In the world of construction and heavy industry, risk and compliance are two sides of the same coin. They aren't just corporate buzzwords; they're the difference between a project running smoothly and a project grinding to a halt because of an accident, a fine, or a failed audit.

Think of risk as anything that could go wrong on your site. Compliance is simply the set of rules you must follow to stop those things from actually happening.

What Risk and Compliance Means on Site

Let’s cut through the jargon. Imagine you’re getting a mandatory inspection for a company truck. The risks are all the potential mechanical failures: worn brake pads, bald tyres, a dodgy sensor. Any one of these could cause a serious accident, delay a critical delivery, or get you slapped with a hefty fine.

The compliance part is the official checklist the mechanic uses. Every single item, from checking tyre pressure to testing the brake fluid, is a specific, non-negotiable action. It's designed to find and fix those risks before they cause a disaster. Following that list isn’t optional; it’s a legal requirement to keep the truck on the road.

Your worksite operates on the exact same principle. Risk is the potential for an incident, while compliance is the documented, repeatable process you follow to control it. It's not about mindlessly ticking boxes; it's about actively managing potential disasters by sticking to proven rules and procedures.

Connecting Risk to Actionable Compliance

Every single task on a busy site, from a simple lift to a complex installation, carries some level of risk. The trick is to draw a straight line from each of those risks to a clear, non-negotiable compliance action. This is how you turn abstract theory into a practical, daily responsibility for every person on your team.

For example, the risk of a fall from height isn't just a vague danger. It triggers very specific compliance requirements:

- Guardrail Installation: All platforms over a certain height must have compliant guardrails installed.

- Harness Inspection: Personal fall arrest systems must be checked according to a strict, documented schedule.

- Worker Training: Every worker operating at height must have a valid, current certification.

This direct link is the backbone of any effective health and safety program. Of course, this extends beyond physical safety. Understanding things like UK data retention policies is also fundamental to managing your organisation’s overall risk profile.

On site, risk is the 'what if,' and compliance is the 'what we do about it.' One cannot exist without the other; they are linked by action and accountability.

To make this crystal clear, let's look at how this plays out with everyday site hazards.

Common Risks vs. Required Compliance Actions

The table below breaks down some common site risks and the specific compliance actions needed to manage them. Notice how each action is a direct response to a potential problem.

| Common Site Risk | Required Compliance Action |

|---|---|

| Unauthorised worker operating machinery | Verify operator licences and certifications during induction and log them in a central system. |

| Chemical spill from improper storage | Store all hazardous materials according to the Safety Data Sheet (SDS) specifications in designated areas. |

| Equipment failure causing an injury | Adhere to a documented preventative maintenance schedule and conduct daily pre-start checks. |

| Subcontractor not following site rules | Require all subcontractors to complete a site-specific induction and sign off on site safety procedures. |

Ultimately, a strong compliance framework isn't about creating more paperwork. It's about building a predictable, controllable environment where everyone knows exactly what they need to do to keep themselves and the project safe.

The Forces Driving Today's Compliance Rules

Compliance rules don’t just pop up out of thin air. They're almost always a direct reaction to real-world events and pressures. Once you understand where these rules come from, you start to see that managing risk and compliance isn't just about paperwork; it's about survival in a tough industry.

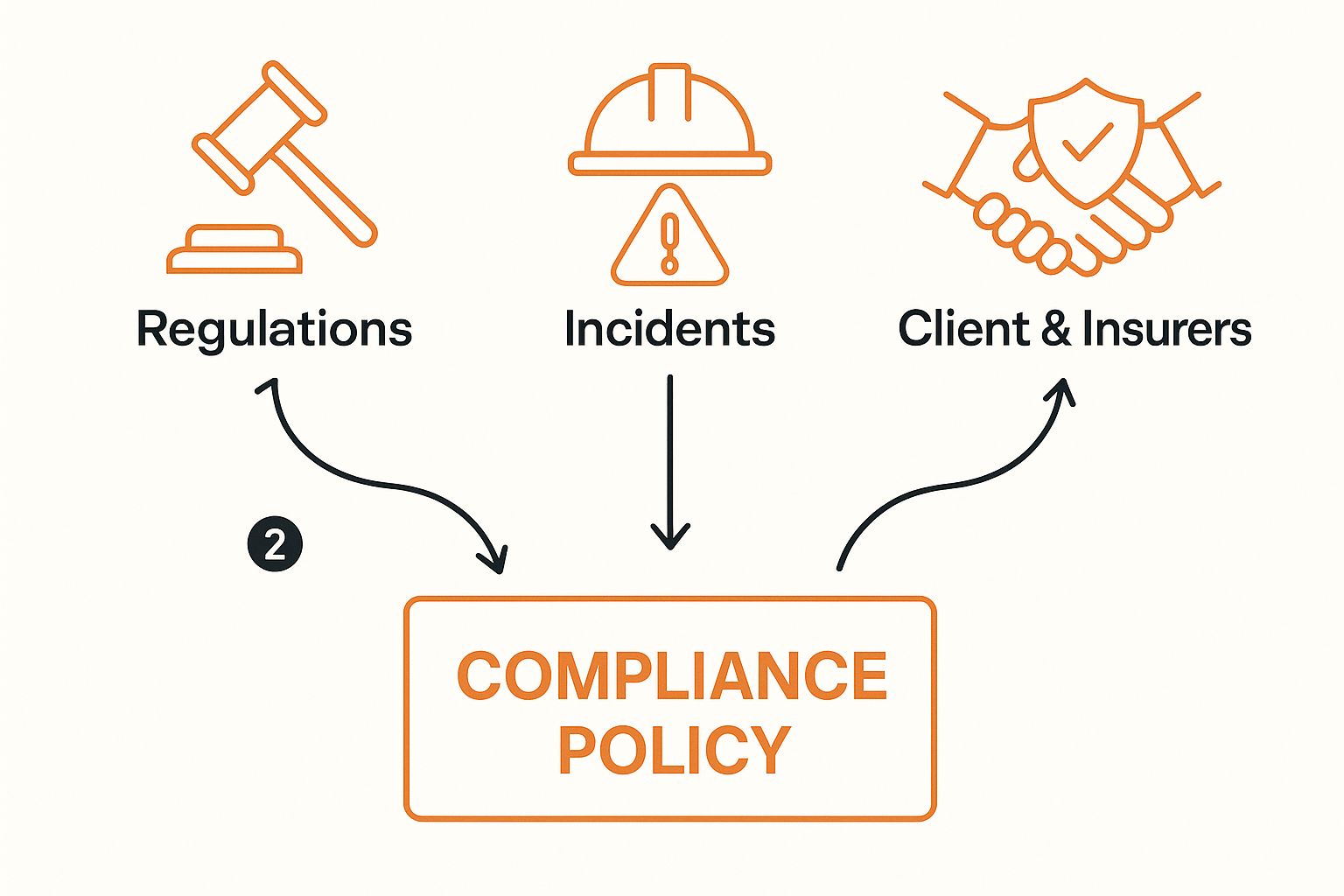

These forces are a mix of government action, industry incidents, and straight-up commercial demands. When a major accident happens on a worksite, it often triggers an official investigation and, eventually, tougher regulations for everyone. Government bodies like Safe Work Australia are constantly updating standards based on incident data and new technology.

But it’s not just the government setting the rules.

More Than Just Government Mandates

The commercial pressures to keep a strong compliance record are just as powerful as the legal ones. These days, clients and principal contractors are more selective than ever. They simply don’t want the liability that comes with hiring a contractor who has a dodgy safety history. A solid, verifiable compliance system is now a non-negotiable for even bidding on many high-value jobs.

Insurers play a massive role here, too. They won’t provide coverage to businesses that can’t show a structured approach to managing risk. No insurance means no work. It really is that simple. These commercial realities have pushed compliance from a back-office chore to a core business function that directly impacts your ability to win contracts and stay profitable.

The infographic below shows how regulations, incidents, and commercial pressures all feed into the compliance policies you have to manage every day.

This flow makes it crystal clear that your compliance framework is shaped by multiple forces at once, not just a single government department.

The Evolving Regulatory Landscape

The world of compliance never stands still; it's constantly changing. For instance, significant Regulatory Reform in Fire Safety Standards continually shapes the landscape, particularly around electrical safety and fire protection systems. What was perfectly acceptable last year might not be today, which means you have to keep a close eye on new legislation and standards.

This constant evolution means that achieving compliance isn't a one-and-done project. It’s an ongoing process. You only have to look at the sharp increase in enforcement actions across different sectors to see this in action.

Fines for non-compliance have escalated massively, with some penalties hitting up to $50 million. This aggressive approach from bodies like ASIC and the ACCC shows a clear trend: businesses are being held more accountable than ever for how they manage their risk and compliance.

Staying compliant is like maintaining a machine. You can’t just set it up and walk away. It needs constant monitoring, adjustment, and updates to keep performing correctly and safely.

The key takeaway is that compliance isn't just about ticking boxes. It's about navigating a complex environment where legal, financial, and client expectations all meet. Being proactive means you're prepared for audits, you're more attractive to new clients, and you’re protected from financial shocks. Keeping up is essential, and understanding your options for things like global compliance certification can give you a major competitive edge.

A Four-Step Process for Managing Site Risk

Managing risk on a busy construction site or in a manufacturing plant doesn't need to be a complicated, academic exercise. Forget getting tangled in complex theories. What you really need is a simple, repeatable process your team can grab and use in any situation.

A good, structured approach to risk and compliance just takes the guesswork out of the equation. It gives everyone on site a clear, logical set of steps to follow.

Think of this practical, four-step framework as a basic operating procedure for site safety. It's designed to be used immediately to spot, assess, and control hazards before they turn into real problems. Whether you're planning a deep excavation or just setting up a new piece of machinery, this process works.

Step 1: Identify the Hazards

First things first, you need to look for anything that has the potential to cause harm. A hazard is just a source of danger; it's not the incident itself.

For example, an unguarded edge on a second-storey platform is the hazard. The risk is someone falling from it.

Spotting hazards has to be an active, ongoing job. You can't just tick a box once and assume you're done.

- Walk the Site: Get out there and walk through the work area regularly. Keep your eyes peeled for changes in conditions, new equipment, or different tasks being performed. This is where you'll find most of your issues.

- Talk to Your Crew: The people on the tools often have the best feel for what's dangerous. Ask them directly: what are you worried about? Which tasks feel a bit sketchy? Their insights are valuable.

- Review Past Incidents: Dig into your near-miss reports and old incident logs. These aren't just bits of paper; they're clues that point to recurring problems that haven't been properly fixed.

By constantly scanning for these sources of danger, you build the foundation for everything that follows.

Step 2: Assess the Risk

Once you've spotted a hazard, the next question is: how bad is it? This is where risk assessment comes in. You're looking at two key things: the likelihood of something going wrong, and the potential consequences if it does. This simple check helps you prioritise what to fix first.

An open trench on a busy site, for instance, has a high likelihood of someone falling in and the consequences would be severe. That makes it a high-priority risk that needs immediate attention.

On the other hand, a slightly uneven patch of pavement in a quiet, low-traffic corner of the site has a much lower likelihood of causing a trip, and the consequences are probably just a twisted ankle. It still needs fixing, but it's not as urgent.

A proper risk assessment isn't about creating paperwork. It's a practical way to focus your time, money, and effort on the hazards that pose the greatest threat to your people and your project.

You don't need a PhD in statistics to do this. A simple high, medium, or low rating for both likelihood and consequence is often more than enough to get you started. For more complex operations, you might want to dig deeper with methods like a bowtie risk assessment to really map things out.

Step 3: Control the Risk

Okay, you've assessed the risk. Now what are you going to do about it? This step is all about putting practical controls in place to either get rid of the hazard completely or, at the very least, reduce the risk to an acceptable level.

There’s a well-known pecking order for this, called the hierarchy of controls. It’s not just a suggestion; it’s the proven way to make sites safer.

- Elimination: The best possible outcome. If you can get rid of the hazard entirely, you've won. For example, designing a building so work can be done from the ground eliminates the need to work at height in the first place.

- Substitution: Can't eliminate it? Try swapping it for something safer. Think using a less toxic chemical for a cleaning task or a different type of equipment that's inherently safer.

- Engineering Controls: This is about physically isolating people from the hazard. We're talking about things like installing guardrails around open edges, putting soundproof enclosures around noisy machinery, or adding machine guarding.

- Administrative Controls: Here, you change the way people work. This includes things like developing safe work procedures (SWMS), putting up clear warning signs, or limiting the amount of time workers are exposed to a hazard.

- Personal Protective Equipment (PPE): This should always be your last line of defence. Hard hats, safety glasses, and harnesses are there to protect workers when all other controls aren't enough to do the job.

Always aim as high up that list as you possibly can. If you find yourself relying only on PPE, it's a huge red flag that you've missed an opportunity to implement a more effective control.

Step 4: Review and Adjust

Finally, you need to check if your controls are actually working and be ready to tweak them. Worksites are dynamic. New people show up, different gear is used, and the weather can change in an hour. A control that was perfect yesterday might be useless today.

Set a schedule to regularly review your risk assessments, especially after an incident, a near miss, or when a new process is introduced.

Most importantly, get feedback from your team. Are the new procedures practical out on site? Is that new guardrail actually in the right spot? This continuous feedback loop is what makes sure your risk and compliance efforts stay effective. It turns risk management from a one-off task into a continuous cycle of improvement.

Overcoming Common Compliance Roadblocks

Even with the best-laid plans, risk and compliance management hits real-world snags. On a busy site, things rarely go to script. Instead, you're left dealing with a messy mix of frustrations that slow things down, create confusion, and can leave you seriously exposed during an audit.

These roadblocks aren't just theoretical problems; they're the daily friction that gets in the way of a safe, productive operation. From chasing down paperwork to proving your team is actually qualified, these issues can feel like a constant battle. The good news? For every common roadblock, there's a practical fix.

Mismatched and Missing Paperwork

One of the biggest headaches is inconsistent paperwork. When different crews and subcontractors all use their own versions of forms, you end up with a jumble of mismatched documents. Come audit time, you’re left trying to piece together a coherent story from a pile of conflicting info, a massive red flag for any inspector.

It gets worse when forms go missing entirely. A lost inspection sheet or a forgotten pre-start check creates a gap in your compliance record that’s almost impossible to fill after the fact.

A strong compliance record is like a brick wall; every missing form is a hole in your defence. When an auditor comes knocking, those gaps are the first thing they'll find.

The most effective fix is to standardise everything through a central digital system. By providing one set of official forms that everyone has to use, you kill the inconsistencies. Digital submission means nothing gets lost, and every record is time-stamped and stored securely, ready for review at a moment's notice.

Tracking Worker Certifications

Keeping on top of worker tickets and certifications is another huge challenge. On a large project with dozens of workers and subcontractors, manually tracking who is qualified for what, and when their tickets expire, is a nightmare. All it takes is one person with an expired high-risk work licence operating a crane to create a massive legal and financial liability.

The risk isn't just about non-compliance. It's about making sure the person doing a critical job is actually qualified to do it safely. Relying on a spreadsheet that someone updates once a month is just asking for trouble.

A simple, workable solution is a system with automated alerts. When you digitise worker records, you can set it up to automatically flag certifications nearing their expiry date. This gives you and the worker plenty of notice to arrange retraining, so you never have unqualified people on site.

The 'Tick-and-Flick' Problem

Perhaps the most dangerous roadblock of all is 'tick-and-flick' compliance. This is where workers just go through the motions, ticking boxes on forms without actually doing the checks. They do it just to get the paperwork done, which means critical safety steps might be skipped entirely. This creates a false sense of security where the paperwork looks perfect, but the reality on site is a completely different story.

This usually happens when forms are too long, too complicated, or just seen as a pointless administrative task. The paperwork becomes the job, instead of the safety check it’s supposed to represent.

To fight this, you need to make compliance meaningful and accountable.

- Simplify Forms: Cut out any unnecessary questions. Make them short, clear, and directly relevant to the task at hand.

- Add Photo Evidence: Require workers to attach a photo to their digital inspection forms. A quick picture of a correctly installed guardrail is a lot harder to fake than a tick in a box.

- Use Digital Signatures: Time-stamped digital sign-offs create a clear line of accountability. It makes people think twice before signing off on something they haven't actually checked.

This shift towards tech-driven solutions is part of a broader trend. In Australia, the market for governance, risk and compliance platforms is booming, projected to hit USD 3.7 billion by 2033. This growth is a direct response to increasing regulatory pressure and a clear move away from reactive checklists toward continuous, technology-enabled compliance. You can dig into more data on this trend by reading the full market analysis on IMARC Group.

By tackling these common roadblocks with practical, modern solutions, you can turn your risk and compliance program from a source of frustration into a genuine asset.

How a Central Platform Transforms Your Compliance

Let's be honest. Trying to manage risk and compliance with a tangled mess of spreadsheets, paper forms, and never-ending email chains is a recipe for disaster. It’s slow, disorganised, and just full of holes.

In a system like that, critical information disappears, updates get missed, and getting a clear, honest picture of your site’s safety status is next to impossible. Then an auditor shows up, and it’s a mad scramble to find documents buried in filing cabinets or lost in someone's inbox. This isn’t just inefficient; it’s a huge liability.

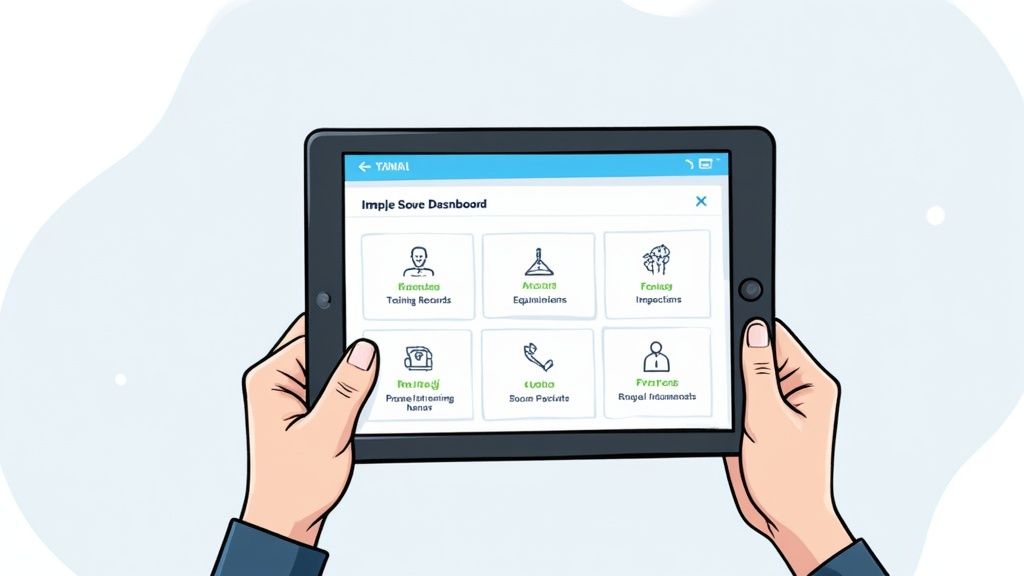

A central software platform cuts through all that chaos by creating a single source of truth for all your health and safety information.

Unifying Your Compliance Efforts

A central platform brings every part of your compliance management into one organised hub. Instead of juggling separate processes for different tasks, everything is connected and accessible from one place. This means you can manage a massive range of activities without constantly switching between programs or digging through paperwork.

- Worker Inductions: Onboard new workers and subcontractors with consistent digital inductions, making sure everyone gets the same critical safety information before they set foot on site.

- Training and Certification Records: Keep a live database of all worker qualifications. You’ll get automated alerts for expiring tickets so you're never caught out with an unqualified operator.

- Incident and Near-Miss Reporting: Let any worker instantly report an incident from their phone, capturing crucial details, photos, and location data right there on the spot.

- Equipment Inspections and Maintenance Logs: Schedule, assign, and track all machinery pre-starts and maintenance, creating an unbreakable digital audit trail.

- Safe Work Method Statements (SWMS): Develop, send out, and get digital sign-offs on your SWMS. This ensures every worker on a high-risk job has actually read and acknowledged the procedures.

By bringing all these functions together, the platform gives you a complete, real-time overview of your site's compliance health. No more guesswork.

The Power of a Single Source of Truth

Having one definitive place for all safety and compliance information is a genuine game-changer. It gets rid of the confusion and contradictions that happen when multiple versions of documents are floating around.

When everyone, from the site supervisor to the newest subcontractor, is working from the same set of data, mistakes and miscommunications plummet.

This single source of truth creates consistency. Everyone uses the same approved forms, follows the latest updated procedures, and accesses the same safety information. You simply can't achieve this level of standardisation with manual, paper-based systems.

A central platform acts like your site's memory. Every action, inspection, and sign-off is recorded, time-stamped, and instantly searchable, building a bulletproof compliance history that stands up to any scrutiny.

It also creates a clear and transparent record. You can see who completed what task, when they did it, and exactly what they reported. This built-in accountability makes it much harder for important steps to be skipped or for that dangerous 'tick-and-flick' mentality to creep in.

Audit-Ready Records on Demand

One of the biggest real-world benefits of a central system is how it prepares you for an audit. Instead of losing days or even weeks hunting for documents, you can pull comprehensive reports with just a few clicks.

Imagine an inspector asks to see the maintenance records for a specific crane over the last six months. With a paper system, that means a deep dive into greasy logbooks and messy filing cabinets. With a digital platform, you just filter by that asset and export a complete, time-stamped history in seconds.

This immediate access to verifiable data shows a professional and organised approach to risk and compliance. It proves to auditors that your processes are solid, consistent, and actively managed. It’s not just about passing the audit; it’s about proving you have a functioning system that protects your people every single day. A platform makes your compliance visible, provable, and always ready for inspection.

What to Look for in a Risk Management Tool

Choosing the right software for your risk and compliance management can make or break your efforts. The goal is to find a practical tool your team on the ground will actually use, not an overly complicated system loaded with features you'll never need.

A flashy interface is useless if it’s too confusing for a supervisor to use on-site. The best tools are designed for the realities of a busy worksite, focusing on functional, easy-to-use features that solve real problems. Before you commit to any platform, make sure it ticks a few essential boxes that align with how your industrial or construction business actually operates.

Core Functional Requirements

Your team needs a tool that works where they work, which often isn't behind a desk. That makes mobile access a non-negotiable. Supervisors and workers must be able to complete forms, report incidents, and access safety information directly from their phones or tablets in the field.

The tool should also adapt to your business, not the other way around. Look for a system with customisable forms. If you can build digital versions of the paper forms your team already knows and uses, adoption will be much faster and smoother. This completely removes the friction of learning a whole new system from scratch.

Finally, the information you collect is only useful if you can understand it quickly.

- Clear Reporting Dashboards: The platform has to give managers a simple, visual overview of what's happening. You should be able to see incident trends, overdue inspections, and compliance gaps at a glance, without digging through endless spreadsheets.

- Actionable Data: Reports shouldn't just be data dumps. They need to help you spot problem areas and make informed decisions about where to focus your resources.

Support and Scalability Are Key

Even the best software is useless without reliable support behind it. When you have a question or hit a technical snag, you need to know you can get a quick, helpful response from someone who understands your industry. Our advice? Test the customer support before you buy.

The tool also needs to grow with your company. A system that works for a small crew should be able to scale up as you take on larger projects or expand to new sites without needing a complete overhaul. This kind of long-term thinking saves you major headaches down the road. You can learn more about how a flexible system works by exploring different options for risk management software.

The right tool feels less like software and more like a reliable piece of equipment. It's there to do a specific job well, it's easy for your crew to operate, and it makes the entire worksite safer and more organised.

This mirrors the approach seen in other highly regulated sectors. For instance, the Reserve Bank of Australia’s latest Financial Stability Review shows that operational resilience and clear governance are top priorities for the financial industry. Their focus on robust risk management provides a valuable lesson for all industries managing compliance in a complex environment. You can discover more about the RBA's approach to financial stability on Regulation Tomorrow.

Got Questions? We've Got Answers

We get asked a lot about the nuts and bolts of managing risk and compliance on busy sites. To cut through the noise, here are some straight answers to the most common questions we hear. No jargon, just practical advice you can use today.

What’s the Real Difference Between Risk and Compliance?

It’s simpler than it sounds. Think of risk as the potential for something to go wrong: that dodgy scaffolding, a slippery floor, or an unguarded piece of machinery. It's the "what if" scenario.

Compliance, on the other hand, is the set of actions you’re legally required to take to control that potential. It's putting up that "wet floor" sign, installing a guard on the machine, or ensuring the scaffolding is certified. Risk is the hazard; compliance is the specific, mandated rule you must follow to deal with it.

So, Who’s Actually Responsible for Compliance on Site?

Legally, the buck stops with the PCBU (Person Conducting a Business or Undertaking), which is usually the company itself. But on the ground, it’s a team effort.

Managers and supervisors are the ones who have to implement and watch over the compliance procedures day-to-day. And every single worker has a duty to follow the rules to keep themselves and their mates safe. It's a shared responsibility, but ultimate accountability flows right to the top.

Compliance isn't one person's job; it's a system that falls apart if even one person fails to play their part. A single shortcut can put the entire site in jeopardy.

How Often Should We Be Reviewing Our Risk Assessments?

The simple rule is: review them whenever anything changes. That could mean bringing in new equipment, starting a different type of work, or unfortunately, after an incident or even a near-miss.

It's also just good practice to give them a look-over on a regular schedule, say, once a year. This ensures they haven’t become stale and are still fit for purpose for how your site operates now, not how it operated 12 months ago.

Can We Be Compliant but Still Have an Accident?

Yes, absolutely. And it’s a tough but important lesson. Being compliant means you're meeting the minimum standards set out in the regulations. You’re ticking the required boxes.

But life on a worksite is unpredictable. A unique combination of events or something truly unforeseen can still lead to an accident. This is precisely why just "ticking the box" isn't enough. Compliance is your baseline, but constantly looking for hazards is what really prevents incidents.

Trying to stay on top of every risk, every rule, and every worker can feel like a losing battle. But it doesn't have to be. Safety Space brings everything into one simple, clear platform, from inductions and inspections to real-time incident reporting, so you're always ready and always in control.

Find out how it works by visiting https://safetyspace.co.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.