A Construction Safety Management Plan (CSMP) is your operational playbook for keeping people safe and your project compliant. It's not just another document to file away; it's a living tool that maps out exactly how you'll manage high-risk work, handle incidents, and make sure every person on site knows their responsibilities.

Think of it as the blueprint for a safe construction site.

The Foundation of a Safe Construction Site

Your CSMP is the central document detailing how you, as the principal contractor, will manage work health and safety (WHS) for a specific project. It’s far more than a generic safety policy. It gets into the details, addressing the unique risks and conditions of a particular worksite.

For any project involving high-risk construction work, having a detailed, site-specific plan isn't just good practice, it's a legal must-have.

The real goal here is to systematically identify potential hazards and lock in clear control measures before anyone even steps on site. This proactive approach is the absolute key to preventing incidents. A solid plan integrates safety into every phase of the project, from the initial site setup right through to the final handover.

Why It’s More Than Just Paperwork

One of the biggest mistakes project managers make is treating the CSMP as a simple box-ticking exercise. Its real value isn't in the file; it's in its practical use on the ground. When done right, a CSMP performs a few critical functions:

- Clarifies Responsibilities: It removes guesswork by defining who is responsible for what, from the project manager down to the newest subcontractor on site.

- Manages High-Risk Activities: It provides a structured way to handle tasks with a high potential for serious injury, like working at heights or using heavy machinery.

- Standardises Procedures: It ensures everyone follows the same process for site inductions, incident reporting, and emergency response.

- Demonstrates Due Diligence: It provides the documented proof that you’ve taken reasonable steps to protect your workers.

A strong construction safety management plan isn't about avoiding fines; it's about making sure every single person goes home safely at the end of the day. It moves safety from being an afterthought to being a core part of how you plan and run your project.

The Role of the Principal Contractor

Under WHS regulations across Australia, the principal contractor has the primary duty of care for managing safety. The CSMP is their main tool for getting it right. This means they are responsible for preparing, maintaining, and reviewing the plan to keep it relevant as the project changes.

For instance, if a new high-risk activity comes up, say, bringing in a crane that wasn't in the original scope, the principal contractor must update the CSMP. This involves developing or sourcing new Safe Work Method Statements (SWMS) and getting that information out to every affected worker.

This responsibility doesn't stop with your own crew. It extends to every single worker, including subcontractors, ensuring they know what’s in the plan and follow its procedures. Effective communication and regular site walks are what bring the document to life. To get a handle on creating a safe work environment, exploring various Occupational Health and Safety courses can provide a deeper understanding.

Ultimately, a successful safety plan is one that's understood, respected, and actively used by everyone, turning words on a page into consistent, safe work practices day in and day out.

The Anatomy of a Solid Safety Plan

An effective Construction Safety Management Plan isn't some huge document you write once and file away. It's a living collection of practical components that work together to manage the real-world risks on your site. When these pieces are clear, specific, and properly communicated, your plan becomes a genuinely useful tool for your daily operations.

Each element tackles a different part of site safety, from identifying hazards before you even break ground to defining precisely how an incident is handled. The whole point is to build a complete system where nothing critical is left to chance.

To give you a clearer picture, let's break down the essential sections every compliant and practical CSMP needs.

Key Components of a Construction Safety Management Plan

This table outlines the foundational parts of a robust CSMP. Think of these as the non-negotiables for building a plan that not only complies with regulations but actively keeps your team safe.

| Component | Purpose | Example Action |

|---|---|---|

| Policy & Objectives | Sets the high-level safety commitment and goals for the project. | "Our objective is to achieve zero lost-time injuries through proactive hazard reporting and weekly toolbox talks." |

| Roles & Responsibilities | Clearly defines who is accountable for specific safety tasks. | "The Site Supervisor is responsible for reviewing all subcontractor SWMS before work commences." |

| Risk Management | Outlines the process for identifying, assessing, and controlling hazards. | Conducting a site-specific risk assessment for working near overhead power lines. |

| SWMS & Procedures | Details the management of high-risk work and other safe operating procedures. | Requiring a signed-off SWMS for all crane lift operations before the lift can proceed. |

| Training & Induction | Ensures all personnel are aware of site-specific rules and hazards. | All new workers must complete a site induction covering emergency assembly points and first aid contacts. |

| Incident Management | Establishes a clear process for reporting and investigating incidents. | A procedure for immediately reporting any near miss to the Site Supervisor for investigation. |

| Emergency Plan | Prepares the site for potential emergencies like fire, medical events, or collapse. | Designating and clearly signing the emergency assembly point and conducting a drill. |

| Monitoring & Review | Sets up a system for auditing the plan's effectiveness and making improvements. | Scheduling monthly site safety inspections and an annual review of the entire CSMP. |

Each of these components is a vital part of the system. A plan missing any one of these has a serious blind spot.

Nailing the Site-Specific Risk Assessment

Every construction site has its own personality and its own set of dangers. That’s why a generic, copy-pasted risk assessment is next to useless. The foundation of your entire safety plan has to be a Site-Specific Risk Assessment. This means getting your boots on the ground and identifying hazards unique to that specific location, layout, and scope of work.

This is about more than just spotting obvious things like an open trench. It’s about looking deeper. Consider the public access points, those overhead power lines you'll be working near, the condition of the ground after a week of rain, or even the logistical puzzle of multiple trades trying to work in the same tight space. The risks on a high-rise build in a busy CBD are worlds away from those on a sprawling residential subdivision.

Once you’ve identified the hazards, you need to map out how you’ll control them. This is where you get practical about prevention. For a deep dive into choosing the most effective controls, our guide on the hierarchy of control measures is a must-read. It’s a proven framework for prioritising solutions that actually eliminate or reduce risk, rather than just putting up signs.

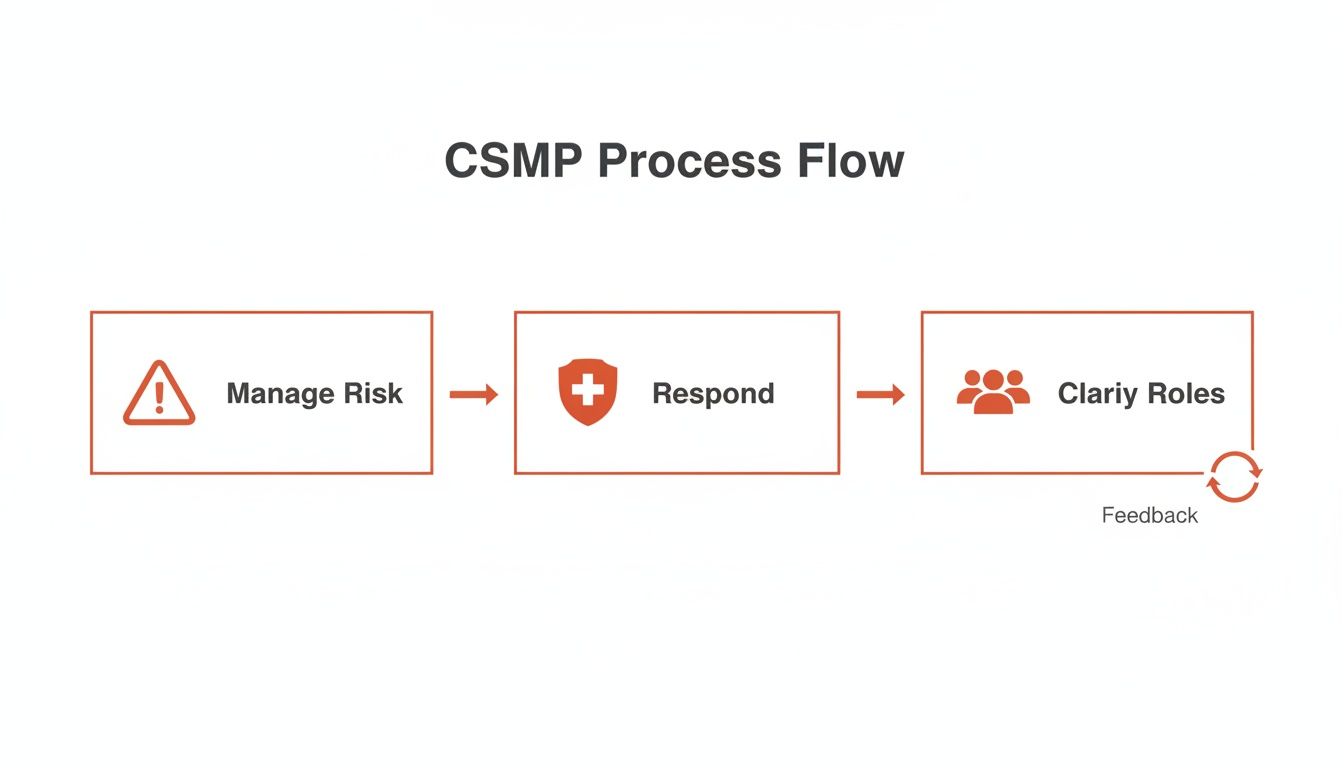

This simple flow chart captures the essence of managing safety on site.

As you can see, it's a continuous cycle. Managing risk, responding when things go wrong, and having clear roles are all interconnected parts of keeping your site safe day in, and day out.

Who’s Doing What? Defining Clear Roles and Responsibilities

In safety, guesswork is the enemy. Your plan absolutely must spell out who is responsible for what. This isn't just about naming a Site Supervisor; it's about drilling down into the specific safety duties for every single role on that project.

For instance, who on your site is explicitly tasked with:

- Running the daily pre-start meetings?

- Checking that subcontractor SWMS are not only in place but are actually being followed?

- Keeping the first aid kit stocked and the incident register up to date?

- Signing off on hot work permits before any grinding or welding starts?

Putting these duties in writing eliminates the grey areas. It stops critical safety tasks from being missed because everyone just assumed someone else was taking care of it.

I’ve seen it happen time and again: when everyone is responsible, no one is. The most effective safety plans are those that assign specific, tangible safety tasks to named roles. It creates true ownership.

Getting Serious About Safe Work Method Statements (SWMS)

For any task that falls under the banner of high-risk construction work, a Safe Work Method Statement (SWMS) isn’t optional, it’s mandatory. Your CSMP must clearly define your process for collecting, reviewing, and monitoring the SWMS from every contractor on your site.

A SWMS is far more than just another form to fill out and file. It's a critical thinking tool. A good one breaks down a high-risk job into a sequence of steps, identifies the potential hazards at each of those steps, and then details the specific control measures that will be put in place to manage the risk.

Picture a team installing trusses on a residential build. Their SWMS needs to address very specific risks like falls from height, how materials will be handled safely, and the protocol for working near power lines. On a large industrial project, you'd be looking for detailed SWMS covering more complex activities like major crane lifts, confined space entry, or work involving hazardous chemicals.

Your CSMP should mandate that all SWMS must be:

- Site-specific: A generic document from a previous job just won't cut it.

- Easily accessible: Workers and supervisors need to be able to pull it up right there on site.

- Actually followed: The Site Supervisor’s role must include actively checking that the work on the ground matches what’s written in the SWMS.

Induction and Training: Your First Line of Defence

Nobody should set foot on your site to work without a thorough induction. Your CSMP needs to detail exactly what your induction process covers, who is responsible for delivering it, and how you’re going to record that it’s been completed.

A solid induction always includes:

- Site-specific hazards: Physically pointing out the actual risks on that project.

- Emergency procedures: Where’s the assembly point? Who are the first aid officers?

- Site rules: Covering no-go zones, PPE requirements, and the traffic management plan.

- Reporting processes: A simple, clear explanation of how to report a hazard or an incident.

But it doesn't stop there. The plan must also cover ongoing training needs. This could be anything from regular toolbox talks on specific topics to verifying that the crane operator has a current high-risk work licence. This isn't just paperwork; it’s your documented proof that you've given every worker the information and training they need to do their job safely.

Getting Compliance Right in Western and South Australia

While the national Work Health and Safety (WHS) laws provide a solid foundation, the real test for any construction safety management plan is how it holds up at the state level. Compliance is definitely not a one-size-fits-all deal, especially if you're working across Western Australia and South Australia. Each state has its own unique spin on the rules, specific codes of practice, and regulatory hot buttons that can easily trip up even seasoned contractors.

This is more than just having different logos on the paperwork. These local variations dig right into your daily operations, dictating what an inspector will zero in on during a site visit and the exact documents you need to have on hand. Getting your head around these nuances is absolutely critical for keeping your project on the right side of the law and, more importantly, keeping your crew safe.

The stakes are terrifyingly high. In 2023 alone, the Australian construction industry saw 45 worker fatalities, which accounted for a staggering 23% of all workplace deaths in the country. That number represents a 36% jump from the five-year average, a harsh reminder of just how dangerous our industry can be.

Western Australia's WHS Act 2020

For anyone running a job in WA, the WHS Act 2020 was a big step towards aligning with the national model laws, but it came with its own distinct flavour. A crucial part of your safety plan must tackle the state-specific codes of practice. These are your practical guides for meeting your legal obligations on the ground.

WorkSafe WA has a particularly sharp focus on high-risk work licensing and notifications. Your safety plan needs to have a solid, documented process for:

- Verifying Licences: Making sure every operator for high-risk tasks, think crane operation, scaffolding over four metres, and rigging, holds a current and valid WA High Risk Work Licence. No exceptions.

- Notifying WorkSafe: Certain activities demand you formally notify the regulator before you even think about starting. This includes specific demolition work, any asbestos removal, and the use of particular types of plant.

- WHS Management Plans for Major Projects: The Act is very clear on this. For projects valued at $500,000 or more, you are legally required to prepare and actively maintain a written WHS management plan.

Let’s put that into practice. Say you’re on a Perth project that involves erecting a massive scaffold structure. Your plan can't just have a generic SWMS tucked away in a folder. It has to clearly show you've verified the lead scaffolder's licence and, if it hits the right triggers, prove you’ve made the required notifications to WorkSafe WA. Missing this is an easy breach for an inspector to spot, and they will.

If you’re working in WA, getting across the local regulations isn't optional. To dig deeper, check out our detailed guide on WHS legislation in Western Australia.

South Australia's Approach

Over in South Australia, they operate under their own WHS Act 2012. While it shares a lot of DNA with the model laws, SafeWork SA has its own areas of emphasis, especially when it comes to major construction projects. Your safety plan has to reflect their specific interpretation of the rules.

One area where SafeWork SA really drills down is the role of the Principal Contractor and their duty to consult, cooperate, and coordinate with everyone else on site. This means your plan has to go way beyond just managing your own people.

You need to document exactly how you will:

- Coordinate with Subcontractors: Lay out your process for pre-qualification, how you'll review their SWMS, and the ongoing monitoring you'll do to ensure their safety systems are up to scratch and align with yours.

- Manage Site Traffic: This is a big one for SafeWork SA inspectors. Your plan must detail specific, practical measures for keeping pedestrians and mobile plant safely separated.

- Consult with Workers: Describe how you will run toolbox talks, facilitate safety committee meetings, and create genuine opportunities for workers to give feedback on safety issues.

Imagine you're running a multi-storey development in Adelaide with half a dozen trades working at the same time. Your CSMP needs a whole section dedicated to coordinating these teams. It should specify how crane lifts are scheduled to avoid working over other crews, and how access to different floors is managed to prevent congestion and the risks that come with it. This is the kind of detail that shows an inspector you're not just ticking boxes, you're actively managing the overlapping safety duties on a complex site.

Managing Subcontractors and Multi-Site Operations

Your safety plan is only as strong as its weakest link. On a busy construction site, that weak link is often a new subcontractor walking on for the first time.

Juggling third-party contractors and keeping safety standards consistent across multiple projects is a massive challenge. Real oversight isn't about creating more paperwork; it's about building practical systems that actually verify competence and ensure everyone is on the same page from day one.

When you bring a subcontractor onto your project, you're not just hiring their skills, you're also taking on a share of their safety risk. It’s your job as the principal contractor to make sure they work to the same high standard you demand from your own crew.

Pre-Qualifying Your Partners

The single best way to manage subcontractor risk is to deal with it before they even set foot on site. A solid pre-qualification process is your first and most important line of defence. This is more than just checking if they have insurance; it's a deep look into their safety track record.

Your pre-qualification checklist needs to be practical and verifiable. Don't be afraid to ask for the evidence:

- Safety Record: Ask for their incident rates or workers' compensation history for the last three years. This gives you a real-world snapshot of their performance, not just promises.

- Training and Licences: Request proof that their team holds all the necessary high-risk work licences or specific competencies for the job they'll be doing. No ticket, no start.

- Example SWMS: Ask them for a Safe Work Method Statement from a previous, similar job. Is it detailed and specific, or just a generic, tick-and-flick document?

This initial screening weeds out the contractors who don't take safety seriously, saving you from major headaches down the track.

Making Site Inductions and SWMS Count

Once a subbie is approved, the next critical steps are the site induction and the review of their site-specific SWMS. Let's be honest: generic inductions and paperwork that sits in a truck are completely useless.

A meaningful site induction isn't just a quick talk. It has to involve a physical walk-around, pointing out the actual hazards they will interact with, from overhead power lines to vehicle exclusion zones. It’s your chance to set crystal-clear expectations about your site's rules.

When you get their SWMS, read it with a critical eye. A good SWMS for a roofing crew, for instance, won't just say "work at heights." It will specify the exact type of fall protection being used, how materials will be lifted to the roof, and the control measures for working in high winds. If it's vague, send it back. Simple as that.

A SWMS that isn't specific to the site and the task is a massive red flag. It shows a lazy, box-ticking mindset, which is exactly what you want to avoid bringing onto your project.

Achieving Consistency Across Multiple Sites

Managing one site is tough enough. When you’re running multiple projects, keeping safety consistent becomes a logistical nightmare. Without a solid system, each site can quickly develop its own "way of doing things," creating dangerous blind spots for management.

The key is to standardise your core safety processes while still allowing for site-specific risks. Your central construction safety management plan should be the master document, but each site must have its own specific risk register and emergency plan.

To keep everything connected and visible, you need practical systems for communication and monitoring. This could include:

- Standardised Reporting: Using the same digital forms across all sites for incident reports, hazard observations, and inspections. This is the only way you’ll spot trends across the whole business.

- Regular Site Audits: Get your safety managers or senior leaders on a schedule to visit each site and run through a consistent audit checklist.

- Cross-Site Meetings: Hold regular virtual or in-person meetings with all site supervisors. Use this time to discuss recent incidents, share lessons learned, and reinforce company-wide safety priorities.

This approach creates a framework that ensures every site is working from the same safety playbook, making your oversight more manageable and your entire operation much safer.

Putting Your Plan into Action with Digital Tools

Let’s be honest. A paper-based construction safety management plan stuffed in a filing cabinet somewhere is a liability, not an asset.

It’s impossible to monitor in real time, a pain to update, and a complete nightmare to manage across multiple sites. This is where digital tools make a real, practical difference, turning your plan from a static document into a living, breathing system.

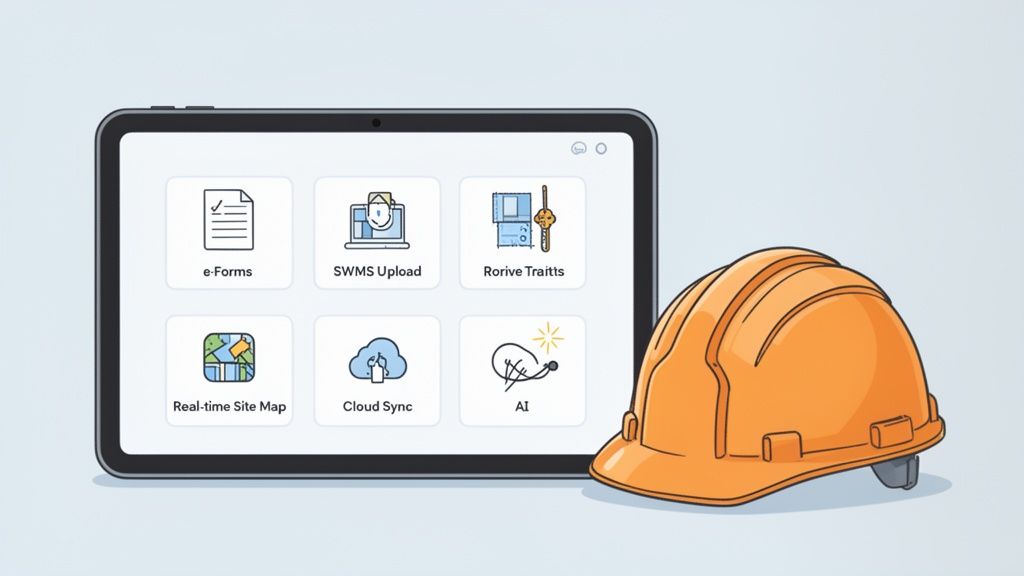

Platforms like Safety Space are built to bring your plan to life right on site, where it actually matters. The whole point is to ditch the clunky paper forms and disconnected spreadsheets for a single, central hub for all your safety processes.

This shift means you can manage everything from site inductions and SWMS submissions to real-time incident reports, all from your phone or tablet. Suddenly, you have instant visibility across every project. You can spot developing issues before they become serious incidents.

A dashboard like this gives you a live snapshot of safety performance, a world away from digging through paperwork after something has already gone wrong.

From Paper Forms to Real-Time Data

The biggest and most immediate change you’ll see when you go digital is in how you collect and use information on site. We all know paper processes are slow and inefficient, often leading to incomplete or lost records. Digital tools fix this by making critical safety tasks faster and easier for the people actually doing the work.

Think about these practical shifts:

- Digital Pre-Starts: Instead of a soggy sign-in sheet, workers complete their pre-start checks on a tablet. The good systems even pre-fill common entries, making it faster while ensuring nothing gets missed.

- Live SWMS Access: Subbies can upload their Safe Work Method Statements directly to the platform. Supervisors can then review, approve, and pull them up on-site in seconds, guaranteeing the right version is always being used.

- Instant Incident Reporting: A worker can report a near-miss, complete with photos, right then and there. That report is instantly flagged to the project manager and safety officer, allowing for a rapid response instead of waiting for end-of-day paperwork to trickle in.

This immediate flow of information is what makes a digital safety plan so powerful. It closes that dangerous gap between an incident happening and the people who can do something about it becoming aware.

Moving to digital isn’t about adding more tech for the sake of it. It’s about getting accurate safety information from the worksite to decision-makers in real-time, which is something paper can never do.

Gaining Visibility Across Multiple Projects

For any business running several projects at once, keeping a consistent safety standard is a massive challenge. A digital platform provides the central oversight you need to manage this without tearing your hair out. You can track key safety metrics across all sites from a single dashboard.

This unified view helps you answer critical questions instantly. Are pre-start checks actually being done on all sites? Are there overdue incident investigations on Project B? Does that new subcontractor on Project C have expired training certificates? A good digital system flags these issues for you automatically. If you're curious about how technology supports other parts of the job, you can explore plenty of construction industry use cases for digital tools.

This kind of proactive oversight simplifies compliance and helps you put your resources where they’re needed most. For a closer look at how these systems work, you can learn more about our health and safety compliance software.

Simplifying Compliance and Training Records

One of the biggest administrative headaches is tracking training records, licences, and certifications for every single person on site. A digital system can automate this process completely.

You can upload all worker qualifications, set expiry dates, and get automatic alerts when renewals are coming due.

It’s a simple feature, but it's incredibly powerful. It ensures you never have a worker operating machinery with an expired licence, a common and very costly compliance breach. The system basically acts as your digital watchdog, protecting the business from preventable fines and risks.

The need for better systems is clear. Despite improvements, the Australian construction industry's rate of serious injury claims remains stubbornly high at 16.9 per 1,000 workers, far exceeding the national average of 10.5. These numbers show the daily risks our teams face and the urgent need for better management tools.

By digitising your construction safety management plan, you shift from a reactive, paper-shuffling approach to a proactive system that makes safety simpler and more effective for everyone involved.

Commonly Asked Questions About Safety Plans

Even with a detailed guide, the real questions always pop up when you're in the thick of a project. Getting your construction safety management plan right often means dealing with specific, on-the-ground situations. Here are some straightforward answers to the questions we hear most from project managers and site supervisors.

How Often Should I Update My Safety Plan?

A construction safety management plan can't be a "set and forget" document. To be effective, it has to be a live plan that reflects what’s actually happening on your project right now.

Think about it, your plan from week one is probably useless by week ten. There are a few key triggers that should signal an immediate update:

- New high-risk activities: Bringing a crane on site or starting a major excavation? That requires a full review and new SWMS.

- A serious incident or near-miss: Any investigation should feed directly back into your plan to make sure it never happens again.

- Changing site conditions: This could be anything from a new public access point being created to unexpected ground conditions after a week of heavy rain.

- A new principal contractor or major subbie: Their team needs to be properly integrated into the site's safety system, and that has to be documented.

Even if none of these big events happen, regular reviews are just good practice. A quick check-in at the start of each major project phase is a simple way to keep the plan relevant and useful.

What’s the Difference Between a CSMP and a SWMS?

This is a really common point of confusion, but the distinction is actually quite simple.

The Construction Safety Management Plan (CSMP) is the big-picture document. It’s your overarching strategy for how you’ll manage health and safety across the entire project, from start to finish.

A Safe Work Method Statement (SWMS), on the other hand, is a very specific, task-level document. It's only required for high-risk construction work.

Your CSMP is the "what" and "who" of project safety. The SWMS is the detailed "how" for a single dangerous task. Your CSMP will state that all high-risk work requires a SWMS, but it won't contain the SWMS itself.

For example, your CSMP will outline the general process for managing work at heights. The SWMS for the roofing crew will then detail the exact, step-by-step process they will follow to do their job safely, including the specific fall protection they’ll use and how they’ll get materials onto the roof.

Does My Small Project Need a Full Safety Plan?

This is where it gets a bit nuanced. The legal requirement for a written, detailed safety plan is usually tied to whether the project involves "high-risk construction work." The project's value can also be a trigger, like in WA, where projects over $500,000 legally require a written WHS management plan.

But here’s the critical part: even if your small project doesn't hit those specific legal triggers, your duty of care to provide a safe workplace still stands. You absolutely still need a system to manage safety.

For a smaller job, your "plan" might be less formal, but it must still cover the non-negotiables:

- Risk Assessment: You have to identify the job's hazards. No exceptions.

- Control Measures: You need to decide, and document, how you'll control those risks.

- Emergency Procedures: Everyone on site needs to know what to do if things go sideways.

So, while you might not need a hundred-page binder for a small renovation, you absolutely need a thought-out and documented approach to safety. Trying to wing it is a massive, unnecessary risk.

Managing safety documentation shouldn't be another job on your list. Safety Space was built to replace paper stacks and confusing spreadsheets, giving you a single, straightforward platform for your entire construction safety management plan. From digital SWMS and real-time incident reports to automated training records, we help you simplify compliance and get instant visibility across all your sites.

See how it works by booking a free demo.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.