A contractor management service is your rulebook for handling external workers, from the moment you vet them to the final sign-off on their job. For anyone running an industrial site, it’s about having a solid process to manage everything: insurance paperwork, site inductions, on-the-job performance, you name it.

It’s the difference between chaotic, reactive firefighting and having a controlled, forward-thinking system.

Defining Your Contractor Management Framework

At its core, a contractor management service is simply how you oversee anyone who isn't a direct employee but works on your site. This covers everyone from specialised maintenance techs and construction crews to temporary project staff. Without a defined system, you’re stuck juggling spreadsheets, chasing down expired licenses via email, and just hoping everyone got the right site briefing.

This ad-hoc approach creates very real operational headaches. I’ve seen Plant Managers discover a critical welding job can't start because the contractor’s insurance certificate expired yesterday. Or a Site Supervisor having to re-explain site hazards because the contractor’s induction was generic and didn't cover the specific risks in their work area. These aren't just minor hiccups; they cause delays and open you up to serious, unnecessary risk.

What Problems Does It Actually Solve?

A good contractor management service isn't just a paperwork exercise. It's a practical tool that deals with the daily frustrations that slow down operations and create compliance gaps. It gives you clear, immediate answers to critical questions.

It helps you fix issues like:

- Inconsistent Vetting: You can make sure every single contractor, no matter the project size, meets your minimum standards for qualifications, licences, and insurance before they even think about stepping on site.

- Lost Records: All induction records, certifications, and work permits are kept in one accessible place. Need to verify someone is cleared for a specific task? You can do it in seconds.

- Variable Standards: A consistent set of rules and expectations gets applied across the board, whether a contractor is on-site for a day or for a six-month capital project. No more double standards.

- Lack of Oversight: It creates a clear method for supervising work, verifying tasks are completed to your standard, and logging performance data to inform future hiring decisions.

A structured system isn’t about adding bureaucracy. It’s about removing the guesswork and firefighting that comes from disorganised contractor oversight, giving you a predictable and defensible process.

The Core Components of a Solid System

Building a dependable contractor management service means putting a few key pillars in place. These parts work together to cover the entire lifecycle of a contractor's engagement with your company. You can see how these elements combine to form a complete contractor management system designed specifically for industrial needs.

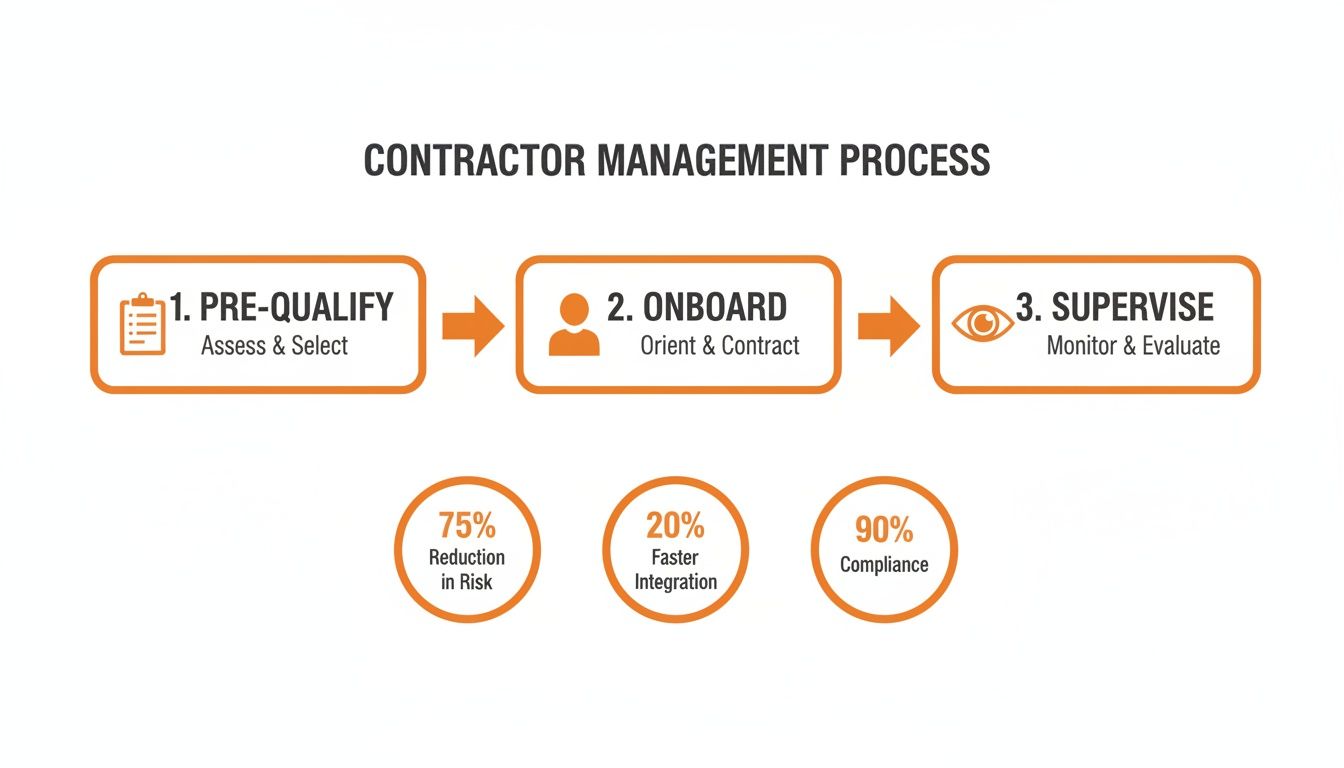

A practical framework includes these four stages:

- Pre-qualification: This is your initial screening. It's where you collect and verify all the essential documents. Think trade licences, public liability insurance, and any other must-have certifications.

- Onboarding and Induction: A formal process to get contractors up to speed on your site-specific rules, emergency procedures, and the specific hazards relevant to their work area.

- Work Authorisation: This is your system for issuing permits for high-risk jobs, like hot work or confined space entry, making sure all the right controls are in place before work begins.

- Monitoring and Performance Review: It’s about the ongoing supervision of contractors while they're on-site, followed by a final review to assess their performance against the agreed-upon scope of work.

Building Your Contractor Management Framework

Putting theory into practice is where a contractor management service truly proves its worth. Building a solid framework isn't about bogging everyone down in red tape; it's about creating a clear, repeatable process for every single contractor who sets foot on your site. This consistency is key. It cuts down on confusion and gives you a defensible system for handling your legal and operational duties.

Let's walk through the entire contractor lifecycle, from the initial checks right through to the final project sign-off. These are practical, real-world steps you can start using at your manufacturing plant or construction site today.

The workflow below shows the core stages in action, from pre-qualification to keeping an eye on things day-to-day.

As you can see, each step logically builds on the last, creating a complete system for managing external workers safely and effectively.

Nailing the Pre-qualification Stage

Think of pre-qualification as your first line of defence. It’s how you verify that a contracting company has the essential credentials, insurance, and safety systems in place before they even get a look-in for a job. Get this wrong, and you’re basically inviting unnecessary risk onto your site from day one.

The goal isn't to drown contractors in paperwork. It's about getting the non-negotiable information you need to make a smart, informed decision. Miss a key document here, and you could be facing serious headaches down the track.

A simple but effective pre-qualification checklist should cover:

- Public Liability Insurance: Get a copy of their certificate of currency. For most industrial work, you should be looking for a minimum of $20 million in coverage.

- Workers' Compensation Insurance: You need to see a valid policy that covers their people while on your site. This one is a non-negotiable legal requirement.

- Relevant Licences and Certifications: This is completely task-specific. For an electrician, you need to see their electrical contractor licence. For someone doing high-risk work, you need their specific licences (e.g., scaffolding, crane operation).

- Previous Work Examples or References: If they're new to you, ask for contacts from two recent, similar jobs. A quick phone call can reveal a lot about their reliability and work quality.

Don't just file these documents away. Actually check them. Verify expiry dates and make sure the company details on the paperwork match who you're engaging. A lapsed insurance policy gives you zero protection.

Creating Onboarding and Inductions That Stick

Once a contractor is pre-qualified, it's time to get them ready for your specific site. This is where tailored onboarding and site-specific inductions are crucial. A generic, one-size-fits-all PowerPoint is a waste of everyone's time and, frankly, does little to address the unique hazards of your workplace.

For instance, an induction for a food manufacturing plant will have completely different critical points (like hygiene protocols and clean zones) compared to one for a heavy fabrication workshop (focusing on overhead cranes and hot work).

Your induction needs to be an active process that checks for understanding, not just a presentation they sit through. For many organisations, digging deeper into what makes training effective can be a game-changer. You can find comprehensive material in a dedicated contractor management course that covers adult learning principles and practical assessment methods.

To make your inductions count, focus on:

- Site-Specific Hazards: Don't just say "watch out for slips, trips, and falls." Point out the uneven ground near Bay 3, show them the chemical storage area, or explain the forklift blind spots at the main intersection. Be specific.

- Emergency Procedures: Show them the actual muster points on a site map. Explain what the different alarm sounds mean and introduce them to the first aiders and fire wardens in their work area.

- Key Site Contacts: Who do they call when something goes wrong? Give them the names and phone numbers for their direct site supervisor, the H&S rep, and the project manager.

- Confirmation of Understanding: End with a simple quiz. Questions like "Where is the primary emergency assembly point for this area?" or "What permit is needed for welding in the workshop?" prove they were actually listening.

Using Permits to Work for High-Risk Tasks

Not all work is created equal. For routine, low-risk jobs, a standard risk assessment is probably fine. But for any task with the potential to cause serious harm, a Permit to Work system is non-negotiable. This is a formal, documented process that authorises specific people to do specific work at a specific time.

Permits aren't just about signing a form. They are a critical communication tool that makes sure everyone, from the crew on the tools to the site supervisor, understands the risks and the controls needed to do the job safely. When building your framework, looking at how public sector procurement frameworks operate can also offer great insights into managing external services, especially for high-risk government contracts.

You absolutely must have a permit system for activities like:

- Hot Work: Anything involving welding, grinding, or cutting that creates sparks or flames.

- Confined Space Entry: Working in tanks, pits, or vessels where there's a risk of atmospheric hazards or engulfment.

- Work at Height: Any task where a fall could cause serious injury, particularly when using scaffolds or EWPs.

- Excavation: Digging trenches where there's a risk of collapse or hitting underground services.

- Isolation of Energy: Working on any equipment that needs to be locked and tagged out to prevent it from starting up unexpectedly.

Supervising and Verifying Work On-Site

Your job isn’t done once the induction is over. Active supervision is a critical part of managing contractors. This isn't about micromanaging their every move. It's about checking that the safety procedures and work standards you both agreed to are actually being followed on the ground.

Even a quick, informal check can make a huge difference. A daily walk-through of the contractor's work area lets you spot potential issues before they become real problems. Are they wearing the right PPE? Is their housekeeping up to scratch? Are they following the controls listed on their permit?

A more structured approach to supervision could include:

- Pre-start Meetings: A quick five-minute chat before work kicks off to run through the day's tasks, the risks, and any changes on site.

- Regular Inspections: Schedule formal checks at key project milestones to verify work quality against the agreed scope.

- Task Verification: For critical jobs, have a sign-off step where your supervisor confirms the work meets your standards before the contractor can move on.

Closing Out with Performance Reviews and Off-boarding

The final step is just as important as the first. A proper off-boarding process makes sure all work is finished, the site is left clean and safe, and the paperwork is finalised. It's also your golden opportunity to review the contractor’s performance.

This review gives you invaluable data for the future. Did they hit their deadlines? Was the quality of their work up to par? Did they follow safety rules without needing constant reminders? Capturing this information helps you make smarter hiring decisions next time. You’ll know exactly which contractors to call back and which ones might not be the right fit.

Your off-boarding checklist should include things like:

- A final site walk-through to confirm completion and cleanliness.

- The return of any company property, like keys, access cards, or tools.

- Submission and approval of the final invoice.

- Completing a simple performance review, rating them on key criteria like quality, timeliness, and safety compliance.

By following these structured steps, you build a contractor management framework that is practical, defensible, and shifts your business from constantly reacting to problems to proactively preventing them.

How to Track Contractor Performance That Matters

You can't manage what you don't measure. But let's be clear: tracking contractor performance isn't about creating mountains of paperwork. It's about focusing on the key performance indicators (KPIs) that give you real, useful insight into your contractor management service and help you stop problems before they even start.

So many businesses fall into the trap of only looking at 'lagging indicators'. These are things like the number of incidents after a project is finished. That tells you what went wrong in the past. To actually get ahead of the curve, you need to track 'leading indicators'. These are the metrics that show you how well your process is working right now. This is how you spot compliance gaps before they escalate.

Moving Beyond Basic Metrics

Most companies track the basics, like project cost and completion dates. While these are obviously important, they don't tell the full story about how effective your contractor management really is. A project can be perfectly on time and on budget but still have underlying compliance or quality issues bubbling just beneath the surface.

Instead, start tracking metrics that give you a live pulse-check on your process health. These leading indicators are direct measures of how well your system is functioning day-to-day.

Here are a few practical KPIs you can start with:

- Pre-qualification Approval Time: How long does it actually take from a contractor submitting their documents to them being approved in your system? A long cycle time can be a sign that your process is too clunky or you’re under-resourced. It creates project delays before a single tool is picked up.

- Induction Completion Rate: What percentage of contractors assigned to a job have completed their site-specific induction before they're due to start? A rate below 100% is a massive red flag for on-site compliance and a risk you don't need to take.

- Permit to Work Compliance: Track the percentage of high-risk tasks that have a correctly completed and authorised permit. This is a direct measure of how well your most critical work controls are being followed.

Setting Up a Simple Reporting Dashboard

You don't need fancy, complex software to get started. Honestly, a simple spreadsheet can work perfectly well when you're just getting off the ground. The goal is to make the data visible so you and your team can act on it.

Create a basic dashboard with your key leading indicators. Make a habit of updating it weekly and sharing it with your site supervisors and project managers. This visibility alone often drives improvement because, as we all know, what gets measured gets managed.

As your operations grow, you might want to see how a dedicated contractor management software can automate all this data collection for you, giving you real-time insights without the manual grind.

The most effective performance tracking isn't about catching people out. It's about finding the weak spots in your own process so you can strengthen them. A low induction completion rate isn't a "contractor problem". It's a system problem you now have the data to solve.

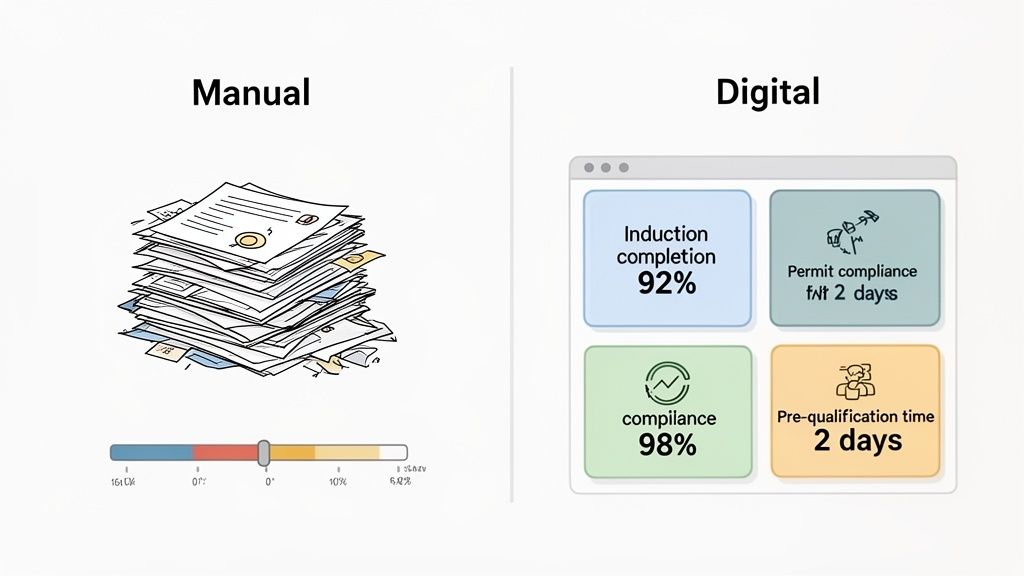

Manual vs Digital Contractor Management Tracking

The way you collect performance data has a massive impact on its quality and how useful it is. Old-school manual methods are better than nothing, but they come with some serious limitations compared to a digital approach. For more insight into how strong project management ties into contractor success, this guide on Project Management for Consultants is a great resource.

The table below breaks down the real-world differences between sticking with spreadsheets and moving to a dedicated platform.

| Metric | Manual Tracking (Spreadsheets/Paper) | Digital Platform (e.g., Safety Space) |

|---|---|---|

| Data Accuracy | Prone to human error from manual data entry. Information can be days or weeks out of date. | Real-time, automated data capture. Information is accurate and current. |

| Visibility | Data is often stuck in one person's spreadsheet, making it hard to share and analyse trends. | Centralised dashboard provides instant visibility for everyone from site supervisors to head office. |

| Efficiency | Requires significant administrative time to chase, collect, and compile data from various sources. | Automatic reminders and workflows do the chasing for you, freeing up your team's time. |

| Reporting | Creating reports is a manual, time-consuming task, often done only on a monthly or quarterly basis. | Instant, customisable reports can be generated on-demand, allowing for faster decision-making. |

Ultimately, choosing a digital system isn't just about efficiency. It's about getting more accurate, timely data that allows your team to be proactive rather than reactive. It frees them up from chasing paperwork to actually managing safety and performance on the ground.

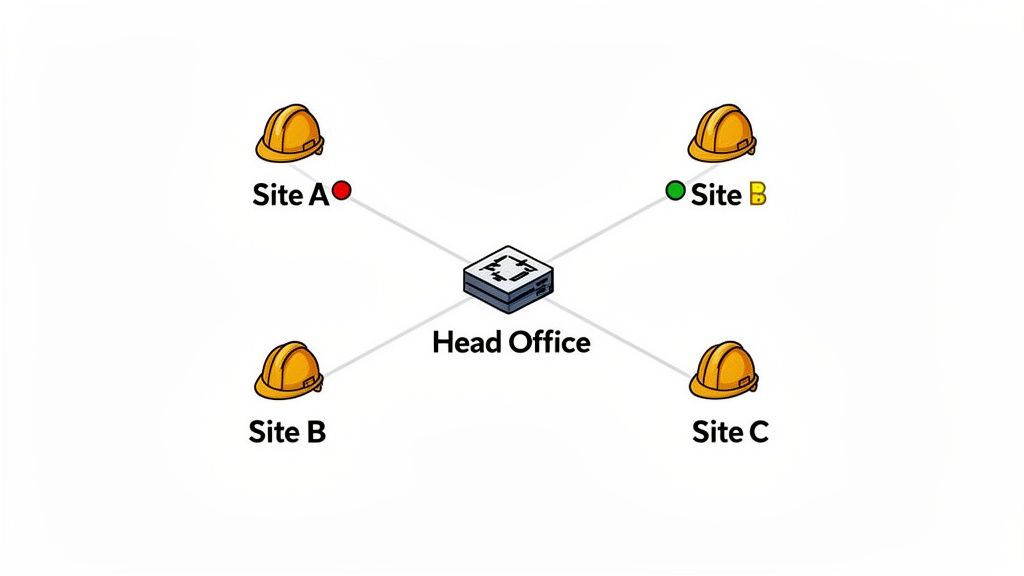

Taming the Beast: Managing Subcontractors Across Multiple Sites

Handling contractors on a single site is challenging enough. The moment your operations expand across multiple locations, the complexity explodes, creating a whole new set of headaches. This is the daily reality for large builders, mining operations, and industrial companies right across Australia.

Trying to manage crews in Perth, Melbourne, and Brisbane from a head office in Sydney creates massive blind spots. Without a consistent system, each site supervisor is left to manage contractors their own way. This inevitably leads to wildly different standards for pre-qualification, inductions, and on-site supervision, introducing unpredictable and unacceptable risks across the business.

This heavy reliance on external teams is a huge operational risk baked into certain industries. Take Australia's construction sector. A staggering 41% of infrastructure construction is carried out by subcontractors. This creates major interface risks and can dilute the core capabilities of the principal contractor, a problem flagged as a contributor to stubbornly low productivity. You can dive deeper into the full report on Australia's infrastructure market capacity for more detail.

Standardise Without Losing Local Control

So, what’s the answer? The key is to standardise the core process while still allowing for site-specific needs. You need a single source of truth that head office can see, but one that remains practical for the teams on the ground. A unified contractor management platform is really the only way to strike this balance.

The goal is to establish a consistent, non-negotiable baseline for how all contractors are managed, no matter where they are. This gives you centralised control over the biggest risks while empowering local teams to handle the unique conditions of their site.

Centralising your core contractor management processes doesn't remove local autonomy. It provides a strong, consistent framework that lets site managers focus on supervision and project delivery, not administrative guesswork.

Creating a Centralised System

A truly practical multi-site system zeros in on standardising the most critical compliance stages. This makes sure that every contractor, whether they're on a remote mining site or in a busy urban factory, meets the same minimum standards before they even think about starting work.

Here’s how you build that consistency:

- Centralised Pre-qualification: All contractors must go through the exact same vetting process, managed through one system. This makes sure insurance, licences, and company history are checked against the same criteria for every single vendor, eliminating weak links from the chain.

- Consistent Digital Inductions: Develop a core company-wide induction that all contractors must complete online. You can then supplement this with a short, sharp site-specific induction when they arrive to cover local hazards and emergency points.

- Uniform Permit to Work Templates: Use the same digital permit templates for high-risk work across all sites. This guarantees that controls for tasks like hot work or confined space entry are consistent, dramatically reducing the chance of critical errors.

Using Technology for Remote Oversight

For a head office team, having real-time visibility across all sites is non-negotiable. You simply can't manage what you can't see. This is where technology becomes essential for any contractor management service operating at scale.

A single platform gives your central safety and operations teams a live dashboard view of what’s happening at every single location.

With the right tools, you get:

- Real-time Compliance Views: Head office can instantly see which contractors are approved to work, whose insurance is about to expire, and induction completion rates for every site. No more chasing emails.

- Instant Access to Records: If an incident occurs on a site in another state, you can immediately access the contractor’s pre-qualification documents, induction records, and signed permits without having to call the site.

- Data-Driven Decisions: Centralised data allows you to spot trends before they become problems. If one site has a consistently lower rate of permit compliance, you know exactly where to direct your support and resources.

Common Contractor Management Pitfalls (And How to Dodge Them)

Even the most well-designed contractor management system can spring a leak if it falls into a few common traps. Learning to spot these pitfalls is the first step toward building a system that actually holds up in the real world, not just on paper.

Frankly, most of these issues pop up when we take shortcuts under pressure. And with industry conditions tightening, that pressure is only mounting. With construction industry revenue forecast to dip to $521.2 billion by 2025, many businesses are leaning more heavily on contractors, which can dial up the compliance risks. It's this economic squeeze that often leads to the very mistakes a solid management system is supposed to prevent.

The 'Set and Forget' Mindset

One of the most common failures I see is the ‘set and forget’ approach. This is where a company puts a ton of energy into pre-qualification but then dusts off their hands and assumes the job is done once the contractor steps on site.

- What it looks like: A contractor’s insurance certificates are collected and neatly filed away on day one. But nobody is tracking the expiry date. Six months down the line, an incident happens, and you discover their public liability insurance actually lapsed weeks ago. Ouch.

- How to fix it: Your system needs automated reminders for expiring documents. It doesn’t have to be fancy. It could be a shared calendar alert or a core feature in a digital platform. The point is, you need a proactive way to track critical dates without someone having to remember to manually check a spreadsheet.

Incomplete or Rushed Pre-qualification

When the pressure is on to get a project kicked off, it’s so tempting to speed through the vetting process. This almost always comes back to bite you. Skipping steps in pre-qualification is like pouring a concrete slab on a foundation of sand.

A critical mistake is just taking a contractor's word that they have the right licences or insurance without actually sighting the documents. Verification isn't about mistrust; it's about basic due diligence to protect your business.

A rushed process means you might not notice that a contractor's licence isn't valid in your state, or that their insurance coverage is miles below your minimum requirement for the job. To fix this, create a non-negotiable pre-qualification checklist. No one gets the green light until every single item is ticked off and verified. No exceptions.

Generic Inductions That Miss the Mark

Another classic pitfall is rolling out a one-size-fits-all induction for every contractor on every site. A generic safety video might tick a compliance box, but it does very little to prepare a worker for the specific hazards they’ll be facing in their actual work area.

- What it looks like: An electrical contractor sits through a standard online induction but is never actually shown the location of the main switchboard for the specific zone they'll be working in.

- How to fix it: Always back up your general company induction with a short, practical, on-site orientation. Walk them through their work area. Point out the nearest fire extinguisher, the first aid kit, and introduce them to their direct site supervisor. That five-minute walk-around is infinitely more valuable than a one-hour generic video.

Got Questions? We've Got Answers

Here are some quick, practical answers to the questions we hear most often about getting a contractor management service up and running.

How Long Does It Take to Set Up?

This really comes down to your approach. If you’re building a manual, paper-based system from the ground up, you could be looking at weeks of work just drafting procedures and creating forms before you even think about rolling it out. It's a huge time sink.

A better way is to use a digital platform. You can get your core framework live in a matter of days. We often see companies start with the essentials, like pre-qualification and inductions, and then layer in other functions like permits to work as they get comfortable.

What Is the Biggest Mistake Companies Make?

Without a doubt, the single biggest mistake is treating contractor management as a one-time, tick-box exercise at the start of a project. This "set and forget" mentality is a massive pitfall.

Companies will often do a brilliant job collecting all the right documents during onboarding, but then they completely drop the ball on monitoring compliance on-site or tracking when insurances expire. This creates a dangerous false sense of security and leaves the business wide open to risk. Good management has to be a continuous loop, not a one-off task.

Can This Actually Work for a Small Business?

Absolutely. The core principles of vetting, inducting, and monitoring contractors are universal, no matter the size of your business. A smaller company might not need a sprawling, enterprise-level system, but the process itself is just as critical for them.

For a small business, a solid contractor management service could be as simple as a digital checklist, a standard induction video, and an automated alert for insurance expiry dates. Modern tools give you powerful features without the hefty price tag, letting you build a system that grows right alongside your business.

How Do I Get My Contractors to Actually Use the System?

Getting contractors on board is make-or-break. The trick is to make it a non-negotiable part of your contract from day one. No surprises, no arguments. It's just how you do business.

But the real key to adoption is choosing a system that’s dead simple and mobile-friendly. If a contractor can upload their documents or complete an induction in a few minutes on their phone, you’ll see far better compliance than you ever would with clunky, paper-based hoops to jump through.

Ready to get a real handle on contractor compliance without drowning in admin? Safety Space gives you a simple, all-in-one platform to manage pre-qualification, inductions, and on-site performance. Book a free demo today and see for yourself how you can get a robust system up and running in just a few days.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.