When you think about workplace safety, what comes to mind? For most people, it’s hard hats, high-vis vests, and steel-toed boots. That’s all correct, but Personal Protective Equipment (PPE) is only one piece of a much larger safety puzzle.

In Australia, your legal duties as an employer go far beyond simply handing out gear. You’re required to provide, pay for, and manage safety equipment as a critical part of your overall safety strategy, stepping in only when other safety measures can’t fully eliminate a hazard.

Understanding Your Core PPE Obligations

Here's the thing about PPE: it's actually the last line of defence against workplace hazards. It doesn't get rid of the danger itself; it just puts a barrier between your worker and the risk.

Think of it this way: fixing a machine's faulty guard is always better than just giving the operator gloves. Why? Because the fixed guard removes the risk for everyone, forever. The gloves only protect one person, one time, and only if they're used correctly. This idea sits at the very heart of Australian Work Health and Safety (WHS) laws, which legally require you to eliminate or reduce risks before you even think about relying on PPE.

The Employer's Legal Duty

As an employer, your primary responsibility is crystal clear: you must provide all necessary PPE to your workers at no cost to them. This isn't just a friendly suggestion; it's a non-negotiable legal requirement enforced by regulators like Safe Work Australia.

But your duty doesn't stop at the purchase order. Your core obligations are ongoing and include:

- Providing Suitable PPE: The gear has to be right for the job and the specific hazard. A simple dust mask is completely useless against chemical fumes.

- Ensuring a Proper Fit: Equipment that’s too loose or too tight can fail or even create new dangers. A respirator that doesn't form a perfect seal offers zero real protection.

- Maintaining the Equipment: You are responsible for the cleaning, repair, and replacement of all PPE to make sure it stays effective.

- Training Your Team: Your workers need to be properly shown how to use, store, and look after their gear. You can't just hand it over and hope for the best.

These duties are a fundamental part of your entire safety system. To see how this fits into the bigger picture, check out our guide on the 9 key elements of a health and safety management system.

A Growing Area of Focus

The focus on getting PPE right is only getting stronger. The Australian PPE market was valued at around USD 1.62 billion in 2024 and is forecast to climb significantly by 2033, all thanks to increasingly strict safety regulations.

This isn't just a number, it shows a major shift in how both regulators and businesses are prioritising this final, critical layer of protection.

PPE is your final safety net. It's the essential barrier that protects your team when all other risk controls have been exhausted. Your legal obligation is to ensure this final net is strong, correctly deployed, and properly maintained for every single worker.

Conducting a Practical Hazard Assessment

Before you can even think about PPE requirements, you first need to know exactly what hazards your team is up against. Simply guessing or grabbing a checklist from another site is a recipe for disaster. Why? Because every single workplace is unique. A thorough hazard assessment is the bedrock of every PPE decision you'll make.

Think of yourself as a detective on your own worksite. Your job is to walk the floor and methodically identify anything with the potential to cause harm. This isn't about pointing fingers; it's about spotting risks before they turn into incidents.

A real assessment is an active, on-the-ground process. You need to see tasks as they're actually being done, not just how they’re described in a manual. Watch your crew, talk to them about what worries them, and keep an eye out for the subtle dangers that are easy to miss from behind a desk.

Breaking Down the Hazards

Most workplace dangers fall into three main buckets. Figuring out which ones exist on your site is the critical first step to choosing the right gear. Taking a complete look helps you build a clear picture of your site's risk profile.

- Physical Hazards: These are the most common and usually the easiest to spot. We're talking about risks like moving machinery, objects falling from scaffolding, extreme heat from welding, deafening noise from grinders, or the sharp edges on sheet metal.

- Chemical Hazards: This category covers any exposure to harmful substances. Think about the risks from inhaling silica dust during concrete cutting, skin contact with industrial cleaning solvents, or breathing in fumes from paints and adhesives.

- Biological Hazards: While often linked to healthcare, these can pop up in other industries too. Examples include exposure to mould during a demolition project or dealing with bacteria in contaminated water systems on a construction site.

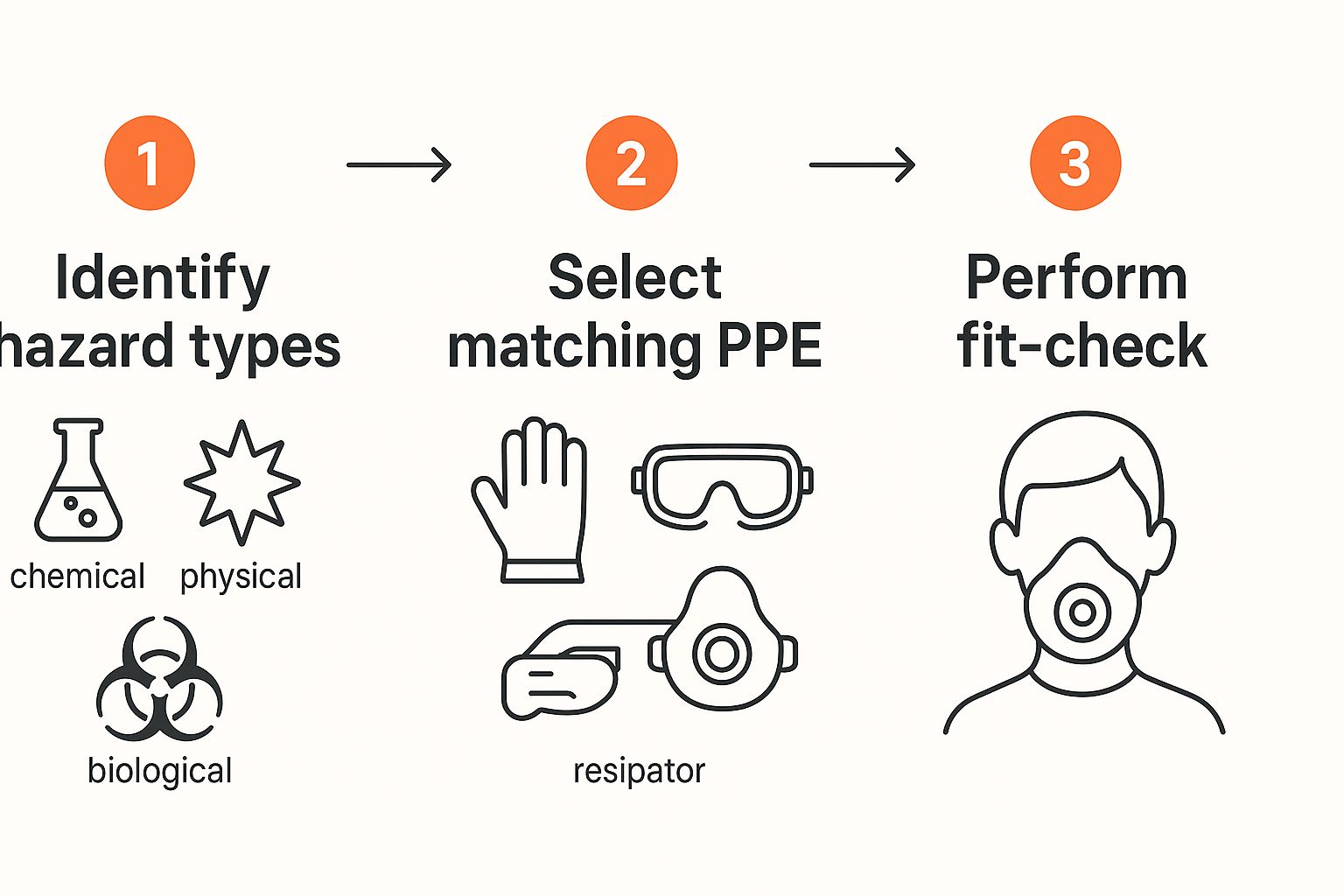

This infographic breaks down the process, showing how you move from spotting these hazards to selecting and checking the right equipment.

This flow, from identifying the hazard right through to checking the fit, makes sure your PPE choices are directly tied to the specific risks your workers face every day.

A Repeatable Framework for Assessment

Once you’ve identified the hazards, the next step is to figure out their risk level. This helps you prioritise what needs your attention most urgently. A simple, repeatable process keeps this from becoming overwhelming.

- Walk the Floor: Start by physically walking through the entire work area. Watch everything, from the daily grind to those infrequent maintenance jobs. Don't rush it; take good notes.

- Talk to Your Team: The people on the tools have invaluable insights. Ask them what tasks make them feel unsafe or what near-misses they’ve had. They almost always know where the real problems are.

- Review Past Incidents: Dig into your records of accidents and near-misses. These documents are goldmines, showing you exactly where hazards have caused harm before and are likely to again.

- Document Everything: Create a formal record of what you find. For each hazard, write down what it is, where it is, and who is at risk. This documentation is non-negotiable for compliance and for tracking your progress.

For a more structured way to visualise and manage these risks, you can explore different methodologies. You can learn more about connecting threats to consequences in our guide on the bowtie risk assessment model.

Turning Assessment into Action

After identifying and documenting hazards, the final step is to decide what controls are needed. And remember, PPE is always the last resort. Your first priority should always be to eliminate or reduce the hazard at its source.

For example, if your assessment flags excessive noise from a machine, the first thought shouldn't be earplugs. It should be: can we replace it with a quieter model? Can we build an enclosure to block the sound? Only when those options aren't feasible do you turn to hearing protection as the necessary control.

This principle applies to every hazard you find. If you spot a welding flash risk, you first explore using welding screens or restricting access to the area. Safety glasses or a welding helmet are the final layer of protection, not the first solution. This practical approach makes sure you are meeting not just the letter of your personal protective equipment requirements, but the true spirit of workplace safety.

How to Select the Right PPE for the Job

Alright, your hazard assessment is done. You now have a clear map of the risks on your site. The next logical step is to pick the gear that puts a reliable barrier between your team and those dangers.

This is where so many safety programs stumble. Choosing the wrong equipment can be just as dangerous as having none at all. It's about looking past brand names and focusing entirely on function and compliance with Australian Standards. Matching the PPE to the hazard isn't just best practice, it's non-negotiable.

Head and Face Protection

The most obvious forms of PPE are usually for the head and face, protecting against everything from a falling spanner to a chemical splash. But it's critical to understand that not all protection is created equal.

A standard hard hat, for instance, is a must-have on any construction site for impact protection from above. Simple enough. But if a worker is also around live electrical hazards, they need a completely different piece of kit: a non-conductive, Class E rated helmet.

Similarly, a face shield gives you great broad coverage against splashes or flying debris. But don't be fooled, it often needs to be paired with primary eye protection like safety glasses underneath to be truly effective.

Eye Protection Safety Classes

Choosing the right eye protection is far more nuanced than just grabbing a pair of safety glasses off the shelf. The specific hazard dictates the exact type of lens and frame you need.

- Impact Hazards: For jobs like grinding, cutting, or drilling where particles are flying, you need glasses that meet the Australian Standard AS/NZS 1337.1 for medium impact resistance. These are specifically designed to stop high-velocity projectiles without shattering.

- Splash Hazards: When you're working with liquids or chemicals, standard safety glasses with side shields just won't cut it. You absolutely need safety goggles that create a complete seal around the eyes, leaving no gaps for fluid to get in.

- Dust Hazards: In environments with fine dust, like from concrete cutting, sealed safety goggles are again the only real choice. They stop fine particles from getting behind the lens where they can irritate or seriously damage the eyes.

Picking the wrong eyewear gives a false sense of security, leaving a worker completely exposed to the very hazard they think they're protected from.

Respiratory Protection Essentials

Respiratory protection is easily one of the most complex areas of PPE selection. Let's be clear: a simple paper dust mask offers next to no protection and is totally inadequate for most industrial hazards.

The right respirator depends entirely on the contaminant and its concentration in the air. For instance, workers cutting engineered stone need a P2 rated respirator (or higher) to protect against deadly silica dust. For welding fumes or certain paint vapours, you'll need a half-face respirator fitted with specific chemical cartridges.

A critical piece of the puzzle is the fit. A top-of-the-line respirator is useless if it doesn't fit properly. An improper seal around the face allows contaminated air to leak in, bypassing the filter entirely and offering zero real protection.

Hand Protection for Specific Tasks

Gloves are definitely not a one-size-fits-all solution. In fact, using the wrong glove can be even worse than using no glove at all. Some chemicals can break down certain materials in seconds, trapping the hazardous substance right against the skin.

The material of the glove has to be matched directly to the chemical or physical hazard it’s meant to protect against.

Here’s a quick guide to help you choose the right glove for common jobs in construction and manufacturing.

Glove Selection Guide for Common Workplace Hazards

| Glove Material | Protects Against | Common Applications (Construction/Manufacturing) | Limitations |

|---|---|---|---|

| Leather | Cuts, abrasions, moderate heat | General material handling, welding, operating machinery | Not effective against liquids or chemicals. |

| Nitrile | Oils, solvents, chemicals, punctures | Mechanical work, handling cleaning agents, painting | Not ideal for very high-cut or abrasion risks. |

| PVC (Vinyl) | Acids, bases, caustics | Chemical handling, concrete work | Poor protection against organic solvents. |

| Kevlar-Lined | Severe cuts and punctures | Handling sheet metal, glass, sharp-edged materials | Can be bulky; low resistance to chemicals. |

As you can see, each material has its specific strengths and weaknesses. Always check the manufacturer's compatibility chart, especially when dealing with chemicals.

Hearing and Fall Protection

When it comes to noise, the choice between earplugs and earmuffs often comes down to the noise level, how long someone is exposed, and what's most comfortable for the worker. The gear must have a Class rating that matches the decibel level you identified in your hazard assessment.

Fall arrest systems are another life-or-death category. Anyone working at heights requires a full-body harness, lanyard, and a suitable anchor point. This equipment has to be rated for the worker's weight and, crucially, inspected before every single use to make sure it hasn't been damaged. Fulfilling these personal protective equipment requirements is absolutely vital for preventing a tragedy.

Running Effective PPE Training and Fit Testing

Handing out gear and ticking a box just doesn't cut it. Your personal protective equipment is only effective when your team knows exactly how to use it, what its limits are, and why it’s so critical for their safety. An effective training program is where your PPE strategy moves from theory to reality.

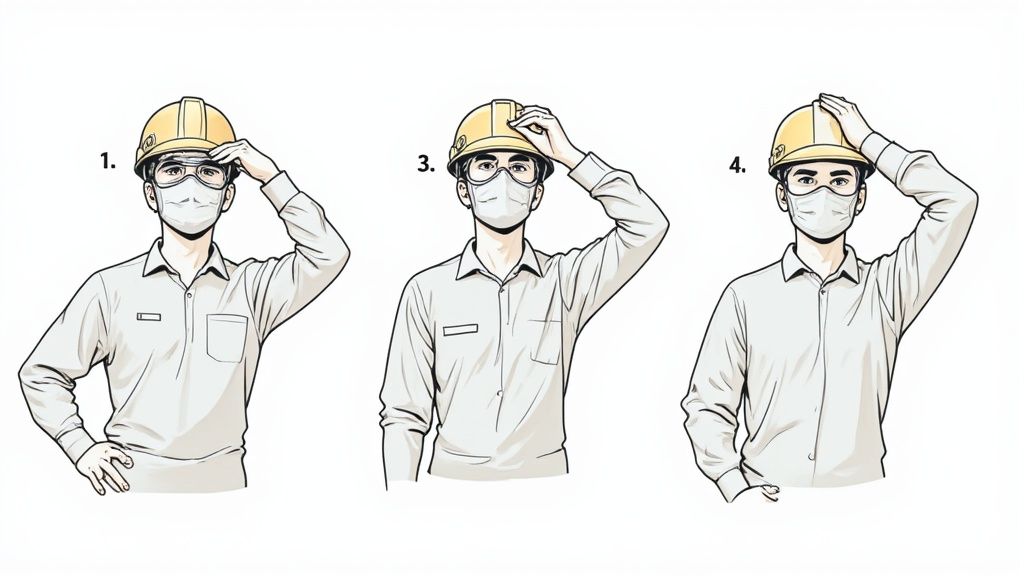

This isn’t about sitting your crew in a room for an hour with a dull slideshow. The only way to make the information stick is with practical, hands-on training. Your team needs to physically handle the equipment, practice putting it on, and learn how to inspect it themselves, every single day.

Without this crucial step, even the most expensive and compliant PPE is just a useless accessory. Proper training is what turns a piece of equipment into a genuine layer of protection.

Beyond the Basics: What Training Must Cover

A successful PPE training session goes far beyond just showing someone how to wear a hard hat. To actually be effective, your program needs to cover several key areas to give workers a complete picture of their gear.

Your training needs to be clear, direct, and focused on what your team needs to know to stay safe on the job.

- When to Use PPE: Workers must know exactly which tasks demand specific gear. For example, safety goggles are mandatory for grinding, but a full face shield is needed for handling certain chemicals.

- How to Use PPE Correctly: This means demonstrating the proper way to put on, adjust, and, just as importantly, take off each piece of equipment. Getting the removal process wrong, for instance, can lead to contamination.

- The Limitations of the Gear: Every piece of PPE has a breaking point. Workers must understand that a P2 respirator won't protect them from chemical vapours, and that standard leather gloves won’t stop a needle puncture.

- Inspection and Maintenance: Your team should be able to spot signs of wear and tear, like fine cracks in a hard hat or worn seals on a respirator. They also need to know the right way to clean and store their equipment to keep it working.

Recent data really highlights how important this is. Studies in Australian healthcare settings revealed that while PPE use has improved, only 29% of workers removed their gear correctly after simulated exercises. This shows a massive gap between simply having the equipment and actually knowing how to use it safely. To learn more about these training challenges, you can discover key insights into PPE compliance in Australia.

The Non-Negotiable Step: Fit Testing

For certain types of PPE, a correct fit is everything. This is especially true for respirators and custom-moulded hearing protection. An ill-fitting respirator is one of the most dangerous forms of false security you can have in the workplace.

A respirator that doesn't form a perfect, airtight seal against the user's face is completely useless. Contaminated air will simply bypass the filter through the gaps, offering zero protection to the worker's lungs.

This is why fit testing isn’t an optional extra; it is a mandatory part of any credible respiratory protection program. There are two main methods:

- Qualitative Fit Testing: This is a simple pass/fail test that relies on the user's senses. The worker puts on the respirator while a test agent, like a sweet or bitter solution, is sprayed into a hood placed over their head. If they can taste or smell it, the mask has a leak. It’s a fail.

- Quantitative Fit Testing: This method uses a machine to measure the actual amount of leakage into the respirator. It gives you a numerical result called a "fit factor," providing hard data on how well the mask seals. It's the far more accurate and preferred method for high-risk environments.

Fit testing has to be done before a worker ever uses a respirator on the job, and it should be repeated regularly, usually every year. It also needs to be redone if anything changes that could affect the fit, like significant weight gain or loss, or major dental work.

Common Training Mistakes to Avoid

Even with the best intentions, PPE training can easily miss the mark. To make sure your efforts are effective, you need to steer clear of these common pitfalls.

- Being Too Generic: Your training must be specific to the actual tasks and equipment used on your site. A generic online video just won't cut it when it comes to the specific risks your team faces every day.

- Forgetting to Document: Always keep detailed records of who was trained, what was covered, and when the training took place. This documentation isn't just paperwork; it's essential for proving compliance.

- Treating it as a One-Off Event: Safety training isn't something you do once and forget about. Regular refresher sessions are vital to keep knowledge sharp and address any new hazards that pop up.

Managing Your Day-to-Day PPE Program

A successful PPE program isn’t a one-and-done job. You can't just hand out gear and tick a box. It’s a living, breathing system that needs constant attention to actually keep people safe.

Once you’ve done the hazard assessment, picked the right equipment, and run the training, the real work begins. This is the day-to-day grind of making sure the system works in practice, not just on paper. It’s about building simple, repeatable processes for issuing, inspecting, and replacing gear without drowning everyone in paperwork.

Establishing an Efficient Issuing and Replacement System

First things first: you need a clear process for getting PPE into your workers' hands. A messy storeroom where people just grab what they think they need is a recipe for disaster. It leads to shortages, incorrect gear being used, and zero accountability.

Your system should track who has what, and when they got it. It doesn’t need to be fancy, a basic sign-out sheet or a simple digital log does the trick. This tells you exactly what’s in circulation and helps you stay on top of stock levels.

Just as critical is your process for replacing damaged gear. Workers have to feel comfortable reporting a worn-out helmet or cracked safety glasses without any fear of being blamed. The process for swapping old for new needs to be fast and easy, so there’s never a temptation to make do with faulty equipment.

A clear and accessible replacement policy is more than just good logistics. It's a powerful signal to your team that you genuinely care about their safety. When someone can easily swap a scratched face shield for a new one, it reinforces the message that only well-maintained, effective gear is acceptable.

Daily Checks and Regular Inspections

The responsibility for checking PPE isn’t just on you. Your team is your first line of defence. Every worker needs to be trained to give their gear a quick once-over before every single shift.

What should they be looking for?

- Hard Hats: Any cracks, deep dents, or that chalky look that signals UV damage.

- Safety Glasses: Deep scratches that block their vision or any cracks in the lens or frame.

- Respirators: Check that the straps are still elastic, the facepiece isn't damaged, and the valves are clear.

- Harnesses: Look closely at the webbing for any frays, cuts, or signs of chemical burns, and make sure every buckle clicks into place properly.

On top of these daily checks, you should schedule more formal, documented inspections weekly or monthly. This is your chance to spot the gradual wear and tear that might get missed in a quick daily look. A simple checklist makes these inspections consistent and makes sure nothing gets overlooked.

Keeping Your Records Audit-Ready

Let's be blunt: good record-keeping is non-negotiable. When a safety inspector shows up, you need to be able to prove you're meeting your obligations. Staying organised is the key to avoiding a world of pain.

Your documentation should be simple, clean, and easy to find. The last thing you want is to be frantically digging through a messy filing cabinet for a fit test result from two years ago while an auditor waits. It’s why so many companies now use health and safety management software to keep everything centralised and accessible.

Here are the absolute must-have records:

- Hazard assessments and any reviews or updates.

- Records of all PPE issued to each worker.

- Training logs, complete with attendee lists and dates.

- Completed fit-test results for anyone who needs a respirator.

- Records from your formal equipment inspections.

The recent COVID-19 pandemic was a stark reminder of why this stuff matters. A 2022 Australian study found that 25% of frontline health workers reported not having enough PPE, while 20% felt their training was inadequate. These gaps show just how quickly a program can fall apart under pressure. You can read the full research about these pandemic findings to get a better handle on the challenges.

Common Questions About PPE Requirements

When you're trying to get the specifics of personal protective equipment right, a lot of practical questions pop up. Answering them correctly is non-negotiable for keeping your site compliant and, more importantly, your team safe. Here are some no-nonsense answers to the most common queries we hear from managers and business owners.

Who Is Responsible for Paying for PPE in Australia?

Under Australian Work Health and Safety (WHS) laws, this one’s crystal clear: the employer is legally responsible for providing and paying for all necessary PPE. Think of it as a non-negotiable cost of doing business. You can't pass this cost on to your workers, whether through payroll deductions or by asking them to buy their own gear.

And your responsibility doesn't stop at the initial purchase. You also have to cover the costs of maintaining, repairing, and replacing any equipment to make sure it’s always up to the job. While you foot the bill, remember that workers have their own part to play, they must use the PPE correctly, just as they've been trained.

How Often Do I Need to Review My PPE Hazard Assessment?

There isn't a single, legally mandated schedule that says "review on this date," but doing it just once is definitely the wrong answer. The best approach is to treat your hazard assessment as a living document. As a rule of thumb, a formal review at least every one to two years is a good idea, even if nothing obvious has changed.

However, there are times when you must conduct an immediate review. These triggers include:

- Introducing a new process, piece of machinery, or chemical.

- After any incident, accident, or even a near-miss that could have led to harm.

- If your workers raise concerns that their current PPE isn't doing its job effectively.

Regular reviews make sure your safety measures are relevant to the real risks on your site today, not the risks that existed a year ago.

What Happens If an Employee Refuses to Wear Their PPE?

This is a situation that needs to be handled carefully but firmly. Before you even think about disciplinary action, your first step should always be to find out why they're refusing. More often than not, there’s a practical problem you can actually solve.

Is the gear uncomfortable? Does it fit poorly? Is it getting in the way of them doing their job? A worker who can't see clearly through scratched safety glasses or has a respirator seal irritating their skin has a legitimate issue, and it's on you to fix it. You might need to source different brands or sizes to find something that works.

If you’ve addressed all their valid concerns and the refusal continues without good reason, then it becomes a disciplinary matter. Your safety policies have to be enforced consistently. This usually means a clear, documented process starting with verbal warnings, moving to written ones, and potentially leading to dismissal for ongoing, wilful non-compliance. Just remember to document every single conversation and action taken.

An employee's refusal to wear PPE is often a symptom of a deeper problem. Investigating the 'why', be it poor fit, discomfort, or inadequate training, is the first and most critical step. Resolving the root cause is always a better outcome than starting disciplinary proceedings.

Can I Let Employees Use Their Own PPE?

Honestly, this is a path filled with risk and is strongly discouraged. As the employer, you hold the legal responsibility for making sure any equipment used on your site meets Australian Standards, is right for the specific hazards, and is in good working order.

That legal responsibility doesn't just vanish if an employee brings their own gear. You would still be on the hook to:

- Inspect it thoroughly: You'd need to verify it meets the required standards and isn't damaged.

- Manage its maintenance: How can you track its age and condition? How do you know it's being cleaned and stored correctly?

- Assume the liability: If that equipment fails and the worker gets hurt, the liability still falls squarely on you.

This creates a massive administrative and legal headache. It's far simpler and safer to keep full control by providing, managing, and maintaining all the required PPE yourself. It guarantees a consistent standard of protection across your whole team and makes your life a lot easier.

Juggling these requirements on top of daily operations can be a real challenge. Safety Space offers a smarter way to handle your health and safety obligations, replacing messy paperwork and spreadsheets with a single, easy-to-use platform. See how you can simplify compliance and protect your team by booking a free demo.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.