A workplace health and safety policy is the official document that spells out your company’s commitment to keeping its people safe. It sets clear expectations on how to manage risks and defines who’s responsible for what, from the managing director right through to the newest worker on site. It’s your blueprint for a structured approach to safety.

Why Your Safety Policy Is More Than Just Paperwork

Think of your safety policy as the operational backbone for your business, especially if you’re in a high-risk game like construction or manufacturing. This isn’t a document designed to sit on a shelf and gather dust; it's a practical tool for managing real-world risk and setting clear expectations for everyone involved.

Getting this right isn’t just about ticking a compliance box. It’s about creating a predictable and safe work environment. A well-defined policy moves your business from reacting to incidents to proactively preventing them. It gives you a clear framework that helps avoid costly fines, reduce downtime from injuries, and show your team you’re serious about their wellbeing.

The Legal Ground You Stand On

Under Australian Work Health and Safety (WHS) law, every Person Conducting a Business or Undertaking (PCBU) has a primary duty of care. What does that mean in simple terms? You are legally on the hook to ensure, as far as is reasonably practicable, the health and safety of your workers.

A written WHS policy is the first, most fundamental step in proving you take this duty seriously. It's not just a recommendation. A documented policy demonstrates you have a system in place to manage risks, and it serves as your foundational evidence of compliance if an incident occurs or a regulator comes knocking. Without it, you’re leaving your business wide open to significant legal and financial heat.

Practical Benefits Beyond Compliance

While meeting legal duties is a must, the real value of a solid safety policy comes from how it works day-to-day.

- Clarity for Everyone: A good policy kills the guesswork. When a new subbie arrives on your construction site, they should immediately know your rules for reporting hazards and what PPE is required.

- Consistent Operations: It ensures safety procedures are applied the same way across all teams and locations. This is absolutely critical for multi-site manufacturing plants or sprawling construction projects.

- A Foundation for Training: Your policy provides the core material for worker inductions and ongoing training. A key part of this is understanding what Safety Data Sheets (SDS) are for, as these documents are the foundation of communicating chemical hazards.

A policy gives your entire team, from the factory floor manager to the greenest apprentice, a shared reference point for safe work practices. It’s the playbook everyone follows to keep themselves and their colleagues safe.

Recent stats show why robust safety systems are still so important. While Australia's workplace fatality rate has thankfully fallen by 24% since 2014, some regional differences are stark. The Northern Territory, for example, has a fatality rate of 2.8 per 100,000 workers. Numbers like that show why a proactive, living policy is completely non-negotiable for managing real-world risks.

Building Your Policy From The Ground Up

A workplace health and safety policy that just sits in a folder gathering dust is useless. To have any real impact, it needs a solid structure that people can actually understand and use on the job.

Let's break down the essential building blocks you need to create a practical, working document.

This isn’t about drafting complicated legal language. It’s about clearly stating what your business will do to manage safety, who is responsible for what, and the procedures everyone must follow. Each piece connects to the others to form a complete system that actually works in the real world.

Every effective WHS policy, regardless of the industry, is built on a few core components. Think of them as the non-negotiables for creating a system that not only complies with the law but actively protects your team.

Here’s a look at the essential sections and why they matter:

Core Components of a WHS Policy

| Policy Section | Purpose and Key Information |

|---|---|

| Policy Statement | The high-level commitment from senior leadership. It sets the tone and authorises the entire safety program. Signed by the CEO or MD. |

| Roles & Responsibilities | Clearly defines who is accountable for what, from management and supervisors right through to every single worker. No ambiguity. |

| Hazard & Risk Management | Outlines the proactive processes used to find, assess, and control hazards before they cause harm (e.g., inspections, risk assessments). |

| Incident Management | The step-by-step procedure for what to do when something goes wrong, covering reporting, investigation, and learning from the event. |

| Consultation & Training | Details how you'll involve workers in safety decisions and ensure everyone has the right skills and knowledge to work safely. |

| Emergency Procedures | Specific plans for responding to emergencies like fire, medical incidents, or chemical spills. |

| Contractor Management | Lays out the rules for managing the safety of subcontractors and visitors on your sites. |

| Review & Improvement | Commits to a regular cycle of reviewing and updating the policy to ensure it remains effective and relevant. |

Getting these sections right provides a solid framework that you can build on. It ensures that your policy is more than just a piece of paper. It’s a living document that guides daily operations.

The Policy Statement: Your Commitment in Black and White

This is the very first part of your policy, and it sets the tone for everything that follows. It should be a short, direct statement from the top, think CEO or Managing Director, confirming the company's absolute commitment to a safe workplace. Make sure it's signed and dated.

This statement isn't just for show. It gives your Health and Safety Manager the authority they need to get things done and shows everyone, from new hires to regulators, that safety starts at the top.

Here’s a practical example you can adapt for your own use:

Sample Policy Statement:

"[Your Company Name] is committed to providing a healthy and safe work environment for all employees, contractors, visitors, and members of the public. Management will work with all personnel to identify and control hazards, meet our legal obligations, and continuously work towards preventing work-related injuries and illnesses. We will provide the necessary resources, training, and supervision to achieve this goal."

Defining Roles and Responsibilities

This is where the policy gets real. I’ve seen countless policies fail because of ambiguity here. If people don't know exactly what they are supposed to do, things get missed. It’s that simple.

Your policy must clearly outline the safety responsibilities for every role in your organisation.

Don’t just use generic titles. What does safety actually look like for a Plant Manager versus a Site Supervisor? Get specific.

- Management: Their job is to provide the resources (budget, time, equipment), champion the policy, and lead by example.

- Supervisors/Foremen: These people are on the front line. Their duties are hands-on: conducting daily pre-start checks, delivering toolbox talks, ensuring their team follows procedures, and correcting unsafe acts on the spot.

- Workers: Everyone has a part to play. Their responsibilities include following the rules, using PPE correctly, reporting hazards immediately, and looking out for their mates.

Here’s how that translates into real-world examples:

For a Manufacturing Plant Manager:

"The Plant Manager is responsible for ensuring all machinery has appropriate guarding, that a regular maintenance schedule is followed, and that all operators are trained and competent on their assigned equipment."

For a Construction Site Supervisor:

"The Site Supervisor is responsible for ensuring a site-specific risk assessment is completed before high-risk work begins, that all subcontractors are inducted, and that Safe Work Method Statements (SWMS) are followed."

Hazard Identification and Risk Management

This section explains how your organisation finds and fixes problems. It’s the proactive engine of your safety system. You need to detail the processes you'll use to systematically hunt for hazards before they can cause an incident.

This is where you outline your core methods for managing risk.

- Workplace Inspections: Be clear about the frequency (e.g., weekly, monthly) and who is responsible for doing them.

- Risk Assessments: Explain when they're required, before starting a new project, introducing new machinery, or using a new hazardous chemical.

- Hazard Reporting: Describe the simple process for any worker to report something they spot. It has to be a no-blame system that encourages people to speak up.

If you’re looking to get a head start, using a structured format can be a lifesaver. You can find an excellent foundation in a well-made WHS policy template, which provides a pre-built framework for these critical sections.

Incident Reporting and Investigation

Despite everyone's best efforts, things will go wrong. Your policy must have a clear, step-by-step procedure for what to do when an incident occurs. This ensures you can respond effectively, care for anyone injured, and most importantly, learn from it so it never happens again.

Your procedure needs to cover everything from a near miss to a serious injury.

Key elements to include:

- Immediate Actions: What to do first. Make the area safe and provide first aid.

- Reporting Process: Who to tell and how quickly. Make it crystal clear that all incidents, including near misses, must be reported.

- Investigation: Who leads the investigation and what the goal is (finding the root cause, not pointing fingers).

- Corrective Actions: How you will implement changes based on what you learned to prevent it from happening again.

This part of your policy is critical for demonstrating due diligence and fuels your continuous improvement cycle. It turns a negative event into a powerful learning opportunity. By building these core components into your document, you create a practical foundation for managing safety across your entire operation.

Defining Who Is Responsible For What

A workplace health and safety policy often fails in the real world for one simple reason: nobody knows exactly who is supposed to do what. A vague line about "management commitment" is useless to a team leader on the factory floor who needs to know precisely which safety checks they’re meant to run before a shift.

This is where you connect the policy to the people. To make your policy actually work, you have to move past generic job titles and assign concrete, actionable safety duties to every level of your organisation. Ambiguity is the enemy of a safe workplace. Clarity creates accountability.

From The Boardroom To The Site Hut

Accountability for safety has to flow from the top down, but the responsibilities look different at each level. Your policy needs to spell out these duties clearly, leaving no gaps.

Directors and Senior Management: Their job isn't just to sign off on the policy. They are ultimately responsible for providing the resources, time, money, and people, to make it a reality. That means approving budgets for new PPE, investing in safety training, and genuinely championing safety initiatives. Commitment is shown through action, not just words on a page.

Managers (Plant, Site, Operations): These are the people who translate the high-level policy into daily operations. They’re responsible for ensuring safety systems are in place and functioning, like machinery maintenance schedules in a factory or site-specific risk assessments on a construction project. They also manage the supervisors, making sure they have the support and training they need to lead their teams safely.

Supervisors and Team Leaders: This is the frontline of safety management. Their duties are hands-on and immediate. Think of a team leader on the factory floor. They’re responsible for pre-start equipment checks, running toolbox talks, and making sure their crew follows the rules. They’re the ones who have to step in and correct unsafe work on the spot.

Giving Workers Clear Responsibilities

Your workers aren't just passive recipients of safety rules; they are active participants. The key to getting them involved is clearly defining their responsibilities. Your policy must state that every single worker has a duty to take reasonable care for their own health and safety, and for others affected by what they do.

This breaks down into specific actions like:

- Following all safety procedures and rules without taking shortcuts.

- Correctly using all personal protective equipment (PPE) provided.

- Reporting any hazards, incidents, or near misses immediately through the proper channels.

When workers understand their specific role, they become the eyes and ears of your safety system on the ground. This active involvement is a crucial layer of defence against incidents. A clear definition of duties can also be important for those in specialised roles, which you can learn more about in our guide on the responsibilities of a health and safety officer.

Managing Contractor and Subcontractor Duties

For any construction or multi-site organisation, getting contractors on the same page is one of the biggest safety hurdles. Your workplace health and safety policy has to explicitly state that it applies to everyone on your site, including every subcontractor and their employees.

The best way to do this is to build their safety duties directly into your process. Make compliance with your policy a condition of their contract. Before they even set foot on site, they must understand your rules on everything from inductions and PPE to incident reporting and emergency procedures.

A policy that doesn't cover your contractors is a policy with a massive blind spot. Make it clear from the start that working on your site means working by your safety rules, no exceptions.

Defining these responsibilities is absolutely critical for high-risk work. For example, vehicle incidents are the leading cause of workplace fatalities in Australia at 42%, with machinery operators and drivers facing the highest risks. Industries like construction and manufacturing account for 80% of all fatalities. With these stakes, clearly assigning responsibility for tasks like vehicle pre-start checks and traffic management isn't just good practice. It's essential for preventing the worst from happening.

A Simple Framework for Assigning Responsibilities

To make sure you haven’t missed anyone, it’s a great idea to create a simple responsibility matrix right inside your policy. A table makes it easy for anyone to quickly find their role and understand their specific safety obligations.

Here is a basic template you can adapt:

| Role | Key Health and Safety Responsibilities |

|---|---|

| Managing Director | Ensure adequate resources are allocated for WHS. Visibly demonstrate leadership in safety. Sign and endorse the WHS policy. |

| Site Supervisor | Conduct daily site safety inspections. Ensure all workers and subcontractors are inducted. Stop any work deemed unsafe. |

| Worker | Report all hazards and incidents immediately. Use equipment and PPE correctly. Participate in safety consultations. |

| Contractor | Comply with all site safety rules and the host's WHS policy. Provide evidence of worker competency and licenses. |

By mapping out duties this way, you create a clear chain of accountability. When everyone knows what they are responsible for, your health and safety policy transforms from a static document into a dynamic tool that actively protects your people.

Putting Your Policy Into Practice

A documented workplace health and safety policy is a solid start, but its real value isn't the paper it's printed on. A policy only works when it gets off the page and into the day-to-day grind of your operations.

For it to be effective, your entire team, from the new apprentice to the seasoned subcontractor, needs to understand what's in it and how to apply it. This all comes down to practical implementation through good old-fashioned consultation, training, and clear communication.

The first step is to bring your workers into the conversation. Under Australian WHS laws, you have a duty to consult with your people and their Health and Safety Representatives (HSRs) on anything that affects their safety. This isn't just a legal hoop to jump through; it’s common sense. The people on the tools are the ones who see the risks up close every day, and they often have the most practical ideas for fixing them.

When you involve them in drafting or updating the policy, it instantly becomes more relevant. More importantly, it builds a sense of ownership. People are far more likely to follow procedures they’ve had a hand in creating.

From Induction to Toolbox Talks

Training is where you turn the words in your policy into safe actions on site. This can't be a one-off, tick-a-box presentation that everyone forgets by morning tea. It needs to be a continuous loop of learning, relevant to the work at hand.

A layered approach always works best:

- Induction Training: This is your first shot at setting safety expectations with new starters. Don't just hand them a booklet. Walk them through the site. Show them the first aid kits, explain your emergency procedures, and introduce them to their supervisor and HSR. Make it real.

- Task-Specific Training: Operating a press brake in a factory or working from a scaffold on a construction site requires specific know-how. Your training has to cover the exact hazards and control measures for these high-risk jobs.

- Toolbox Talks: These short, sharp safety meetings are perfect for keeping safety front-of-mind. Use them to chat about a recent near-miss, introduce a new piece of gear, or just refresh everyone on a core procedure from your policy.

The most useful training ditches the generic slide decks for real-world scenarios from your own sites. Talk about an incident that actually happened last month and what was learned from it. Use a piece of your own machinery for a practical demo.

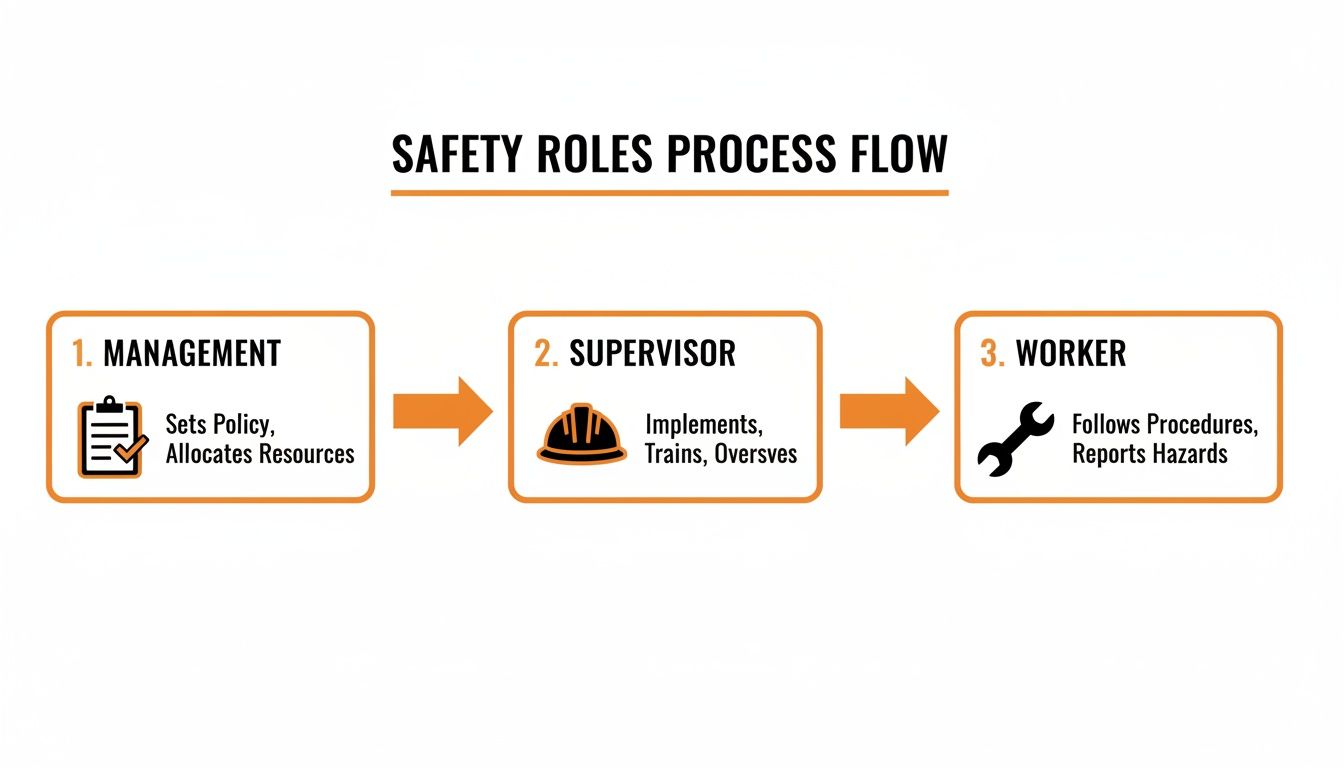

The flowchart below shows how safety responsibilities flow through the business, a key concept to drive home during training.

It’s a simple but powerful model: management provides the direction and resources, supervisors drive it on the ground, and workers are responsible for doing the job safely according to the plan.

Making Information Accessible

Your team can't follow a policy they can't find. Pinning a faded copy to the breakroom noticeboard just doesn't cut it anymore, especially when you're running multiple sites with a constant flow of subcontractors.

When putting your policy into action, you have to cover all the operational details, like specific hose safety guidelines for your industrial equipment. This kind of vital information needs to be right at the fingertips of the people doing the work.

This is where a digital system like Safety Space can be a game-changer. It centralises your workplace health and safety policy and all your related documents, making everything instantly available to anyone on their phone. A subbie can review a SWMS right before they start a job, or a worker can pull up an equipment manual without having to walk back to the site office.

It also takes the headache out of record-keeping. A digital platform automatically tracks who's completed which training modules and pings them when a refresher is due. This gives you a clear, real-time picture of your team's competency and makes proving compliance incredibly straightforward.

Keeping Your Safety Policy Relevant

Your workplace health and safety policy isn't a 'set and forget' document. It can't be. A policy that was perfect a year ago might have serious gaps today because of a new piece of machinery on the factory floor or a subtle but important change in construction regulations.

For a policy to have any real impact, you need a practical system for checking that it’s actually being followed and keeping it up to date. This means actively monitoring what’s happening on the ground. A policy might look great on paper, but its real test is whether it holds up during a busy shift or on a chaotic site.

This isn't about micromanaging your team; it's about making sure the safety systems you've designed are actually working as intended.

Checking Policy Effectiveness in the Real World

So, how do you see if your policy is being put into practice? You need a clear, unfiltered view of day-to-day operations. A few straightforward methods will get you there.

Workplace Inspections: These are your planned walk-throughs to spot hazards and check that controls are in place. For example, is machine guarding always being used? Are walkways consistently clear of trip hazards? Regular, documented inspections give you a consistent snapshot of compliance over time.

Safety Observations: Think of this as a less formal check-in. It simply involves watching a task being performed to see if the safe work procedure is being followed correctly. It’s a fantastic way to identify where extra coaching or a slight tweak to a process might be needed.

Internal Audits: This is a more structured, deep review of your entire safety management system against the standards set in your policy. You can get into the details of structuring these in our guide on the importance of regular safety audits for your business.

Tracking What Matters Most

To truly understand how well your policy is working, you have to track the right key performance indicators (KPIs). Too many companies get stuck only looking at lagging indicators like injury rates. While these numbers are obviously important, they only tell you about past failures.

The real gold is in leading indicators. These are the proactive measures that show you're actively preventing incidents before they happen.

Focus on tracking near-miss reports, the number of safety observations completed, and how quickly identified hazards are fixed. These metrics show you where your system is working and highlight potential problems before anyone gets hurt.

By tracking these forward-looking KPIs, you can spot negative trends early and adjust your approach before they lead to a serious incident.

Establishing a Practical Review Schedule

A living policy needs a regular heartbeat. You must have a set schedule for reviewing your workplace health and safety policy, but you also need the agility to review it immediately when certain events happen.

Your policy should be formally reviewed at least annually, but a review should also be triggered by:

- A serious incident or near miss: This is a glaring red flag that something in your system failed and needs immediate attention.

- Changes in legislation: WHS laws change, and your policy must always reflect current legal requirements. No excuses.

- New equipment or processes: Introducing a new CNC machine or a different construction method brings new risks that your policy absolutely must address.

- Feedback from workers: If your team on the ground tells you a procedure is impractical or unsafe, that’s an immediate trigger for review. Listen to them.

This ongoing review cycle is also critical for identifying emerging risks. For instance, mental health-related workers' compensation claims have risen significantly over the past decade. With 400 serious claims lodged daily and significant underreporting, it is vital that your policy reviews consider psychosocial hazards alongside the physical ones.

Using a digital platform like Safety Space makes this entire process much easier. It gives you real-time data on incidents, hazards, and inspections, all in one place. Instead of digging through mountains of paperwork, you can see trends instantly, helping you make informed decisions about what in your policy needs to change to keep your people safe.

Answering Your Common WHS Policy Questions

Even the best-laid plans run into practical questions on the ground. When it comes to drafting or refreshing your WHS policy, a few queries pop up time and time again from managers in construction, manufacturing, and other high-risk sectors.

Getting these details right is what separates a policy that sits on the shelf from one that actually keeps your team safe. Let's get into the practical answers you need.

How Often Should We Review Our Workplace Health and Safety Policy?

The simple answer is at least once a year. But that yearly check-in is just the bare minimum. Certain events should trigger an immediate review, regardless of when you last looked at it.

Legally, you're required to review it after any notifiable incident or if a regulator tells you to. But good safety management is proactive, not just reactive.

You need to pull the policy out for an immediate review whenever there's a major operational shift. Think things like:

- Bringing new machinery or a different chemical process onto the factory floor.

- Kicking off work on a new construction site with a different environment.

- Changes in key personnel who hold specific safety responsibilities.

- When a new hazard is identified that wasn't on your radar before.

A proper review isn't just a paperwork shuffle. It’s about getting out on the floor, walking the site, and talking to your workers and their Health and Safety Reps (HSRs). They're the ones who know firsthand if the policy still reflects the real-world risks they face every day.

What Is The Difference Between A Safety Policy And A SWMS?

This is a really common point of confusion, but the distinction is actually quite simple. Think of it as your overall strategy versus a specific battle plan.

Your workplace health and safety policy is the high-level, big-picture document. It’s your company's mission statement for safety, spelling out your commitment, who is responsible for what, and the general systems you’ll use to manage risk. It’s the foundation for everything you do.

A Safe Work Method Statement (SWMS), on the other hand, is a specific, task-based document required for high-risk construction work. It doesn't cover the entire business; it covers one specific, dangerous job.

A SWMS breaks down a high-risk task step-by-step, identifies the hazards at each stage, and details the exact controls that must be used to do the job safely. Your policy might state that you use SWMS for high-risk work, but the SWMS itself is the granular, on-the-ground plan for that specific activity.

For example, your policy will state that you’re committed to managing risks associated with working at heights. The SWMS for installing roof trusses is the document that details the specific type of fall protection, exclusion zones, and inspection protocols required for that job, on that day.

How Do We Make Sure Subcontractors Follow Our Safety Policy?

This is a massive one, especially on busy construction sites juggling multiple trades. Just hoping your subcontractors will follow your rules isn't a strategy, it's a liability. You have to build their compliance into your system from day one.

First, it needs to be crystal clear that your safety policy applies to everyone on your site. No exceptions. Make this a non-negotiable part of their contract and any pre-qualification process you use. Hand them a copy of the policy before they even price the job.

Next, every single subcontractor and their workers must go through a site-specific safety induction before they set foot on the work area. This is your chance to personally walk them through your key site rules, emergency procedures, and how you want incidents reported. Don’t just get a signature; make sure they’re engaged and understand what’s expected.

Finally, consistent visibility on site is crucial. Your supervisors need to be actively checking that subcontractors are working in line with your policy and their own SWMS. If you spot a breach, you have to address it immediately and decisively. It’s the only way to reinforce that you’re serious about your site rules.

Juggling all these moving parts, policy reviews, subcontractor inductions, SWMS collection, and incident tracking, can quickly become an administrative nightmare. A platform like Safety Space is designed to take that load off your shoulders. It gives you a central hub to manage your policies, track compliance in real-time, and ensure nothing falls through the cracks, letting you focus on what really matters: keeping your site safe.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.