Navigating Queensland's WHS legislation can feel like trying to assemble flat-pack furniture without the instructions. It seems complicated, but once you understand the core principles, everything starts to click into place. The main piece you need to know about is the Work Health and safety Act 2011. It’s the foundation for every safety rule in the state.

Getting to Grips with WHS Law

At its heart, Queensland's WHS legislation is all about one thing: stopping people from getting hurt or sick at work. It marks a huge shift away from the old, reactive approach of pointing fingers after an incident. Instead, it’s about managing risks before they cause harm.

The whole legal framework really comes down to two key documents.

Think of it like building a house:

- The WHS Act 2011 is your blueprint. It lays out the big picture. It sets out your fundamental, non-negotiable duties to keep people safe.

- The WHS Regulation 2011 is your set of detailed instructions. It tells you how to build safely, giving you specific rules for high-risk jobs like working at heights, handling chemicals, or operating heavy machinery.

These two work together to create a legally binding structure for every business in Queensland. Understanding how they connect is the first real step toward getting compliance right.

The Move to Harmonised Laws

Queensland's laws didn't just appear out of thin air. The Work Health and Safety Act 2011 was a game-changer, bringing the state in line with a national push for more consistent safety standards across Australia.

This all kicked off back in 2008 when the Council of Australian Governments (COAG) agreed to create a 'model' set of WHS laws that every state and territory could adopt. The idea was to stop reinventing the wheel and create a more unified approach.

This "harmonised" model means that if you run a business that operates across state lines, you’re not starting from scratch with a completely different rulebook every time you cross a border. Your core duties remain largely the same, which makes life a lot simpler.

The single most important principle is that everyone deserves the highest possible level of protection from workplace hazards and risks, so far as is reasonably practicable.

What This Means for Your Business

So, how do you turn all this legal theory into practical, everyday action? It helps to focus on a few key ideas that are found throughout the legislation. These are your daily instructions.

Here are the big three:

- Manage Your Risks: Don't wait for something to go wrong. You have to actively look for hazards, figure out how serious the risks are, and put solid controls in place to either eliminate or minimise them.

- Everyone Has a Duty of Care: From the CEO in the boardroom to the supervisor on the factory floor, anyone in a position of influence has a legal duty to protect the health and safety of their team and others.

- Talk to Your Team: You must consult with your workers on safety issues. That means actually listening to their feedback and taking it on board when you make decisions that affect their health and safety.

Keeping up with changes to these laws is just as important as understanding them in the first place. Staying on top of Regulatory Change Management is non-negotiable for ensuring you remain compliant over the long term.

Who's Actually Responsible for Safety? A No-Nonsense Guide

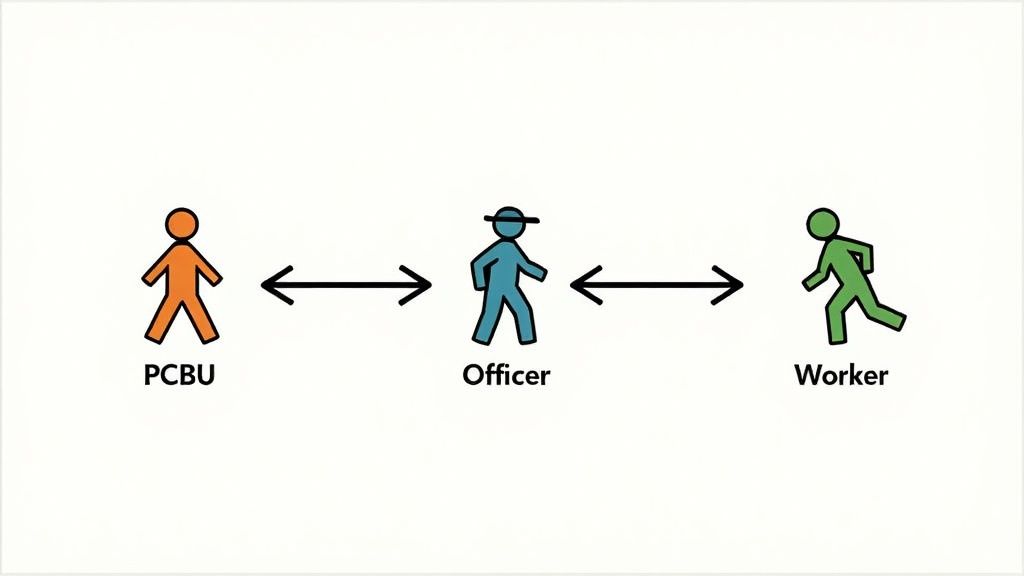

When an incident happens, the first question is always, "Who was responsible?" But under Queensland’s WHS legislation, the answer isn't a single person. The law establishes a clear chain of responsibility, assigning specific legal duties to different roles within a business.

If you don't know who these ‘duty holders’ are and what they’re accountable for, you can't effectively manage safety or meet your legal obligations. It’s that simple.

This isn't about pointing fingers. It's a framework to ensure everyone, from the CEO down to the apprentice on their first day, understands their role in keeping the workplace safe. It’s designed so nothing and no one falls through the cracks.

The PCBU: The Buck Stops Here

The first and most important term you need to understand is PCBU, which stands for a Person Conducting a Business or Undertaking. This is the broadest and most fundamental duty holder in the eyes of the law.

Don't just think "company." A PCBU could be a sole trader, a partnership, a government department, or even a not-for-profit club. If you're running any kind of operation, you're almost certainly a PCBU.

The PCBU holds the primary duty of care. This means you must ensure, so far as is reasonably practicable, the health and safety of your workers and anyone else who could be affected by what you do. That includes visitors, contractors, and the public. It’s a responsibility covering everything from the physical environment to your work processes.

A PCBU’s duty is proactive, not reactive. The law demands you hunt down risks and implement controls before something goes wrong, not just clean up the mess afterward.

What Is an Officer’s Job?

Next up are the Officers. An officer is anyone who makes or helps make decisions that affect a significant part of the business. We're talking about company directors, CEOs, and senior executives with real influence over how the business runs and where the money goes.

Officers can't just palm off their safety duties. They have a personal, active duty to exercise due diligence to make sure the PCBU is actually meeting its obligations.

This is a very hands-on role. Due diligence isn't a box-ticking exercise; it requires officers to take reasonable steps to:

- Keep their knowledge of WHS matters current.

- Understand the business's operations and its specific hazards and risks.

- Ensure the PCBU has the right resources and processes to manage those risks.

- Check that there are systems for hearing about incidents, hazards, and risks, and for responding quickly.

- Verify that all these resources and processes are actually being used and are working.

In short, an officer needs to be able to prove they are actively overseeing the company's safety management. You can't just set up a system and walk away.

The Role of Workers and Others on Site

Safety isn't just a management problem. Everyone on site has a part to play. Workers have a duty to take reasonable care of their own health and safety. Just as importantly, they must ensure their actions (or lack thereof) don't put others at risk.

This means workers are legally required to follow reasonable safety instructions and cooperate with company policies. If the rule says wear a hard hat, you wear a hard hat. It also means using equipment correctly and speaking up when you spot a hazard.

Finally, the law covers Other Persons at the Workplace. Think visitors, customers, or delivery drivers. Just like workers, they have a basic duty to look after their own safety and follow any reasonable instructions given by the PCBU.

To make this crystal clear, let's look at how these duties play out in a real-world setting. The table below summarises the key responsibilities for each duty holder, using a construction site as a practical example.

Key Duty Holder Responsibilities Under the WHS Act

| Duty Holder | Primary Responsibility | Practical Example (Construction Site) |

|---|---|---|

| PCBU | Provide and maintain a safe work environment, safe plant, and safe systems of work. | Ensuring all scaffolding is erected correctly by a licensed scaffolder and is inspected regularly before use. |

| Officer | Exercise due diligence to ensure the PCBU meets its duties. | Reviewing incident trend data, approving the budget for new fall arrest systems, and asking pointed questions about the site traffic management plan. |

| Worker | Take reasonable care for their own safety and follow instructions and procedures. | Conducting a pre-start check on a scissor lift, wearing their safety harness when working at height, and reporting a damaged power lead immediately. |

| Other Person | Take reasonable care for their own safety and follow site rules and instructions. | A concrete truck driver following the designated vehicle pathways and waiting for a spotter before reversing. |

As you can see, everyone has a distinct but connected role.

Putting all this into practice hinges on clear communication and solid documentation. Having well-defined WHS policies and procedures is non-negotiable; it gives everyone the playbook they need to meet their obligations every single day.

A Practical Process for Managing Risks

Knowing your duties is one thing, but Queensland's WHS legislation is all about action. It demands a hands-on, systematic process for managing risks. The goal is to build a practical loop of finding, assessing, and controlling hazards before they can hurt someone.

The whole system is built on a simple idea: be proactive, not reactive. The law expects you to actively look for trouble spots, not wait for an incident to show you where the problems are.

This simple, three-step process is the heart of your day-to-day safety obligations.

This visual shows the continuous loop required by the legislation, constantly moving from identification through to action and back again.

Step 1: Find the Hazards

You can't fix a problem you don't know exists. The first step, known in the legislation as hazard identification, is to methodically find anything in your workplace that could potentially harm someone.

Think of it like being a detective on your own worksite. You need to look at every task, piece of equipment, and work area with fresh eyes.

Common methods for finding hazards include:

- Workplace Inspections: Regularly walk the site with the specific goal of spotting potential issues. Look for things like unguarded machinery, messy walkways, or unsafe work practices.

- Worker Consultation: This is crucial. Talk to the people actually doing the jobs. They have firsthand experience and often know exactly where the real-world risks are hiding.

- Reviewing Incident Reports: Your own incident and near-miss reports are a goldmine of information about what could go wrong.

Let’s take a real-world example: a forklift operating in a busy manufacturing warehouse. A hazard identification process might uncover blind corners where the forklift could collide with pedestrians, unstable pallets that could fall, or a noisy environment where workers can't hear the forklift coming.

Step 2: Assess the Risks

Once you have a list of hazards, you need to figure out how serious they are. This is the risk assessment phase. For each hazard, you need to work out the likelihood of something going wrong and the potential consequences if it does.

A forklift colliding with a worker in a busy warehouse with blind corners is highly likely, and the consequences could be catastrophic. This is a high-priority risk demanding immediate attention.

Under Queensland WHS law, your duty is to manage risks 'so far as is reasonably practicable'. This means you must tackle the most serious risks first, directing your resources where they'll have the biggest impact.

Step 3: Control the Risks

Now it's time to take action. The legislation requires you to control risks using a specific method called the hierarchy of controls. This is a ranked system, from most effective to least effective. You must always aim as high up the hierarchy as you can.

Let's apply this to our forklift example.

- Elimination: The best option. Can you get rid of the hazard completely? Maybe you can automate the movement of goods so no forklift is needed in pedestrian areas at all.

- Substitution: Can you replace the hazard with something safer? Perhaps using a smaller, slower automated guided vehicle (AGV) instead of a traditional forklift.

- Isolation: Can you physically separate people from the hazard? Installing safety barriers and creating designated, protected walkways for pedestrians is a great example.

- Engineering Controls: Can you change the equipment or environment? This could mean fitting the forklift with proximity sensors that automatically slow it down near people, or installing convex mirrors on blind corners.

- Administrative Controls: These are rules and procedures. Think of things like a traffic management plan with speed limits, extensive operator training, and using spotters. A dedicated Learning Management System (LMS) is a great way to manage and track this training.

- Personal Protective Equipment (PPE): This is your last line of defence. Requiring workers to wear high-visibility vests is a PPE control. It doesn't stop the incident from happening, but it might reduce its severity.

You have to work your way down this list. You can’t just jump to handing out hi-vis vests without first properly considering if you can eliminate, substitute, or isolate the hazard.

Step 4: Review Your Controls

Finally, risk management isn't a "set and forget" activity. You have a legal duty to regularly review your control measures to make sure they're still working. A control that was effective yesterday might not be tomorrow if a process changes or new equipment is introduced.

This review process keeps your safety system alive, relevant, and compliant with your ongoing duties under the Queensland WHS legislation.

Making Consultation and Worker Input Count

If there's one thing the Queensland WHS legislation is absolutely clear on, it's this: you must consult with your workers on safety. This isn't just a nice-to-have or a box-ticking exercise; it’s a non-negotiable legal duty. The people actually doing the work are often the ones who have the sharpest insights into the real-world risks.

"Consultation" isn't about putting up a poster, sending out a memo, or telling your team what’s already been decided. It’s a two-way street. You share information, you give your workers a real chance to voice their opinions, and you take those views into account before making a final call.

This legal duty kicks in any time you’re making a decision that could impact your workers' health and safety. You can't just change a work process, roll out new machinery, or tweak safety procedures without first talking to the people on the ground who will be affected by it.

When You Are Legally Required to Consult

Under the Act, certain situations trigger a mandatory requirement to consult. Getting this wrong can land you in serious trouble with the regulator. The whole point is to ensure decisions are made with input from those doing the work, not just from an office.

You must consult your team when you are:

- Identifying hazards and assessing risks: Your workers’ hands-on experience is gold. They’ll spot things a manager might miss.

- Making decisions about risk controls: Before you implement a new control measure, you need to talk to the people who will actually have to use it. Is it practical? Will it create other problems?

- Changing workplace facilities: This covers everything from the adequacy of first aid kits and break rooms to the type of personal protective equipment (PPE) you provide.

- Altering procedures: Any changes to how work gets done, especially procedures for resolving safety issues or monitoring health, require proper consultation.

This process is what makes safety measures work in the real world, not just on a piece of paper.

Practical Ways to Get Worker Input

The legislation outlines a few formal structures for consultation, but it’s flexible enough to allow for less formal methods, too. The trick is to find a system that actually works for your specific workplace and your team.

The two most common formal structures are Health and Safety Representatives (HSRs) and Health and Safety Committees (HSCs).

- A Health and Safety Representative (HSR) is a worker elected by their colleagues to represent them on safety matters. They have real legal powers, like inspecting the workplace after an incident or issuing a Provisional Improvement Notice (PIN) if they spot a legislative breach.

- A Health and Safety Committee (HSC) is a forum that brings workers and management to the same table to work out safety issues together. They are perfect for developing and reviewing WHS policies and procedures collaboratively.

Consultation isn't about reaching 100% agreement; it's about genuinely seeking input. The final decision-making power still rests with the PCBU, but you must be able to prove you seriously considered what your workers had to say.

The Role of Health and Safety Representatives

If your workers ask for an HSR, you are legally obligated to facilitate the election process. Once elected, that HSR becomes a central figure in your consultation framework. It's crucial to understand their role: they are not the company's unpaid safety officer. They are the voice for their work group.

An HSR has specific powers and functions, including:

- Representing their work group on all WHS matters.

- Monitoring the safety measures you've put in place.

- Investigating complaints from workers about health and safety.

- Inspecting the workplace after an incident or if there's a situation with an immediate risk.

It's vital that you give HSRs the time and resources they need to do their job properly, which includes paying for them to attend approved HSR training. Building a constructive relationship with your HSRs is one of the most effective ways to meet your consultation duties under the Queensland WHS legislation.

Responding to Workplace Incidents

Knowing what to do after a workplace incident goes beyond first aid and paperwork. It's a critical legal process under the Queensland WHS legislation, and how you react in those first few hours directly impacts your team’s wellbeing and your business’s compliance.

The law is clear about certain types of events, which it calls notifiable incidents. We're not talking about minor cuts or scrapes here. These are serious events that legally require you to pick up the phone and inform Workplace Health and Safety Queensland (WHSQ) immediately.

Understanding Notifiable Incidents

A notifiable incident isn't just safety jargon; it's a specific legal category that covers the death of a person, a ‘serious injury or illness’, or a ‘dangerous incident’. Understanding this definition is the first step to meeting your obligations.

A serious injury or illness is one that requires a person to have:

- Immediate treatment as an in-patient in a hospital.

- Immediate treatment for major injuries like amputation, serious head or eye trauma, or severe burns.

- Medical treatment within 48 hours of being exposed to a substance.

A dangerous incident is what you might call a massive near-miss. An event that exposes anyone to a serious risk to their health or safety. Think of a collapsing structure, an uncontrolled explosion, or the catastrophic failure of major equipment.

The rule of thumb is simple: if in doubt, notify. The penalties for failing to report a notifiable incident are far more severe than reporting something that, after review, doesn't quite meet the threshold.

Your Immediate Legal Duties

When a notifiable incident occurs, you have two urgent legal duties. First, you must notify WHSQ by the fastest means possible, which almost always means a phone call. After that initial call, you’re required to submit a written notification within 48 hours.

Your second critical duty is to preserve the incident scene. You can’t disturb the site where the incident happened until an inspector gives you the all-clear. That means no cleaning up or moving equipment, unless it's absolutely necessary to make the site safe or to help an injured person.

From Reaction to Prevention

Once the immediate response is under control, your focus has to shift to learning from what went wrong. The goal of an internal investigation isn't to point fingers or assign blame. It's about digging deep to find the root causes so it never happens again.

A solid investigation involves a few key steps:

- Gathering physical information from the scene (think photos, measurements, and a clear picture of the environment).

- Interviewing everyone involved and any witnesses, always one-on-one.

- Analysing all the information to pinpoint the contributing factors and systemic failures.

This whole process is about understanding why your existing safety controls failed. Documenting everything is crucial, and using a structured system makes a world of difference. To see what a good system looks like, check out our guide with an incident reporting sample.

The history of the WHS Act underscores why this is so vital. While reforms have helped reduce workplace fatalities over the years, tragic events like the 2016 Dreamworld incident, where four people died, serve as a stark reminder that significant risks remain. These major events often trigger further reviews and a tightening of safety laws, which you can learn more about in this review of the Work Health and Safety Act.

What Happens During a WHSQ Inspection?

Knowing your duties under the Queensland WHS legislation is one thing, but understanding how it's enforced is just as critical. The regulator on the ground is Workplace Health and Safety Queensland (WHSQ), and an inspector's visit is a key part of how the law is upheld.

Knowing what to expect if an inspector walks through your door helps you manage the situation calmly and professionally.

First things first, an inspector's visit isn’t automatically a sign that you've done something wrong. WHSQ runs proactive inspections as part of broader safety campaigns, but they also conduct reactive visits if there’s been an incident report or a complaint. Either way, their purpose is the same: to check that you're meeting your legal safety obligations.

The Powers of a WHSQ Inspector

Don't underestimate the authority of a WHSQ inspector. They have significant legal powers to do their job effectively, and they don't need your permission or a warrant to enter your workplace during business hours.

Once they're on-site, an inspector is legally allowed to:

- Inspect and examine every part of the workplace, including equipment and substances.

- Take measurements, conduct tests, and capture photos or videos.

- Seize equipment or take samples of materials for later analysis.

- Review and take copies of any documents related to health and safety.

- Interview anyone at the workplace and require them to answer questions.

Let me be clear: obstructing, intimidating, or even just failing to give an inspector reasonable help is a serious offence. Your cooperation isn't just good practice; it's a legal requirement.

What Inspectors Are Actually Looking For

During an inspection, the WHSQ representative is hunting for objective evidence. They aren't there to give you their personal opinion; they're there to see if your safety systems and processes stack up against the Work Health and Safety Act and Regulation.

They’ll usually focus on your risk management for the biggest hazards on your site. If you run a manufacturing plant, for example, that probably means they'll be looking closely at your machine guarding, your traffic management plan, and how you handle hazardous chemicals.

An inspector will almost always ask for your paperwork. Think risk assessments, safe work procedures, training records, and consultation meeting minutes. Having these documents well-organised and ready to go is one of the simplest ways to demonstrate you're on top of your compliance.

Potential Outcomes of an Inspection

If an inspector does find a breach of the Queensland WHS legislation, they have a few different tools they can use. The action they take will depend entirely on how serious the risk is.

- Improvement Notice: This is the most common outcome. It’s a formal direction to fix a specific problem within a set timeframe.

- Prohibition Notice: This is much more serious. It's issued when an activity poses an immediate or imminent risk to someone's health. It legally forces you to stop that activity immediately until the risk is properly controlled.

- Infringement Notice: For less severe breaches, an inspector can issue an on-the-spot fine, much like a traffic ticket.

In the most serious cases of negligence or reckless conduct, WHSQ won't hesitate to pursue legal prosecution. This can lead to massive fines for the business and, for company officers, the very real possibility of imprisonment.

Common Questions About Queensland WHS Legislation

Getting your head around Queensland's WHS legislation can feel like a mammoth task. It’s easy to get bogged down in the details, so let's clear up a few of the most common questions that trip people up.

What Is the Main Difference Between the Act and Regulation?

This is a classic point of confusion. The simplest way to look at it is the WHS Act 2011 is the ‘what,’ and the WHS Regulation 2011 is the ‘how.’

The Act lays out the big picture. It establishes your fundamental, non-negotiable legal duties, like the primary duty of care. It’s the foundational document that defines who holds responsibility for safety.

The Regulation then drills down into the details. It provides the specific, practical instructions you need to follow to actually meet those duties. For example, the Act tells you that you must manage risks. The Regulation gives you the detailed rules for how to do that for high-risk work, like operating cranes, working in confined spaces, or handling asbestos.

Do I Legally Need a Formal Safety System?

You won't find the exact phrase 'Safety Management System' in the legislation. But don't let that fool you. The law absolutely requires you to have solid, working processes in place to manage risks, consult with your people, provide training, and handle incidents.

For most businesses, especially if you're in a high-risk industry like construction or manufacturing, a documented system is really the only practical way to prove you’re doing what’s required. The complexity of that system just needs to be scaled to the size of your business and the seriousness of your risks.

A documented process isn't just about ticking a compliance box; it's your proof that you take safety seriously and have a structured, repeatable way of managing it.

Am I Responsible for Contractor Safety On My Site?

Yes, one hundred percent. As the PCBU (Person Conducting a Business or Undertaking), your primary duty of care covers everyone at your workplace. That absolutely includes contractors and their workers.

You have a legal duty to ensure, so far as is reasonably practicable, that their health and safety isn't put at risk by the work they're doing for you.

This isn’t just a handshake agreement. It means you need robust processes for:

- Choosing contractors who are actually competent for the job.

- Giving them proper, site-specific inductions so they know your rules.

- Keeping an eye on their work while they are on your site.

And critically, you must consult, cooperate, and coordinate with the contractor (who is also a PCBU). Where your work overlaps, you have a shared responsibility to manage the risks together.

At Safety Space, we get that managing all of this with spreadsheets and paperwork is a nightmare. Our platform brings it all together, helping you manage risks, track training, and handle incidents in one simple place. See how we can help you stay compliant with Queensland WHS laws by booking a free demo.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.