A daily pre-start checklist for a forklift is a practical routine operators use to confirm the machine is safe and ready to go before a shift. Think of it as a quick but critical inspection covering everything from mechanical soundness to safety features, designed to catch problems before they cause unexpected failures.

Why Daily Forklift Checks Are Non-Negotiable

A daily forklift check is not just about ticking boxes. It’s a key part of a professional operator's routine that keeps the machine running reliably and, more importantly, keeps everyone on the worksite safe.

This pre-start inspection is your most basic risk management tool. It helps you spot small problems before they become major breakdowns or a serious accident. Imagine finding a slight hydraulic fluid leak during a morning check. Fixing it then and there prevents a potential system failure under a heavy load later in the day. That is the point of being proactive.

Prevent Downtime and Major Repairs

From experience, I can tell you that consistent daily inspections are your first line of defense against surprise equipment failures. Catching minor issues early, like worn tires or a fraying mast chain, prevents them from causing much larger, more expensive problems down the track.

A proper check does not just keep your equipment ready for action; it also ensures you're aligned with Australian OHS standards without needing to be a lawyer. This proactive approach is a core part of any solid health and safety management system. You can learn more about the 9 key elements of a health and safety management system in our detailed guide.

In Australia, a pre-start forklift checklist is not just a good idea, it's a legally recommended practice. Guidelines require a daily pre-operational inspection of critical components like brakes, steering, hydraulics, and warning devices before the forklift is used.

If any faults are found, they must be reported immediately. The forklift then needs to be tagged and taken out of service to prevent anyone from using faulty equipment by mistake. To get the full picture, you can review the official government guidelines for forklift safety for workers.

The Forklift Walk-Around: What You Need to See

Before you turn the key, a thorough walk-around is the first order of business. This is not just about ticking boxes; it is a required routine that every single operator needs to have ingrained in their muscle memory.

Think of it this way: you are looking for small problems before they turn into major incidents or equipment failures mid-shift.

Your pre-start checklist forklift inspection actually begins before you get right up to the machine. Take a moment to look at the ground around and underneath it. See any puddles or fresh drips of oil or hydraulic fluid? A minor leak can quickly become a complete system failure when the forklift is under load, so spotting these early is critical.

Physical Structure and Integrity

Okay, now it is time to get up close with the forklift's frame and hardware. This is not a quick once-over. You need to pay close attention to the key structural components that bear immense stress every day.

I always tell new operators to focus their eyes on these areas:

- Tires: Check their condition and pressure. Look for any deep cuts, gouges, or bits of metal embedded in the tread that could cause a blowout. For solid (cushion) tires, you are looking for any significant wear or "chunking" where large pieces have broken off.

- Forks: Inspect both forks closely, especially at the heel, the part where they bend upwards. This is a common stress point for cracks. Make sure the top clip and retaining pin are present and secure. A bent or damaged fork is a recipe for disaster, seriously compromising the stability of your load.

- Mast and Chains: Run your eyes over the mast, looking for any cracked welds, broken chain links, or other obvious damage. Check the chain tension, it should feel taut, but not stretched to its limit. An important reminder: never put your hands inside the mast assembly to check the tension.

- Overhead Guard: This is your primary protection from falling objects, so give it a good check. Make sure it is solid and free from any cracks, bends, or damage.

A forklift’s data plate (or nameplate) is non-negotiable. It must be in place, secure, and completely legible. This plate holds vital information about the forklift’s capacity and approved attachments. If it’s missing or you can’t read it, the machine is out of service. Period.

Fluid Levels and Hoses

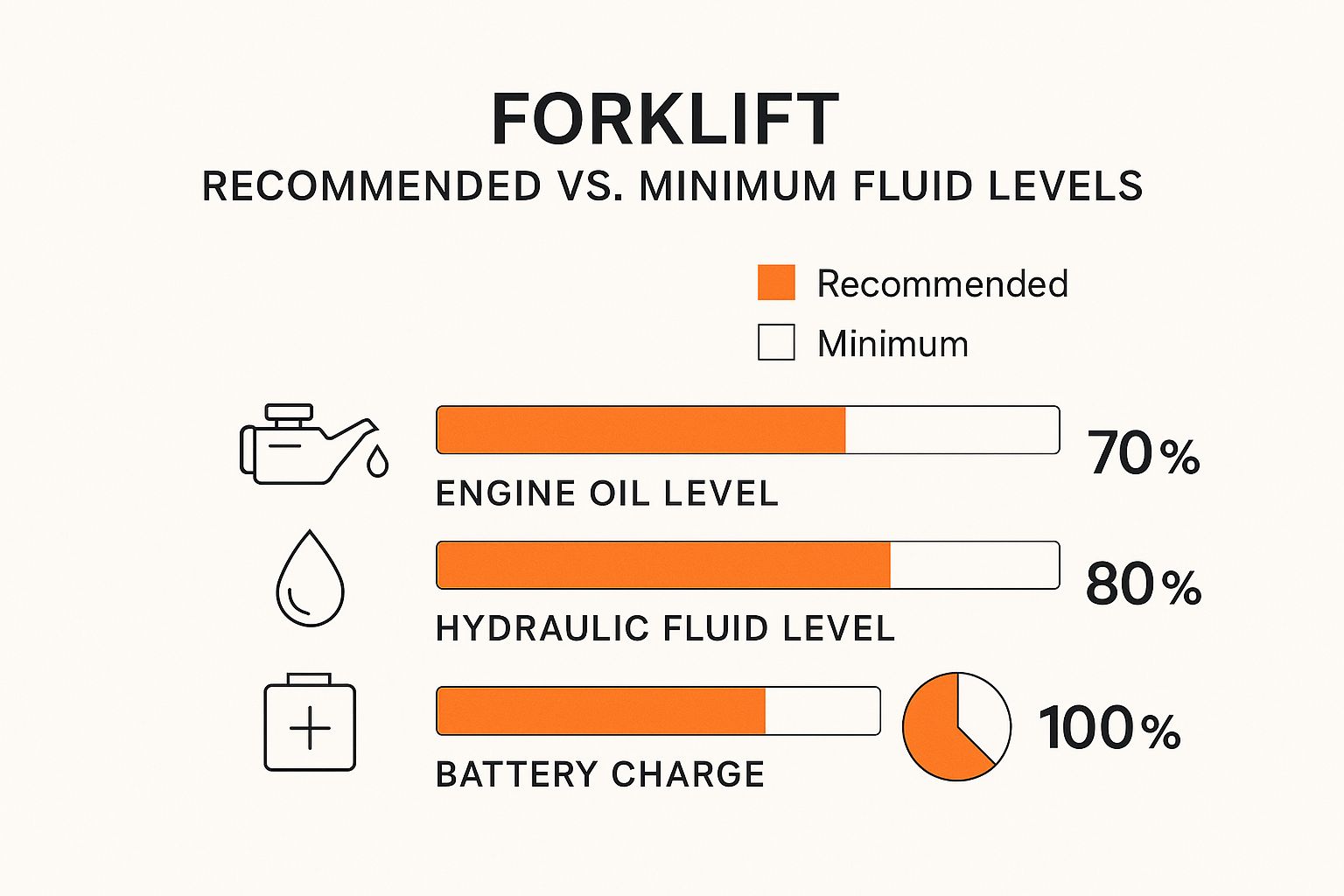

Once you are satisfied with the main structure, it is time to pop the hood and check the machine's lifeblood, its fluids. This is a vital part of any proper forklift walk-around.

You will need to check the engine oil, hydraulic fluid, and coolant levels. Make sure they all fall within the manufacturer's recommended range in the operator's manual.

Next, trace the hydraulic hoses. Carefully examine them for any leaks, cracks, bulges, or other obvious signs of wear. A failing hose is one of the most common causes of sudden hydraulic system failure, which is incredibly dangerous, especially if a load is elevated at the time.

Making a habit of checking fluids and hoses might seem tedious, but this simple five-minute task prevents a massive number of potential breakdowns and serious safety incidents.

Inspecting The Operator's Compartment

Alright, you have finished the walk-around. Now it is time to climb in and get a feel for the machine from where it really counts: the operator's seat. Before you turn the key, this part of the pre-start checklist for a forklift is where you make sure everything you need to operate safely is working perfectly.

Hop in and get comfortable. The very first thing you should do is grab the seatbelt. Buckle it up to ensure the latch engages properly, then unbuckle it. Does it retract smoothly? A seatbelt that is slow, frayed, or does not latch is useless in a tip-over, making this a required check.

Next, give the controls a quick run-through. Without starting the engine, move the levers and push the pedals. You are checking for any stiffness, sticking, or unusual resistance. They should all move freely and feel right.

Verifying Alarms and Capacity

Now, turn the key to the 'on' position but keep the engine off. This lets you test all the electrical systems.

Give the horn a good, solid blast. It needs to be loud enough for everyone in the area to hear clearly. Then, put the forklift into reverse. The backup alarm should sound immediately. These audible alarms are your first line of defense for alerting pedestrians and other workers that you are on the move. Do not skip them.

Finally, find the load capacity plate. This is one of the most critical safety features on the entire forklift, yet it is often overlooked. You need to confirm two things: that it is securely attached and, most importantly, that every word and number is legible. A worn-out or damaged plate is a massive risk, potentially leading to a catastrophic overload. Making sure you can read it is fundamental to applying safe manual handling techniques when lifting.

I have seen this firsthand on work sites. A hire company once told me they make operators photograph the load capacity plate weekly. Why? Because an unreadable plate led to an operator misjudging a load's weight, nearly causing a tip-over. They realized that verifying the plate's legibility and testing alarms was not just a daily check; it was a key risk control that needed constant validation. This aligns with what you'll see in professional forklift pre-start documentation, where these checks are tracked to catch faults early.

Once you are confident that every control, alarm, and safety feature inside the cab is in working order, you are finally ready to start the engine.

Key Operational Checks with the Engine On

Alright, with the engine running, we get to the most important part of your pre-start inspection. These final checks are all about confirming the forklift’s core functions are responding correctly before you think about lifting a load. This is less about looking and more about feeling how the machine behaves under power.

First up, the steering. Turn the wheel from lock to lock. What you are looking for is a smooth, responsive action. You should not have to fight it. If it feels stiff, jerky, or has too much play, that is an immediate red flag. It could signal anything from low hydraulic fluid to a more serious mechanical issue.

Next, give the brakes a proper test. Move the forklift forward slowly and apply the service brakes. They need to bring the machine to a firm, smooth stop, not a screeching halt or a lazy roll. If you have a safe, slight incline nearby, test the parking brake to make sure it holds the forklift securely without any slipping.

Testing Hydraulic and Mechanical Functions

Now it is time to put the hydraulics through their paces. This system does all the heavy lifting, so you need to be confident it is working perfectly. With no load on the forks, cycle through all the hydraulic functions.

- Mast Operation: Run the mast all the way up and all the way down. It should be a steady, controlled movement, free of any juddering or hesitation.

- Tilt Control: Tilt the mast fully forward and then all the way back. Again, feel for smooth control and listen for anything that sounds out of place.

- Attachments: If your forklift has a side shifter, rotator, or any other hydraulic attachment, test its full range of motion now.

Throughout these checks, keep your ears open. Odd grinding sounds or a high-pitched whine from the engine or hydraulic pump are often the first warnings of trouble. Catching these sounds early can be the difference between a quick fix and a major failure down the line.

Completing these operational checks is not just good practice; it is a critical safety requirement. A significant number of workplace injuries and fatalities each year involve forklifts, and many are preventable.

Properly checking the brakes, steering, and hydraulics is your best defense against becoming a statistic. For a deeper dive into the specific risks and regulations, the forklift safety standards from WorkSafe are an excellent resource. These operational tests are what tell you the machine is genuinely ready for a full, safe shift.

Moving Your Forklift Checklist from Paper to Digital

We have all seen them: the dog-eared, grease-stained paper checklists hanging off a clipboard in the workshop. While they feel familiar, paper checklists come with a lot of baggage. They get lost, damaged by rain, or worse, just "pencil-whipped" without a real inspection ever taking place. For a task as critical as your pre start checklist forklift inspection, relying on a system with so many weak points is a huge risk.

Imagine an operator spots a minor hydraulic leak. They tick the box and drop the sheet into an overflowing "in" tray. That vital piece of information could sit there for hours, or even a whole shift, before a supervisor or the maintenance team sees it. Meanwhile, a faulty forklift remains in service, putting people and productivity at risk.

The Problem with Paper Trails

A clipboard and pen might seem simple, but they introduce a ton of friction into your safety process. Think about the real-world consequences when an issue is found:

- Delayed Reporting: The fault is not communicated until someone physically hands that piece of paper over. This creates a critical lag time, slowing down repairs and increasing the odds that another operator, unaware of the problem, jumps on the machine.

- Poor Record-Keeping: Paperwork gets misplaced, filed incorrectly, or becomes completely unreadable over time. When it is time for an audit or you need to track recurring faults on a specific machine, you are left sifting through stacks of messy forms. It is a massive waste of time.

- No Verifiable Proof: A simple tick in a box does not actually prove the check was done properly. There is no easy way to include photo evidence of damage or verify precisely when and where the check was completed.

Switching to a digital system is not about adding complexity; it is about eliminating these classic failure points. A tool like Safety Space creates an immediate, clean, and searchable trail for every single inspection.

Real Advantages of Going Digital

A digital checklist solves these problems head-on. When an operator logs a fault on a tablet or phone, an instant notification can be sent straight to the maintenance crew. They get an alert with exactly what is wrong, which machine is affected, and can even see a photo of the issue attached to the report.

This makes it easy to track trends over time, like a forklift that is consistently low on hydraulic fluid, a clear sign of a bigger problem brewing.

This kind of data-driven insight is something paper forms just cannot offer.

Paper Checklist vs Digital Checklist

The practical differences between sticking with paper and moving to a digital solution are night and day. Here is a quick breakdown of what that looks like in practice.

| Feature | Paper Checklist | Digital Checklist |

|---|---|---|

| Reporting Speed | Manual hand-off; delays are common | Instant notifications sent to relevant teams |

| Evidence | Tick boxes only; no proof | Photos and videos can be attached directly to the report |

| Record Retrieval | Slow, manual search through physical files | Instant, searchable access to all historical records in the cloud |

| Data & Trends | Impossible to track trends without manual data entry | Automatically tracks recurring faults and fluid levels |

| Accountability | Easy to "pencil-whip" with no real checks | GPS and time-stamping verify when and where the check was done |

| Lost/Damaged Records | High risk; paper is easily lost, damaged, or unreadable | Secure cloud storage eliminates risk of loss or damage |

The takeaway is clear. While paper has been the standard for decades, it introduces unnecessary risks and inefficiencies that modern workplaces cannot afford.

The advantages are practical and immediate. Digital forms are automatically time-stamped and stored securely, creating a perfect audit trail for compliance. Finding a specific forklift's inspection history from six months ago takes seconds, not hours of digging through a dusty filing cabinet. This is about making a critical safety task more reliable, transparent, and efficient.

Your Forklift Check Questions Answered

When it comes to forklift pre-start inspections, the same questions tend to pop up time and time again. Let’s cut through the noise and get straight to the practical answers you need on the ground.

What Should I Do if I Find a Fault?

If you spot a problem during your check, especially a critical one involving the brakes, steering, or mast, the answer is simple: do not use the forklift. Stop right there.

Your first move is to tag the machine 'Out of Service' immediately. This ensures no one else on the shift hops on and drives it, unaware of the danger. Then, you need to report it to your supervisor or the maintenance team, following whatever your site's specific process is. The forklift stays parked until a qualified mechanic has fixed it and officially signed it off as safe to use. Cutting corners here just is not worth the risk to you or your mates.

How Often Does a Pre-Start Check Need to Be Done?

A full pre start checklist forklift inspection needs to be completed at the very beginning of every shift, before the forklift is used for the first time. Think of it as a required part of your daily routine.

It does not stop there. If you switch to a different forklift halfway through your shift, you must complete a fresh pre-start check on that new machine. You cannot just assume the last operator did it properly or that their check covers your responsibility. Every machine, every shift, it is that simple.

The operator is responsible for performing the daily pre-start check. However, supervisors and site managers are ultimately responsible for ensuring all operators are trained on the procedure and that checks are completed and documented correctly. It's a shared responsibility.

Who Is Responsible for Making Sure the Check Is Done?

While the operator is the one with the checklist in hand, the responsibility is definitely shared across the team.

The operator has the direct, hands-on responsibility to carry out a thorough check every single day. But it goes higher than that.

The site supervisor or manager holds the ultimate accountability. They are responsible for making sure:

- Every operator has been properly trained on how to do the inspection.

- There is a solid system in place to document that the checks are actually happening.

- The procedures for reporting and fixing faults are crystal clear and followed by everyone.

This idea of shared responsibility is the glue that holds a safe workplace together. It is a core principle that you can explore further by understanding the importance of regular safety audits for your business, which helps connect these daily tasks to the bigger picture of site-wide compliance.

Ready to move past paper and get your inspections organized? Safety Space offers a fully customisable platform that makes your forklift checks faster, more accurate, and easier to track. Book a free demo today and see how you can simplify compliance and protect your team.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.