An incident management procedure is your playbook for when things go wrong. It’s a documented, step-by-step plan that guides your team through responding to unexpected workplace events. The goal is to get everyone from the initial alert through to resolution and recovery with a consistent, effective approach every time. Think of it as having your game plan sorted before the whistle blows.

Why a Documented Procedure Is Not Negotiable

When an incident hits, chaos is your biggest enemy. Without a clear plan, your team is left guessing, communication falls apart, and small problems can quickly snowball into major shutdowns. A solid incident management procedure is what replaces that panic with a structured, predictable response.

For any industrial workplace, like a manufacturing plant or a construction site, the stakes are high. A single machine failure can bring an entire production line to a halt, costing thousands of dollars for every minute of lost output.

From Chaos to Control: A Real-World Scenario

Let’s picture it. A critical hydraulic press on your factory floor suddenly dies during a peak production run.

Without a procedure: The operator panics. Who do they call first? They try their direct supervisor, who’s tied up in a meeting. Maintenance eventually gets a vague report about a "broken machine" ten minutes later. By the time the right technician even shows up, precious time has been lost, and the production backlog is piling up.

With a procedure: The operator immediately follows the checklist posted at their station. They use a dedicated comms channel to alert the on-call maintenance lead and shift supervisor at the same time, giving them a specific machine ID and error code. The procedure automatically triggers an alert to the supply chain manager to adjust the raw material flow. The response is instant, coordinated, and completely under control.

The difference isn't about how skilled the team is; it's the quality of their plan. A documented procedure gives them the framework they need to act decisively under pressure, turning a potential disaster into just another managed event.

Key Benefits of a Formal Procedure

Having a formal plan is about more than just faster fixes. It delivers a few core advantages that directly protect your operations and your bottom line.

- Reduced Downtime: A clear process means you can detect, diagnose, and resolve issues much faster, getting operations back online with minimal delay.

- Consistent Responses: Everyone follows the same script. This eliminates guesswork and ensures no critical steps get missed in the heat of the moment.

- Improved Communication: The procedure clearly defines who gets told what and when, keeping all the key stakeholders in the loop and cutting out confusion.

- Easier Post-Incident Analysis: When you have a documented process, it’s far simpler to review what went down, pinpoint the root causes, and make smart improvements to stop it from happening again. To get the bigger picture, it helps to look at resources that outline a comprehensive incident response plan.

At the end of the day, your procedure is the foundation of your operational resilience. A well-designed plan is a must, but it needs to be backed by the right tools. Find out more about how a modern incident management system can bring your procedures to life and make them work in the real world.

Getting Your Incident Response Team in Place

A procedure is only as good as the people who use it. When things go sideways, you need a dedicated crew, an Incident Management Support Team (IMST), who can execute the plan under pressure.

This isn't a job for senior managers sitting in an office. It requires practical input from the people who know the equipment, the processes, and the real-world challenges of your worksite.

Building this team isn't about just adding names to a list. It’s about assigning clear, practical responsibilities before an incident ever happens. That way, everyone knows their exact role, who to report to, and what decisions they're authorised to make without a second thought.

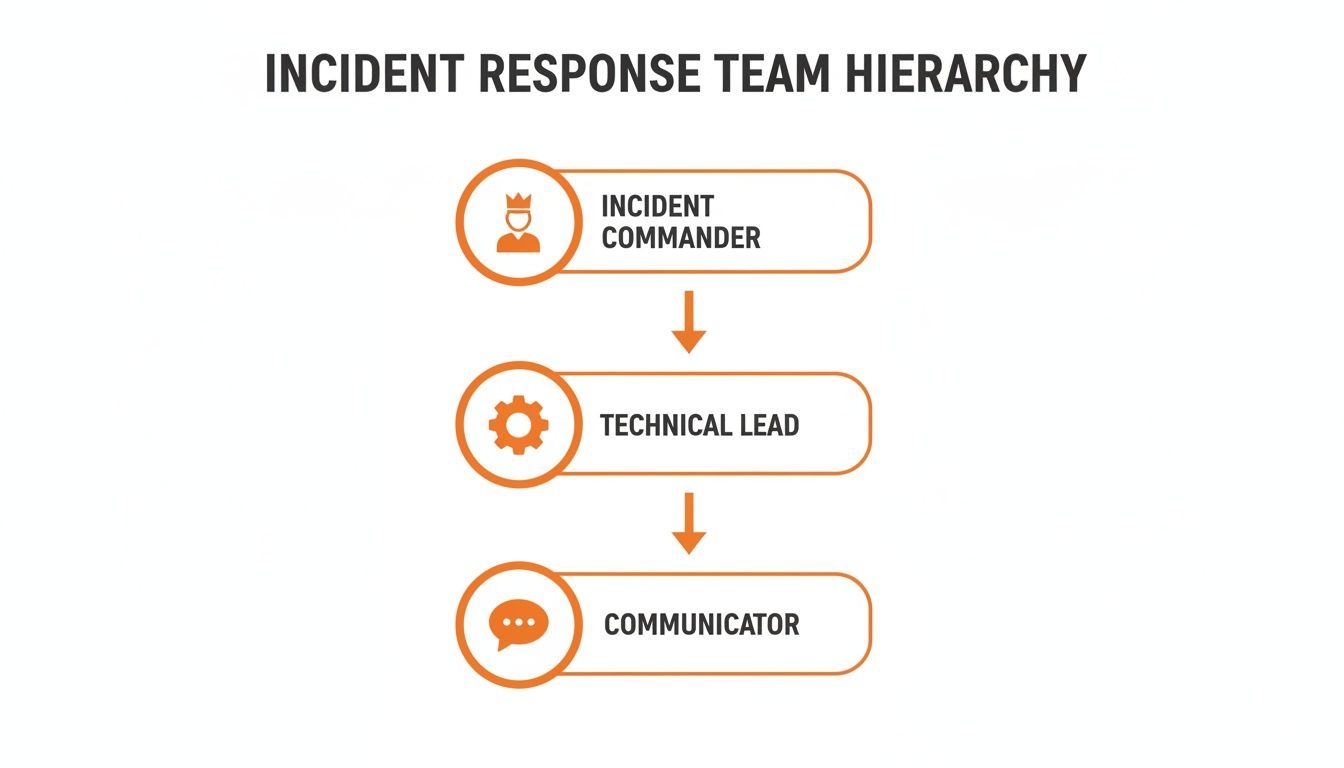

Defining Key Roles for a Crisis

Your team structure needs to be simple and functional. The last thing you want is a complex hierarchy that slows things down when every second counts. The goal is rapid, coordinated action.

Here are the essential roles you need to fill:

- Incident Commander: This person is the quarterback. They are the single point of contact who directs the response, allocates resources, and makes the final call on critical decisions. They don’t necessarily fix the problem themselves, but they manage the people who do.

- Technical Leads: These are your subject matter experts from the shop floor or the site. This could be a lead mechanic for a machinery failure, an IT specialist for a network outage, or a structural engineer on a construction project. Their job is to diagnose and resolve the technical side of the incident.

- Communications Lead: This person manages the flow of information. They keep internal teams updated, handle any necessary external notifications to clients or regulators, and make sure everyone is working from the same script. This is crucial for preventing misinformation and confusion.

Assigning these roles ahead of time removes the 'who's in charge?' question that cripples so many initial responses. When an incident occurs, people should immediately know their job and get to it.

This team-based approach has been proven effective on a massive scale. For example, the Africa CDC and the World Health Organization co-led an IMST that acted as the nerve centre for information sharing and on-the-ground support during a major health crisis. It shows how a structured team can manage a complex, continent-wide event. You can learn more about how their coordinated incident management worked in practice.

A Construction Site Scenario

Let's make this real. Imagine a crane malfunctions on a busy construction site, dropping a load of materials from a low height. With a pre-defined IMST, the response is immediate and organised.

The site foreman, assigned as the Incident Commander, immediately secures the area and confirms no one is injured.

They contact the Technical Lead (the head rigger or crane mechanic) to assess the equipment. At the same time, the Communications Lead (the project administrator) informs the project manager and logs the initial report.

Because the roles were already defined, there was no confusion. The commander directed the response, the technical expert diagnosed the mechanical failure, and the communicator kept key stakeholders informed.

This structure contained what could have been a chaotic and dangerous situation in minutes, turning it into a manageable operational problem. A clear incident management procedure, supported by a well-defined team, is what makes that difference.

The Four Phases of Managing an Incident

A solid incident management procedure isn’t a single action; it’s a lifecycle. When you break it down into four distinct phases, you give your team a repeatable framework that works for any type of incident, from a minor equipment fault to a major plant shutdown.

This approach strips out the guesswork and builds a consistent, controlled response. Getting one phase right makes the next one easier. Let's walk through them with practical examples from a manufacturing floor.

Phase 1: Preparation

This is all the work you do before something goes wrong. Good preparation is what separates a smooth, professional response from a frantic scramble. It’s about having the right tools, training, and information ready to go at a moment's notice.

Your preparation checklist should cover:

- Clear Roles and Responsibilities: Everyone on the Incident Management Support Team (IMST) must know their job. Who is the Incident Commander for each shift? Who are the designated technical experts for the critical machinery?

- Accessible Documentation: Are your checklists and contact lists available right where they're needed, not buried in a filing cabinet somewhere? This could be a laminated card at a machine station or a quick link on a workshop tablet.

- Regular Drills: Run simple, unannounced drills. For instance, simulate a coolant leak from a CNC machine and watch how the team responds. This is the fastest way to find the gaps in your procedure.

Think of it like a fire drill. You don't wait for a fire to figure out where the exits are. The same logic applies here.

Phase 2: Detection and Analysis

This phase kicks in the second an incident is identified. The goals are simple: speed and accuracy. You need to quickly understand what's happening, how serious it is, and what the immediate impact might be.

This is where a priority classification system is absolutely essential. Not all incidents are created equal, and a simple system helps your team allocate resources effectively instead of treating everything like a five-alarm fire.

Incident Priority Level Examples

To help your teams classify incidents quickly and get the right resources moving, a simple table like this can be a lifesaver. It takes the ambiguity out of the initial response.

| Priority Level | Example Scenario (Manufacturing) | Required Initial Action |

|---|---|---|

| P1 - Critical | A key assembly line conveyor belt snaps during peak production. | Immediate all-hands response. Halt upstream processes. Notify plant manager. |

| P2 - High | A secondary packaging machine is malfunctioning, causing intermittent errors. | Assign dedicated technician within 15 minutes. Reroute product if possible. |

| P3 - Medium | A non-critical sensor on a storage tank is reporting faulty data. | Create a work order for the next available maintenance slot. No immediate action needed. |

| P4 - Low | The light bulb in a storeroom has burnt out. | Add to the weekly maintenance task list. |

Having this guide removes hesitation. Once an incident is detected and its priority is set, the real analysis begins. What exactly failed? What other systems are affected? This early information gathering is critical for what comes next.

Phase 3: Containment and Resolution

Now the team moves to stop the problem from getting worse and then to fix it.

Containment is about isolating the issue. For a chemical spill, it means deploying containment booms. For a machine failure, it might mean shutting down power and diverting production to another line.

Resolution is the fix itself. This is where the technical lead directs the repair, whether that’s replacing a broken part or recalibrating a complex system. Throughout this phase, the Communications Lead keeps everyone in the loop with regular, simple updates.

Here’s a common and effective hierarchy for the incident response team.

This structure ensures that one person (the Commander) directs the overall response, leaving the specialists to focus on their specific tasks without distraction.

Phase 4: Post-Incident Review

The job isn't over just because the machine is back online. This final phase is about learning, with the goal of understanding the root cause and identifying actions to prevent it from happening again.

This review has to be blameless. The focus is on fixing systems, not pointing fingers at people. A successful review makes the entire organisation stronger.

You need to be asking the right questions:

- What was the true impact on production numbers and delivery schedules?

- What parts of our procedure worked well? Where did we do a good job?

- Where were the communication breakdowns or delays?

- What specific, actionable changes can we make to prevent this exact issue in the future?

This continuous improvement loop turns every incident into an opportunity to strengthen your operations. To support this process, many organisations use specialised tools. You can learn more about how incident management software helps track events from detection right through to post-incident review and action tracking.

Getting Your Procedure Down on Paper (and into People's Hands)

An incident management procedure that only exists in your head or in a dusty binder on a shelf is useless when things go wrong. For your plan to work, it needs to be written down clearly and shared with every person who might need it. The goal here is practicality, not a 50-page novel nobody will read.

Think less about writing a dense manual and more about creating quick-reference tools. Simple flowcharts for decision-making and straightforward checklists for immediate actions are your best friends. A laminated, one-page checklist zip-tied to a piece of machinery is more effective than a detailed document buried on a shared drive.

Making Your Procedure Easy to Find and Use

When an incident kicks off, your team needs to find and follow the procedure in seconds, not minutes. This means putting the information where your people actually work.

Your documentation strategy should be practical and built for the real world:

- Visual Aids: Create simple flowcharts that map out the "if this, then that" steps. Visuals are much easier to process under pressure than a wall of text.

- Actionable Checklists: Build role-specific checklists. What an operator needs to do is different from a maintenance technician's first steps, and both are different from what the Incident Commander needs to focus on.

- A Central Digital Hub: While physical copies are crucial for the shop floor, you also need a single, easy-to-find digital location for all updated documents. This is key to preventing people from accidentally using an outdated version.

A procedure isn't just a document; it's a tool. If your team can't pick it up and use it immediately during a high-stress event, then the tool isn't fit for purpose.

Creating a Communication Plan That Actually Works

In a crisis, communication is almost always the first thing to break down. Your procedure must outline exactly how information flows, both inside the response team and to the outside world. This means defining clear channels and responsibilities before you need them.

For internal updates, set up a primary channel, like a specific radio frequency or a dedicated messaging group, to keep the response team and key stakeholders in the loop without creating a lot of noise. This simple step helps prevent conflicting information and keeps everyone on the same page.

You can see the power of strong communication plans in large-scale operations. For instance, the coordinated mpox outbreak response across AU member states, led by the African CDC and WHO, relied on daily briefings to help teams make real-time adjustments across multiple countries. This systematic communication was a big part of the program's success. You can read more about this joint continental plan.

For any external communication with clients or stakeholders, you need a single, designated point of contact. This is non-negotiable. It ensures your messaging stays consistent, accurate, and controlled.

Finally, a critical part of documenting your procedure is having the right forms ready to go. To get a clear idea of how to structure your reports for clarity and compliance, take a look at this helpful incident reporting sample.

Learning and Improving After an Incident

The incident might be over, but the work isn't finished. The most critical part of any incident management procedure is what you do after the dust settles. This is your chance to learn from what happened and make sure it doesn't happen again. It's how you shift from simply reacting to proactively strengthening your entire operation.

This debriefing session is often called a 'post-mortem' or a post-incident review. The whole point is to dig into what happened, figure out why it happened, and identify concrete actions you can take to prevent a repeat performance.

There's one golden rule here: these reviews must be completely blameless. We’re not looking to point fingers at people. The focus has to be on finding weak spots in your systems, processes, or equipment.

Running a Blameless Post-Incident Review

A productive review is sharp, structured, and gets straight to the point. You want to walk out of that meeting with a clear list of actions, each with an owner and a due date. If the meeting devolves into blaming people, they’ll just hide information next time, and that’s the last thing you want.

To keep the conversation on track, it helps to stick to a few simple questions:

- What was the actual impact? Get specific. Quantify the downtime, production loss, or cost.

- What went well during the response? Don't forget to acknowledge what worked. Which parts of your procedure held up under pressure?

- What could we do better next time? This is where you pinpoint communication gaps, delays, or confusion.

- What was the root cause? Keep asking "why" until you get past the surface-level symptoms and find the real underlying issue.

This review process is the engine of continuous improvement. It's how you build a more resilient organisation over time, turning every incident into a valuable lesson.

From Review to Action

Nailing down the root cause is only half the battle. The next step is turning those findings into effective corrective actions to prevent the incident from recurring. This mirrors the systematic approach to corrective action used in formal management systems. It means assigning clear, tangible tasks to fix the problems you found.

This structured response isn't just for workplaces; it's used globally to manage complex events. Take the response to a cholera outbreak, where African leaders used a coordinated procedure involving task forces, improved surveillance, and strict accountability. This approach led to a 25% improvement in case reporting speed. You can discover more about their coordinated response.

It’s a powerful example of how a formal process of review and action delivers measurable results, turning good intentions into real-world improvements.

Got Questions About Your Incident Management Procedure?

Even with the best-laid plans, questions always pop up once you start putting an incident management procedure into practice. Let's walk through some of the most common ones we hear from teams on the ground. Getting these sorted helps everyone understand what to do and, just as importantly, why they're doing it.

How Often Should We Be Updating Our Procedure?

Look, your incident management procedure isn't a "set and forget" document. It has to be a living thing that changes with your business.

As a minimum, you should be giving it a full review at least once a year. But the real trigger for an update is change. Any time something significant happens, it's time for a refresh.

Think about triggers like these:

- After a major incident: This is a no-brainer. Your post-incident review will uncover gaps or better ways of doing things. Get those lessons learned into the procedure immediately.

- New gear or processes: Just installed a new production line or changed a critical workflow? Your procedure needs to reflect that new reality.

- People changes: If key people on your Incident Management Support Team move on or change roles, you need to update contact lists and responsibilities right away.

We’re a Small Company. Do We Really Need All This?

Yes, absolutely. In fact, a small business can be hit even harder by an incident than a huge corporation. Why? Because you have less of a buffer: fewer resources, less cash flow, and not as many people to absorb the impact. A single machine breakdown can bring a small workshop to its knees.

But "formal procedure" doesn't have to mean a 100-page binder collecting dust on a shelf. For a small business, it could be a simple one-page flowchart and a crystal-clear contact list. The goal isn't bureaucracy; it's clarity.

The aim is the same regardless of your size: have a clear, structured response ready to go that minimises downtime and stops a bad situation from getting worse.

An incident’s impact isn’t relative to your company's size; it’s relative to your company's ability to recover. A simple plan gives a small business the structure it needs to manage a crisis effectively.

What’s the Difference Between an "Incident" and a "Crisis"?

This is a really important distinction to get right.

An incident is an event that messes with your normal day-to-day operations but can be managed using your standard procedures and the resources you have on hand. A single machine failing on the production line is a perfect example of an incident. It's a problem, but a manageable one.

A crisis, on the other hand, is when an incident escalates beyond your ability to handle it with routine measures. It's a genuine threat to the business itself. Think of a major factory fire or a catastrophic structural failure on a construction site.

Your incident management procedure is your first line of defence. It’s designed to handle incidents so effectively that they never have a chance to become crises. It's all about stopping small problems from spiralling out of control.

Still managing your incident procedures with paper forms and messy spreadsheets? That's a recipe for confusion and critical delays when things go wrong. Safety Space replaces that outdated system with a simple, all-in-one platform that makes it easy to document, communicate, and track your response to any workplace event. Book a free demo today and see how you can build a safer, more efficient workplace.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.