A workplace health and safety (WHS) management plan is your operational playbook for safety. It is a working document that spells out exactly how your business spots hazards, figures out the risks, and puts controls in place to keep people safe on site. For high-risk industries like construction and manufacturing, it's not just about ticking a box; it's a practical guide for getting things done day-to-day.

Why a WHS Management Plan Is Not Just Paperwork

It’s a common mistake to treat a WHS plan as a one-off document you create to satisfy the regulators and then shove in a drawer. In reality, it’s a tool that should guide every action on the factory floor or construction site.

This plan is the difference between simply having safety rules and having a coordinated system that actively prevents incidents from happening in the first place.

It gives everyone, from the site manager to the new apprentice, clear instructions on what they're responsible for. It lays out the "who, what, when, and how" for managing safety, making sure nothing slips through the cracks. It’s this systematic approach that stops people from getting hurt and keeps the workplace productive.

The Real-World Impact on Safety

When safety planning is organised and intentional, the results are clear. Across Australia, a real commitment to better WHS management has led to measurable improvements.

The workplace fatality rate recently dropped to 1.3 deaths per 100,000 workers, a welcome decrease from the five-year average of 1.4. This steady downward trend proves that structured safety strategies genuinely work to reduce serious harm on the job. You can dig into more of these key WHS statistics on the Safe Work Australia website.

This progress really hammers home why we need to move beyond a simple checklist. A proper plan anticipates problems and puts solutions in place before an incident ever occurs.

What Goes into a Practical WHS Plan

A useful WHS management plan isn't padded out with vague, corporate-speak statements. It’s packed with specific, actionable components that tackle the unique risks of your workplace. Think of it less as a single document and more as a toolkit for managing safety, all kept in one place.

For instance, it will detail the exact procedure for a new worker's site induction in a manufacturing plant, including which machinery they need specific training on. Or, it might outline the precise steps for getting a permit for high-risk work, like operating a crane on a busy construction project.

A strong WHS management plan answers one simple question: "What do we actually do to keep people safe here?" It should be written for the people doing the work, not just for the auditors.

A solid plan is built on a few non-negotiable elements. These aren't just items on a list; they're the foundational pillars of a system that protects your team and your business. The table below breaks down these core components.

Table: Core Components of a WHS Management Plan

| Component | What It Covers | Why It Matters |

|---|---|---|

| Safety Policies & Procedures | The company's safety commitment and step-by-step instructions for specific tasks (e.g., lockout/tagout, confined spaces). | Sets clear expectations for everyone and provides consistent, safe methods for completing high-risk jobs. |

| Hazard Identification & Risk Assessment | How hazards are spotted (e.g., inspections, reports), how risks are evaluated, and the hierarchy of controls used to manage them. | Forms the proactive core of your safety system, helping you fix problems before they cause an injury. |

| Roles & Responsibilities | Clearly defines who is accountable for what, from senior leadership down to frontline workers. Includes specific safety duties for each role. | Eliminates confusion and ensures that critical safety tasks are owned by specific people. No more "I thought someone else was doing it." |

| Training & Competency | Details the safety training required for different roles, including inductions, specific skill training, and refresher courses. | Ensures your team has the knowledge and skills they need to work safely and manage the risks they face every day. |

| Emergency Preparedness | Plans for responding to emergencies like fires, medical incidents, or chemical spills. Includes evacuation routes, contact lists, and first aid procedures. | When things go wrong, a clear, well-rehearsed plan can be the difference between a minor issue and a major disaster. |

| Incident Reporting & Investigation | The process for reporting all incidents (including near misses), investigating them to find the root cause, and tracking corrective actions. | Helps you learn from mistakes and prevent similar incidents from happening again. It turns every event into a learning opportunity. |

| Monitoring, Review & Auditing | A schedule for regularly reviewing the WHS plan's effectiveness, conducting site inspections, and auditing the system to ensure it's working as intended. | A safety plan is never "finished." This ensures it stays relevant, effective, and continuously improves over time. |

Getting these parts right from the start is what makes your plan a practical, effective tool instead of just another piece of paper.

How to Identify Hazards and Assess Risks

A health and safety management plan is only as good as your ability to find problems before they hurt someone. Identifying hazards isn't a one-and-done job; it's a constant process of looking at your workplace with fresh eyes. This is where the real work of preventing incidents actually begins.

It’s all part of a continuous cycle of improvement.

As you can see, a proactive safety plan moves logically from identifying a risk to managing it and having a response ready. It's a loop that never really stops.

The most effective way to kick this off? Get out on the floor. Whether you're on a construction site or in a manufacturing plant, you need to see the work as it's happening.

Practical Techniques for Finding Hazards

Your best tools are a clipboard and a keen eye. Generic checklists have their place, but nothing beats observing the real work environment and, crucially, talking to the people doing the jobs every single day.

- Regular Site Walkthroughs: Don’t just stroll through the site; really observe it. Look for obvious slip, trip, and fall hazards like trailing cables or oily floors. Notice if machine guards have been removed or if workers are taking shortcuts that could be dangerous.

- Job Safety Analyses (JSAs): A JSA breaks a task down into its basic steps to pinpoint potential hazards at each stage. For example, a JSA for operating a press brake would examine the risks of loading material, the pressing operation itself, and removing the finished part. For a deeper look, you can explore the fundamentals of what is hazard identification.

- Talk to Your Team: Your workers are your greatest asset here. They know the informal workarounds and the near misses that never get reported. Ask them directly: "What's the most dangerous part of your job?" or "What's the one thing you wish we would fix?"

The goal is to build a complete picture of the real risks, not just the ones written down in a manual. All of this, of course, is much more effective when it's supported by a robust risk management policy that provides the framework for these activities.

Prioritising Risks with a Risk Matrix

Once you have a list of hazards, you need to decide what to tackle first. You can’t fix everything at once, so prioritisation is key. This is where a risk matrix becomes incredibly useful.

A risk matrix helps you evaluate two simple things for each hazard:

- Likelihood: How likely is it that something will go wrong?

- Consequence: If it does go wrong, how bad will it be?

By plotting these two factors on a chart, you can quickly sort risks into high, medium, or low priority.

For example, a trailing air hose across a main walkway is a high-likelihood hazard, but the consequence might be a minor trip (low severity). In contrast, an unguarded saw blade is a lower-likelihood hazard (if workers are trained), but it has a catastrophic consequence (high severity). The unguarded blade is the clear priority.

This practical tool turns a long list of problems into a clear action plan, directing your time and money to the hazards that pose the greatest threat to your team.

From Identification to Action

Identifying what could go wrong is the critical first step. Without it, any safety plan is just guesswork.

This process is so vital because, despite improvements, the workplace remains a significant source of injury. In Australia, there were 146,700 serious workers' compensation claims in a recent period, that’s over 400 claims every single day. Our national injury rate of 3.5% is far better than the global average, but these numbers show why we can't afford to be complacent.

By using practical methods like site walkthroughs and JSAs, you gather the real-world data needed to make your workplace safer. A risk matrix then gives you the logic to act on that data intelligently, ensuring your efforts are focused where they'll have the biggest impact.

Developing Practical Risk Control Measures

Alright, you've done the hard work of identifying the hazards lurking around your worksite. What now? This is the point where your health and safety management plan shifts from thinking to doing. The goal isn't to just slap a band-aid on the problem. It's about putting solid, effective controls in place that genuinely reduce risk for the long haul.

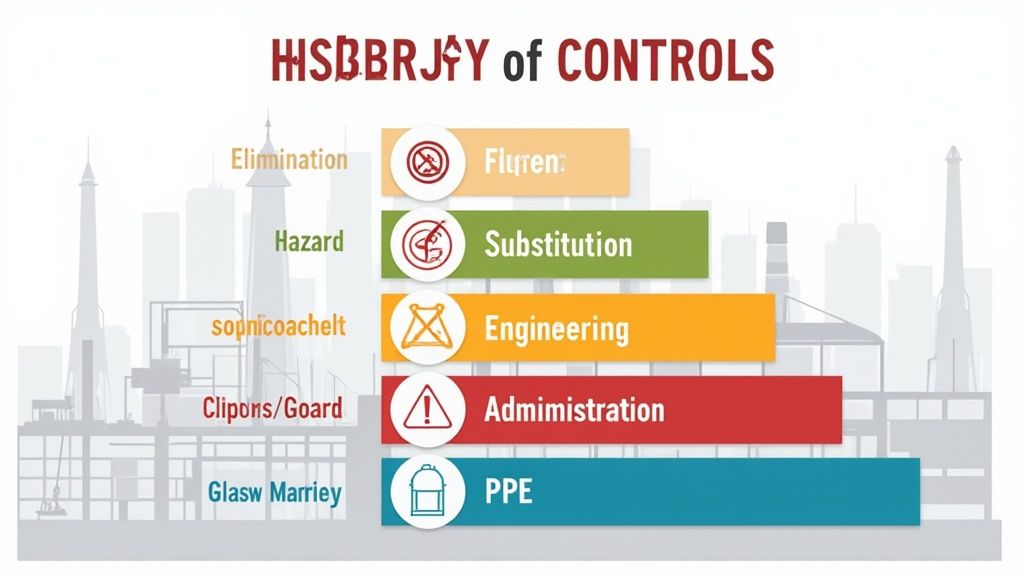

A proven framework for this is the hierarchy of controls. Think of it as a step-by-step guide for picking the most effective way to manage a risk. You start at the top with the most effective solutions and only move down to the less reliable ones when you have to.

This method forces you to look past simply handing someone a pair of gloves and to consider more permanent fixes first. Let’s break down each level with some real-world examples you’d see on a construction site or in a factory.

The Most Effective Controls: Elimination and Substitution

Right at the top of the pyramid are elimination and substitution. These are your best options by a long shot because they either get rid of the hazard completely or swap it out for something much safer. Always consider these two first.

- Elimination: This is the gold standard; it means getting rid of the hazard entirely. In a manufacturing plant, you could automate a dangerous manual task so no one ever has to be exposed to that risk. On a construction site, this might mean prefabricating wall frames on the ground to drastically reduce the need for working at height.

- Substitution: Can't eliminate it? See if you can replace it with something less dangerous. A classic example is switching out a toxic, solvent-based paint for a non-toxic, water-based alternative. That one change can massively lower the risk of chemical exposure for your crew.

While you won't always be able to eliminate or substitute, aiming for them first is how you design a fundamentally safer workplace from the ground up.

Engineering Controls: A Physical Barrier

When elimination or substitution isn't on the cards, your next best bet is an engineering control. We're talking about physical changes to the workplace that put a barrier between people and the hazard. These are designed to be permanent or semi-permanent fixes that don't rely on someone remembering to do the right thing.

For instance, instead of just giving workers earplugs for a noisy machine (which is PPE, your last resort), you could build a sound-dampening enclosure around it.

Other common-sense examples include:

- Installing guardrails on elevated work platforms to prevent falls.

- Using local exhaust ventilation to suck harmful fumes right out of the air at their source.

- Putting fixed guards on the moving parts of machinery to stop people from getting caught.

These controls are so effective because they are literally built into the environment. They're on the job protecting your team 24/7, even if someone has an off day or gets distracted.

Engineering controls are about changing the work environment, not trying to change the worker. This makes them far more reliable than controls that depend on people always doing the right thing.

Administrative Controls and PPE: The Last Line of Defence

Down at the bottom of the hierarchy, we have administrative controls and Personal Protective Equipment (PPE). These are your last lines of defence because they depend entirely on people following rules and using gear correctly, every single time. They don’t remove the hazard; they just create a process or a barrier to protect against it.

Administrative controls are the rules, procedures, and training you put in place. Think of things like:

- Developing Safe Work Method Statements (SWMS) for high-risk jobs.

- Implementing job rotation to limit how long a worker is exposed to a repetitive strain risk.

- Using clear warning signs and painting safety lines on the factory floor.

Personal Protective Equipment (PPE) is the gear workers wear to protect themselves: hard hats, safety glasses, hi-vis vests, gloves, respirators, you name it.

While absolutely essential in many situations, PPE must be your final consideration after you've exhausted all other options up the hierarchy. Why? Because if the PPE fails, is damaged, or isn't worn correctly, the worker is completely exposed to the raw hazard. It's the final buffer, not the primary solution.

For a deeper look, our guide on effective control measures for risks offers more detailed insights.

Putting Your Plan into Action with Your Team

A perfectly written workplace health and safety management plan is useless if it just lives in a folder on a shelf. The real success of your plan comes down to one thing: how well it's understood and used by the people on the ground.

Rolling it out effectively isn’t about sending a mass email and hoping for the best. It's about clear communication, practical training, and genuine consultation. The goal is to move your plan from a static document into a set of daily, ingrained actions. Every single person, from the managing director to a first-year apprentice, needs to understand not just the rules, but their specific role in keeping themselves and their workmates safe. This is where your plan becomes a real, living part of your operation.

This is especially critical in high-risk industries. Recent data shows that a staggering 80% of work-related traumatic injury fatalities in Australia happened in just six sectors, including construction and manufacturing. When an industry like agriculture, forestry and fishing has a fatality rate of 13.7 per 100,000 workers, it's a stark reminder that targeted, well-communicated safety plans are non-negotiable. You can find out more in these key Australian work health and safety statistics.

Making Communication Practical

To get your plan working, you have to meet your team where they are. Forget long, formal meetings that everyone forgets the moment they walk out. Focus on short, sharp, and relevant methods that actually stick.

- Toolbox Talks: These are your best friend for day-to-day safety communication. Keep them focused on a single topic that’s relevant to the work happening that day. For example, if a crew is about to start a job near live power lines, the toolbox talk should be exclusively about electrical safety and the specific controls for that task. Nothing else.

- Site Inductions: An induction is your first chance to set the standard. Don't just show a generic video. Walk new workers through the site, pointing out specific hazards like forklift-only zones, emergency assembly points, and the location of first aid kits. Make it interactive and directly relevant to their job.

- Visual Aids: Simple is often best. Use posters, signs, and floor markings to reinforce key messages from your plan. A clear sign showing the required PPE for a specific area is often far more effective than a page buried in a manual.

A great plan that isn't communicated is just a suggestion. Clear, constant, and practical communication turns that suggestion into a standard way of working for everyone on site.

Specific Training for High-Risk Jobs

General safety awareness is important, but it’s nowhere near enough for high-risk work. Your rollout must include specific training for tasks where the consequences of getting it wrong are severe. This is a non-negotiable part of any effective workplace health and safety management plan.

This kind of specialised instruction goes way beyond basic inductions. Think about activities like:

- Working at heights: This requires hands-on training on how to properly inspect, fit, and use fall arrest systems. Watching a video doesn't cut it.

- Confined space entry: Workers need practical drills on entry procedures, atmospheric testing, and what to do in an emergency. They need to have done it before it counts.

- Operating specific machinery: A worker qualified to use one type of press isn't automatically competent on another. Training has to be machine-specific.

Tailoring your approach is everything. Our guide to workplace safety training can give you more detailed strategies for developing programs that actually stick. The goal is simple: ensure that the workers facing the biggest risks have the most robust knowledge and skills to manage them.

Why Consultation Is a Must

Finally, one of the biggest mistakes you can make is creating a plan in an office and simply handing it down from on high. The people actually doing the work are your real subject matter experts. They know the shortcuts people take, the tools that don't work properly, and the procedures that are impractical on a busy day.

Involving your team in the rollout is a powerful form of consultation. Ask for their feedback on the procedures you’ve developed. Are they clear? Do they make sense in the real world? This two-way conversation does more than just improve the plan; it gives workers a sense of ownership.

When people feel they've had a say in creating the rules, they are far more likely to follow them.

How to Monitor and Review Your Safety Plan

A workplace health and safety management plan isn't a "set and forget" document you can just file away. Your worksite is a living thing: new people, new gear, new projects. If you want your plan to actually work, you need to treat it the same way. It needs to be regularly checked and adapted as your business evolves.

This isn't about creating more paperwork. It's about getting into a rhythm of checking in, spotting gaps before they become incidents, and making sure the safety measures you've got in place are still the right ones for the job. Consistent monitoring and review are what keep a safety plan from gathering dust on a shelf.

Setting a Schedule for Regular Monitoring

Waiting for an incident to happen is the worst way to find out your plan has a flaw. Proactive monitoring means you're actively looking for issues on a set schedule, turning safety checks into a normal part of your operations.

The key here is consistency. There’s no single "right" frequency for every check, but here’s a solid starting point that works for most sites:

- Daily Checks: Quick pre-start checks of equipment and the immediate work area. Think of it as a 5-minute scan before the tools are picked up.

- Weekly Inspections: A more structured walkthrough of a specific area or process. This is where you’ll look closer at things like housekeeping, machine guarding, and whether the team is using their PPE correctly.

- Monthly Reviews: Taking a step back to look at the data. Go through the incident reports, near misses, and inspection findings from the past month to see if any trends are popping up.

This regular schedule builds a constant feedback loop. It helps you catch the small stuff, like a damaged guard rail or a blocked fire exit, before it has a chance to contribute to something serious.

Analysing Incident Reports and Near Misses

Every incident, no matter how minor, is a lesson. And near misses? They're basically free lessons on what could have gone wrong. How you review these events is one of the most critical parts of monitoring your workplace health and safety management plan.

When you're looking at a report, don't just stop at the immediate cause. You have to dig deeper and ask why.

For instance, a worker slips on an oil spill. The oil is the immediate cause, sure. But a proper review would keep asking:

- Why was oil on the floor in the first place? (Maybe a machine is leaking).

- Why wasn't it cleaned up? (No spill kits nearby? Workers not trained on the procedure?).

- Did our last inspection of that area miss the leak? (Is our inspection checklist even looking for that?).

A near miss is a gift. It’s a clear warning that one of your safety controls failed, but you got lucky and no one was hurt. Ignoring it is like ignoring the smoke alarm because you don't see flames yet.

By analysing these events properly, you start fixing the underlying system failures, not just patching up the surface-level problems. That’s how you stop the same type of incident from happening again and again.

Conducting a Formal Annual Review

At least once a year, it's time to step back and give your entire WHS management plan a thorough review. This is the big-picture exercise to make sure the whole system is still fit for purpose. It’s your chance to update procedures, re-evaluate your biggest risks, and bake in all the feedback you’ve gotten from the team on the ground.

Get your key people in a room, such as supervisors, health and safety reps, and experienced workers, and work through a structured checklist. This isn’t just about ticking compliance boxes; it’s about genuinely questioning how effective your plan is in the real world.

Your annual review checklist should be built around critical questions that spark a proper discussion.

Annual WHS Plan Review Checklist

- Changes in the Workplace:

- Have we brought in any new machinery, equipment, or chemicals in the last 12 months?

- Have any of our work processes or job roles changed in a major way?

- Are there new projects or site layouts that introduce hazards we hadn't planned for?

- Performance of Controls:

- Are our current risk controls still working the way we thought they would?

- Do our incident and near-miss reports show any recurring problems that we haven’t solved?

- What feedback have we gotten from workers during toolbox talks or safety meetings?

- System and Compliance:

- Are our emergency procedures still up-to-date with current site contacts and layouts?

- Is our training register current? Are there any gaps in legally required training?

- Have there been any changes to WHS legislation or codes of practice that we need to incorporate into our plan?

This structured review turns the vague idea of "continuous improvement" into a concrete, annual event. It’s what stops your plan from becoming outdated and ensures it remains a practical tool for keeping your team safe as the business grows.

Common Questions About WHS Management Plans

Even with a rock-solid plan on paper, questions always pop up when it's time to put it into action. Getting straight answers to these common queries helps you stay on track and ensures your plan actually works in the real world. Let's break down some of the most frequent questions we hear.

How Often Should We Update the Plan?

This is a big one. While an annual review is the standard baseline, it’s definitely not a "set and forget" rule.

The best practice is to review your plan whenever there is a significant change in your workplace. This isn't just about a date on the calendar; it's about keeping the plan relevant to your current operations.

So, what counts as a "significant change"? It could be installing a new piece of heavy machinery in your factory, or maybe starting a new construction project with completely different site hazards. Any time a new, significant risk is introduced, your plan needs to be updated to tackle it head-on.

How Do We Get People to Actually Follow the Plan?

This is probably the most practical challenge of all. A beautifully written plan is useless if your team doesn't buy into it and follow the procedures every single day. Getting this right comes down to two things: consultation and communication.

First, get your workers involved when you're developing or reviewing procedures. Ask for their feedback. What works and what doesn't on the factory floor or the construction site? When people have a say in creating the rules, they're far more likely to see them as practical and necessary, not just another piece of paperwork.

Second, communication has to be relentless and clear. Use daily toolbox talks and pre-start meetings to reinforce specific parts of the plan relevant to the day's tasks. This keeps safety at the front of everyone's mind and weaves the plan into the daily rhythm of work.

What Are the Key Legal Requirements in Australia?

Knowing your legal duties isn't just important, it's fundamental. In Australia, the core legal framework is the model Work Health and Safety (WHS) Act, which most states and territories have adopted (Victoria is the main exception with its own comparable laws, but the principles are similar).

This legislation puts a primary duty of care on the "Person Conducting a Business or Undertaking" (PCBU). In simple terms, this means the business must ensure, so far as is reasonably practicable, the health and safety of its workers. Your WHS management plan is the main way you prove how you're meeting this duty.

Your plan absolutely must address key legal obligations, including:

- Providing a safe work environment: This covers everything from the physical condition of your site to preventing exposure to hazardous substances.

- Ensuring safe use of plant and structures: Your plan must detail clear procedures for machinery operation, maintenance, and regular inspections.

- Providing adequate facilities: This includes basics like access to clean drinking water, toilets, and proper first aid.

- Giving workers necessary information, training, and supervision: This is a huge part of the law and a core function of your plan's implementation.

Failing to meet these obligations can result in serious penalties, so your plan has to be built around these legal cornerstones. A well-documented workplace health and safety management plan is your best defence and your best evidence of compliance.

Ready to move your safety management from paper and spreadsheets to a single, easy-to-use platform? Safety Space gives you real-time oversight and simplifies compliance for your entire operation. Book a free demo and see how you can protect your team and your business at https://safetyspace.co.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.