. Any reputable app provider will use industry-standard security measures, including full data encryption, to protect your information from day one.

When you’re vetting a work safety app, don't be shy about asking for specifics on their security protocols. It’s also smart to check where your data is being hosted, onshore Australian hosting is often better for local compliance and peace of mind.

And one final point that is absolutely critical: clarify their data ownership policies upfront. Your company must always be the sole, undisputed owner of its safety data. Full stop.

Ready to see how a truly customisable work safety app can fit your specific operational needs? Book a free demo and H&S consultation with Safety Space today to get expert advice and a clear path forward.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.