A Job Safety Analysis (JSA) is a practical tool for breaking down a job into its basic steps, identifying potential hazards at each point, and determining the safest way to complete the work. It moves safety planning from abstract ideas to concrete actions on the job site. This article gets straight to the point, providing six detailed job safety analysis sample documents that you can actually use. We won't just show you blank templates; we'll break down filled-in examples for common high-risk tasks.

Each sample is analyzed to show you what makes it effective and how to apply the same logic to your own procedures. Before diving into specific Job Safety Analysis samples, it's a good idea to understand the fundamental risk assessment principles that support all effective safety practices. This understanding ensures your JSAs are built on a solid foundation.

From construction scaffolding to chemical handling, these examples are designed to give you a clear, replicable framework. You'll learn how to identify critical steps, foresee realistic hazards, and implement practical controls that prevent incidents. Let's look at some real-world examples you can adapt for your workplace today.

1. Construction Site Scaffolding Installation JSA

Scaffolding work is one of the highest-risk activities on a construction site, making a specific and thorough Job Safety Analysis (JSA) non-negotiable. This type of JSA goes beyond generic safety checklists by breaking down the entire scaffolding erection and dismantling process into a sequence of distinct tasks. For each task, from unloading components to tying off the final structure, it identifies potential hazards and specifies the exact control measures needed to prevent incidents.

This detailed job safety analysis sample focuses on critical risks like falls from height, structural collapse from improper assembly, and electrocution from nearby power lines. By forcing a step-by-step review, it makes sure that supervisors and workers think through the entire process before work begins, rather than reacting to problems as they happen.

Successful Implementation

- Turner Construction reported a 65% reduction in scaffolding-related incidents after implementing a detailed, task-specific JSA program.

- Skanska USA equips its crews with digital JSA tablets, allowing for real-time updates and verifications on-site, which is particularly useful for complex or multi-phase scaffolding builds.

- Bechtel Corporation standardizes its scaffolding JSA across massive infrastructure projects, ensuring consistent safety protocols regardless of location or crew.

Actionable Tips for Your JSA

- Involve experienced scaffolders: The workers who do the job every day have the most practical knowledge. Involve them directly in developing the JSA to identify realistic hazards and effective controls.

- Use visual aids: For complex assembly steps, include diagrams or photos directly in the JSA document. A simple picture showing the correct placement of bracing can prevent a critical assembly error.

- Conduct pre-start toolbox talks: Before each shift begins, use the JSA as the agenda for a brief meeting. Review the day's specific tasks, hazards, and controls to make sure everyone is on the same page.

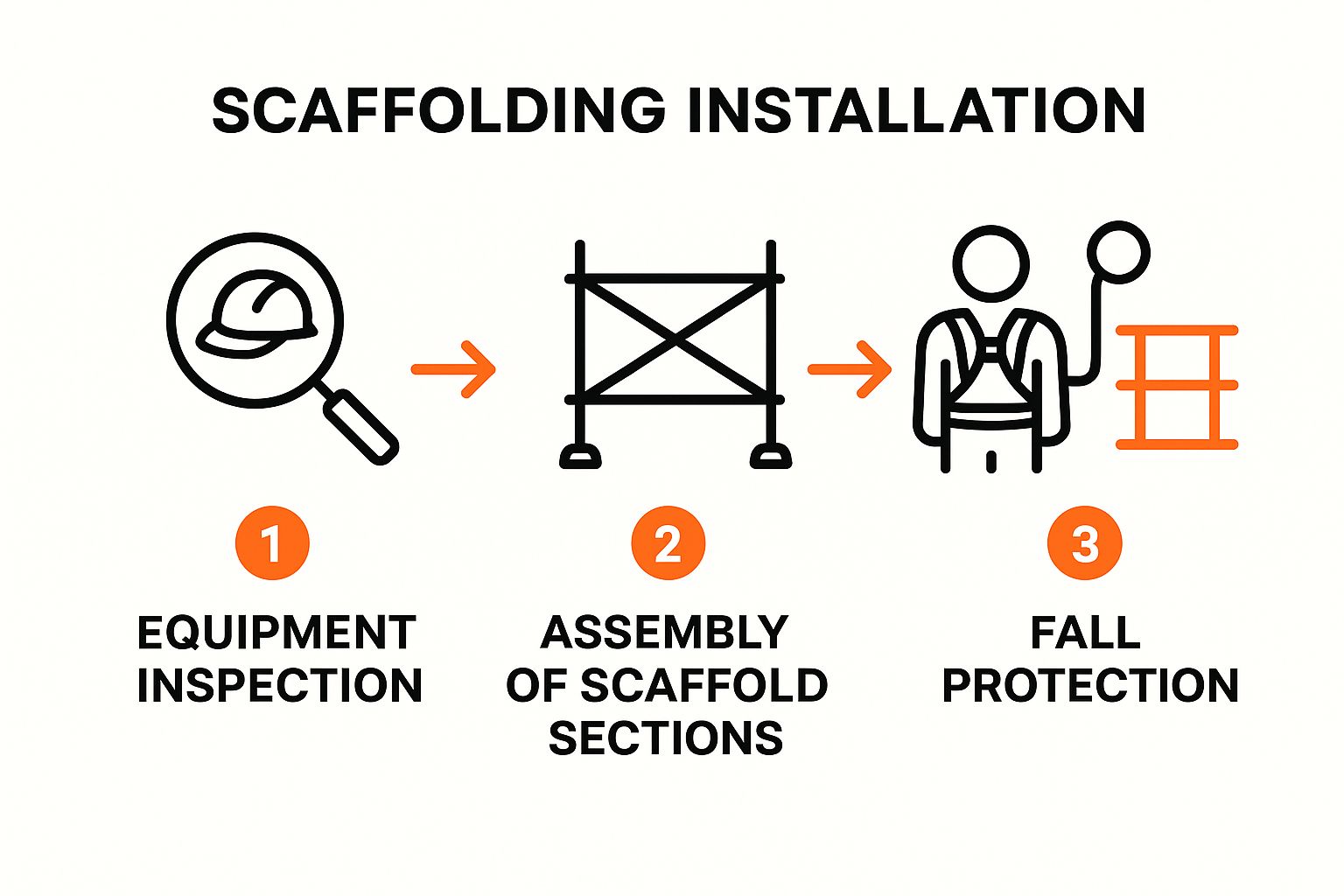

The JSA process for scaffolding follows a clear, logical progression to make sure safety is covered at every stage. This process flow diagram illustrates the basic steps of a safe scaffolding installation.

The diagram shows that a safe assembly depends on a strict sequence, where each step builds upon the successful completion of the previous one.

2. Manufacturing Machine Operation JSA

Operating heavy machinery in a manufacturing plant introduces significant risks, from crushing and entanglement to electrical hazards. A Job Safety Analysis (JSA) for machine operation is a systematic process that dissects each step of using equipment like CNC machines, hydraulic presses, or conveyor systems. It moves beyond generic safety warnings by detailing specific hazards for each task, such as loading material or changing a tool, and lists precise control measures like lockout/tagout (LOTO) procedures.

This type of job safety analysis sample is critical for preventing serious incidents. By methodically identifying potential dangers before operation begins, it establishes a clear, safe work procedure. This shifts safety from being an afterthought to a core part of the operational process, making sure operators are actively aware of the risks and the controls needed to manage them. For more complex risk scenarios, some facilities integrate JSAs with other methods to visualize safety barriers, and you can learn more about bowtie risk assessment to see how these concepts connect.

Successful Implementation

- Toyota integrated JSAs directly into its Toyota Production System, leading to a reported 40% reduction in manufacturing accidents by making safety a standard part of every operational task.

- 3M manufacturing facilities use QR codes on machinery that link directly to the relevant JSA, giving operators instant access to updated procedures and safety information on their mobile devices.

- Ford Motor Company has standardized its machine operation JSA across global assembly plants, creating a consistent safety baseline for all its manufacturing facilities worldwide.

Actionable Tips for Your JSA

- Create machine-specific JSAs: Avoid generic "machine operation" documents. A JSA for a hydraulic press will have different hazards and controls than one for a conveyor system. Be specific.

- Involve the operators: Experienced machine operators have invaluable, hands-on knowledge. Include them in creating and reviewing the JSA to make sure the identified hazards and controls are practical and relevant.

- Use visual management: Incorporate color-coded safety zones on the floor around machinery and post key JSA steps visually at the workstation. This reinforces safe practices without relying solely on a document.

- Conduct pre-shift JSA reviews: Start each shift with a quick toolbox talk focused on the JSA for the machines being used that day. This makes sure every operator is reminded of the key risks and safety protocols.

3. Chemical Handling and Storage JSA

Working with hazardous chemicals demands a very methodical approach to safety, which is where a specialized Job Safety Analysis (JSA) becomes essential. This JSA breaks down every activity involving chemicals, from receiving and decanting to final use and disposal. For each step, it identifies specific hazards like toxic fume inhalation, chemical burns, fire, or environmental contamination and outlines precise control measures.

This job safety analysis sample moves beyond generic advice by requiring a detailed assessment of each chemical's unique properties. It forces teams to consider worst-case scenarios, such as spills or incompatible mixtures, and establish clear, pre-planned responses. This proactive analysis is critical for preventing serious incidents in industrial or laboratory settings.

Successful Implementation

- DuPont credits its robust chemical safety management system, built on the principles of task-specific JSAs, with preventing thousands of potential worker exposures and environmental releases.

- Dow Chemical has adopted a digital JSA platform that provides workers with real-time hazard updates and safety data sheet (SDS) information directly on their mobile devices before they begin a task.

- BASF uses standardized chemical handling JSAs across its global operations, which ensures that all sites, regardless of location, adhere to the same high safety standards for common chemical processes.

Actionable Tips for Your JSA

- Integrate SDS information: Don't just reference the Safety Data Sheet; pull key information like required PPE, first aid measures, and spill cleanup procedures directly into the JSA document. This makes the critical data immediately accessible.

- Establish chemical-specific emergency plans: Your JSA should inform specific response protocols. For a corrosive acid spill, the response is different from a flammable solvent leak. Document these distinct plans.

- Link JSAs to inventory management: A good system connects your chemical inventory directly to your JSA library. When a worker scans a container, they should be able to instantly access the relevant JSA for that specific substance. Beyond handling procedures, evaluating the physical infrastructure is vital; for instance, careful consideration should be given to choosing the right chemical storage tank for your facility.

- Run regular emergency drills: Use your JSA scenarios as a script for practical drills. This tests the effectiveness of your documented controls and makes sure your team knows exactly what to do in a real emergency. For more precise risk management, you can learn more about how to calculate chemical exposure limits.

4. Electrical Work and Maintenance JSA

Electrical work involves severe, often invisible, hazards, demanding a job safety analysis that is both precise and rigorously followed. This type of JSA breaks down tasks like installation, maintenance, and repair into their core components. For every step, from isolating a circuit to re-energizing equipment, it identifies potential dangers such as arc flash, electric shock, and stored energy release, then mandates specific control measures.

This job safety analysis sample is critical for preventing serious incidents. It forces teams to verify de-energization, confirm correct lockout/tagout (LOTO) procedures are in place, and select the right personal protective equipment (PPE) before a single tool is picked up. It transforms electrical safety from a general policy into a concrete, verifiable, and task-specific plan.

Successful Implementation

- Schneider Electric reported a 70% reduction in electrical incidents after rolling out a global JSA program that standardizes protocols for all technicians.

- General Electric uses a digital safety management system to ensure JSAs for electrical work are completed and approved before work permits are issued, linking the analysis directly to operational control.

- Siemens has built a comprehensive training program around its electrical JSA, ensuring that every qualified worker not only understands the procedure but can also correctly identify hazards and apply controls in the field.

Actionable Tips for Your JSA

- Verify isolation with testing: Never trust a switch or breaker. Always use a properly rated multimeter or voltage tester to confirm a circuit is de-energized before starting work. This "test before you touch" rule must be a non-negotiable step in the JSA.

- Implement a qualified person system: Make sure that the JSA is reviewed and signed off by a person officially deemed qualified and competent to assess the specific electrical hazards involved. This adds a critical layer of expert oversight.

- Use incident energy calculations: For work on or near live equipment, the JSA must specify the required arc-rated PPE. This should be based on incident energy calculations that determine the potential severity of an arc flash at that specific point in the system.

5. Confined Space Entry JSA

Working in a confined space like a tank, silo, or sewer presents some of the most severe hazards in any industry, primarily due to dangerous atmospheres and limited means of escape. A Confined Space Entry JSA is a mandatory planning document that systematically identifies these risks before anyone enters the space. It breaks down the job into key stages: isolation, atmospheric testing, entry, work inside, and exit, assigning specific safety controls to each step.

This job safety analysis sample is critical for preventing incidents related to oxygen deficiency, toxic gases, or engulfment. The JSA acts as both a plan and a permit, making sure that every protocol, from ventilation requirements to rescue procedures, is confirmed and in place. The structured approach forces teams to verify conditions and communicate clearly, which is essential when a situation can become life-threatening in seconds.

Successful Implementation

- ExxonMobil's confined space program uses a rigorous JSA and permit-to-work system that has been credited with preventing multiple potential fatalities from atmospheric hazards.

- Chevron uses a digital permit system linked to its JSA process, which provides real-time tracking of atmospheric tests and entry authorizations across its facilities.

- Shell has standardized its Confined Space Entry JSA across all global operations, ensuring that the same high safety standards for gas testing and rescue planning are applied everywhere.

Actionable Tips for Your JSA

- Never compromise on atmospheric testing: The JSA must specify the exact testing sequence (oxygen, flammable gases, then toxic gases) and require re-testing after any break or change in conditions.

- Ensure rescue is ready: Your JSA must confirm that a trained and equipped rescue team is on standby outside the space and ready for immediate action. A plan on paper is not enough.

- Use continuous monitoring: For any entry, the JSA should require workers inside the space to wear personal gas monitors with audible and vibrating alarms that provide continuous real-time readings.

- Practice emergency rescues: Conduct regular drills using the actual equipment specified in the JSA. This makes sure the rescue plan is practical and that the team can perform it effectively under pressure.

6. Hot Work Operations JSA

Hot work, which includes welding, cutting, grinding, and other spark-producing activities, poses a significant fire and explosion risk, particularly in industrial settings. A specific Job Safety Analysis (JSA) for these operations is critical for preventing serious incidents. This JSA methodically breaks down each phase of hot work, from initial area preparation and permit issuance to the final post-work fire watch, identifying specific hazards and mandating precise control measures.

This detailed job safety analysis sample moves beyond a simple checklist by focusing on the entire fire prevention ecosystem. It addresses risks like ignition of flammable vapors, combustion of nearby materials, and personnel exposure to fumes and radiation. By forcing a systematic review, it makes sure that supervisors, workers, and fire watch personnel understand their roles and responsibilities before a single spark is created, preventing fires before they can start.

Successful Implementation

- Phillips 66 has refined its hot work management program across its refineries, using detailed JSAs to prevent numerous potential fires in high-hazard environments.

- Valero Energy uses a digital hot work permit system integrated with its JSA process, allowing for real-time monitoring and verification of safety protocols.

- BP implements a standardized global hot work JSA across its oil and gas facilities, ensuring consistent and proven safety procedures are followed regardless of the location.

Actionable Tips for Your JSA

- Establish clear boundaries: Use the JSA to define the exact hot work zone and set firm time limits on the permit. This prevents scope creep and ensures the area is re-evaluated if work runs longer than planned.

- Train your fire watch properly: The fire watch is a critical control. Involve them in the JSA and make sure they are trained in using the correct fire suppression equipment for the specific hazards present.

- Implement a post-work inspection: Mandate a cool-down and monitoring period in the JSA after the work is complete. This fire watch period should be based on the type of combustible materials nearby and is crucial for catching smoldering fires.

Job Safety Analysis: 6 Sample Comparisons

| Job Safety Analysis Type | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Construction Site Scaffolding Installation JSA | Medium - Stepwise procedures, frequent updates | High - Daily inspections, equipment checks | High - Significant fall risk reduction | Construction sites with scaffolding erection and maintenance | Reduces fall injuries, ensures OSHA compliance, standardized process |

| Manufacturing Machine Operation JSA | High - Complex lockout/tagout and PPE protocols | High - Specialized training and PPE | High - Reduced machinery injuries and downtime | Manufacturing plants operating heavy machinery like CNC, presses | Prevents amputations, helps with compliance, improves maintenance |

| Chemical Handling and Storage JSA | High - Complex chemical compatibility and spill response | High - Training, specialized PPE, containment systems | High - Prevents exposure, ensures spill response readiness | Industrial/lab settings dealing with hazardous chemicals | Prevents chemical incidents, protects workers and environment |

| Electrical Work and Maintenance JSA | High - Specialized electrical safety procedures and certifications | High - Certified workers, specialized equipment | Very High - Prevents electrical fatalities and damages | Electrical installations and maintenance for low/high voltage | Ensures NFPA 70E compliance, prevents severe injuries |

| Confined Space Entry JSA | High - Intensive monitoring, rescue preparedness | High - Atmosphere testing and rescue gear | Very High - Prevents fatalities in confined environments | Tanks, manholes, underground utility work requiring confined space access | Ensures continuous monitoring, improves rescue readiness |

| Hot Work Operations JSA | Medium - Permit system and coordination required | Medium - Fire watch personnel, suppression equipment | High - Reduces fires and explosion risk | Welding, cutting, grinding in combustible material areas | Prevents industrial fires, manages ignition sources |

Making These JSA Samples Work for You

The six job safety analysis sample examples we've explored, from scaffolding on a construction site to handling chemicals in a factory, all demonstrate a crucial point. A useful JSA is never a generic, one-size-fits-all document. Its real value comes from being a practical, task-specific plan created for a particular job in a particular environment. The goal is not just to fill out a form, but to proactively identify and control hazards before they can cause harm.

The most effective takeaway from reviewing these templates is the need for customization. Your JSA for operating a press brake will look very different from a generic manufacturing template, just as a confined space entry plan for a specific tank on your site requires more detail than a general example. The process of creating the JSA is just as important as the final document. Involving the workers who perform the task is not just a good idea; it's essential for uncovering the real-world steps and potential risks that a manager might overlook from their office.

Key Learnings from the JSA Samples

To turn these examples into a functional part of your safety system, focus on three core principles that were consistent across all the effective samples:

- Specificity is Paramount: Vague descriptions like "use caution" are useless. As seen in the electrical work JSA, specific controls like "lockout-tagout procedure #ELEC-004 applied to breaker panel B" are actionable and verifiable. Always connect controls to your site's specific procedures, equipment, and personnel.

- Focus on the 'How': The best JSAs don't just list a hazard; they detail the control measures. Instead of just "fall from height," the scaffolding sample broke it down into checks for guardrails, toe boards, and correct planking. This level of detail makes the control measure a clear instruction, not a suggestion.

- Keep it Clear and Concise: The document must be easy to read and understand for the people actually doing the work. Avoid jargon where possible and use simple language. The purpose is clear communication, not complex documentation that no one reads. Each job safety analysis sample here serves as a guide for structure, not a script to be copied verbatim.

Putting Your JSA into Action

The true measure of a JSA is its use in the field. The goal is to move beyond a paperwork exercise and create a living document that guides safe work practices. Start by selecting one high-risk task at your workplace. Gather the team who performs that task and walk through the process step by step, using one of our samples as a structural guide.

By adapting these principles and focusing on a collaborative, detailed approach, you transform the JSA from a compliance hurdle into a fundamental tool for preventing incidents. It becomes a blueprint for getting the job done safely and correctly, making sure that every team member, from the site supervisor to the newest apprentice, understands the risks and the exact steps needed to control them. This practical application is what gives a job safety analysis sample its true power.

Tired of chasing paperwork and managing messy JSA spreadsheets? Safety Space provides a simple, powerful platform to create, distribute, and track your JSAs digitally. See how you can standardize your safety processes and get real-time oversight of your operations at Safety Space.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.