If you're running a business in Western Australia, getting your head around the current WHS legislation isn't just a good idea, it's critical. The rules changed in a big way back in March 2022, when WA moved on from its old framework to sync up with the national model. This wasn't just a fresh coat of paint; it brought in much heavier responsibilities and penalties.

The Story Behind WA's New WHS Legislation

For decades, the Occupational Safety and Health (OSH) Act 1984 was the law of the land for workplace safety in WA. It laid some important groundwork, but as time went on, it became obvious that the old laws weren't cutting it for the modern workplace or, more importantly, doing enough to stop people from getting seriously hurt or killed.

This realisation kicked off a massive overhaul.

The shift to the new Work Health and Safety (WHS) Act 2020 was far more than a name change. It was a fundamental rethink, designed to drag safety standards into the 21st century and get WA on the same page as most other Australian states. For any business operating across the country, this harmonisation makes life simpler. For everyone else, it raises the bar for safety.

Key Drivers for the Legislative Change

So, what pushed WA to finally make the switch from the old OSH Act? The changes were a direct response to real-world tragedies and a growing public demand for better protection for workers.

The main drivers were clear:

- A Need for Real Consequences: The penalties under the old system were often seen as little more than a slap on the wrist. The new WHS Act brought in massive fines and the very real threat of jail time to make sure individuals and companies take their duties seriously.

- Introducing Industrial Manslaughter: This was a huge addition. For the first time, the most extreme cases of negligence leading to a worker's death can now result in industrial manslaughter charges, with life imprisonment as a potential outcome.

- Putting Mental Health on the Agenda: Another big step forward was making psychosocial health an explicit part of the law. Businesses are now required to manage risks like workplace bullying, harassment, and burnout with the same seriousness they apply to physical hazards like trip falls or faulty machinery.

From OSH 1984 to WHS 2022

The journey to the new laws was a long time coming. The Work Health and Safety (WHS) legislation was passed in late 2020 but didn't officially kick in until March 2022. The old OSH Act 1984 hadn't made a big enough dent in fatality rates, especially in high-risk industries like construction and mining. This new legislation was the answer to that problem. If you want a deeper dive, you can read more about the evolution of these workplace safety laws and their impact.

The heart of the new WHS legislation is all about proactive risk management. It's no longer good enough to clean up the mess after an incident. Now, you are legally required to spot potential hazards and do what's reasonable to control them before anyone gets hurt.

This change marks a move away from the old, reactive "blame and fix" model to a smarter, proactive "predict and prevent" system. For your business, this means building safety into every decision you make, from the tools you buy to how you manage your team's workload.

Who Is a PCBU and What Are Your Primary Duties?

When the WHS legislation in Western Australia rolled out, it brought with it a term that completely changed the game: the PCBU, or "Person Conducting a Business or Undertaking."

Getting your head around this concept is non-negotiable. If you're a PCBU, the buck stops with you when it comes to the health and safety of everyone involved in your operations. It’s a much wider net than the old "employer" label ever was.

A PCBU isn't just a big corporation. It can be a partnership, a sole trader, or even an unincorporated association. The real question is whether you're conducting a business or undertaking, regardless of whether you're in it for profit.

Moving Beyond the "Employer" Mindset

If you're still thinking your responsibility ends with the people on your payroll, you're making a dangerous mistake under the WHS Act. The PCBU model was designed for the reality of modern work, complex sites buzzing with contractors, subcontractors, labour-hire workers, and even volunteers.

Think of a busy construction site. The site manager's company is the PCBU, and their duty isn't just to their direct employees. It extends to the subcontracted electricians, the delivery driver dropping off supplies, and the apprentice on work experience. They're all owed a duty of care.

It's the same story in a manufacturing plant. The company is the PCBU, and its responsibility covers the maintenance crew that comes in over the weekend and any visitors being given a tour of the facility.

The Primary Duty of Care: What It Really Means

At the absolute core of your obligations as a PCBU is the primary duty of care. This isn't a passive, set-and-forget task. It’s an active, ongoing responsibility to protect the health and safety of your workers and anyone else affected by your work, so far as is reasonably practicable.

"Reasonably practicable" isn't a get-out-of-jail-free card. It’s a legal test that forces you to weigh up a few key things:

- How likely is it that the hazard or risk will happen?

- How bad would the harm be if it did?

- What do you know, or what should you reasonably know, about the hazard and the ways to fix it?

- Are there suitable and available ways to eliminate or minimise that risk?

Only after you’ve worked through those points can you even begin to consider the cost. You can't sidestep a necessary safety fix just because it's expensive, especially if the risk is high.

Put simply, your fundamental job as a PCBU is to do everything that is reasonable and possible to stop people from getting hurt. This duty is welded to you; you can't palm it off to a safety manager or a contractor and wash your hands of the responsibility.

What Does This Look Like on the Ground?

So, how do you actually fulfil this duty? It's about taking tangible, practical steps to make your workplace safer. The WHS Act spells out the bare minimums.

To give you a clearer picture, we've broken down the key responsibility areas for a PCBU and the practical actions needed to meet them.

Key Responsibilities of a PCBU

| Responsibility Area | Practical Actions Required |

|---|---|

| A Safe Work Environment | Keep the physical workplace (e.g., workshop, site, office) free from hazards like trip risks, unguarded machinery, or poor lighting. |

| Safe Plant and Structures | Make sure all equipment, from power tools to heavy machinery and scaffolding, is fit for purpose, maintained, and inspected regularly. |

| Safe Systems of Work | Develop and enforce clear, safe procedures for tasks, like a documented lock-out/tag-out process or a Safe Work Method Statement (SWMS). |

| Safe Use of Substances | If using chemicals or hazardous materials, have robust procedures for their safe handling, storage, transport, and disposal. |

| Adequate Worker Facilities | Provide the essentials: clean drinking water, accessible toilets, and properly stocked first aid facilities. |

| Information & Training | Make sure workers know the hazards of their job, are properly trained to work safely, and receive adequate supervision, especially if they are new or young. |

Nailing these duties is the bedrock of compliance with WHS legislation in Western Australia. It demands a proactive, hands-on approach to finding risks and putting solid controls in place to protect every single person who steps into your workplace.

While the PCBU might carry the primary duty of care, the WHS legislation in Western Australia is clear: safety is a team sport. The law deliberately spreads accountability across different roles, making sure everyone from the boardroom to the workshop floor has specific, legally binding duties.

This structure means you can't just pass the buck. Whether you're an officer, a worker, or just visiting a site, understanding your specific obligations is non-negotiable, not just for compliance, but for the simple reason of keeping people safe.

The Critical Role of an Officer

One of the biggest shifts in the WHS Act was putting company "officers" squarely in the spotlight. This isn't just a title; the term is defined broadly to capture any senior leader whose decisions can substantially affect the business. Think company directors, secretaries, and other executives with real management clout.

An officer's main job is to exercise due diligence. This is a proactive, hands-on duty. It requires them to take reasonable steps to ensure the PCBU is meeting its health and safety obligations. It’s not enough to just assume everything is under control; they have to actively check.

Due diligence is about verification, not just trust. An officer can't simply rely on a manager's report saying, "safety is handled." They need to be asking the tough questions and seeing the proof for themselves that the business is actually doing what it's supposed to.

This active verification is a cornerstone of the WHS legislation in Western Australia and pushes accountability right to the very top of the organisation.

What Due Diligence Looks Like in Practice

Exercising due diligence doesn't mean an officer has to do the safety manager's job. It’s all about high-level oversight and making sure the right systems are in place, and that they actually work. For an officer, this boils down to a few key actions:

- Staying Informed: Keeping their finger on the pulse of work health and safety matters relevant to their industry and operations.

- Understanding Operations: Having a solid grasp of the business's core activities and the specific hazards and risks that come with them.

- Ensuring Resources are Available: Making sure the business has, and uses, the right resources and processes to manage risks. This covers everything from the budget for new safety gear to allocating time for proper training.

- Checking Compliance: Having processes in place to receive and review information about incidents, hazards, and risks, and then acting on it promptly.

- Verifying Systems: Ensuring the PCBU has, and actually implements, processes for meeting its duties, like reporting incidents, consulting with workers, and providing training.

For instance, a director on the board of a manufacturing company should be asking for and reviewing reports on machinery maintenance, incident trends, and the outcomes of worker consultations. They need to verify that the company is truly following its own safety procedures, not just paying them lip service.

The Duties of Workers

Every single worker has duties under the WHS Act. While the PCBU is responsible for providing a safe workplace, workers have to play their part in making it happen. These duties are straightforward but vital.

A worker's duties include:

- Taking Reasonable Care: Workers have to look after their own health and safety. That means no shortcuts or reckless behaviour that could put them or others in the firing line.

- Considering Others: They also need to make sure their actions (or inaction) don't put the health and safety of other people at risk.

- Following Instructions: Workers must comply with any reasonable instruction from the PCBU that helps the business meet its WHS duties.

- Cooperating with Policies: They need to cooperate with any reasonable safety policy or procedure that's been shared with them.

In short, if a worker is told to wear specific PPE for a task or follow a safe work procedure, they are legally required to do so. It's as simple as that.

Responsibilities of Other Persons at the Workplace

Finally, the WHS Act even extends duties to "other persons" at a workplace. This is a catch-all category for visitors, customers, and contractors from other companies who are on-site.

Just like workers, these individuals have a duty to take reasonable care of their own safety. They also have to make sure their actions don't create a risk for anyone else. And importantly, they must follow any reasonable safety instructions given by the PCBU. For example, a delivery driver must follow the site's traffic management plan, and a visitor must stick to designated walkways and wear any required visitor PPE.

Managing Psychosocial Hazards Under WA WHS Law

One of the biggest shifts in the WHS legislation in Western Australia is the legal requirement to manage psychosocial hazards. This means things like work-related stress, burnout, and bullying are no longer just an ‘HR issue’. They now have the same legal weight as physical risks, like a forklift with faulty brakes or an unguarded machine.

For anyone running a business (a PCBU), you can no longer afford to treat the mental and emotional wellbeing of your workers as an afterthought. You have the same clear-cut legal duty to identify these psychological risks and do everything reasonably practicable to control them.

What Are Psychosocial Hazards?

So, what are we actually talking about here? Psychosocial hazards are the invisible risks, the parts of work design, management styles, and workplace interactions that can cause real psychological harm. Their impact can be devastating, leading to anxiety, depression, and even physical illness.

Think of them as the silent hazards. A slippery floor is obvious, but a constantly crushing workload or a toxic team dynamic can be just as damaging over time.

Let's ground this in some real-world examples you might see on any demanding worksite:

- High Workload: A factory floor team is constantly under the pump to hit unrealistic production targets. People start working through breaks, cutting corners on safety checks, and exhaustion becomes the norm.

- Low Job Control: A team of road workers are told exactly what to do, how to do it, and when, with zero input. This creates a sense of powerlessness and kills motivation.

- Poor Support: A fly-in, fly-out worker on a remote site barely hears from their supervisor, feels disconnected, and has no one to turn to when issues crop up.

- Workplace Bullying: An experienced tradie constantly belittles an apprentice, making sarcastic comments and undermining them in front of the rest of the crew.

These aren't just 'tough days at the office'. Under WA law, they are hazards you have a legal duty to actively manage. A great starting point is understanding the core principles of risk management, and you can learn more about what is hazard identification to build that foundation.

Identifying Psychosocial Risks in Your Workplace

Just like spotting a physical hazard, your first job is to find the potential problems. But you can't just do a walkthrough with a clipboard. Spotting psychosocial risks means looking for the warning signs and, most importantly, talking to your people.

Consultation isn't just a good idea; it's a mandatory part of the process. Your workers are on the front line. They know better than anyone what's causing stress, friction, or burnout.

Here are a few practical ways to get started:

- Talk to Your Workers: This can be as simple as informal chats on the floor, adding it to the agenda in team meetings, or using simple, anonymous surveys to ask about workload, stress, and team dynamics.

- Review Your Data: Look for the patterns hiding in your records. Is absenteeism or staff turnover unusually high in one department? Are incident reports showing a spike in human error? These can be red flags.

- Observe Work Practices: Pay attention to how work actually gets done. Are people constantly rushing? Is there visible tension between team members? Do managers communicate with respect or through pressure?

The goal is to get to the root cause, not just patch up the symptoms. If a team is stressed, is it the volume of work? A lack of training? Or is it poor communication from their manager? You have to dig deeper to find a solution that actually works.

Practical Steps for Controlling Psychosocial Hazards

Once you’ve spotted the hazards, the WHS legislation in Western Australia requires you to put control measures in place. This is all about making practical, tangible changes to the work environment to either eliminate the risk or reduce it as much as possible.

Here are some effective controls you can implement:

- Redesigning Jobs: Where you can, adjust workloads to be more realistic. Give workers more say in how they manage their tasks and pace their day. A little autonomy can go a long way.

- Improving Communication: Set clear expectations with policies on respectful behaviour and bullying. Crucially, make sure your supervisors are trained to communicate well and properly support their teams.

- Providing Training: Equip your managers and supervisors to spot the early signs of psychological distress. Train them on how to have supportive, constructive conversations before things escalate.

- Creating Support Systems: Make sure everyone knows how to raise an issue without fear of being penalised. Clear reporting channels for grievances are essential, and a well-promoted Employee Assistance Program (EAP) can offer a confidential lifeline.

Taking these proactive steps isn't just about ticking a compliance box. It’s about building a workplace where people feel safe, respected, and capable of doing their best work.

Putting Compliance and Consultation into Practice

Alright, so we’ve covered the duties. Now for the important part: turning that knowledge into real-world action. This is where compliance with WHS legislation in Western Australia really comes to life. It’s about building practical, on-the-ground systems to manage risk and, crucially, getting your workers involved every step of the way. Consultation isn’t just a nice idea; it's a non-negotiable part of the law.

Think about it. Who knows the job better than the people doing it every day? They’re the ones with the best insights into the real hazards and whether a proposed safety fix will actually work in the real world. Ignoring their input isn’t just a legal breach; it’s a massive missed opportunity to make your workplace genuinely safer.

The Power of Worker Consultation

Effective consultation means giving your people a genuine chance to shape health and safety decisions. The WHS Act lays out a few structured ways to do this, making sure it’s more than just a box-ticking exercise.

You are legally required to consult with workers on key WHS matters, such as:

- Pinpointing hazards and assessing the risks they pose.

- Making decisions on how to control those risks.

- Suggesting changes that could impact worker health and safety.

- Deciding on safety procedures or workplace facilities.

To make this happen, you might establish formal roles like Health and Safety Representatives (HSRs). These are workers elected by their colleagues to speak for them on safety issues. Another option is forming a Health and Safety Committee (HSC), where managers and workers meet regularly to tackle WHS issues together.

The Four Steps of Risk Management

At the core of WHS compliance is a simple, four-step risk management process. This is the practical framework for fulfilling your primary duty of care. It’s not a one-and-done task; it’s a continuous cycle.

The process breaks down like this:

- Identify Hazards: What could actually cause harm?

- Assess Risks: How serious could the harm be, and how likely is it to happen?

- Control Risks: Put the most effective and reasonably practicable control measures in place.

- Review Controls: Regularly check if your controls are still working as intended.

Having clear documentation is essential for managing this process. To get this right, check out our detailed guide on creating effective WHS policy and procedures.

A Practical Example: Managing Machinery Risk

Let's walk through this with a common scenario: bringing a new metal press into a manufacturing workshop.

Step 1: Identify the Hazard

The press itself is the obvious hazard. We’re talking crushing, amputation from moving parts, noise, and electrical dangers. But when you consult with the workshop crew, they point out something else: its new location creates a dangerous blind spot for forklift traffic.

Step 2: Assess the Risk

The risk of a crushing injury is high, with the potential for severe, life-changing harm. The forklift collision risk is assessed as medium; it could cause serious injury, but it's less likely if drivers are careful.

Step 3: Control the Risk

Now, you have to apply the hierarchy of controls. This means starting with the most effective solutions first and working your way down.

The hierarchy of controls is a system that ranks risk controls from the highest level of protection down to the lowest. You must always aim for the highest, most reliable control that is reasonably practicable.

For the metal press, this looks like:

- Elimination (Most Effective): Not an option. The press is essential for production.

- Substitution: Can a safer machine do the same job? In this case, no.

- Isolation/Engineering: Install fixed guarding around the press to prevent anyone from touching moving parts. Install convex mirrors to get rid of the forklift blind spot.

- Administration: Develop a Safe Work Procedure (SWP) for operating the press, provide proper training, and put up clear warning signs.

- PPE (Least Effective): Make safety glasses and hearing protection mandatory for anyone operating the machine.

Step 4: Review the Controls

A month later, you review the measures. The guarding is working, but a supervisor notices some operators are propping it open to clear jams faster. This is a red flag. It calls for immediate retraining and disciplinary action to reinforce the procedure. On the bright side, the mirrors have completely eliminated the blind spot.

This example shows that risk management is a living process. It needs constant attention and adjustment to stay effective.

While this article is zeroed in on WHS legislation in Western Australia, having a broader grasp of general principles is always a good idea. For a comprehensive guide to workplace safety regulations, you might find this resource helpful.

Penalties and Enforcement for Non-Compliance

Knowing your duties under WA’s WHS legislation is one thing, but understanding what happens when things go wrong is just as crucial. The consequences for dropping the ball aren't just a slap on the wrist. We're talking about serious, tiered penalties designed to make businesses and individuals truly accountable for failing to keep people safe.

The legislation sorts offences into three distinct categories. The penalties climb steeply depending on how severe the breach was and the level of blame. It’s a clear signal that the greater the risk of harm, the heavier the consequences for those responsible. This is a deliberate shift away from the often toothless fines of the past.

The Three Categories of Offences

The WHS Act lays out a very clear penalty structure. Think of it as a ladder of accountability, the more reckless the behaviour and the higher the risk, the steeper the financial and personal cost. The whole system is built to make sure the punishment fits the failure.

Here’s how the offence categories break down:

- Category 3: This is the entry-level offence. It applies when a business fails to meet a health and safety duty, but no one was exposed to a risk of death or serious injury.

- Category 2: This is a major step up. It involves a failure that exposes someone to a risk of death or serious injury or illness. The critical factor here isn't whether someone was actually hurt, but that they were exposed to that serious risk.

- Category 1: This is the most serious offence short of a fatality. It applies when a duty holder's conduct exposes a person to a risk of death or serious injury, and they were reckless about that risk.

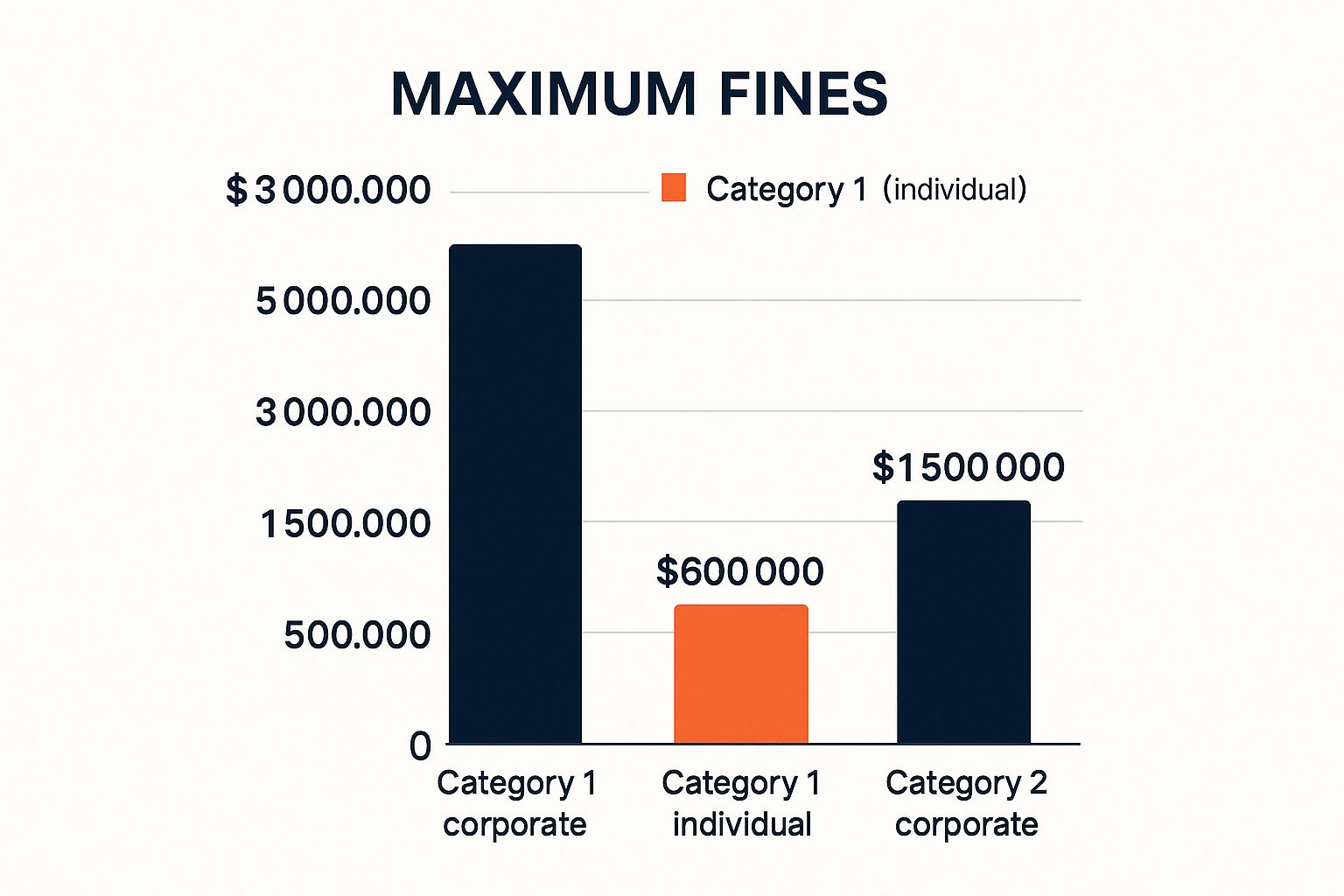

The image below gives you a snapshot of the maximum fines for the two most serious categories, showing just how high the financial stakes are.

As you can see, a company faces fines of up to $3.5 million for a Category 1 offence. That's a number designed to get the attention of even the biggest organisations.

To give you a clearer picture, here’s a table outlining the maximum penalties for each category.

WHS Act Offence Categories and Maximum Penalties (WA)

| Offence Category | Maximum Penalty for Body Corporate | Maximum Penalty for Individual PCBU or Officer |

|---|---|---|

| Category 1 | $3.5 million | $680,000 and/or 5 years jail |

| Category 2 | $1.8 million | $350,000 |

| Category 3 | $570,000 | $115,000 |

These figures aren't just abstract numbers; they represent a fundamental shift in how seriously WA treats workplace safety failures.

Industrial Manslaughter: The Ultimate Penalty

One of the most significant changes to the WA WHS Act was the introduction of industrial manslaughter laws. These aren't just another category, they are criminal offences and carry the most severe penalties for a workplace safety failure.

An industrial manslaughter charge can be laid when a PCBU or its officer engages in conduct that causes a person's death, knowing that conduct was likely to cause death or serious harm, and acted in disregard of that fact.

For a corporation, the maximum penalty for industrial manslaughter is a massive $10 million fine. For an individual officer, it could mean up to 20 years behind bars. The message couldn't be clearer: a person's life is not a cost of doing business.

Powers of WorkSafe WA Inspectors

Enforcement isn’t just about reacting after a tragedy. WorkSafe WA inspectors have extensive powers to get on the front foot and enforce the WHS legislation in Western Australia before someone gets hurt. They can walk into any workplace to conduct inspections, talk to people, and review documents.

If an inspector finds a breach, they have a few tools they can use:

- Improvement Notices: These are issued when the Act has been breached. They give the person a specific deadline to fix the problem.

- Prohibition Notices: If an activity poses an immediate and serious risk to health and safety, an inspector can issue a notice to stop it right away until the risk is managed.

- Non-disturbance Notices: After an incident, an inspector can secure the site to make sure evidence is preserved for an investigation.

Ignoring one of these notices is a serious offence in its own right, with its own set of significant penalties. Getting a firm grip on your obligations is the first step, and you can learn more about the details of WHS Act compliance to ensure your business is fully prepared.

Common Questions About WA WHS Laws

When it comes to the nuts and bolts of WHS legislation in Western Australia, it’s easy to get bogged down in the details. Here are some clear, straightforward answers to the questions we hear most often from business owners and managers on the ground.

Key Legislative Differences and Scope

What's the biggest difference between the old OSH Act and the new WHS Act?

The most significant change is the introduction of the term PCBU (Person Conducting a Business or Undertaking). This broadens responsibility beyond just the direct employer.

On top of that, the new laws place a positive duty on company officers to exercise due diligence, explicitly recognise psychosocial hazards like stress and bullying, and bring in industrial manslaughter offences with severe penalties.

Does the WHS Act apply to my small business?

Yes, absolutely. The WHS legislation applies to every business in Western Australia, no matter its size. If you run a business, you are a PCBU and have a primary duty of care to protect your workers.

Understanding Core Duties

What does 'so far as is reasonably practicable' actually mean?

This is one of those legal terms that can seem a bit fuzzy, but it's actually quite logical. It means you must do what is reasonable in your specific situation to manage health and safety risks.

Think of it as a balancing act. You have to weigh the likelihood and severity of potential harm against what you know about the hazard, how to control it, and whether suitable control measures are available. Cost only comes into the equation after you've considered all those other factors.

Managing these duties is far simpler when you aren't buried in paper and spreadsheets. Safety Space gives you a single, easy-to-use platform for real-time oversight of your entire health and safety system. Book a free demo today and see how you can simplify compliance and protect your team.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.