A solid policies and procedure template is more than just a document; it's the foundation of a system that keeps your people safe and your business compliant. It gives you a structured way to lay out critical safety protocols, assign responsibilities, and plan for emergencies in your specific workplace.

Why Generic Safety Paperwork Creates Real-World Problems

Let’s be honest. That old binder on the shelf, stuffed with generic, outdated documents? It’s more than just clutter. In high-risk industries like construction and manufacturing, it’s a serious liability. Relying on paper-based systems or scattered spreadsheets creates genuine problems on the ground, where clear instructions and fast access to information are everything.

These old-school systems almost always fail when you need them most. Picture a busy construction site. A new subbie arrives, and their team needs to get inducted and on the tools, now. Hunting down the right paperwork, making sure it’s the latest version, and then chasing their sign-off becomes a painful admin task that holds up the whole job.

Or think about a factory floor. An incident happens on the night shift. Can the supervisor quickly pull up the correct reporting procedure and emergency contacts, or are they stuck trying to get into a locked office to find a folder?

The True Cost of Ineffective Policies

The fallout from weak or inaccessible procedures goes way beyond a bit of inconvenience. It directly hits your project timelines, your budget, and most importantly, your team's wellbeing. Ineffective systems almost always lead to:

- Project Delays: Time gets torched searching for documents or trying to clarify rules that haven't been updated in years.

- Compliance Fines: Auditors have a knack for spotting inconsistent or poorly managed safety documents, which can lead to hefty financial penalties.

- Accountability Gaps: Without a clear, central system, it’s nearly impossible to track who has actually read and understood critical procedures.

The core issue with generic paperwork is that it isn’t connected to the real work being done. A document in a folder doesn't stop an accident; a clear, accessible procedure that is part of the daily workflow does.

From Paper Liability to Digital Control

Moving away from paper and spreadsheets isn't just about looking modern; it's about gaining real-time control over what’s happening on site. The stats paint a pretty stark picture. For instance, Western Australia recorded a worker fatality rate of 1.9 per 100,000 workers, contributing to a national total of 188 deaths.

A well-designed policies and procedure template is fundamental for standardising how you identify hazards and respond to emergencies. It can directly help prevent incidents like falls from height, which caused a staggering 13% of national fatalities.

For construction directors, digitising these procedures has been proven to cut down on audit headaches and reduce the risk of fines, which can skyrocket to as high as $3.5 million under WHS laws.

This shift means turning your policies from static documents into active, living tools. A digital system ensures the right procedure is always available to the right person at the right time. It lets you track acknowledgements, push out updates instantly across all sites, and prove your compliance with just a few clicks. That's the difference between just having paperwork and having a functional safety system.

To see how this works in the real world, you can learn more about developing effective WHS policies and procedures that are actually built for action.

Building Your Core Policies and Procedures Template

Alright, let's get into the bones of your safety system. A solid policies and procedures template is your master document, the single source of truth you can adapt for different sites, teams, and jobs. This isn't about writing some dense legal manual no one will ever read. It’s about creating a clear, practical guide your team on the ground can actually pick up and use.

The idea is to build one core document that covers all the non-negotiables. From high-level policy commitments right down to the specific steps for high-risk work, this master template ensures everyone starts from the same page, no matter the project.

To make sure your template is comprehensive, here’s a breakdown of the essential components it absolutely needs to include. Think of this as your checklist for building a rock-solid foundation.

Essential Components for Your WHS Policies Template

| Component | What It Should Cover | Why It's Important |

|---|---|---|

| Policy Statement | A high-level declaration of the company's commitment to safety, signed by senior management. | Sets the tone from the top and demonstrates leadership buy-in. |

| Roles & Responsibilities | Clear duties for management, supervisors, workers, and subcontractors regarding safety. | Eliminates confusion and creates clear lines of accountability. |

| Core Safety Procedures | Step-by-step instructions for high-risk tasks (e.g., working at heights, LOTO, machinery operation). | Provides actionable guidance to prevent incidents during critical work. |

| Psychosocial Hazards | Frameworks for managing workload, bullying, harassment, and providing mental health support. | Addresses legal requirements and protects the psychological wellbeing of your team. |

| Emergency & Incident Response | Procedures for emergency response, incident reporting, and investigation processes. | Ensures a consistent and effective response when things go wrong, aiding compliance and learning. |

| Consultation & Communication | How safety information is shared (e.g., toolbox talks) and how workers can raise concerns. | Encourages worker involvement and makes sure everyone has a voice. |

| Training & Competency | Requirements for inductions, specific training, and verification of skills for different roles. | Guarantees that workers are equipped with the knowledge to perform their jobs safely. |

| Review & Improvement | A schedule and process for regularly reviewing and updating policies and procedures. | Keeps your safety system relevant, effective, and compliant with changing regulations. |

By building these sections into your master document, you create a powerful and practical foundation for your entire safety management system. Let's dig a little deeper into a few of these key areas.

Start with a Clear Policy Statement

Every template needs a strong opening. Your WHS policy statement is a brief, high-level declaration of your company's commitment to providing a safe workplace. Make sure it's signed by senior management. This shows everyone that the commitment starts at the very top.

This statement sets the tone for everything that follows. It doesn't need to be long, but it has to be direct and unambiguous.

Defining Roles and Responsibilities

One of the most common points of failure in safety systems is confusion over who is responsible for what. It’s a classic problem. Your template must have a section that clearly lays out the safety duties for every role in the company.

This should cover:

- Management: What are their obligations for providing resources, oversight, and leadership?

- Supervisors: What are their duties for daily enforcement, training, toolbox talks, and site inspections?

- Workers: What are their responsibilities to follow procedures, wear PPE, and report hazards?

- Subcontractors: How do they fit into your safety structure and who do they report to on-site?

When you define these roles up front, you eliminate the guesswork and create clear lines of accountability. Everyone knows exactly what’s expected of them before they even step onto the site.

Include Core Health and Safety Procedures

Next, your template needs sections for the essential safety procedures that apply across most of your operations. These are the fundamentals that protect your team from common, serious risks. I’m talking about the step-by-step processes for critical tasks like working at heights, electrical safety, lockout/tagout (LOTO), and operating heavy machinery.

A great template doesn't just list rules; it provides the how. It breaks down complex tasks into simple, actionable steps that prevent errors when it matters most.

This section is also the perfect place to link out to more detailed documents. For instance, your master template can simply reference a specific safe operating procedure for each piece of high-risk equipment. This keeps the main document from getting bogged down while still providing easy access to detailed instructions when needed.

Addressing Psychosocial Hazards

It’s no longer enough to just focus on physical safety. With mental health conditions now representing 12% of all serious workers' compensation claims in Australia, a 161% increase over the last decade, policies addressing psychosocial hazards are a non-negotiable.

Updated WHS codes of practice now mandate this. Your template must include frameworks for managing things like excessive workload, workplace conflict, bullying, and providing genuine mental health support. It’s a critical part of a modern safety system.

Planning for When Things Go Wrong

No system is perfect, which is why your policies and procedures template must clearly outline what to do when an incident occurs. This section is vital not only for compliance but for learning from mistakes to ensure they don't happen again.

Your template needs to provide clear, step-by-step instructions for:

- Emergency Response: Who to call, site evacuation maps, muster points, and first aid procedures.

- Incident Reporting: How to report an incident, what information to collect, and who needs to be notified immediately.

- Investigation Process: The steps for investigating an incident to find the root cause, not just to assign blame.

By the way, these templates are incredibly versatile. You can use the same foundational structure to develop all sorts of operational policies, even something like a workplace tidy desk policy that helps boost productivity and keep things organised. It all comes back to having that strong, consistent core document.

Making Your Template Work On-Site

A master policy and procedure template is a fantastic starting point, but let’s be honest, safety is never a one-size-fits-all deal. A procedure that works perfectly in a controlled factory environment can be completely useless on a dynamic, muddy construction site. The real value of a template comes from knowing how to adapt it to fit the specific needs of each job and location.

Without this customisation, your procedures are just generic documents sitting in a folder. They won't address the unique, day-to-day risks your teams are actually facing, which means they’re far less likely to be followed. The goal here is to create practical, relevant documents that make sense to the people doing the work.

Think of your template as a living document, not something you write once and file away. It has to evolve with every new project, site, or piece of machinery that comes along.

Start with a Site-Specific Risk Assessment

Before you can tweak your policies, you have to know what you’re adapting them for. This always starts with a thorough, on-the-ground risk assessment for the specific site or job. You can't do this properly from your desk; you need to get your boots on, walk the site, and see the reality for yourself.

Look for the hazards that are unique to that environment. For example, a busy construction site will have its own set of challenges:

- Unstable ground, deep excavations, or hidden services.

- Close proximity to public roads, pedestrians, and live traffic.

- Constantly changing work areas as the project moves from foundations to fit-out.

- Multiple subcontractors all working in the same space, often at the same time.

A factory floor, on the other hand, presents a different set of risks:

- Fixed machinery with specific pinch points or guarding requirements.

- Potential exposure to chemicals or fumes in contained spaces.

- Repetitive motion injuries from assembly line work.

- Designated high-traffic routes for both pedestrians and forklifts.

This assessment is your roadmap. It tells you exactly which sections of your master policies and procedure template need to be beefed up, modified, or even created from scratch.

Customising Procedures for the Environment

Once you've identified the unique hazards, you can start modifying your core procedures. This is where you get into the nitty-gritty details that make a policy genuinely useful.

Let's take a common procedure like "Receiving Deliveries" and see how it changes based on the environment.

Scenario 1: Multi-Storey Construction Site

On a tight inner-city construction site, this procedure needs to be incredibly specific. You’ll need to add details about traffic management on public roads, designated crane lifting zones, and clear communication protocols between the delivery driver, the crane operator, and the crew on the upper floors. The procedure has to specify exact exclusion zones and what happens when a lift is in progress.

Scenario 2: Fast-Paced Factory Floor

In a factory, the "Receiving Deliveries" procedure looks completely different. It will focus on designated forklift-only zones, clearly marked pedestrian walkways, speed limits for vehicles inside the building, and the right process for safely unloading pallets at the loading dock. The risks are worlds apart, so the instructions must be too.

The key is to think through the actual workflow of a task in that specific environment. If your procedure doesn't match the reality of the job, it will be ignored.

Assigning Role-Specific Duties

One of the most common mistakes is writing procedures without assigning clear responsibility. Your adapted policies have to state exactly who is meant to do what. This builds accountability and makes sure critical steps don’t get missed.

Using your master template as a base, add in the responsibilities for key roles on that specific site.

- Site Supervisor: Responsible for conducting daily pre-start checks and ensuring all workers have signed onto the updated risk assessment.

- Machine Operator: Responsible for completing the pre-operational checklist for their specific equipment before every single shift.

- Storeperson: Responsible for managing the chemical register and making sure Safety Data Sheets are available right where they're needed.

- All Workers: Responsible for reporting any new hazards immediately to their supervisor using the designated process.

By defining these duties, you turn a general policy into a set of actionable tasks for each person on the ground. This is especially vital for high-risk work where a specific, documented process is legally required. For those tasks, it's crucial to consult detailed guides like a SWMS template for Queensland to ensure you’re hitting all your compliance points. This level of detail ensures everyone knows exactly what their part is in keeping the site safe.

Putting Your Policies and Procedures into Action

Creating a solid policies and procedure template is a huge step, but let's be honest, it’s only half the job. A document, no matter how perfectly written, doesn’t do anything on its own.

The real test is getting it off the page and into the hands of your team in a way that actually sticks. This is where your carefully crafted template becomes consistent, safe work practices on the workshop floor or construction site.

Successful implementation is never about just sending a mass email with a new PDF attached. It demands a proper plan to communicate the changes, provide practical, hands-on training, and get buy-in from the people who will be using these procedures every single day. Get this part wrong, and even the best template will just gather dust.

Effective Training and Communication

Simply telling your team that new procedures exist is a recipe for failure. You need to show them what's different and, crucially, why it matters to their specific role. Those vague, one-size-fits-all training sessions in a stuffy meeting room? They rarely work.

Instead, get practical and focus on role-specific, hands-on training. If you've updated the lockout/tagout procedure, don't just talk about it. Take the maintenance crew to the actual machinery and walk them through the new steps, one by one. Let them physically perform the task while you supervise. This is what builds muscle memory and real confidence.

Your communication plan needs to be just as targeted:

- For Supervisors: Hold a dedicated session just for them. Explain their new responsibilities for enforcing the procedures and give them the authority and tools they need to coach their teams effectively.

- For Machine Operators: Use toolbox talks to cover the specific changes that affect their equipment. Keep it short, direct, and focused on what they need to know for that day's work.

- For Subcontractors: Make the new procedures a non-negotiable part of your site induction process. Ensure they receive and acknowledge the key documents before they start work, not after something has already gone wrong.

A common mistake is assuming that sending out a document is the same as communicating its contents. True communication is a two-way street that involves demonstration, questions, and checking for understanding.

Getting Subcontractors Onboard

Let's face it, managing subcontractors can be one of the biggest headaches when rolling out new procedures. They arrive on-site with their own habits and ways of working, but as the person in control of the site, you are ultimately responsible for their safety. Your policies and procedures have to be crystal clear from day one.

A robust induction is your best tool here. This is your chance to set clear expectations and ensure every single subcontractor understands your site-specific rules. Don't just hand them a folder and hope for the best; walk them through the critical procedures, like your emergency plan and how to report an incident.

From Paper Piles to Digital Efficiency

How you share and manage these procedures makes a massive difference. Traditional paper-based systems create friction. Documents get lost, versions become outdated, and tracking who has seen what is a nightmare. A digital system, on the other hand, can make this process almost seamless. You can require subcontractors to review and digitally sign off on key procedures before they even set foot on site, creating a clear, time-stamped record that keeps everyone on the same page.

Here’s a look at how the two approaches stack up in the real world.

Implementation Methods Paper vs Digital

| Action | Paper-Based System | Digital System |

|---|---|---|

| Distribution | Printing and manually handing out documents to every individual. | Instant distribution to all relevant personnel via the platform. |

| Updates | Requires recalling all old copies and re-distributing new ones. | Centralised updates ensure everyone has the latest version instantly. |

| Acknowledgement | Relies on manual sign-off sheets that can be lost or incomplete. | Automated, time-stamped digital sign-offs for a clear audit trail. |

| Accessibility | Documents are often stuck in a site office or vehicle. | Accessible 24/7 on any device, right where the work is happening. |

| Tracking | A manual, time-consuming process using spreadsheets or folders. | Real-time dashboards show exactly who has completed their training. |

The difference is clear. While paper might feel familiar, a digital platform gives you control, visibility, and confidence that your procedures are actually being used.

A System for Ongoing Review

Your workplace is never static. New equipment is installed, projects evolve, and people come and go. Because of this, your policies and procedures must be living documents that keep pace with change. A procedure that is six months out of date can be just as dangerous as having no procedure at all.

Set up a clear schedule for reviewing your documents. A good rule of thumb is an annual review for all procedures, but you must also trigger an immediate review when:

- A new piece of high-risk machinery is introduced.

- There is a significant near miss or an incident occurs.

- WHS legislation or codes of practice are updated.

- A worksite or process fundamentally changes.

Involving your team in these reviews is vital. They're the ones on the tools, and they can provide priceless feedback on what is practical and what isn’t. After all, the goal of any policy is to drive real-world results, so it's critical to understand how to use what you learn for real-world success. This feedback loop is what keeps your safety system relevant, respected, and effective.

How to Manage Your Templates in Safety Space

You’ve put in the hard yards and built a solid policies and procedure template. Fantastic. Now, how do you stop it from gathering dust in a shared drive?

This is where you bring it to life. Moving your safety documents into a platform like Safety Space is how you turn them from static files into active, automated tools that are actually part of your day-to-day operations. It’s not just about cloud storage; it’s about making your policies functional, trackable, and dead simple for everyone to use.

Let's walk through how to manage your templates in the platform, uploading them, assigning them to the right people, and using the system to make sure they're being followed on the ground.

Getting Your Templates into the System

First things first, you need to get your master policies and procedure template into Safety Space. The platform is built to work with your existing documents, so there's no need to start from scratch.

Just upload your Word docs or PDFs directly. All that work you've already done is preserved.

Once it's uploaded, your template becomes a live document. You can edit and customise it right inside the platform, which is perfect for tweaking a master template for a specific site or project without creating a confusing mess of file versions.

Assigning Responsibilities and Tracking Sign-Offs

A policy is pretty useless if people don’t know it exists or what their role is. Safety Space closes this gap by connecting your procedures to specific people and job roles.

This is where accountability gets real:

- Assign to Roles: You can assign a specific procedure, like your lockout/tagout protocol, directly to all maintenance staff or machine operators with a few clicks.

- Track Acknowledgements: The system handles the rest, sending notifications and tracking when each person has reviewed and digitally signed off on the document.

- Get Real-Time Visibility: A simple dashboard shows you at a glance who has and who hasn’t completed their required sign-offs. No more guesswork, you know exactly who needs a follow-up.

This digital audit trail is a game-changer. It completely eliminates the need for chasing paper sign-off sheets and gives you clear, undeniable evidence that your team has been briefed on their responsibilities.

The real shift here is moving from a passive system, where you just hope people read the documents, to an active one where you can confirm it. It replaces assumptions with certainty.

Setting Up Automated Reviews and Updates

Safety documents get stale. It happens. A forgotten procedure can quickly become a serious liability if a new piece of equipment is installed or regulations change. Trying to track this manually is a recipe for failure, which is why automated reminders are so crucial.

Within Safety Space, you can set a review date for every single policy and procedure template. The system will then automatically notify the responsible manager when a document is due for its annual review or needs updating.

It's a simple feature that ensures your safety system stays current. And when you do update a procedure, you can push the new version out to all relevant personnel instantly. The system will then prompt them to acknowledge the changes, keeping the loop closed.

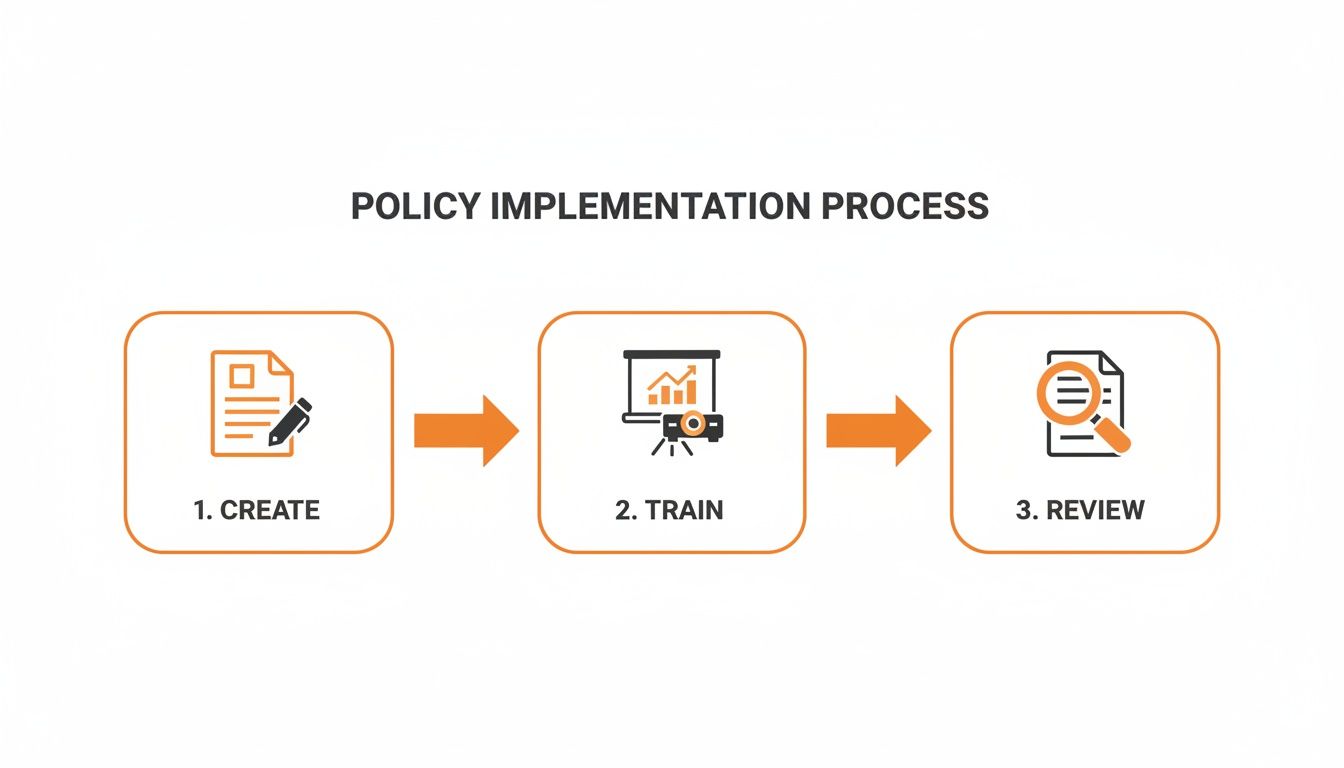

The entire process of turning policy into action is a simple, continuous cycle.

You create the document, you train your team on it, and you constantly review it to make sure it’s still effective and relevant.

Connecting Policies to Daily Safety Tasks

Here’s the biggest win: connecting your high-level policies to the actual safety tasks happening on site. This is how you make safety a practical part of the job, not just another administrative chore.

Safety Space does this by linking your procedures directly to its other features. For example, when a worker is filling out a pre-start checklist on a piece of machinery, the form can automatically link to the relevant safe operating procedure, right there on their phone or tablet.

This integration means your policies aren't just sitting in a folder somewhere. They're connected to real-time actions like incident reporting and risk assessments. It creates a cohesive system where everything works together.

Features like AI-powered form completion can even help fill out incident reports by pulling information directly from your established procedures, ensuring every report is consistent and accurate. This connection turns your policies and procedure template from a reference document into a hands-on tool that guides safe work practices in the moment.

Your Top Questions Answered

When you're knee-deep in building and implementing policies and procedures, a lot of questions pop up. It’s completely normal. Here are some of the most common ones we hear from safety managers and business owners, along with some straight-to-the-point answers from our experience.

How Often Should We Really Be Reviewing Our Policies and Procedures?

The textbook answer is at least once a year. But in the real world, an annual review is just the bare minimum. You can't just set a calendar reminder and forget about it.

Your policies and procedures need an immediate review whenever something significant changes or goes wrong. Think of these as triggers:

- A serious incident or a near-miss that could have been catastrophic.

- WHS legislation gets an update, or a new code of practice is released.

- You bring in new machinery, tech, or chemicals.

- Your core work processes are overhauled.

Let's say your manufacturing plant just installed a new automated assembly line. You can't wait until next year's review to update your procedures for operation, maintenance, and emergency stops. That needs to happen now, before anyone even touches it. This is where a digital system like Safety Space is a game-changer. You can set automated review reminders tied to specific people and assets, so nothing ever slips through the cracks.

What’s the Single Biggest Mistake Companies Make with Safety Policies?

Easy. It's creating a monster of a document just to tick a box for compliance, then letting it gather dust on a shelf (or in a forgotten folder on the server). A policy that isn't read, understood, or used by your team is completely worthless when it counts.

Good policies are written in simple, direct language. They’re specific to the actual tasks your team performs every single day and are woven into your inductions and toolbox talks.

The other huge mistake is not involving the people on the tools. Your crew on the floor are the real experts on their jobs, they know what’s practical and what’s a complete waste of time. Ignoring their input is the fastest way to write a procedure that gets ignored from day one.

Can a Solid Policies and Procedures Template Actually Reduce Our Legal Risk?

Absolutely. If an incident happens or a regulator shows up for an audit, your documented procedures are your first and best line of defence. They're your proof of due diligence. It shows you have a formal system for identifying and managing risks, which is at the heart of your legal duties.

A good template provides consistency across all your sites and projects. When you can back that up with training records and signed acknowledgements, you’re in a much stronger position to defend your safety practices and sidestep hefty fines.

This documentation is tangible proof that you've taken reasonable steps to keep your people safe. Without it, you’re walking into an inspector’s office empty-handed.

Our Subbies Have Their Own Policies. Do We Still Need to Cover Them in Ours?

Yes, 100%. As the PCBU (Person Conducting a Business or Undertaking), you have a primary duty of care for everyone on your site. That absolutely includes subcontractors. While they should have their own safety systems, your policies must spell out how they’ll work safely within your site's specific rules and environment.

Your procedures need to cover subcontractor management, from minimum induction requirements to how their methods will integrate with yours, especially for high-risk work. It’s all about making sure there are no dangerous gaps between your system and theirs.

For instance, if your site has a specific permit-to-work system for hot works, their team must follow your process. No exceptions. It's your site, so your rules have to take precedence to ensure everyone is on the same page and working to the same standard.

Ready to turn your policies from static documents into an active safety system? Safety Space gives you the tools to upload, manage, and track your procedures with ease, ensuring your team is always working from the latest information. Get a free demo and see how it works.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.