A non conformity report (NCR) isn't just another piece of paperwork. Think of it as the formal flag you raise the moment something goes wrong: a product, process, or material that doesn't meet the specified requirements.

It’s the official starting gun for fixing a problem before it spirals into something much bigger and more expensive.

What Is a Non Conformity Report and Why It Matters

Let's be clear: a non conformity report is a critical quality control tool, especially in industries like construction and manufacturing. When a batch of concrete has the wrong mix or a shipment of parts doesn’t match the engineering drawings, an NCR gives you a structured way to document it.

This isn’t about pointing fingers. It's about spotting a flaw in the system. Without a formal process, it's far too easy for these issues to get swept under the rug, leading to bigger problems later. A minor defect missed on the production line today could become a major product failure for a customer tomorrow.

The Real-World Impact of an NCR

At its core, an NCR’s job is to stop a problem in its tracks. It ensures a non-conforming item is properly identified, quarantined, and handled so it doesn’t accidentally get passed down the line or shipped out the door.

But the real value is much deeper than that. When you use NCRs consistently, your organization starts to see some powerful benefits:

- Cut Rework and Waste: It's always cheaper to catch an issue early than to fix it after the fact.

- Spot Recurring Problems: Are you constantly raising NCRs for the same supplier or process? That’s not a coincidence; it’s a systemic issue that needs a permanent fix.

- Drive Process Improvement: Every NCR is a valuable data point. When you analyze this data, you uncover insights that help you strengthen your procedures and lift your overall quality.

A well-managed NCR process is the difference between constantly reacting to problems and proactively preventing them. It shifts your team’s focus from firefighting to building a more resilient system.

Ultimately, these reports are foundational to any serious quality management system. The issues they flag aren't confined to one sector. For example, in the first half of 2025, the Australian Securities and Investments Commission (ASIC) received 7,561 reports of misconduct, a sharp reminder that non-conformity is a widespread challenge. You can learn more about the findings from ASIC’s misconduct reports.

To truly appreciate their power, it helps to view NCRs as strategic business records that provide the intelligence needed for continuous improvement.

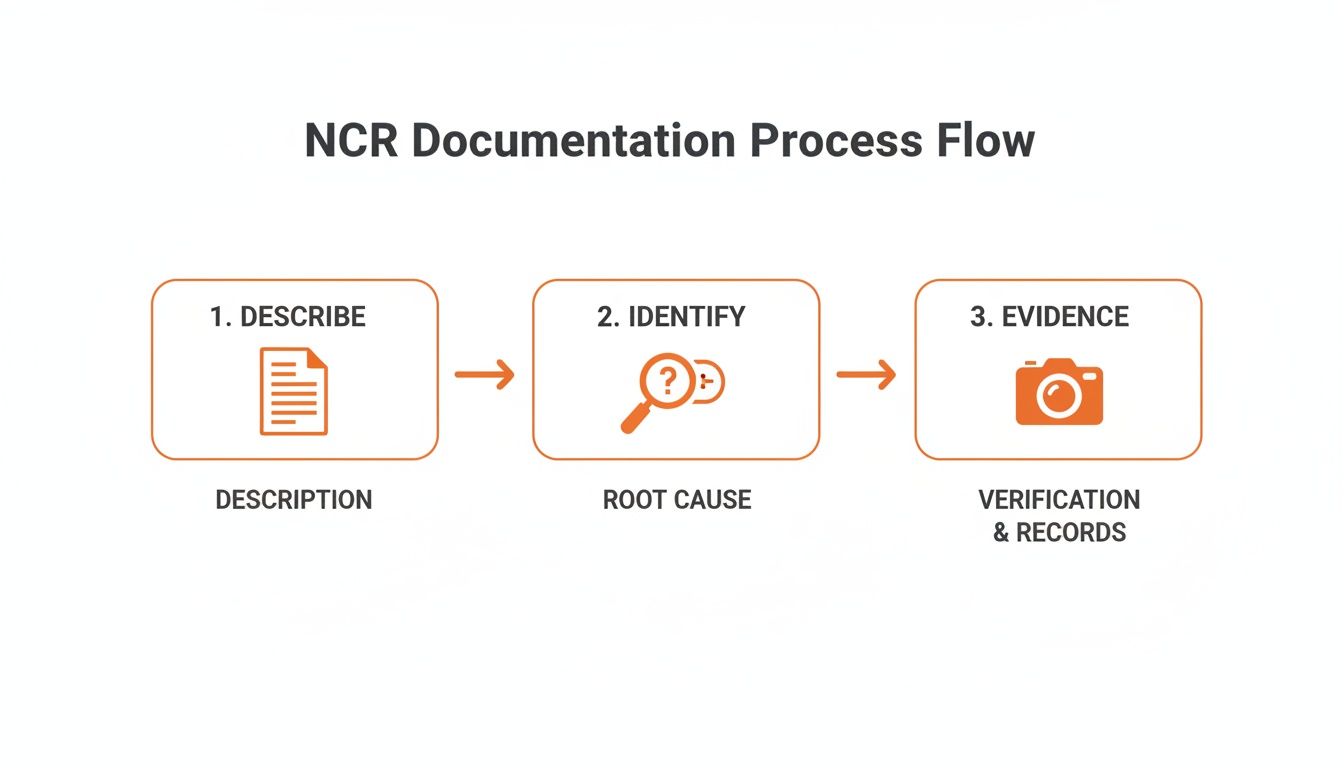

How to Clearly Document a Non-Conformity

When writing a non-conformity report, think less about filling out a form and more about telling a clear, factual story. The whole point is to create a record so precise that someone who wasn't there can understand exactly what went wrong. Vague descriptions only lead to weak solutions, so clarity is everything.

The first rule is to stay objective. Just stick to the facts and avoid any language that points fingers. Instead of writing, "John assembled the unit incorrectly," you need to focus on the process itself.

A much better, more useful description would be: "Unit 74B failed final inspection because the primary actuator was installed upside down, contrary to drawing 4.2-A." This approach keeps the focus on the what, not the who, which is where it needs to be.

What to Actually Write in the Report

When you start documenting the issue, remember that every field on that form matters. The details you put in now become the foundation for the entire investigation and any corrective actions that follow. You're the detective gathering evidence at the scene.

Here’s what you absolutely need to nail down:

- Specific Identification: Don't just say "the part was wrong." Get granular. Use serial numbers, batch codes, part numbers, or purchase order details. For instance, "Bracket P/N 45-901 from Batch #B772 supplied by ACME Steel on PO #12345."

- Exact Location: Pinpoint where the non-conforming item was found. Was it in receiving inspection? On the assembly line at Station 3? Or sitting in the finished goods warehouse? This context is crucial for narrowing down the potential cause.

- Clear Description of the Problem: Be descriptive and, wherever possible, use actual measurements. Instead of writing something vague like "the bracket is too big," be precise: "The overall length of Bracket P/N 45-901 measures 155mm, but the specification on drawing 8-C requires 150mm +/- 2mm."

The core principle here is simple: describe, don't diagnose. Your job in the initial report is to state the facts of the deviation, not to guess why it happened. The root cause analysis will come later.

Providing Good Evidence

Words are great, but solid evidence is undeniable. Attaching clear, relevant proof makes your non-conformity report airtight and gives the investigation team a massive head start. A single picture showing a crack, a burr, or a misaligned component is often more powerful than a paragraph of text.

Try to include these types of evidence:

- Photographs: Take well-lit, focused pictures of the defect. If the scale is important, put a ruler or measuring tape in the photo for context.

- Measurements: Document any readings from calipers, micrometers, or other inspection tools that clearly show the deviation from the standard.

- Relevant Documents: Attach a copy of the specific drawing, work instruction, or specification that the product or process failed to meet.

This level of detail isn’t unique to non-conformity reports; it’s a best practice for any formal reporting. If you want more guidance on structuring factual reports, this incident reporting sample is a great resource to see how clear documentation works in a real-world context.

Getting this part right from the start is critical. A well-documented non-conformity provides the clear, factual basis needed to find a real solution and stop the problem from happening again. It sets the stage for a successful resolution instead of trapping you in a frustrating cycle of recurring failures.

Finding the Real Root Cause of the Problem

A completed non-conformity report isn't the finish line; it’s the starting pistol for the investigation. Your first move is always containment. That means quarantining faulty parts or hitting pause on the affected process to prevent the problem from spreading. But let's be clear, that's just a temporary fix.

The real mission is to dig deeper and figure out why the problem happened in the first place. This is the crucial difference between containment (a quick patch) and corrective action (a permanent solution). If you skip this step, you're just setting yourself up to deal with the same headache again and again.

Moving Beyond the Obvious Symptom

To get to the bottom of a non-conformity, you need to be methodical. It’s all too easy to point the finger at an operator or a single machine, but these are almost always just symptoms of a deeper process failure. To really nail the root cause, it helps to use a structured research methodology that forces you to look at the whole picture.

A simple but powerful technique for this is the '5 Whys'. You just keep asking "Why?" until you peel back the layers of symptoms and hit the foundational cause. It’s a great way to push your thinking beyond the immediate failure point and examine the entire system.

Here's how it plays out in a real-world manufacturing scenario:

- Problem: A welded joint on a steel frame just failed inspection.

- Why? The weld was too brittle.

- Why? The welding machine's temperature was set way too high.

- Why? The operator set the temperature based on the work instruction document.

- Why? The work instruction had the wrong temperature listed for this specific grade of steel.

- Why? An engineering change for the new steel grade was never properly communicated to the team responsible for updating the documentation.

See what happened there? The actual root cause wasn't operator error or a dodgy machine. It was a communication breakdown in the process for updating documents. If you only fixed the weld, you'd be guaranteeing the problem would happen again.

Who to Involve in the Investigation

You can't find a root cause sitting in an office by yourself. A proper investigation needs input from the people who live and breathe the process every day. The best approach is to pull together a small, focused team to get a 360-degree view of what went wrong.

Your investigation team should always include:

- The operator or person who found the issue: They have hands-on experience nobody else does.

- A production supervisor or team lead: They get the workflow, the operational pressures, and the bigger picture on the floor.

- Someone from the quality team: They bring expertise in standards, specifications, and how to run an effective investigation.

Bringing these different perspectives together lets you analyze the problem from all angles. For a deeper dive into structuring your analysis, check out our guide on the root cause analysis format. This kind of collaboration is what ensures the solution you come up with will actually work in the real world.

Creating Corrective Actions That Actually Work

Identifying the root cause is a huge step, but let's be honest, it doesn't fix anything on its own. Now comes the critical part: creating a solid plan to make sure the problem doesn't come back. A corrective action isn't just an idea; it's the specific, tangible task you'll carry out to eliminate that root cause for good.

This is exactly where many organizations stumble. I've seen countless reports filled with vague, well-intentioned actions that are impossible to track or verify. That pretty much guarantees the issue will pop up again down the line. The goal here is to move from fuzzy ideas to concrete, measurable steps.

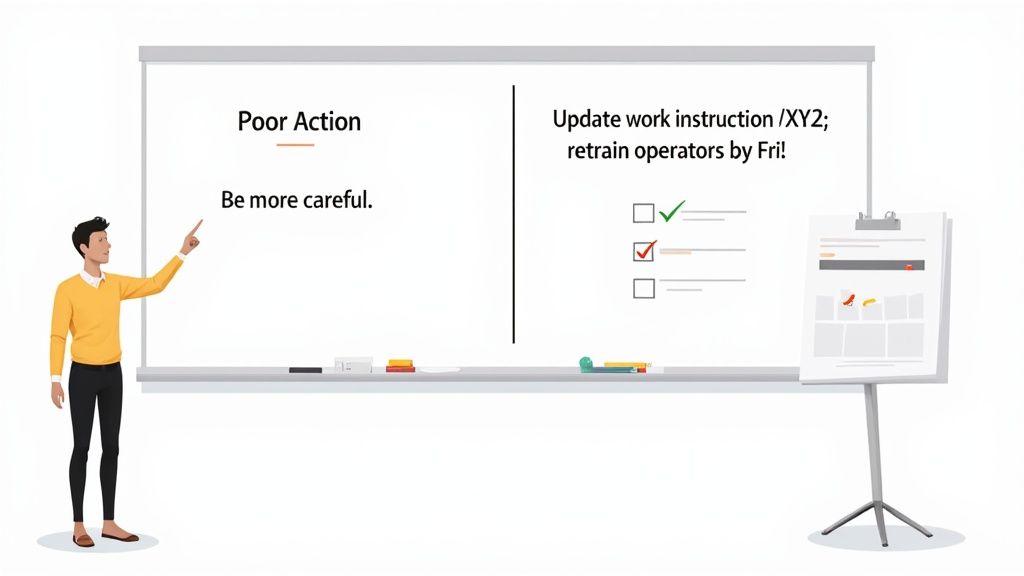

From Poor to Practical Corrective Actions

The real difference between a weak corrective action and a strong one comes down to clarity. A good action plan leaves zero room for interpretation. Anyone, from the CEO to a new hire, should be able to read it and understand exactly what needs to be done, who is doing it, and when it needs to be finished.

Let's look at some real-world examples I've run into to see the difference.

Poor Action: "The operator needs to be more careful when setting up the machine."

- Why it's bad: This isn't a process fix; it’s a blame statement. "Be more careful" is not a measurable action and solves nothing.

Good Action: "Update work instruction WI-45B to include a verification step where a second operator confirms the machine temperature setting before starting the production run. Train all night-shift operators on the new procedure by Friday."

- Why it's good: It’s specific, actionable, and you can measure it. It changes the process to prevent the error, rather than just hoping a person won't make a mistake again.

Here's another classic I see on factory floors all the time:

Poor Action: "Inspect incoming materials better."

- Why it's bad: It's hopelessly vague. Who is "inspecting"? What are they looking for? How are they supposed to do it "better"?

Good Action: "Revise the goods-in inspection checklist (Form #F-102) to include a mandatory dimensional check for Bracket P/N 45-901. Require the receiving inspector to record the measurement and sign off before moving parts to stock. Implement by June 30th."

- Why it's good: It nails down the what (dimensional check), the how (update the checklist), the who (receiving inspector), and the when (June 30th). No ambiguity.

Assigning Responsibility and Setting Deadlines

Every single corrective action must have a clear owner and a realistic deadline. Without these two elements, even the most brilliant plans fall apart because there's no accountability.

- Assign a Single Owner: Don't assign a task to a department; a department can't be held responsible, but a person can. "Sarah Jenkins (Quality Engineer)" is a clear owner.

- Set Realistic Deadlines: The due date needs to be achievable but also create a sense of urgency. An open-ended deadline means the action will get shoved aside for more "pressing" daily tasks.

Your non-conformity report isn't truly closed until every single corrective action is complete. The goal is a permanent fix, and that requires follow-through.

Verifying That the Fix Actually Worked

This final step is easily the most important and, unfortunately, the most frequently skipped. You absolutely have to circle back and check that the action was not only completed but that it was also effective. Did it actually stop the problem from happening again?

This goes way beyond just getting a signature confirming a task is "done." True verification might mean:

- Auditing the process a month later to see if the new work instruction is actually being followed.

- Analyzing production data for the next three months to ensure the defect rate has dropped to zero.

- Speaking directly with the operators on the floor to confirm the new procedure is working as intended and hasn't created new problems.

This verification "closes the loop" on your non-conformity report. It's the proof that your investigation and hard work led to lasting improvement, turning a costly problem into a stronger, more reliable process. In many ways, thinking about these fixes is similar to developing control measures for risks, where the whole point is to implement a robust, lasting solution.

Common NCR Mistakes and How to Avoid Them

Even with a solid system, it's surprisingly easy to fall into common traps when managing a non-conformity report. These mistakes can quickly turn a valuable improvement tool into a frustrating paper-shuffling exercise.

Knowing what these pitfalls look like is the first step to making sure your NCR process actually delivers results.

One of the biggest culprits is a vague description. A report that just says "part is faulty" is completely useless. It gives the investigation team nothing to work with and makes finding the root cause next to impossible. Always, always aim for specifics, use part numbers, pull measurements, and write in plain, clear language.

Blaming People Instead of Fixing Processes

Here's another classic error: letting the NCR process turn into a blame game. When a report points the finger at "operator error," it misses the point entirely.

The real question should always be, "What part of the process allowed this error to happen?"

Key Takeaway: A non-conformity report should investigate the system, not the individual. A process that relies on a person never making a mistake is a flawed process from the get-go.

When you focus on the system, you get robust solutions like mistake-proofing an assembly sequence or clarifying a confusing work instruction. These are the kinds of changes that make the process stronger for everyone, no matter who is doing the job that day.

Failing to Close the Loop

Perhaps the most damaging mistake of all is leaving corrective actions open indefinitely. An NCR with an unresolved action plan isn't a solution; it's just a documented problem. This creates a backlog of risk and, worse, sends a message that follow-through isn't a priority.

This kind of oversight can have serious consequences, especially as regulatory scrutiny gets tougher. In Australia, the enforcement landscape has shifted, with regulators handing out massive penalties for non-compliance. In the 2024 financial year alone, court-awarded fines from ACCC actions shot past $500 million. This isn't slowing down, with aggressive prosecution strategies continuing into 2025. You can read more about these compliance and enforcement priorities directly from the source.

To avoid this trap, make sure every single action has:

- A single, named owner: Accountability starts when one person is responsible. No committees.

- A realistic due date: An open-ended deadline is just an invitation for inaction.

- A verification step: The report isn't truly closed until you've proven the fix actually worked.

Finally, a surprisingly common failure is not analyzing NCR data over time. Every single report is a valuable piece of data. By tracking trends, you can spot recurring issues with a supplier or a weakness in a specific production area. This lets you get ahead of systemic problems before they snowball.

Your NCR Questions Answered

Got a few lingering questions about how non-conformity reports work in the real world? Let's clear up some of the most common queries we hear from teams on the ground.

How Much Detail Is Really Needed in an NCR?

Enough detail to be unmistakable. The goal is to provide a clear record so that someone completely unfamiliar with the situation can understand exactly what happened, why it mattered, and what needs to be looked at.

While you don't need to write a novel, you absolutely must go beyond vague statements.

The rule of thumb is this: if another person has to ask you for more information to begin an investigation, the report isn’t detailed enough. Always include specific part numbers, batch codes, locations, measurements, and references to the exact standard or requirement that wasn't met.

Who Is Responsible for Closing an NCR?

This is a common point of confusion. The ultimate responsibility for closing a non-conformity report usually falls to a designated quality manager or team leader. They're the gatekeeper.

However, "closing" the report is the final tick in the box. The responsibility for completing the corrective actions belongs to the individuals or teams assigned those specific tasks. The quality manager’s job is to chase up those actions and verify they've been completed effectively before officially closing the NCR in the system.

How Long Should the Whole Process Take?

There's no single magic number here, it depends entirely on the complexity of the issue. A simple material defect might be sorted in a few days. A deep-seated process failure, on the other hand, could take several weeks to investigate and fix properly.

The key isn't necessarily speed, but momentum. You can't let things stall. Here’s a practical timeline to aim for:

- Initial Containment: This needs to happen fast. Aim for within 24 hours to stop the problem from spreading.

- Root Cause Analysis: This takes a bit of digging. Plan to complete it within 3-5 business days.

- Corrective Action Plan: Once you know the 'why', the 'what' should follow quickly. Have a plan defined and assigned within a week of the initial report.

- Action Implementation: This is the most variable part, but every action needs a specific, realistic deadline that gets tracked.

Setting these internal targets creates urgency and stops reports from getting buried in a backlog. An NCR that sits idle for a month is a clear sign of a broken process.

Can Software Really Help Manage This?

Absolutely. In fact, trying to manage a non-conformity report process with spreadsheets and long email chains is a recipe for missed deadlines, lost information, and zero real-time visibility. It’s a reactive nightmare.

A dedicated platform like Safety Space gives you a central, single source of truth for everything.

It makes sure reports are logged consistently, assigned to the right people automatically, and tracked through to completion. This gives managers an instant view of all open issues, helps you spot recurring trends, and most importantly, ensures nothing ever falls through the cracks. It turns a reactive paper-chase into a proactive quality management system.

Managing your NCR process doesn't have to be a constant struggle. With Safety Space, you can replace outdated spreadsheets and paperwork with a simple, all-in-one platform that makes tracking and resolving non-conformities easy. Get a clear view of every issue, assign actions, and ensure nothing gets missed. Book a free demo today and see how you can build a more efficient and compliant workplace.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.