An incident management system is your single source of truth for tracking, reporting, and resolving workplace health and safety issues. It's designed to pull you out of the messy world of scattered paperwork and confusing spreadsheets, giving you a clear, organised hub for everything from near misses to serious injuries.

What an Incident Management System Actually Does

Think of it like this: managing safety without a proper system is like trying to run an airport's air traffic control with handwritten notes and disconnected radio calls. It’s chaotic, inefficient, and you only find out about problems after they happen. Each plane, or in our case, each incident report, is flying blind.

An incident management system acts as that central control tower. It gets every piece of safety information onto one radar screen. A near-miss report from the factory floor, a hazard spotted on a construction site, a minor injury in the warehouse, it all feeds into the same place. This is what shifts your approach from being purely reactive to genuinely proactive.

From Paperwork to Practical Action

We've all seen the old way of doing things. It's a jumble of paper forms, endless email chains, and spreadsheets that are impossible to make sense of. This approach is fundamentally broken.

- Information gets lost. Paper reports vanish, and finding specific data in a spreadsheet is a nightmare.

- Responses are slow. A report has to physically move from the person who filed it to the manager who needs to act, causing critical delays.

- You get no real insight. You might be collecting reports, but you can’t see the patterns. You don't know which problems are cropping up again and again.

A digital system cuts through that noise. It creates a direct line of communication. A worker on-site can spot an unsecured ladder, snap a photo with their phone, and report it instantly. The right manager gets an alert immediately and can assign someone to fix it. Simple as that.

This isn't just about convenience. This digital record-keeping is a key part of modern safety management. It gives you a clear, time-stamped log of every issue, its investigation, and the actions taken. For demonstrating due diligence, that kind of evidence is invaluable.

The table below breaks down the real-world differences between sticking with manual methods and adopting a modern system.

Manual vs. System-Based Incident Management

| Aspect | Manual Reporting (Paper/Spreadsheets) | Incident Management System |

|---|---|---|

| Reporting Speed | Slow and delayed. Relies on paperwork being physically handed in. | Instant. Reports are submitted in real-time via mobile devices. |

| Data Visibility | Fragmented. Information is siloed in different files or binders. | Centralised. All data is in one dashboard, visible to relevant staff. |

| Trend Analysis | Almost impossible. Requires manually sorting and collating data. | Automated. The system flags recurring issues and identifies patterns. |

| Accountability | Unclear. Hard to track who is responsible for what and when. | Clear. Tasks are assigned to specific people with due dates. |

| Audit Trail | Messy and incomplete. Paperwork can get lost or altered easily. | Robust. Creates a secure, time-stamped digital record of all actions. |

| Accessibility | Limited to the office. Can't be accessed easily from the field. | Accessible anywhere. Fieldworkers and managers can access from any device. |

As you can see, the shift isn't just about going digital. It's about building a smarter, more responsive safety process from the ground up.

A Central Hub for All Safety Information

The real value of an incident management system is its ability to connect the dots. It brings hazard reports, incident logs, and corrective actions together. Instead of being treated as separate events, they’re linked.

For example, if several near-miss reports are filed about the same faulty machine, the system makes that pattern impossible to ignore. This prompts you to address the root cause, maybe by scheduling new training or replacing the equipment, long before a serious injury occurs.

This structured, accountable approach is fast becoming a standard requirement. In Australian aged care, for instance, having a formal system is essential for protecting vulnerable people by ensuring every incident is documented and learned from. You can find out more about these requirements from the Aged Care Quality and Safety Commission. The exact same principle applies to high-risk industries like manufacturing and construction, where staying ahead of risks is the only way to keep teams safe and operations running smoothly.

How a System Helps with H&S Compliance

Let's be blunt: beyond just making day-to-day operations smoother, a modern incident management system is critical for meeting your health and safety (H&S) compliance obligations in Australia. It shifts your record-keeping from a reactive, paper-shuffling nightmare into a proactive, organised process. And that’s exactly what regulators want to see.

The biggest compliance win is the creation of a rock-solid, auditable trail. Every report, every investigation, and every single corrective action is logged in one central hub. This isn't just a list; it's a complete, time-stamped history of how your organisation actually responds to risk.

Proving Due Diligence During Inspections

Picture this: a WorkSafe inspector turns up on your site. They start asking questions about a hazard that was reported three months ago involving a piece of machinery. Without a system, you’re scrambling, digging through old emails, messy spreadsheets, and piles of paper forms. It's slow, stressful, and it screams disorganisation.

Now, imagine that same scenario with an incident management system. The experience couldn't be more different. You can pull up the entire record in seconds. The inspector can see it all, clear as day:

- Initial Report: The exact date and time the hazard was first flagged, including any photos a worker snapped on their phone.

- Investigation: Who was assigned to look into it, what their root cause analysis found, and how they reached that conclusion.

- Actions Taken: The specific fixes assigned, who was responsible for them, and the date they were completed.

- Closure: A clear confirmation that the problem was solved and the hazard was properly controlled.

This kind of structured data is concrete proof that you're exercising due diligence. It shows you have a reliable, repeatable process for identifying and managing risks, a core requirement under Australian WHS laws. The system becomes your evidence, demonstrating a serious, ongoing commitment to safety.

Managing Claims and Reducing Legal Risk

A robust incident management system also plays a huge part in managing workers' compensation claims and minimising your legal liability. When an incident does happen, the system provides an immediate, factual record of events. This time-stamped evidence is absolutely crucial.

Think about it: if a dispute ever arises over the circumstances of an injury, your system holds the original report, witness statements, and investigation findings, all logged before memories get fuzzy. That clarity can be the deciding factor in a claim.

This centralised data helps you get on the front foot with legal and financial risks. It’s not just about defending against claims; it’s about preventing the incidents that lead to them in the first place. The system gives you the hard data needed to spot weak points in your safety procedures before they result in costly downtime or, worse, a serious injury.

This is a key function of broader safety frameworks. To see how these pieces fit together, you can learn more about how a comprehensive health and safety management software builds a stronger, more compliant workplace.

From Checking a Box to Actively Managing Risk

At the end of the day, using an incident management system for compliance isn’t about just ticking a box. It’s about fundamentally changing your relationship with risk. Manual, paper-based systems almost always lead to a "file and forget" mentality, where reports are collected but never really acted on.

A digital system makes it impossible to ignore what needs to be done. Open tasks, overdue investigations, and recurring incidents are flagged automatically on dashboards for everyone to see. This drives accountability and ensures that risks are managed from the moment they're identified right through to resolution.

This active management is what regulators look for, and it’s what truly protects your workers and your business. By providing this level of real-time oversight, the system helps you build a more resilient and legally sound operation.

Key Features for Your Incident Management System

Choosing the right incident management system can feel like a deep dive into an endless, technical list of features. But it doesn't have to be. Let's think about this practically. For high-risk places like construction sites and factory floors, the best systems are built around how your teams actually work, not how a software developer thinks they should.

The real goal isn't just to tick a box and buy some software. It's about getting a tool that makes finding and fixing problems faster and easier for every single person involved. We can break down the most important capabilities into three core jobs: reporting issues on the ground, figuring out why they happened, and making sure they get fixed automatically.

On-Site Reporting Tools

The entire incident management process lives or dies with that first report. If that initial step is slow, clunky, or just plain difficult, your system is dead in the water before it even starts. The key is making it so ridiculously simple that a worker can flag an issue in under a minute, right from where they’re standing.

Mobile Access is Non-Negotiable

Your crew isn't sitting behind desks. They’re out on factory floors, scattered across multi-level construction sites, or working in remote locations. Any system that forces someone to trek back to an office to fill out a paper form is already a relic.

For on-site reporting to actually work, the system has to be completely functional on a phone or tablet. A worker needs to be able to:

- Instantly log a hazard or near miss the second they spot it.

- Attach photos or videos straight from their device to show exactly what the problem is. A quick photo of a frayed electrical cord or an unsecured scaffold tells a much better story than a form ever could.

- Use GPS to automatically tag the location of the incident, eliminating any guesswork about where the issue is.

This kind of immediate, media-rich reporting gives managers a crystal-clear view of the situation without having to leave their office, paving the way for a much faster and more accurate response.

The easier you make it for your team to report a problem, the more likely they are to actually do it. We've seen that user-friendly digital systems can cut reporting time from over 30 minutes with paper forms to less than two minutes on a mobile device.

Customisable Forms and Workflows

Let's face it, your business has its own unique processes, language, and risk profile. A one-size-fits-all system that forces you to change how you work to fit the software is a recipe for disaster.

A top-tier system gives you deep customisation. You need the flexibility to:

- Build your own forms with drag-and-drop tools that mirror the paper forms your team is already familiar with.

- Define your own workflows so reports are instantly routed to the right people. For example, an electrical hazard report should ping the maintenance supervisor directly, not get lost in a general inbox.

- Use your company's language, making sure everyone understands the fields and terminology without needing a dictionary or extra training.

This kind of adaptability ensures the system moulds to your business, not the other way around. It makes adoption infinitely smoother because it feels familiar to your team right out of the gate.

Investigation and Analysis Tools

Once an incident is logged, the next job is to understand what happened and, more importantly, why. This is where your incident management system grows from a simple logging tool into an active part of your risk management strategy. The goal here is to get to the root cause, not just slap a bandage on the symptom.

A solid system gives you built-in tools to guide this process. Look for features like root cause analysis (RCA) templates, such as the "5 Whys" or fishbone diagrams. These frameworks push your managers to dig deeper than just the surface-level explanation. So instead of just noting "worker slipped," the system prompts them to ask why, uncovering the real issue, like a leaky pipe that was never reported.

A central dashboard that visualises trends is also vital. It should automatically flag recurring issues, common incident types, or high-risk locations. When you can see that 70% of your near misses are happening in one specific part of the factory, the problem becomes impossible to ignore, and gives you the hard data to justify taking action.

Automated Actions and Alerts

Reporting and investigating are only useful if they lead to action. The final piece of a great incident management system is its power to automate the follow-up, creating clear and undeniable accountability.

You want a system that can:

- Automatically assign corrective actions to the right person or department based on the incident type and location.

- Send real-time alerts and reminders to make sure tasks don't fall through the cracks. If a fix is overdue, the system should automatically escalate it to a manager.

- Provide a transparent view of all open actions, including who is responsible and the due date.

This automation is what closes the loop. It ensures every single reported incident results in a documented action, giving you peace of mind that risks are being systematically controlled across the entire organisation.

A Step-by-Step System Implementation Plan

Bringing in a new incident management system isn’t just an IT project; it’s about changing how your team operates for the better. A solid plan is what separates a smooth, successful transition from a frustrating, disruptive one. Breaking the process down into four clear stages, planning, setup, training, and launch, makes it far more manageable and sets you up for a win.

The first, and most crucial, step is always planning. This is where you map out what you actually need the system to do and, just as importantly, get the right people on your side. You absolutely need buy-in from both senior management and the crews who will be using it day in, day out. For managers, the conversation is about compliance and reducing risk. For your field teams, focus on the real-world benefits: no more lost paperwork, quicker responses to hazards, and way less time wasted on admin.

A common roadblock is the assumption that new software just means more work. You need to frame this as a solution to existing headaches. Show them how a good system actually reduces their admin load, freeing them up to focus on their actual jobs, not just filling out forms.

Stage 1: Gaining Support and Setting Goals

Before you even glance at a single software demo, you need crystal-clear objectives. What specific problems are you trying to fix? Are you aiming to cut incident response times by a certain percentage, or is the main goal to finally get reliable data on near misses?

To get the project moving, find your champions within the organisation. You'll need a senior manager who can fight for the budget and a respected supervisor on the floor who can win over their peers. Put together a clear business case that focuses on tangible results, like fixing issues faster and nailing your safety compliance.

Stage 2: System Setup and Data Migration

Once your plan is solid, it's time for the technical part. This means configuring the software to match your company’s unique workflows. A good incident management system should let you customise forms, approval chains, and user permissions without needing a developer. The goal is to make the digital system feel like a smarter, faster version of your proven processes.

This stage is also when you have to tackle data migration, and honestly, moving information from old spreadsheets or paper files is often the biggest headache. Be realistic here. Decide what historical data is truly essential and what can be archived. And a pro tip: clean up your existing data before you move it. There's no point importing old mistakes into your shiny new system.

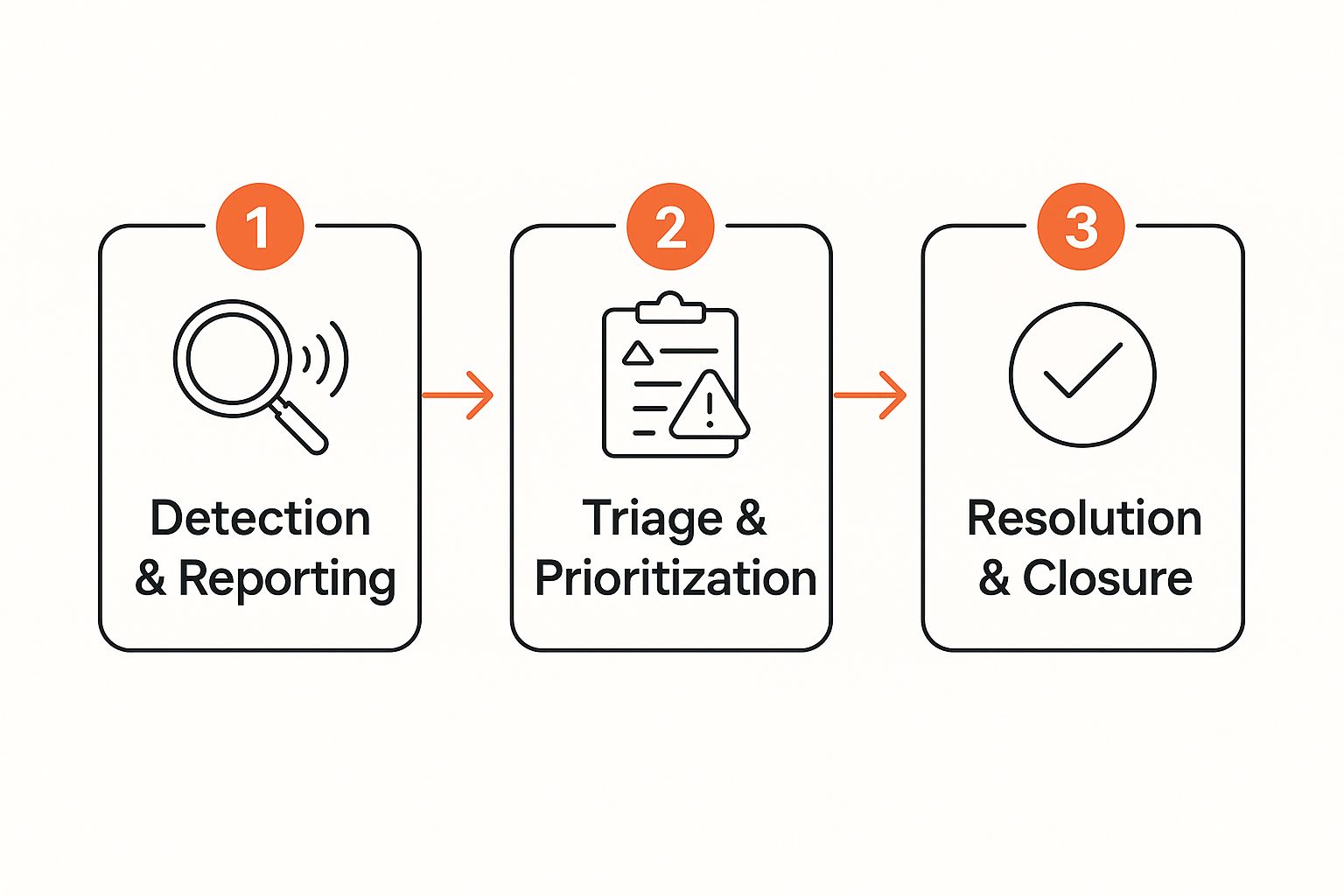

This is the simple, three-step process that sits at the heart of any effective incident management system.

This flow from detection to resolution shows how a structured system stops reports from getting lost and ensures every single issue is dealt with.

The problem of legacy systems isn't just an H&S issue. In IT incident management, for example, 48% of Australian executives say that having limited real-time data is a major risk. Research from PagerDuty also found that outdated tech (50%) and overly complex systems create massive problems, pushing staff towards manual workarounds (44%). It just reinforces the need for modern, integrated platforms that give you clear, immediate information.

Stage 3: Training and a Pilot Program

With the system configured, the focus shifts to your people. Your training needs to be practical and tailored to each role. A fieldworker needs to know how to log a hazard on their phone in under a minute. A manager needs to know how to assign corrective actions and check the dashboard for progress.

Before you go all-in, run a pilot program with a single, motivated team. This is your chance to test-drive the system in the real world and catch any issues on a small scale.

- Gather Feedback: Actively ask the pilot team what works and what’s clunky.

- Fix Problems: Address any confusing steps or technical glitches before the main launch.

- Build Success Stories: Use positive feedback from the pilot group to get other teams excited and show them the tangible benefits.

This controlled test is invaluable. It lets you iron out the kinks and builds confidence across the board, making the full launch go much, much smoother. To see how this fits into the bigger picture, our guide on building a complete safety management system provides more context.

Stage 4: Full Launch and Continuous Improvement

The final stage is going live. Communicate the launch date clearly and make sure everyone knows where to turn for support. For the first few weeks, have your project champions on hand to answer questions and help colleagues who might be struggling to adapt.

But implementation doesn't stop at launch. A great incident management system provides a constant stream of data you can use to fine-tune your safety processes. Regularly review the analytics to spot emerging trends and identify new areas for improvement. Think of the system not as a finished product, but as a living tool that evolves right alongside your business.

Calculating the Real-World ROI of Your System

Investing in any new business tool means you need to justify the spend, and an incident management system is no exception. You know it will improve safety and compliance, but management needs to see the cold, hard numbers. How does this system actually pay for itself?

The answer is all about calculating its return on investment (ROI). This isn't just one number; it breaks down into two key areas: hard savings and soft savings.

Hard ROI covers the direct, measurable financial wins. These are the figures you can confidently put on a spreadsheet and show the leadership team. Think about the big-ticket items that hit your bottom line year after year.

Soft ROI, on the other hand, is all about efficiency gains and risk avoidance. These benefits are just as valuable but can be a bit trickier to quantify. It’s things like a stronger safety program and the huge amount of time your team gets back when they ditch manual paperwork.

Uncovering the Hard ROI

The most direct financial benefits of an incident management system come from cutting the costs tied to workplace incidents. When you have a faster, more organised way to report, track, and resolve hazards, you start preventing incidents before they can even happen.

Here are the main areas where you’ll see concrete, bottom-line savings:

- Reduced Workers' Compensation Costs: It’s simple: fewer injuries lead to fewer claims. A system that helps you spot and fix recurring hazards can drastically cut down on the events that drive up your insurance premiums.

- Lower Insurance Premiums: Insurers love businesses that can prove they’re proactive about risk. An organised, digital system gives them clear evidence that you take safety seriously, which can often lead to better terms on your liability insurance.

- Less Operational Downtime: In manufacturing or construction, even a minor incident can grind a production line or an entire work area to a halt. A system that enables instant reporting and rapid resolution gets things back up and running much faster, saving you from eye-watering delays.

Think about the true cost of a single serious incident. It goes way beyond the immediate medical and compensation bills. You've got lost productivity, potential equipment damage, and the massive time sink of investigations and reporting. A good system is your best defence against these events ever occurring.

Identifying the Soft ROI

While it's not as easy to slot into a financial model, soft ROI has a massive impact on your business's health and day-to-day efficiency. It’s about giving time back to your most valuable asset: your people.

Just think about the hours your team currently burns on manual, paper-based reporting. A supervisor might spend 30-45 minutes filling out a single incident form, walking it to the office, and then making copies. A modern incident management system cuts that process down to just a few minutes on a mobile device, right there on the spot.

And the importance of good data capture can't be overstated. The volume of emergencies is on the rise, highlighting the urgent need for robust systems. In 2023-24, Australian fire services (excluding NSW) attended 452,292 incidents, a 15.5% increase since 2018-19. Yet, with only 23.8% of accidental residential fires having complete incident data, it's clear that better systems are needed to improve performance through data. You can explore the full government report on emergency services data.

A Framework for Estimating Your Savings

You don't need a complex financial degree to build your business case. Just start by asking a few straightforward questions about how you do things right now.

Time Saved on Admin:

- How many incidents or hazards do you report each month?

- How long does each one take to document and process by hand?

- What's the average hourly wage of the people stuck doing that paperwork?

Cost of Incidents:

- How many recordable injuries did you have last year?

- What was the average cost of a claim (factoring in downtime and admin)?

- What would a 10% or 20% reduction in these incidents save you?

Downtime Avoidance:

- How many times did operations stop last year because of a safety issue?

- How much revenue or productivity do you lose per hour of downtime?

Answering these questions will give you a solid, evidence-based estimate of the financial value an incident management system can bring to your organisation. This is how you transform the conversation from "it feels safer" to "it saves us money."

Common Questions About Incident Management Systems

When you're looking at moving to a dedicated incident management system, it's completely normal to have a few questions. Let's face it, switching from the old paper forms or spreadsheets you know inside-out to a new software platform is a big step.

We get it. Here are some straight-up answers to the most common questions we hear from businesses in construction, manufacturing, and other high-risk industries.

How Long Does System Implementation Take?

This is usually the first question on everyone's mind, and the honest answer is: it depends on the size and complexity of your business.

For a small to medium-sized company with pretty straightforward safety processes, you can generally expect to be up and running in 4 to 8 weeks. This window covers the initial setup, getting your reporting forms customised, and training your core team.

If you’re a larger company with multiple sites or a mountain of historical safety data to migrate, the process naturally takes a bit longer, typically somewhere between 3 to 6 months. A really smart way to speed things up is to kick off with a pilot program. By testing the system with just one team or in a single department, you can iron out any kinks on a smaller scale before rolling it out across the entire company.

Will My Workers Actually Use a New Software System?

Getting your team on board isn't just important, it's everything. And it's absolutely achievable if you nail the approach. Worker adoption really boils down to one critical factor: simplicity. The system has to be genuinely easy to use, especially on a mobile phone.

Think about it. If a worker on a busy construction site can snap a photo and report a hazard in under 60 seconds, they’re far more likely to do it. If the process is clunky or forces them to find a laptop, they'll either fall back to the old way or, worse, not report it at all.

But it’s not just about the tech. Success also hangs on clear communication from management. Don't just announce the new system; explain why you're bringing it in. Frame it around how it keeps them safer and, just as importantly, how it cuts down their paperwork.

The final piece of the puzzle is hands-on training that shows them the direct benefits. Once they see for themselves that it makes their job easier, buy-in will follow.

Can This System Connect to Our Other Software?

Yes, any modern incident management system worth its salt should be able to integrate with the other business software you're already using. This is a crucial feature you should be asking about when weighing up your options.

Common integrations include:

- HR Software: Syncing with your HR platform automatically keeps employee data up to date, making sure reports are always assigned to the right people without manual entry.

- Business Intelligence (BI) Tools: Connecting to tools like Power BI or Tableau lets you build custom safety dashboards and dive deeper into your incident data for powerful insights.

- Project Management Tools: Linking up with software like Procore or Asana helps align safety tasks directly with broader project schedules and milestones.

You'll want to look for a system that offers an open API (Application Programming Interface). An API is what gives you the flexibility to build custom connections to the specific mix of software your business relies on day-to-day.

What Is the Difference Between an Incident and a Near Miss?

This is a really common point of confusion, but the distinction is vital for creating a strong safety program.

An incident is any unplanned event that results in an injury, illness, or damage to property. A worker falling from a ladder and breaking their arm is a clear-cut incident.

A near miss, on the other hand, is an event that did not cause any harm, but easily could have under slightly different circumstances. For instance, if that same worker slipped on the ladder but managed to catch their balance and avoid the fall, that’s a near miss. Capturing these moments is incredibly valuable because they shine a light on risks before someone gets hurt.

We've got a more detailed breakdown in our complete guide explaining what is a near miss and why tracking them is a game-changer for proactive safety.

Ultimately, a good incident management system should make it simple for your team to report both, giving you a complete picture of workplace risks, not just the ones that end in a recordable injury.

Ready to see how a modern, user-friendly system can work for your business? The Safety Space platform is designed to simplify compliance and make safety management practical. Book a free demo to see how you can replace messy paperwork and get real-time oversight of your operations.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.