Workplace health and safety apps are digital tools that move safety management out of the filing cabinet and onto the worksite, using smartphones and tablets. It’s a shift from paper forms to real-time monitoring, and it’s a big deal for high-risk industries like construction and manufacturing.

Why Your Worksite Needs a WHS App

Let's get straight to the point. Bringing a new app onto the site isn’t about chasing the latest tech. It’s about giving your crew a practical tool that makes their job safer and simpler, ditching the mess of paper forms and clunky spreadsheets for good.

On a busy construction site, things move fast. Hazards pop up, incidents happen, and compliance checks are a constant. The old way of managing this? Paper forms that get lost, damaged by weather, or just sit in a ute until knock-off time. By then, important details are forgotten, and the chance for a quick response is gone.

This is where a good WHS app changes things. It takes those paper-based processes and puts them into a real-time digital format on the one device everyone has: their phone. This is a big deal in high-risk sectors where the speed of information can be the difference between a near-miss and a serious incident.

From Clipboards to Clicks

Imagine a site manager spots an exposed wire. Instead of making a mental note or scribbling something on a notepad they’ll lose later, they pull out their phone. In less than a minute, they can log the hazard, snap a photo, and assign a corrective action directly to the site electrician. Done.

This real-time capability is where these apps deliver their biggest value. It’s not just about better record-keeping; it’s about getting things done.

Key safety processes become instant, trackable, and transparent:

- Incident Reporting: A near-miss can be logged in seconds, with photos and witness details, before anyone even leaves the site.

- Risk Assessments: Digital Safe Work Method Statements (SWMS) can be pulled up, reviewed, and signed off on a tablet right where the work is happening.

- Compliance Checks: Audits and inspections are done with simple checklists, making sure nothing gets missed and generating an instant report for the office.

By putting these tools directly into the hands of your team on the ground, you close the gap between identifying a risk and getting it fixed. The information is immediate, accurate, and leads to action.

A Practical Tool for Your Crew

At the end of the day, the goal is to give your team a tool they will actually use. A good WHS app simplifies their workflow, it doesn't add another complicated step. Think about it: instead of spending ten minutes filling out a paper pre-start checklist, they can tap through it on their phone in half the time.

This digital approach helps you build a much stronger safety management system. It creates a clear, permanent, and easily accessible record of all safety activities on site. This makes it far easier to spot recurring issues, show compliance, and ultimately, keep your project moving forward safely and efficiently.

How to Pick the Right App for Your Crew

Choosing from the hundreds of workplace health and safety apps out there can feel overwhelming. But really, it all comes down to one simple question: will your crew actually use it?

I’ve seen it happen time and again. An app looks great in a sales demo but completely falls flat in the real world of a noisy, muddy, or remote worksite. The secret is to focus on practical features that solve real problems for your team on the ground, not just add another layer of digital paperwork.

An app has to work where your crew works. For many clients in construction or manufacturing, that means dealing with patchy or non-existent mobile reception. This makes offline functionality a non-negotiable. A worker needs to be able to complete a risk assessment or log a near-miss on their device, knowing it will automatically sync up the moment they're back in range. If it can’t do that, the app is basically useless.

Focus on Features That Matter on Site

The user interface needs to be dead simple. We're talking big buttons, clear text, and a logical flow that doesn't require a user manual. Your team won't spend 20 minutes trying to figure out a complicated form; they’ll just go back to the paper version they already know.

When you're looking at an app, look for these core functions:

- Simple Reporting Forms: Can a worker log an incident with a quick photo and a few taps? Or are they stuck trying to type long descriptions on a tiny phone screen?

- SWMS and JSA Management: The app should make it easy to access, review, and sign off on Safe Work Method Statements or Job Safety Analyses right there on a tablet or phone.

- Compliance Tracking: It should help you keep track of training records, equipment maintenance, and certifications without needing a separate, complicated spreadsheet.

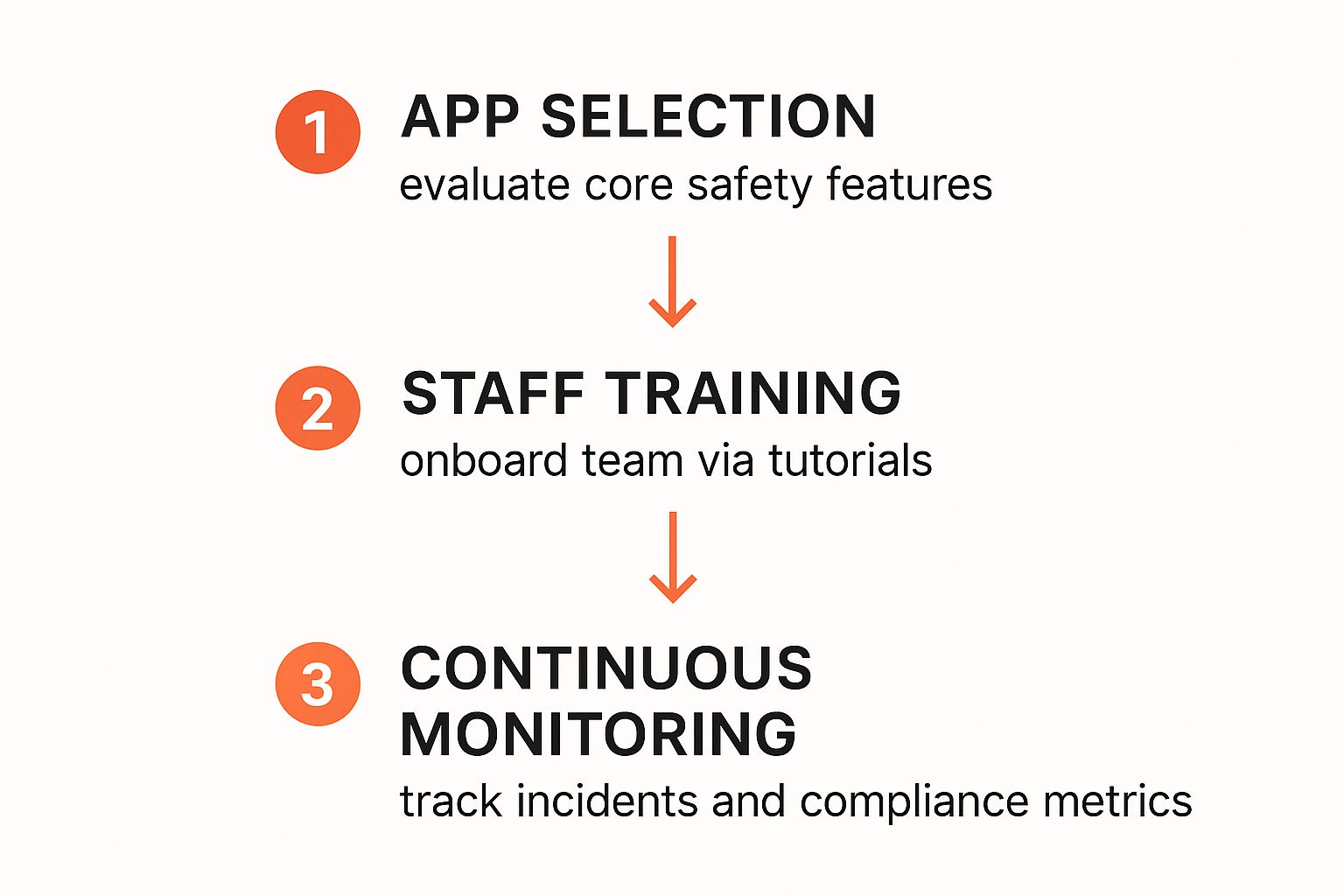

This graphic breaks down the basic process for selecting, training, and monitoring a new WHS app.

As you can see, choosing the right features is just the first step. It's the ongoing use and the data you get back that deliver the real results for your business.

To help you compare your options, I've put together a quick checklist. Use this to cut through the marketing noise and focus on what will actually make a difference for your team.

Essential Features Checklist for WHS Apps

| Feature | What to Look For | Why It Matters for Your Crew |

|---|---|---|

| Offline Mode | Can users complete forms, access documents, and log data without an internet connection? Does it sync automatically later? | Essential for remote sites or areas with poor reception. It ensures work doesn't stop just because the signal does. |

| Intuitive Interface | Is it easy to navigate? Are buttons large and clear? Can a new user figure it out in under five minutes? | Complex apps get ignored. A simple design means higher adoption rates and less frustration for your workers. |

| Photo & GPS Tagging | Can users easily attach photos to reports? Does it automatically capture the location and time? | A picture provides clear, undeniable evidence for incident reports and hazard logs. |

| Customisable Forms | Can you easily adapt templates for your specific site needs, like SWMS, inspections, or toolbox talks? | Every worksite is different. One-size-fits-all forms rarely capture the specific risks your team faces. |

| Real-Time Dashboards | Does the app provide an instant view of what’s happening on-site through clear, visual reports? | You can spot trends and address issues proactively instead of waiting for weekly paper reports to come in. |

| Automated Alerts | Can you set up automatic notifications for overdue actions, expiring certifications, or high-risk incidents? | This ensures nothing falls through the cracks and helps your safety team focus their attention where it's needed most. |

This checklist isn't exhaustive, but it covers the core functionalities that separate a useful tool from just another piece of software.

Match the App to Your Industry Needs

The Australian OHS services industry is getting more tech-driven every year, with companies needing solutions that meet strict Safe Work Australia regulations. The app you choose has to reflect this, aligning with the specific hazards and compliance needs of your sector. For a look into the wide range of tools available for different operational needs, check out examples like Resgrid's range of WHS applications.

The best way to know if an app will work is to test it in the real world. Run a short trial with a small, trusted group of workers on one of your sites. Give them a few key tasks to complete and ask for their direct, honest feedback.

Was it easy to use? Did it slow them down? What was frustrating? Their answers will tell you far more than any sales pitch ever could. This real-world test is the only way to know the tool you choose becomes a valued part of your team's daily routine, not just another piece of ignored software.

Ultimately, your choice in health and safety management software should be about simplifying compliance, not making it more complicated.

Rolling Out the App Without Work Stoppages

Introducing any new tech to a construction site can easily turn into a massive headache. The key to getting a new workplace health and safety app into your team's hands isn't a big, disruptive launch. It’s a planned rollout that avoids work stoppages and frustration.

The goal here is to make the app a normal, helpful part of the daily routine, not just another complicated task your crew has to deal with.

Trust me, a full, company-wide launch on day one is a recipe for disaster.

Instead, start small. Select a single site or a specific crew to act as your pilot group. This lets you test the app in a real-world setting, identify any glitches, and gather honest feedback before you go live everywhere.

This initial phase is your chance to find out what works and what doesn't. You can refine your training process and fix any app-related issues with a small, manageable group, preventing small problems from blowing up into major disruptions across all your operations.

Get Your Supervisors on Board First

Before you even mention the app to the wider crew, your supervisors and team leaders must be completely confident using it. They're the ones who will be answering questions and setting the example on site. If they see the app as a burden, so will their teams.

Your supervisors are your most critical champions. When they actively use the app for their daily checks, toolbox talks, and hazard reporting, it sends a clear message that this new tool is here to stay and is part of how work gets done.

Schedule dedicated sessions with your leadership team first. Let them play around with the app for a week to get comfortable with its functions. Once they see the practical benefits for themselves, they'll be much more effective at encouraging their crews to adopt it.

Focus Training on Practical Wins

Forget long, boring classroom sessions. Your training needs to be hands-on, short, and directly relevant to your team's daily tasks. Show your crew exactly how the app makes their job easier, not just how it helps the company tick a compliance box.

Organise training around specific, tangible benefits:

- Faster Pre-Starts: Show them how they can complete their pre-start checklist in under two minutes on their phone, instead of wrestling with a soggy piece of paper for ten minutes.

- Instant Hazard Reporting: Walk them through logging a hazard with a photo. Point out how it’s faster and more effective than trying to describe the issue over the radio or waiting until the end of their shift.

- Easy SWMS Access: Demonstrate how they can pull up the Safe Work Method Statement for any task directly on a tablet, without having to hunt down the site folder.

When your team sees the app as a tool that saves them time and hassle, they are far more likely to use it consistently. This focus on practical, on-the-ground advantages is the most effective way to get buy-in and make the rollout a success, without causing delays or pushback.

Using App Data to Make Real Safety Improvements

A workplace health and safety app is only as good as the information you get out of it. It’s one thing to collect data, but the real work starts when you turn those digital reports into real safety improvements on the factory floor or construction site.

This is the point where the app shifts from a simple record-keeper into a proactive safety tool.

The raw data from incident reports, inspections, and hazard logs is your direct line of sight into what’s actually happening across your operations. Instead of relying on gut feelings or sifting through stacks of old paper records, you get a clear, evidence-based picture of your biggest risks.

This isn't about getting lost in complex spreadsheets. It’s about spotting simple patterns that point directly to recurring problems. For example, if you notice three different near-miss reports in a month are all tied to the same piece of machinery, you know exactly where to focus your next toolbox talk and maintenance check.

Turning Data Into Action

First things first: set up simple, automated reports within your app. Most modern platforms have dashboards that give you an at-a-glance view of key metrics, so you're not constantly digging for information. To really make a WHS app work for you, understanding its app analytics capabilities is crucial for turning that raw data into real safety insights.

Keep an eye out for trends in these key areas:

- Incident Hotspots: Are specific locations on your site showing up repeatedly in hazard reports? This could point to a problem with the site layout, poor lighting, or a particular process that needs reviewing.

- Equipment Issues: Is a certain type of equipment consistently being flagged during pre-start checks or linked to near-misses? That’s a clear signal for a maintenance review or a need for better training.

- Common Hazards: Do your reports frequently mention slips, trips, and falls in the same area? Maybe it's a recurring spill or a cable management issue that needs a permanent fix, not just a temporary clean-up.

By focusing on these patterns, you move from just reacting to individual incidents to proactively addressing the root causes. It’s the difference between patching a leak and fixing the faulty pipe.

Making Data-Driven Decisions

This data-first approach gives you the hard evidence you need to justify safety investments and procedural changes. Instead of just saying, "I think we need to replace that machine," you can walk into the meeting with a report showing it has been involved in four near-misses and six failed inspections in the last quarter.

Suddenly, the conversation becomes objective and focused on tangible risk, not opinion. This makes getting buy-in from management a whole lot easier.

The statistical trends back this up. We've seen a notable decrease in serious work-related injury claims in Australia over the last decade, which lines up with the wider adoption of WHS apps. These tools are helping teams get on the front foot with risk management through real-time reporting and early hazard detection.

Ultimately, using your app’s data allows you to focus your limited time, budget, and resources where they will have the greatest impact. For a deeper look at this, check out our guide on how to use predictive safety analytics to anticipate and prevent incidents before they even happen.

Common Mistakes to Avoid With Safety Apps

Adopting a new workplace health and safety app should make life easier, not add another headache to your day. Yet, so many businesses fall into the same predictable traps that turn a promising tool into an expensive, ignored piece of software.

Sidestepping these common mistakes right from the start is the key to a smooth rollout that your team will actually get behind.

It always starts with good intentions. But the road to failed adoption is often paved with overly complicated software that workers on the ground simply refuse to use. The trick is to stay focused on solving the real, practical problems your crew faces every single day.

Choosing Complexity Over Practicality

One of the biggest blunders is picking an app that's way too complicated for your team. A flashy dashboard and dozens of features might look great in a sales demo, but they’re useless if a worker can't figure out how to log a simple hazard report in under a minute.

Don’t get swayed by a long list of features you’ll never touch. You have to be ruthless here. Avoid any app with a clunky interface, tiny buttons, or multi-step processes for what should be simple tasks.

The better approach? Prioritise simplicity and speed. During your trials, give your team one simple job, like completing a pre-start check. If they can’t do it easily without needing a manual, it’s not the right fit for a busy construction site.

A safety app should reduce the administrative load, not add to it. If it takes longer to report a hazard on the app than it did on paper, your team will see it as a step backwards, and adoption will fail. Guaranteed.

Providing Inadequate Training

Another classic pitfall is assuming your crew will just "figure it out." Handing over a tablet with a new app and no proper guidance is a recipe for instant pushback and frustration.

Effective training isn't a one-hour PowerPoint presentation. It’s about hands-on, practical demonstration that connects directly to their daily work. Don't just send out a login and a user guide and hope for the best.

Instead, show them exactly how the app solves their specific problems. Demonstrate how they can complete an inspection in five minutes on the app, versus the 15 minutes it used to take with the old clipboard and pen. You have to focus on the "what's in it for me" factor.

Ignoring the App's Data

I've seen this happen so many times. A company gets the app rolled out, but then completely fails to use the information it gathers. The app quickly becomes a digital filing cabinet where reports go to be forgotten. This is a massive missed opportunity to spot risks before they lead to incidents.

Don’t just collect data for the sake of compliance. The real value is in the trends.

Schedule a weekly 15-minute review of the app's dashboard. Look for patterns: recurring hazards on a specific machine, near misses on a particular task, or common issues raised in inspections. Use this intelligence to guide your next toolbox talk or safety walk, turning that data into real, preventive action on the ground.

To help you stay on track, I've put together a quick table summarising these common slip-ups and how to steer clear of them. Think of it as a cheat sheet for a successful rollout.

Common Pitfalls and Practical Solutions

| Common Mistake | Why It Happens | How to Avoid It |

|---|---|---|

| Feature Overload | Getting impressed by a long feature list during a sales demo, losing sight of day-to-day needs. | Focus on your top 3-5 core problems. Test those specific workflows with your team before buying. |

| "Set and Forget" Training | Assuming tech-savvy staff won't need help or that a single training session is enough. | Provide role-specific, hands-on training. Show them the benefits, not just the buttons. Create champions in each team. |

| Data for Compliance Only | Viewing the app as a digital paper trail rather than an active risk management tool. | Schedule regular, brief reviews of the app's dashboard. Use the data to inform safety meetings and proactive interventions. |

Ultimately, avoiding these mistakes comes down to a simple principle: put your people first. Choose a tool that makes their job easier, train them on how it benefits them, and use the insights to make their workplace safer. Do that, and you'll be well on your way.

Got Questions About WHS Apps? We've Got Answers

Making the jump from paper and spreadsheets to a proper workplace health and safety app can feel like a massive leap. It's normal to have questions about the cost, the time it'll take, and the big one: will your crew even bother using it?

Here are some straight-up answers to the questions we hear all the time from businesses in manufacturing and construction.

What's This Going to Cost Us?

The price tag on WHS apps is all over the place, but most run on a subscription. You're usually looking at a monthly or yearly fee that depends on how many people are using it or the specific features you need.

For a small to medium-sized business, a ballpark figure is anywhere from $10 to $50 per user, per month. Some providers have tiered plans, so the cost per person drops as your team gets bigger. But it’s a huge mistake to just look at the sticker price.

Don’t get caught up comparing the monthly fee alone. Make sure you ask about any hidden setup costs, fees for extra data storage, or charges for training and ongoing support. An app that costs a bit more but comes with great support will often save you a fortune in the long run compared to a cheaper, clunkier option.

Will My Team Actually Use It?

Honestly, this is the make-or-break question. The answer comes down to two things: the app you pick and how you roll it out. If the app is slow, confusing, or just a pain to navigate, you can bet your crew will be back to their old ways within a week.

The secret to getting everyone on board is to choose an app that was clearly designed for someone on-site, not just a manager sitting in an office. Think simple layouts, big buttons, and the ability to work offline. When you introduce it, don't just talk about compliance; show them how it makes their job easier, like completing a pre-start check in two minutes instead of ten.

What Happens if We Have Rubbish Internet on Site?

We hear this one a lot, especially from teams on construction sites or in massive manufacturing plants where reception is spotty at best. Any WHS app worth its salt and built for your industry will have solid offline functionality.

This means your workers can fill out their forms, log a hazard, or pull up a safety doc on their device without needing any internet at all. The app just saves the data locally and then automatically syncs it all up to the cloud the second it gets a connection. Make this a non-negotiable feature you test thoroughly during your free trial.

How Long Does It Take to Get Everything Set Up?

The setup time can be anything from a few hours to a few weeks. It really depends on the complexity of the app and how much you want to tweak it to fit your business. The simpler, ready-to-go solutions can be up and running in a flash. You could easily spend an afternoon uploading your current forms, adding your team, and getting the basic settings dialled in.

More powerful systems that need to link up with your other business software will take a bit longer. A good provider will walk you through a clear onboarding plan, help you get all your existing safety documents moved over, and make sure the platform is configured to match how you actually work. Get them to give you a realistic timeline before you sign anything.

Ready to see how a simple, powerful WHS app can work for your team? Safety Space replaces paper and spreadsheets with a customisable platform that simplifies compliance and protects your people. Book a free demo today and see the difference for yourself.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.