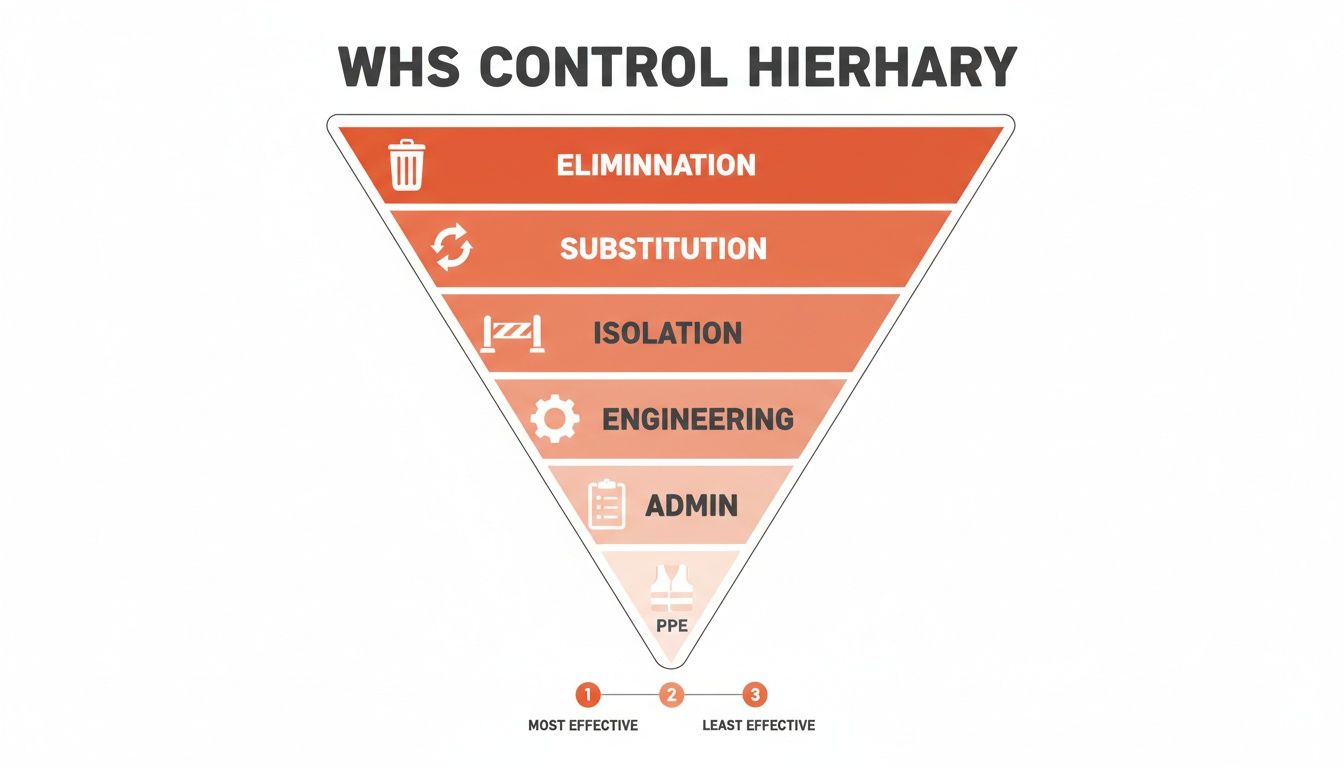

When it comes to workplace safety, not all solutions are created equal. Some are very powerful and get right to the root of a problem, while others are more like a last line of defence. This is where the WHS hierarchy of control comes in; it’s a strategic playbook for tackling hazards.

The core idea is to rank risk controls from the most effective (getting rid of the hazard entirely) down to the least effective (simply wearing protective gear). It forces us to stop and think, pushing us to find smarter, more permanent solutions instead of just patching over the symptoms of a risk.

Understanding the Hierarchy of Control Framework

At its heart, the hierarchy of control is the foundation of modern Work Health and Safety (WHS) management in Australia. It’s not just a guideline; it's a systematic process required by law for dealing with anything that could cause harm in the workplace.

Let's make this real with a common scenario: securing a construction site from unauthorised entry after hours.

You could jump straight to hiring a security guard, but the hierarchy of control challenges you to think more strategically.

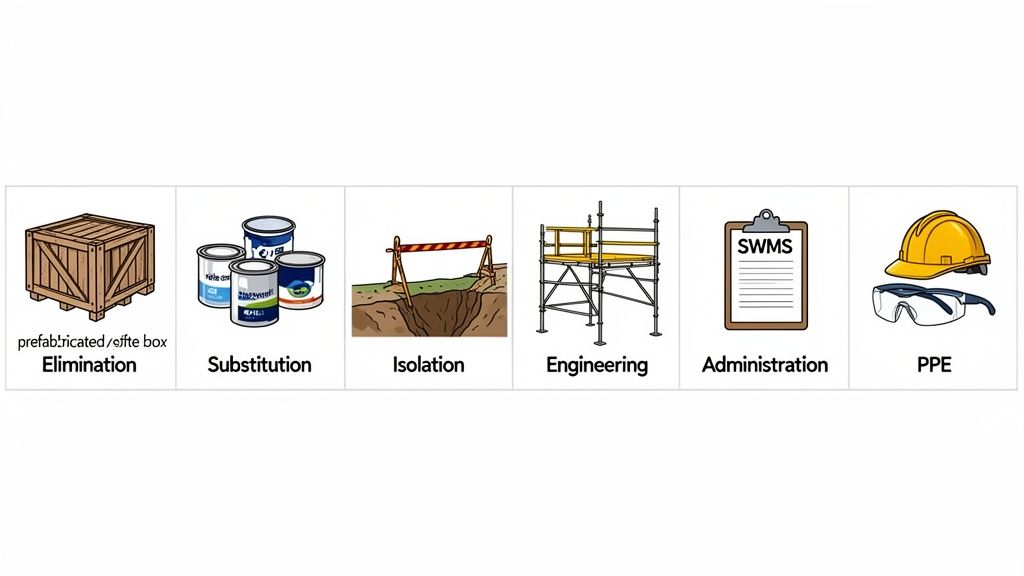

- Elimination (Most Effective): What if you could remove the hazard completely? By using prefabricated modules built off-site in a secure factory, you might eliminate the need for a vulnerable, open construction site altogether. No site, no trespassers.

- Substitution: Okay, you need a physical site. Could you substitute the location for a much safer one? Moving it to a remote, naturally inaccessible area replaces the hazard of easy public access with a safer alternative.

- Isolation & Engineering: If the location is fixed, you can physically separate people from the hazard. A high, locked fence around the entire perimeter is a classic example of an engineering control that isolates the work area.

- Administration: Now we're getting into controls that rely on people. Putting up "No Trespassing" signs and creating a strict site access policy are administrative controls. They only work if people see them and decide to follow the rules.

- PPE (Least Effective): Finally, you could give a security guard a high-vis vest and a torch. This does absolutely nothing to remove the trespassing hazard itself; it just offers a small amount of protection to one person.

This inverted pyramid is the classic way to visualise the framework. The most effective, proactive controls are at the top, while the least effective, reactive ones are at the bottom.

The real insight here is that the controls at the top of the pyramid are designed to be permanent fixes that protect everyone, while the controls at the bottom are temporary and only protect individuals.

Why This Framework Is So Effective

The whole point is to build safety into your processes from the very beginning, rather than adding it on as an afterthought. By working your way down from the top, you address risks in the most logical and reliable way possible.

And it works. This structured approach has had a massive impact on safety outcomes across the country.

Australia's work-related injury rate is around 3.5%, which is low compared to the global average of 12.1%. This isn't an accident; it's the result of a strong WHS framework where the hierarchy of controls is a required part of the process. You can dig into more of these national statistics over on the Safe Work Australia website.

To give you a quick overview, here’s a simple table breaking down each level of the hierarchy. We’ll go deeper into each of these in the next section.

The WHS Hierarchy of Control At a Glance

| Control Level | Effectiveness | Core Function |

|---|---|---|

| Elimination | Most Effective | Physically remove the hazard completely. |

| Substitution | Very Effective | Replace the hazard with a safer alternative. |

| Isolation | Effective | Separate people from the hazard with a barrier. |

| Engineering | Effective | Use physical changes to reduce the risk. |

| Administration | Less Effective | Change work procedures or provide training. |

| PPE | Least Effective | Protect the worker with personal equipment. |

This table gives you a snapshot of the logic, ranking each control by how well it actually prevents harm. The goal is always to start at the top and only move down when the higher-level controls aren't reasonably practicable.

Breaking Down Each Level of the Hierarchy

Knowing the theory behind the hierarchy of control is one thing. Making it actually work on a noisy, busy worksite is something else entirely. To get this right, you need to understand what each level looks like in the real world. It's all about moving from abstract ideas to concrete actions that protect your team.

The framework gives us six distinct levels of control, arranged from most to least reliable: elimination, substitution, isolation, engineering controls, administrative controls, and finally, personal protective equipment (PPE). Experience and research both show that the best safety systems come from layering controls from different levels, rather than just relying on one.

Let's unpack each level with some practical examples you'd see in construction and manufacturing.

Level 1: Elimination

This is the gold standard. It’s the most powerful control because it removes the hazard at the source. If the hazard doesn't exist, it can't cause harm. Getting here often means you have to think differently about how the job gets done.

Elimination isn't always possible, but it must be the first thing you consider. It's the only control that guarantees a 100% reduction in risk from that specific hazard.

- Construction Example: Instead of workers cutting large steel beams at height, the components are prefabricated in a controlled factory. This completely eliminates the risk of falls associated with that specific task, not to mention reducing noise and fume exposure on the active site.

- Manufacturing Example: A factory has to clean large vats, a task that normally involves risky confined space entry. They redesign the vats with a built-in, automated cleaning system, and just like that, the need for a worker to enter that space is eliminated entirely.

Level 2: Substitution

If you can't get rid of the hazard, can you swap it for something safer? That's substitution. It’s about replacing a hazardous material, process, or piece of equipment with a less dangerous alternative that still gets the job done.

This is a really effective control because it lowers the potential severity of harm without depending on people to follow complex rules.

Key Takeaway: Substitution is all about changing the 'what' of the job. You're finding a safer ingredient or a less dangerous tool to get the same result.

- Construction Example: A painting crew is using solvent-based paints that release harmful volatile organic compounds (VOCs). They substitute them with low-VOC, water-based paints. The walls still get painted, but the risk of respiratory illness is massively reduced.

- Manufacturing Example: A metal fabrication workshop swaps out a powerful and toxic chemical degreaser for a citrus-based, biodegradable cleaning agent. It's just as effective but poses a far lower health risk to the team.

Level 3: Isolation

When you can't eliminate or substitute, the next best thing is to physically separate people from the hazard. Isolation relies on barriers or enclosures to put a safe distance between your workers and the danger.

This is a reliable control because it doesn't depend on worker action. A physical barrier works whether someone is having a good day or a bad one.

- Construction Example: An excavation team is digging a deep trench. To stop anyone from accidentally falling in, sturdy physical barriers and trench shields are installed around the whole perimeter. This isolates the fall hazard from the rest of the worksite.

- Manufacturing Example: A huge, noisy machine is housed inside a soundproof enclosure. Workers can still operate and monitor it from the outside, but they aren't exposed to dangerous noise levels. The hazard has been isolated.

Level 4: Engineering Controls

Engineering controls are all about making physical changes to the workplace, equipment, or the process itself to cut down the risk. While isolation puts a barrier around a hazard, engineering controls are often designed into the equipment or environment.

These are highly effective because they tend to be permanent or semi-permanent solutions that protect workers automatically, without them having to do anything. For a deeper dive, check out our guide on choosing the right control measures for risks.

- Construction Example: Scaffolding is going up on a multi-story site. Instead of relying on temporary ropes, permanent guardrails and toe boards are installed on all working platforms. It’s an engineered solution that provides passive fall protection for everyone on the scaffold.

- Manufacturing Example: A conveyor belt on a production line has exposed gears. A fixed machine guard is engineered and bolted on to completely cover these moving parts, making it impossible for workers to get their hands or clothing caught.

Level 5: Administrative Controls

Now we're getting into controls that rely heavily on people doing the right thing. Administrative controls are all about changing work procedures, policies, training, and sticking up signs.

These are less reliable simply because they are vulnerable to human error. People forget their training, ignore signs, or take shortcuts when they're under pressure. It happens.

- Construction Example: A crane is operating on-site. The site manager creates a detailed Safe Work Method Statement (SWMS) that maps out exclusion zones and communication protocols. Regular toolbox talks are held to make sure everyone is on the same page.

- Manufacturing Example: To limit exposure to vibrations from power tools, the company brings in a job rotation schedule. Workers only spend a set amount of time on high-vibration tasks before moving to other duties, administratively controlling their total exposure.

Level 6: Personal Protective Equipment (PPE)

Right at the bottom of the hierarchy, PPE is our last line of defence. It is the least effective control because it does nothing to remove or reduce the hazard itself; it just puts a barrier on the person, hoping it will protect them if everything else fails.

You should only turn to PPE after all the higher-level controls have been properly considered and put in place, or maybe as a stop-gap measure while you're getting better controls installed.

- Construction Example: Every worker on a building site must wear a hard hat, safety glasses, and steel-capped boots. This gear protects them from falling objects and impact injuries, but only if it's worn correctly and is in good shape.

- Manufacturing Example: Welders have to wear respirators, welding helmets, and fire-retardant clothing. This protects them from toxic fumes and burns, but its effectiveness relies entirely on the individual using the right gear, the right way, for every single task.

Meeting Your Legal Obligations Under WHS Law

Let’s be clear: the hierarchy of control isn’t just a nice-to-have model or a suggestion for best practice. In Australia, it’s a legal requirement baked into Work Health and Safety (WHS) law.

If you’re a business owner, director, or manager, this isn’t optional reading. It’s the very core of your legal duty of care to give your team a safe place to work.

Put simply, your duty of care means you must do everything that is reasonably possible to protect your workers. The law doesn’t leave this open to interpretation. It points directly to the hierarchy of control as the official playbook for managing risks the right way.

This legal framework means you can’t just skip to the easiest or cheapest fix. Regulators expect to see that you started at the top of the pyramid (Elimination) and methodically worked your way down.

The Rule of Working from the Top Down

When you spot a hazard, the first question you must ask is: "Can we get rid of this hazard completely?" If that's not possible, you move to the next level: "Can we swap it out for something safer?" This thinking process continues step-by-step down the hierarchy.

A critical piece of this is documentation. If you decide a higher-level control isn’t feasible, you better be able to prove why. You can’t just ignore elimination and go straight to handing out safety glasses because it’s quicker. You need a documented reason explaining why eliminating or substituting the hazard wasn’t a reasonable option for your specific situation.

Under Australia's model WHS Regulations, you are legally required to apply the hierarchy in descending order. Defaulting to lower-level controls like PPE without properly evaluating the higher-order options is a direct breach of your duty of care. For a deeper dive, it’s worth reviewing the government's guidance on control measures.

Understanding ‘Reasonably Practicable’

So, what does the law actually mean by ‘reasonably practicable’? This is the crucial test you’ll apply when deciding on controls. It’s not a loophole for cutting costs; it's a careful balancing act.

To figure out what’s reasonably practicable, you have to weigh up a few key factors:

- The likelihood of the hazard causing harm: How likely is it that someone will actually get hurt?

- The degree of harm: If they do get hurt, how bad will it be? A paper cut is worlds away from a fatality.

- What you know about the hazard and its control: Are there well-known, industry-standard solutions for this risk?

- The availability and suitability of controls: Are there practical fixes available on the market?

- The cost of the control: Cost is definitely a factor, but it must be weighed against the level of risk. A high risk of serious injury will almost always justify a significant expense.

Crucial Point: Cost can never be your only reason for not implementing a safety control, especially when the risk is high. Your team's safety has to come first.

For example, imagine workers are exposed to an unprotected edge with a high risk of a serious fall. Arguing that installing guardrails is "too expensive" simply won’t fly. The severe potential harm makes the cost of a guardrail a reasonably practicable measure. Getting this wrong doesn’t just put your people in danger; it opens you up to massive fines and serious legal trouble.

How to Put the Hierarchy of Controls Into Practice

Knowing the different levels of the hierarchy of control whs is a great start, but the real test is applying it on a busy, fast-moving worksite. It's one thing to understand the theory in an office, and another entirely to put it into action where the risks are real. This isn't about ticking boxes on a form; it's about making smart, practical decisions that genuinely keep people from getting hurt.

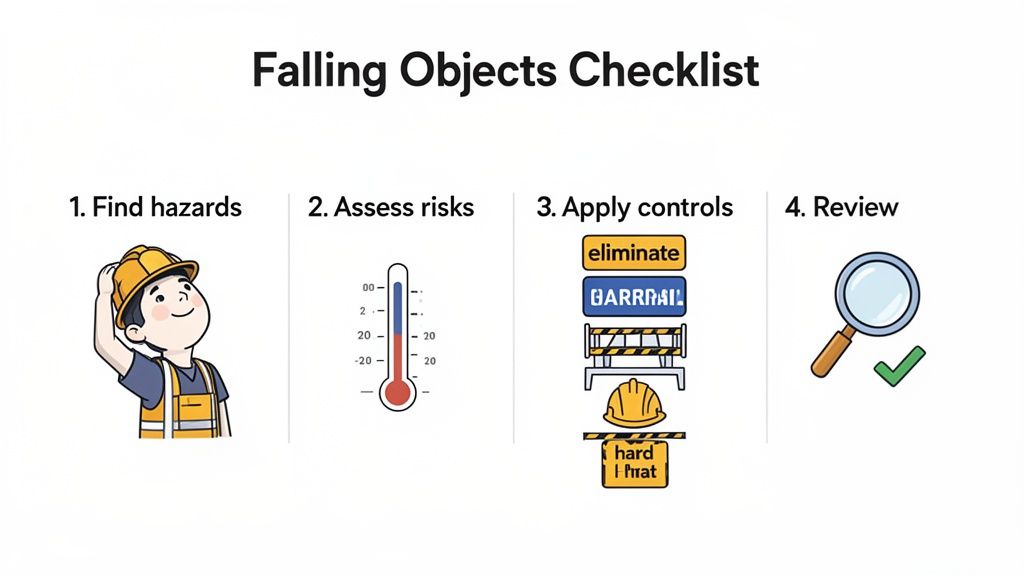

The good news? You don't need a complicated system. A simple, four-step process is all it takes to move from theory to reality. Let’s walk through it using a classic worksite problem: managing the risk of falling objects on a multi-level construction project.

Step 1: Find the Hazards

You can’t control a risk you don't even know exists. So, the first step is always to get out there and actively look for things that could go wrong. This means leaving the site office and getting your boots on the ground.

The best way to do this is by combining two simple but powerful methods:

- Walk the Site: Get into the habit of doing regular site inspections with the sole purpose of spotting hazards. Are there loose materials stacked near edges? Tools left on scaffolding? Areas where people are working above others?

- Talk to Your Crew: Your team on the tools sees things you don't. They are your best resource. Ask them directly: "What are you worried about out here? What near misses have you seen that gave you a scare?" They'll often flag risks that a formal inspection might miss.

In our falling objects scenario, a site walk reveals subcontractors are stacking bricks right near an unprotected edge on the third floor. A quick chat with the crew also brings up another issue. Small tools are often passed up and down between levels by hand, creating a completely separate risk.

Step 2: Assess the Risks

Once you've got a list of hazards, you need to figure out which ones to tackle first. Risk assessment is really just about understanding two things: the likelihood of an incident happening and the potential consequences if it does.

A brick falling three stories has a very high chance of causing a life-changing injury or worse. A dropped spanner is also serious, but maybe slightly less severe. You have to prioritise the hazards that pose the biggest threat.

To do this right, you need a solid risk assessment process. Using a proper construction risk assessment template can guide you through this, making sure no stone is left unturned. A structured approach here is what makes your safety decisions robust and defensible.

Step 3: Apply Controls from the Top Down

This is where the real work begins. You now need to work through the hierarchy of control whs framework, starting at the top (Elimination) and moving your way down. Crucially, you should only move to a lower-level control when you can justify why the higher-level ones weren't reasonably practicable.

Let's apply this to our falling objects problem:

- Elimination: Can we get rid of the hazard altogether? Maybe some wall sections can be pre-assembled on the ground and craned into place as a single unit. If we can do that, we’ve just eliminated a huge chunk of the risk.

- Substitution: This one doesn't really fit for falling bricks, but you could perhaps substitute heavy metal hand tools with lighter composite versions if they do the same job.

- Isolation & Engineering: Here’s where we can make a real difference. Installing physical barriers like toe boards and mesh screening around all open edges is a fantastic engineering control. We can also use barricades to create "no-go zones" on the ground below, a simple but effective form of isolation.

- Administrative: Now we layer on procedures. We can implement a strict rule that no materials are to be stored within two metres of an unprotected edge. We also develop a Safe Work Method Statement (SWMS) for lifting materials, mandating the use of cranes or material hoists instead of passing things by hand.

- PPE: Finally, as the last line of defence, we make sure hard hats are mandatory for everyone on site, no exceptions.

Key Insight: Notice how we didn't just jump straight to telling everyone to wear hard hats. We built layers of protection, starting with the most effective ones. The engineering controls (toe boards, screens, barriers) do the heavy lifting, while the admin rules and PPE act as the final safety net. To see this in action across different industries, check out these detailed hierarchy of control examples.

Step 4: Review Your Work

Putting controls in place isn't a "set and forget" task. The job's not done until you've checked that your solutions are actually working. Are the barriers still in place? Is the crew actually following the new SWMS? Did your solution accidentally create a new, unexpected hazard?

This review needs to be ongoing. Use your daily toolbox talks to ask for feedback. Schedule regular safety walks just to check on the controls you’ve implemented. If you find something isn't working as it should, you loop straight back to step one and start again. This cycle—identify, assess, control, and review—is the engine that drives a safe worksite.

Common Mistakes to Avoid When Using the Hierarchy

Even with the best of intentions, it’s easy to get the hierarchy of control whs wrong. Knowing where the common traps lie is the first step to side-stepping them and making sure your safety processes are effective, not just a paper-shuffling exercise.

Getting this right means moving beyond the path of least resistance. It requires a commitment to thinking more rigorously about risk, with the goal of building a system where the easiest option is also the safest one.

Time and again, we see organisations fall into the same patterns. By recognising these pitfalls, you can build a much more robust safety system on your site.

Defaulting to PPE

This is the big one. The most common mistake by a long shot is jumping straight to the bottom of the pyramid. Handing out hard hats, hi-vis vests, or earplugs feels like a quick, visible fix. But PPE is the least effective control because it does absolutely nothing to fix the source of the problem.

It puts the entire weight of safety on the individual worker. If their gear fails, isn't worn correctly, or is simply the wrong type for the job, their protection instantly vanishes.

Practical Example: A factory has a noisy machine, so they make earplugs mandatory. A far better approach would be to first see if engineering controls are viable. Could they build a soundproof box around the machine? Or move it to an isolated room? PPE should always be the final layer of defence, never the first and only one.

Neglecting Worker Consultation

Another common mistake is making safety decisions from an office, completely disconnected from the people actually doing the work. The crew on the floor or out on site has direct, hands-on experience with every hazard. They’re the ones who know the shortcuts people take and the real-world frustrations of the job.

If you ignore this firsthand knowledge, you’re almost guaranteed to miss critical risk factors. Worse, you'll end up designing controls that are impractical, get ignored, or simply don't work.

Poor Documentation and Justification

WHS law is very clear: you must work your way down the hierarchy. This means if you decide to skip a higher-level control like elimination or engineering, you have to be able to document why it wasn't reasonably practicable to implement it.

Many businesses fail on this front. They’ll pick a lower-level control without creating any record of their decision-making process. This failure to document can become a massive compliance headache during an audit or after an incident, as it suggests the hierarchy wasn't properly considered.

Confusing Admin Controls with Physical Barriers

Sticking up a sign is an administrative control, not a physical one. A "Hearing Protection Required" sign is far less effective than installing sound-dampening panels (an engineering control) that physically reduce the noise at its source.

Relying on signs, procedures, or training alone is a weak strategy because it depends entirely on someone seeing the sign, remembering the rule, and then following it. A physical barrier, on the other hand, works 24/7 without anyone having to do a thing. Whenever you have the choice, always favour a physical solution over a procedural one.

Managing Your Controls with a Digital Platform

Trying to manage the hierarchy of control with paper forms, emails, and confusing spreadsheets is a nightmare. Documentation gets lost, risk assessments go stale, and getting a clear, real-time picture of what’s actually happening across your worksites is impossible. This administrative mess doesn't just waste time; it creates dangerous gaps in your safety system.

A digital platform helps you move from reactive paperwork to proactive safety management. When all your WHS information is in one central spot, everything gets easier, from tracking risk assessments to pulling up records during an audit.

Centralise Your Safety System

Instead of digging through filing cabinets or searching through email chains, a digital tool gives you instant access to every Safe Work Method Statement (SWMS), inspection report, and training record. This creates a single source of truth for your entire operation.

When an incident occurs or a new hazard is spotted, the information is captured on the spot and is immediately visible to managers. This means faster responses and smarter decisions, ensuring controls are reviewed and updated without delay. A digital system gives you the solid foundation you need to manage risk properly.

By digitising your WHS processes, you create a clear, auditable trail of how you're applying the hierarchy of control. This isn't just about ticking a compliance box; it's about having the visibility to know your controls are actually working in the field.

Improve Tracking and Accountability

Digital platforms are built to make the review and implementation steps of the hierarchy more robust. You can assign corrective actions to specific people, set deadlines, and track their completion automatically. It builds accountability right into your process, making sure nothing falls through the cracks.

Here’s how that works in practice:

- Real-time Monitoring: Get live updates from the site, allowing you to see if controls are in place and working as they should be, without having to be physically there.

- Automated Reporting: Generate compliance and performance reports in minutes, not hours. This data helps you spot trends and identify recurring problem areas that need higher-level controls.

- Simplified Audits: When a regulator asks for documentation, you can provide a complete, organised record of your risk management process with just a few clicks.

Ultimately, a platform with dedicated risk control software helps cut down on human error and gives you a clear, accurate overview of your safety performance. This shift from manual work to a smarter, digital approach is key to managing the hierarchy of control whs effectively in any modern workplace.

Common Questions About the Hierarchy of Control WHS

Even with a perfect plan on paper, questions always pop up when you try to apply the hierarchy of control WHS in the real world. Let’s tackle some of the most common ones we hear from managers and business owners.

Are We Legally Required to Eliminate Every Single Risk?

No, the law doesn’t demand the impossible. Your duty is to eliminate or minimise risks ‘so far as is reasonably practicable’. What this means in practice is that you must start at the top of the hierarchy and justify every step you take down.

If you can’t completely eliminate a risk, you need to look at substitution, then isolation, and so on. It's crucial to document why a higher-level control wasn’t practical before you settle on a lower-level one like PPE. It’s all about having a clear, defensible process.

What if the Most Effective Control Is Too Expensive?

Cost is a real-world factor, and the law recognises that. It’s a valid part of the ‘reasonably practicable’ assessment, but it can't be your only reason for skipping a control, especially when the risk is high. It’s a balancing act between the cost of the control and the potential harm to your workers.

Think of it this way: a high probability of a serious injury or fatality will almost always justify a significant expense for a better control. Regulators expect to see a proper cost-benefit analysis where worker safety is the priority, not just a line item on the budget.

Can We Just Use PPE if Everyone Is Trained Properly?

This is a common one, but the short answer is no. Relying solely on PPE is the least effective option and is highly unlikely to meet your legal duties under WHS law if better, more practical controls are available.

PPE's effectiveness hangs entirely on people using it correctly, every single time, without fail. It gets damaged, it might not fit properly, and it does absolutely nothing to remove the actual hazard from the workplace. It should always be your last resort, often used to protect workers from any leftover risk after you’ve put higher-level controls in place.

Trying to manage these complex decisions with spreadsheets and overflowing binders is a recipe for things getting missed. Safety Space provides a single platform to track your hazards, document your control decisions, and create a clear, auditable record of your WHS compliance. Learn how you can simplify your safety management at https://safetyspace.co.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.