A construction site safety management plan isn't just another document in a thick folder. Think of it as the operational playbook for managing health and safety on a specific project. It’s a practical, on-the-ground guide detailing who is responsible for what, how to handle emergencies, and the specific rules for that site.

Essentially, it's how you translate your legal duties under Australian WHS legislation into real-world actions that keep people safe.

Why Your Plan Is More Than Just Paperwork

Let's be clear: a construction site safety management plan is the absolute foundation for a safe and compliant project. It’s not about ticking a box; it’s about creating a living system that actively prevents incidents before they happen. This plan becomes the single source of truth for everyone on site, from the project manager right through to the newest apprentice.

The stark reality is that construction remains one of Australia's most dangerous industries. In 2023, there was a significant rise in on-site fatalities, with 45 construction workers losing their lives, a shocking 36% increase over the five-year average.

The fatality rate in construction sits at 3.4 deaths per 100,000 workers, more than double the national average. These aren't just numbers; they're a powerful reminder that effective safety planning is a non-negotiable part of the job.

The Core Purpose of a Safety Plan

At its heart, a safety plan is designed to be a practical tool. It systematically identifies the hazards specific to your project, not some generic site, and documents the control measures you will actually use to manage them. For instance, a plan for a high-rise in a busy CBD will look completely different from one for a residential build in a new suburb. The risks just aren't the same.

Before you even start writing, it’s worth mapping out the core components your plan will need. A good plan isn't just a list of rules; it's a structured system covering everything from policies to emergency responses.

Core Components of a Safety Management Plan

| Component | What It Covers | Why It's Important |

|---|---|---|

| Policy & Objectives | The company's overall commitment to safety and specific, measurable safety goals for the project. | Sets the tone from the top and makes safety a clear priority for everyone involved. |

| Roles & Responsibilities | Clearly defines who is accountable for what, from the site manager to subcontractors. | Eliminates confusion and ensures safety tasks don't fall through the cracks. No more "I thought they were doing it." |

| Hazard Identification & Risk Assessment | Procedures for identifying potential hazards (e.g., working at heights, electrical) and assessing their risk. | This is the proactive core of the plan. It’s how you spot trouble before it happens. |

| Control Measures | Specific actions to eliminate or minimise risks, such as SWMS, guardrails, or specific PPE requirements. | Translates the risk assessment into concrete actions that protect workers on site. |

| Emergency Procedures | Detailed steps for responding to incidents like medical emergencies, fires, or structural collapses. | Ensures a coordinated and effective response when seconds count, potentially saving lives. |

| Training & Induction | Requirements for site-specific inductions, toolbox talks, and verification of worker competencies. | Guarantees that everyone on site, including contractors, understands the specific risks and rules. |

| Consultation & Communication | How safety information will be shared and how workers will be consulted on H&S matters. | Ensures everyone feels they have a voice and ownership of safety. |

| Incident Reporting & Investigation | A clear process for reporting all incidents and near misses, and how they will be investigated. | Helps you learn from mistakes and near misses to prevent them from happening again. |

This table gives you a bird's-eye view of the non-negotiables. A well-developed plan built around these elements achieves several key goals.

- Clarifies Responsibilities: Everyone knows exactly who is accountable for specific safety tasks, from daily pre-start checks to emergency response coordination.

- Ensures Legal Compliance: It demonstrates how you are meeting your obligations under Work Health and Safety (WHS) laws, helping to avoid hefty fines and project shutdowns.

- Standardises Procedures: It provides consistent, reliable instructions for high-risk activities, site inductions, and incident reporting.

A great safety plan is a living document. It should be developed before work begins, communicated to everyone involved, and updated as site conditions or work processes change.

This document is your first step towards building a structured, repeatable approach to safety. If you're starting from scratch, grabbing an occupational health and safety management plan template can give you a solid framework for the key sections you'll need to include.

Get Your Ducks in a Row Before You Start Writing

A good construction site safety management plan isn't born in an office vacuum. The best ones, the ones that actually work on site, are built on a solid foundation of project detail. You need to gather all this information before you even think about writing.

Skipping this prep work is like trying to frame a house without looking at the blueprints. Sure, you’ll build something, but it won’t be right, it won’t be safe, and it definitely won’t be fit for purpose.

The whole point here is to get your hands on all the operational documents that map out the project's scope, its sequence, and the physical lay of the land. This isn't just a paper-pushing exercise; it’s about genuinely understanding the specific challenges your team will face on this particular job.

Start with the Project Fundamentals

First things first, you need to round up the core project documents. These are the files that tell you what you’re building, where you’re building it, and how all the pieces are meant to come together.

Your initial document checklist should have these at the top:

- Architectural and Engineering Drawings: These aren't just for the finished look. They reveal hidden hazards like confined spaces, tricky structural elements, and any areas that will require specialised work at height.

- Site Surveys and Geotechnical Reports: This is where you find the dirt on the dirt. They'll flag ground conditions, existing underground services, and potential environmental nasties like contaminated soil. A good geotechnical report can warn you about excavation risks before a single scoop is taken.

- Full Work Schedules and Timelines: Knowing the sequence of works is absolutely critical. Your safety plan has to account for overlapping trades, like when your roofers are working directly above the electricians, creating a massive risk of falling objects.

- Subcontractor Agreements and Scopes of Work: You must know exactly which high-risk activities each subbie is handling. This covers everything from demolition and crane operations right through to asbestos removal.

Pulling these documents together gives you a 360-degree view of the entire project lifecycle. It lets you get ahead of the hazards, rather than just reacting to them when they pop up on site.

Pinpoint the Right Codes and Standards

Once you have a clear picture of the project's tasks, you can zero in on the specific legal and industry standards that apply. Australia has a very clear framework of regulations, and your plan needs to show exactly how you'll comply.

For instance, if your project involves:

- Work over two metres high: You'll be referencing the Code of Practice for Managing the Risk of Falls at Workplaces.

- Demolition work: Your key documents will be the Code of Practice for Demolition Work and AS 2601: The demolition of structures.

- Excavation deeper than 1.5 metres: You must follow the Code of Practice for Excavation Work.

Your construction site safety management plan isn't just an internal guide; it's a formal record of your compliance strategy. Directly referencing the right Australian Standards and Codes of Practice proves you’ve done your homework and understand your legal duties for each high-risk task.

Specificity is everything. Don’t just write a vague statement like, "We will manage electrical risks." Your plan should explicitly reference AS/NZS 3000 (Wiring Rules) and detail your process for ensuring compliance with temporary site wiring.

Talk to the People on the Tools

Finally, and this is probably the most important step, get out there and consult with your workers and subcontractors. They're the ones on the front line with real, practical experience of what works, and what doesn't, on a busy job site. They see risks that are completely invisible on a set of drawings.

Hold a few quick, informal toolbox talks and ask direct questions:

- "Looking at this excavation sequence, what are your biggest safety worries?"

- "How can we manage material deliveries better to stop creating trip hazards all over the place?"

- "From your experience, what’s the safest way to sequence the steel erection and the concrete pour?"

This isn’t about ticking a consultation box. It’s about stress-testing your assumptions and getting real-world feedback. Their insights are gold, helping you create control measures that are both effective and practical. This is what turns your plan from a document that gathers dust into a living tool the team actually uses and respects every single day.

Conducting a Practical Site-Specific Risk Assessment

Your risk assessment is the engine room of the entire safety management plan. A generic checklist you've downloaded from the internet just isn't going to cut it here. To be effective, your assessment has to be tied directly to the unique conditions of your specific site. This is where you get your boots dirty and move from theory to the practical work of spotting real-world hazards.

Forget abstract concepts. A practical risk assessment means walking the site, looking at the project through a critical lens, and understanding how the location, physical layout, and sequence of work create specific dangers that need to be managed.

This process isn't just about preventing the big, catastrophic events. The Australian construction sector is responsible for about 14% of all serious workers’ compensation claims, with fractures and musculoskeletal disorders being incredibly common. This shows that solid safety planning is just as much about preventing those day-to-day injuries as it is about stopping fatalities.

Identifying Hazards Beyond the Obvious

The best way to start is to break the site down into logical areas and phases. Don't try to assess everything at once, or you'll miss the details. Focus on specific activities and locations to systematically uncover what could go wrong.

Here’s a practical way to approach this:

- Site Location and Surroundings: Are you on a tight urban block right next to a primary school? That immediately introduces risks from public interaction and heavy traffic. A regional site, on the other hand, might have different challenges like overhead powerlines or unstable ground that you wouldn't see in the city.

- Site Layout and Conditions: Look for trouble spots created by the site itself. This could be anything from poor drainage creating constant slip hazards, to restricted access points causing bottlenecks for mobile plant, or even existing structures that are in dodgy condition.

- Specific Work Tasks: Now, analyse the actual work being done. A concrete pour comes with risks like chemical burns, pump blockages, and trip hazards from hoses snaking across the slab. Steel erection brings the obvious risks of working at heights and the constant danger of dropped objects. Each task has its own set of potential dangers.

For a more structured way to visualise these connections, our guide on the Bowtie risk assessment method offers a great visual approach to mapping out threats and controls. And if you want to see how problems can be solved before they even hit the site, check out these clash detection and coordination case studies to see how design-phase planning prevents on-site hazards.

Using a Simple Risk Matrix to Prioritise

Once you have a list of hazards, you need a way to sort them. Not all risks are created equal. A simple risk matrix is the best tool for the job, helping you weigh up two key factors for each hazard: likelihood and consequence.

You're just asking two simple questions:

- Likelihood: How likely is it that something will go wrong?

- Consequence: If it does, how bad will it be?

You don't need a complicated system. A basic 3x3 or 5x5 matrix works perfectly well for most construction projects. By rating each factor on a simple scale (e.g., low, medium, high), you can quickly determine a risk score.

The real point of the matrix isn't to generate a perfect number; it's to force a structured conversation about which hazards demand your immediate and most robust attention. A high-likelihood, high-consequence risk (like a deep, unshored trench) needs a much more urgent and rigorous control measure than a low-likelihood, low-consequence risk (like a minor trip hazard in a storage area).

Let's put this into a real-world scenario.

Scenario: A cramped inner-city site with constant deliveries and multiple subcontractors working over each other.

- Hazard: Collision between a reversing delivery truck and a worker on foot.

- Likelihood: High. This is happening multiple times a day in a congested, busy space.

- Consequence: Severe. An incident would almost certainly result in a critical injury or fatality.

- Risk Rating: Extreme. This needs immediate, high-level controls put in place.

That simple analysis tells you instantly that managing vehicle and pedestrian interaction is a top priority for your safety plan.

Documenting Your Findings for Action

The final piece of the puzzle is to document your risk assessment clearly. This isn't about creating a bureaucratic document to file away; it's a practical, working tool that forms the foundation for the control measures you'll develop next.

Your risk register should include, at a minimum:

- A clear description of the hazard (e.g., "Unprotected rebar starter bars in footing").

- The specific task or area affected (e.g., "Ground floor slab preparation").

- The assessed risk rating (e.g., "High").

- A space to later document the control measure you will implement.

This document becomes a living part of your project management. It ensures that every single risk you've identified is tracked until it’s properly controlled, turning your proactive analysis into tangible safety improvements on site.

Developing Effective and Documented Control Measures

Once you've done the hard yards of identifying and assessing the risks on your site, it’s time to decide what you’re actually going to do about them. This is where your construction site safety management plan gets practical, moving from theory to specific, documented controls that tackle the real-world hazards your team will face.

This isn’t just about ticking boxes or telling everyone to wear a hard hat. It’s a systematic approach to making the work itself safer, using a proven framework called the Hierarchy of Controls. The goal is always to eliminate the risk entirely if you can. If not, you work your way down the list to less effective, but still crucial, measures like Personal Protective Equipment (PPE).

Applying the Hierarchy of Controls in the Real World

The Hierarchy of Controls gives you a structured way to think about managing risk. It forces you to look for more effective, permanent solutions before falling back on the easy fixes. Honestly, this is the core of any robust safety plan.

Let's walk through a common construction scenario: dealing with excessive noise from a generator on a tight residential site.

- Elimination: The best-case scenario. Can you connect to mains power instead of using the generator at all? This completely removes the noise hazard at its source. Game over for that risk.

- Substitution: If elimination is off the table, can you swap out that old, rattling diesel generator for a modern, super-silenced model? This replaces a significant hazard with a much smaller one.

- Engineering Controls: Think physical barriers. Could you build a temporary acoustic enclosure around the generator? This physically isolates the hazard from your workers, reducing their exposure without relying on them to do anything.

- Administrative Controls: This is all about changing how people work. You could schedule the generator to run only during specific times, or implement job rotation so no single person is exposed to the noise for too long.

- Personal Protective Equipment (PPE): This is your last line of defence. Requiring workers to wear hearing protection is essential when other controls can't bring the noise down to a safe level, but remember, it relies 100% on correct and consistent use.

Working through this hierarchy for each major risk turns your plan into a thought-out strategy for risk reduction, not just a list of rules. It ensures you’ve explored every practical option to make the site as safe as possible.

To make this even clearer, here are some practical examples of how these controls apply to other high-risk tasks you’ll see on-site every day.

Hierarchy of Controls Applied to Construction Tasks

| Hazard | Elimination/Substitution | Engineering Control | Admin Control | PPE |

|---|---|---|---|---|

| Working at Heights | Do the work at ground level (e.g., prefabricating wall frames). | Install guardrails or edge protection. Use a scissor lift instead of a ladder. | Create "no-go" zones near open edges. | Fall arrest harness and lanyard system. |

| Silica Dust from Concrete Cutting | Use pre-cast concrete elements that don’t require cutting. | Use on-tool water suppression (wet cutting) or dust extraction systems. | Schedule cutting for times with minimal personnel on-site. Rotate tasks. | P2/P3 respirator, eye protection. |

| Mobile Plant Movement | Design the site layout to remove the need for reversing vehicles. | Install physical barriers to separate pedestrian walkways from vehicle routes. | Use a spotter for reversing. Implement a site traffic management plan. | High-visibility clothing. |

As you can see, PPE is always the last resort. The most effective safety plans focus heavily on the top three tiers of the hierarchy to engineer hazards out of the job entirely.

Documenting Controls and Assigning Responsibility

Coming up with a brilliant control measure is only half the battle. If it's not written down and assigned to someone, it may as well not exist. Your safety plan must clearly document each control and assign responsibility for getting it done. Without clear ownership, even the best ideas fall through the cracks on a busy site.

For every control, your risk register should specify:

- The Control Measure: A clear description of the action (e.g., "Install temporary edge protection on all open-sided floors above 2 metres").

- The Responsible Person: The specific role accountable (e.g., "Site Supervisor" or "Leading Hand Carpenter").

- The Due Date: A realistic timeline for when it must be in place.

- Verification Method: How you’ll check it’s been done right (e.g., "Daily pre-start inspection" or "Weekly site safety walk").

A control measure doesn't truly exist until it's written down, assigned to someone, and regularly checked. This creates a clear chain of accountability that is vital for ensuring your safety plan is actively working on site every day.

This level of detail turns your plan from a static document into a living, practical management tool. It cuts out ambiguity and makes sure everyone knows their specific role in keeping the site safe.

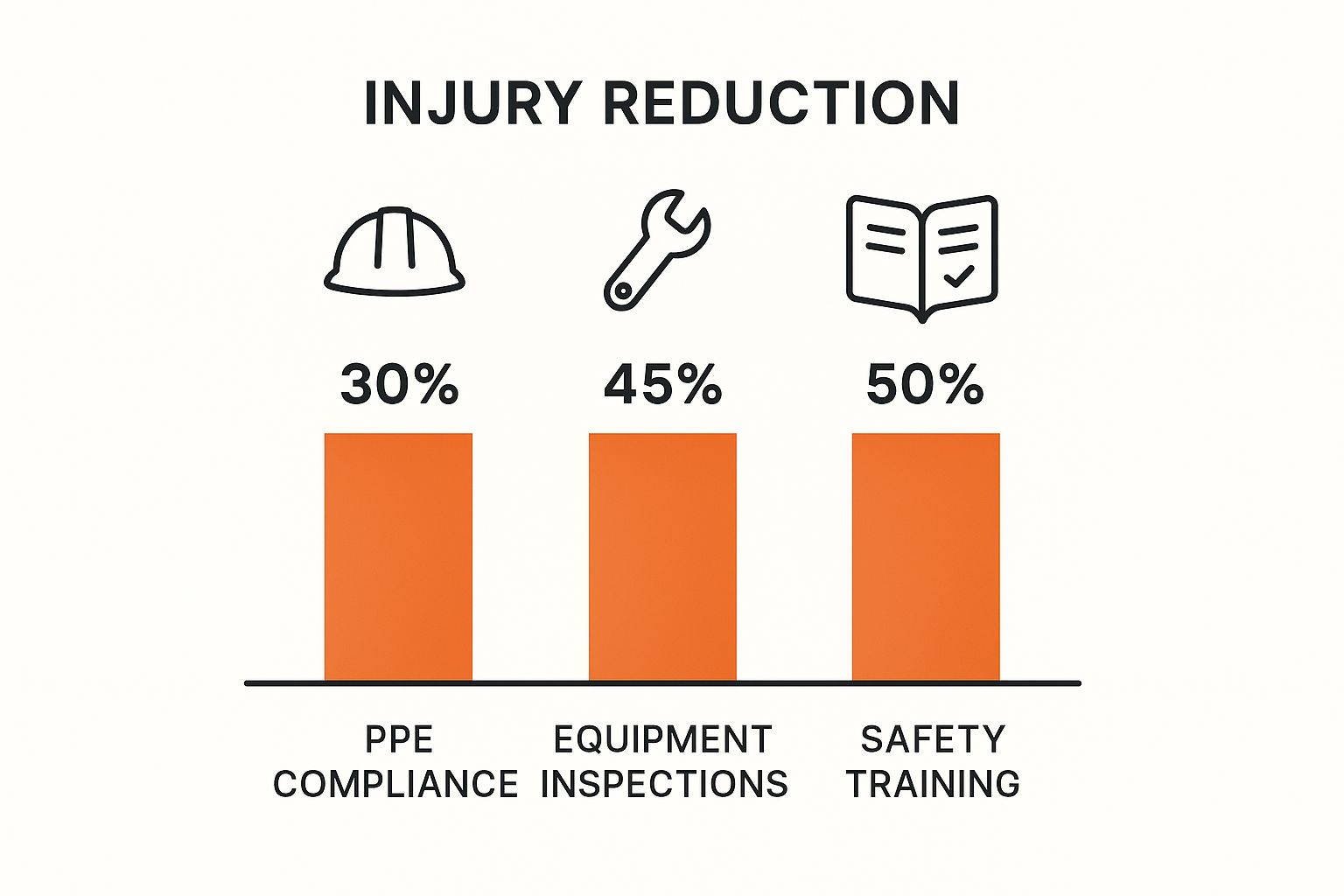

The infographic below highlights just how impactful different safety measures can be, reinforcing the value of a multi-layered approach.

The data is clear: while PPE helps, proactive steps like solid training and regular gear checks have a much bigger impact on stopping incidents before they happen.

Creating Safe Work Method Statements for High-Risk Work

For any task defined as 'high-risk construction work' under WHS regulations, you need to drill down even further with a Safe Work Method Statement (SWMS). Think of a SWMS as a mini-safety plan for a single, specific job. It breaks the task into sequential steps, identifies the hazards at each stage, and details the exact controls to be used.

High-risk construction work covers a lot of common ground, including:

- Work where there's a risk of a person falling more than 2 metres.

- Work on or near energised electrical installations.

- Work in or near a trench with an excavated depth over 1.5 metres.

- The use of explosives.

Your main safety plan should define the process for how SWMS are created, authorised, and reviewed. The SWMS themselves are the on-the-ground documents your crew will follow. Crucially, they must be developed in consultation with the workers doing the job, their practical input is gold. As you develop these controls, remember that well-placed workplace safety signs are a simple but critical tool for communicating hazards and procedures.

A good SWMS isn't just a compliance document; it’s a vital communication and planning tool. It ensures everyone involved in a risky job has thought through the process and agreed on the safest way to get it done before they start. For more practical guidance, you can find a wealth of information on https://safetyspace.co/control-measures-for-risks that will help you flesh out both your SWMS and your overall plan.

Putting Your Safety Plan into Action on Site

A construction site safety management plan is just a stack of paper until you bring it to life on site. The implementation phase is where your planning meets the real world of mud, machinery, and daily deadlines. This is all about clear communication and consistent monitoring, turning that document into a daily guide for getting the work done safely.

It all starts with getting the information out of the site office and into the hands of the people actually doing the work. If the crew doesn't understand the plan, they can't follow it. It’s that simple.

Communicating the Plan Effectively

Your most powerful tools here are site inductions and pre-start meetings. A proper site induction is way more than just a quick tour and a signature. It's your first real chance to set the standard and walk everyone through the site-specific rules you’ve laid out in your safety plan.

During induction, you need to hit these essentials hard:

- Key Site Hazards: Pinpoint the major risks you’ve already identified, like overhead powerlines, deep excavations, or high-traffic zones.

- Emergency Procedures: Explain exactly what to do and where to go if things go wrong. Everyone must know the location of first aid stations and muster points, no exceptions.

- Site-Specific Rules: Detail the non-negotiables, like traffic management procedures, mandatory PPE zones, and how everyone communicates on site.

Pre-start meetings and toolbox talks are what keep this information fresh every single day. These aren't just for handing out tasks; they're your prime opportunity to discuss the day's specific hazards. A good toolbox talk is a two-way street, giving workers a platform to raise concerns they’ve spotted on the ground.

A safety plan only works if it’s a living document. Daily pre-starts and toolbox talks are how you keep it relevant and front-of-mind for everyone on the tools, every single day.

The key is to keep these talks engaging. Instead of just reading from a sheet, ask questions, use visual aids, and focus on one or two topics directly relevant to the work happening that day.

Monitoring Compliance on Site

Once you’ve communicated the plan, you have to verify it’s being followed. This means getting out there and doing both regular and unscheduled site inspections. A weekly safety walk-around with a checklist based on your plan is a solid starting point.

During a site walk, you should be actively looking for:

- Adherence to SWMS: Are crews actually following the documented steps for high-risk work?

- Correct Use of Controls: Are guardrails in place? Is dust suppression being used for cutting? Is the gear being used correctly?

- General Housekeeping: Are access ways clear? Are materials stored safely to prevent trips and falls?

- PPE Compliance: Is everyone wearing the required gear for their task and location?

The construction industry in Australia remains one of the most hazardous sectors, which is why regulatory bodies are so focused on compliance. For instance, SafeWork SA has run extensive campaigns targeting high-risk construction sites, issuing statutory notices to enforce standards for dangers like working at heights. You can get more details on their focus on protecting vulnerable workers and improving site safety.

Managing the Safety Paperwork

A busy construction site generates a mountain of safety-related paperwork. It's crucial to have a simple, organised system to manage it all. This documentation is your proof that the plan isn’t just sitting in a folder, it’s being implemented correctly.

Here are the key documents you need to keep organised and accessible:

- Training Records and Licences: Your proof that everyone, including subbies, is competent and qualified for their work.

- Plant Risk Assessments and Maintenance Logs: Essential for ensuring all machinery on site is safe to operate and has been regularly inspected.

- Signed SWMS: A clear record that high-risk work procedures have been communicated and understood by the relevant teams.

- Site Induction Records: A register of every single person who has been inducted onto the site and when.

This isn't about creating bureaucracy for its own sake. Each document is a critical piece of the puzzle that shows you're actively managing your safety obligations and putting your plan into action where it counts: on the ground.

Got Questions About Your Safety Management Plan?

If you're managing a construction project, you've probably got questions about your safety management plan. It's a critical document, and getting it right can feel overwhelming. Here are some straight answers to the questions we hear most often from project managers and site supervisors.

How Often Should I Be Reviewing My Safety Plan?

A safety plan isn’t a document you create once and file away. It’s a living document that needs to adapt as your site changes. This isn't about ticking a box for compliance; it's about making sure your plan actually reflects the work happening on the ground.

Think about it: if your plan was written for a single-storey build and the client adds a basement excavation, your entire risk profile just shifted. That original plan is now dangerously out of date.

You absolutely need to pull it out for a review when:

- The project scope changes, like adding a new structure or work phase.

- New high-risk gear shows up, like a crane or heavy demolition equipment.

- An incident or a near-miss occurs, this is a non-negotiable learning opportunity.

- New subcontractors arrive on site with their own methods and machinery.

Even if nothing major changes, you should still schedule a formal review at key project milestones. A good rule of thumb is to take a hard look at it every few months, just to ensure it's still fit for purpose.

Does Every Single Project Need a Formal Safety Plan?

Here's the deal in Australia. Under WHS regulations, you are legally required to have a written WHS Management Plan for any construction project valued at $250,000 or more. These are what the regulators call "principal contractor" projects, and they have very specific requirements.

But what about smaller jobs? Even if you're under that threshold, a documented safety plan is still a massive best practice. It’s the clearest way to prove you’ve actually thought through the risks and have a system in place to control them. It doesn't need to be a 100-page novel, but it should still cover your risk assessments, control measures, and what to do in an emergency.

Don't get caught out. An inspector's first request on-site is often to see your plan. Not having one when it’s legally required can lead to hefty fines and an immediate stop-work order.

So, Who’s Actually Responsible for This Thing?

Ultimately, the buck stops with the Principal Contractor. That’s the person or company with overall command and control of the worksite. They are the ones legally accountable.

But creating the plan should never be a one-person job. The best plans are built with input from everyone involved:

- Project Managers

- Site Supervisors

- Health and Safety Representatives

- And, crucially, the subcontractors and workers doing the actual work.

When it comes to putting the plan into action, that responsibility usually falls to the Site Supervisor or Project Manager. They're the ones on the ground running inductions, leading toolbox talks, and making damn sure the safety controls you wrote down are actually being followed.

Keeping a safety management plan live and effective across a busy site involves constant oversight and clear communication. Safety Space takes the headache out of the paperwork, giving you a simple, all-in-one platform to track compliance, manage documents, and ensure everyone on site is on the same page.

See how you can simplify your safety management by booking a free demo.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.