Let's be honest, workplace health and safety can feel like it’s buried under a mountain of jargon. But when you cut through the noise, understanding risks and compliance is actually pretty straightforward.

It really boils down to two things: spotting what could hurt someone, and then doing what’s required to stop it from happening. This isn't just about endless paperwork; it's about building a practical system to keep your team safe and your business on track.

What Risks and Compliance Mean for Your Business

To get our heads around the core ideas, let’s use a simple example you’d find on any construction site or factory floor. Picture a small oil spill in a walkway.

The puddle of oil itself is a hazard. A hazard is simply any source of potential harm, the thing or situation that could cause trouble.

The risk is the chance that someone might slip on that oil, fall, and get hurt. Risk is a combination of how likely it is that something will go wrong and how bad it could be if it does. A tiny spill tucked away in a corner has a much lower risk than a large one right in the middle of a busy walkway.

Finally, the actions you take are the controls. This is everything from putting up a warning sign to cleaning the spill properly. Controls are the practical steps you take to either get rid of the risk or at least shrink it down to an acceptable level.

Defining Compliance in Practical Terms

Compliance isn't about ticking boxes for an auditor. Think of it as your company’s documented promise to meet its obligations. It’s the structure you build to make sure you're consistently using the right controls to manage your risks.

This commitment works on two levels:

- Legal Duties: These are the non-negotiables set by workplace health and safety (WHS/OHS) laws. Getting this wrong can lead to heavy fines, work stoppages, and serious legal headaches.

- Internal Standards: These are your own rules and procedures. Often, they go above and beyond the legal minimum to tackle the specific risks that are unique to your worksites.

This image shows a worker putting a control measure into action, a perfect example of managing a hazard on the spot.

By dealing with the spill, this worker is preventing a slip-and-fall incident. It's a clear demonstration of how proactive controls are at the heart of both safety and compliance.

To make these key terms even clearer, here's a quick cheat sheet.

Hazard vs Risk vs Compliance At a Glance

| Concept | Simple Definition | Example on a Construction Site |

|---|---|---|

| Hazard | The thing that could cause harm. | An unguarded edge on the second floor of a building. |

| Risk | The chance of harm occurring and how severe it could be. | A worker falling from that edge, resulting in serious injury or death. |

| Compliance | The actions and systems in place to manage the risk. | Installing temporary guardrails (control) as required by safety regulations (legal duty). |

This simple breakdown helps everyone get on the same page, turning abstract concepts into real-world actions.

Why This Foundation Matters

Nailing these basics is non-negotiable. When your team understands the difference between a hazard and a risk, they can spot problems before anyone gets hurt.

A solid grasp of risks and compliance transforms safety from a vague concept into a clear set of actionable steps anyone can follow.

By clearly defining hazards, risks, and controls, you create a common language for safety across your entire organization. This shared understanding is the first step toward building a reliable system that protects your people and your operations from preventable incidents.

Ultimately, this isn't just theory. It directly prevents costly accidents, reduces downtime, and ensures your business meets its legal and ethical responsibilities. It’s all about creating a predictable, controlled work environment where people feel confident they can do their jobs safely.

Understanding Your Legal and Operational Duties

It’s one thing to spot a hazard, but managing risk and compliance properly means knowing exactly what the law expects from you. In Australia, workplace health and safety (WHS/OHS) law revolves around one central idea: the primary duty of care. This is your fundamental obligation to ensure the health and safety of your workers, so far as is reasonably practicable.

This duty doesn’t just fall on the company as a faceless entity. It applies to any ‘person conducting a business or undertaking’ (PCBU). This is a deliberately broad term that catches everyone from sole traders and partners to large corporations. If you direct or influence work, you're likely a PCBU.

As a PCBU, you're on the hook for providing a safe work environment, safe equipment and structures, and safe ways of working. This isn't just a recommendation; it's the bedrock of every safety decision you make.

What Does ‘Reasonably Practicable’ Actually Mean?

The phrase ‘reasonably practicable’ is the engine room of WHS law, but it can feel a bit fuzzy. The best way to think about it is as a balancing act. You need to do everything you reasonably can to manage a risk, weighing how likely an incident is and how severe it could be against the cost, time, and effort needed to control it.

For example, on a construction site, the risk of a worker falling from a height is severe, potentially fatal. Installing guardrails is a well-known, affordable control. In this case, it's absolutely reasonably practicable to install them.

On the other hand, would it be reasonably practicable to wrap the entire building in a giant safety net? Probably not. The astronomical cost and complexity would be completely out of proportion to the extra safety it might offer over standard controls like railings and harnesses.

To figure out what’s reasonably practicable in any situation, you need to weigh up a few things:

- The likelihood of the hazard causing harm. How often are people exposed to this danger?

- The degree of harm. Are we talking about a minor cut or a life-changing injury?

- What you know (or should know) about the risk. "I didn't know" isn't a valid excuse. You're expected to stay up-to-date with industry standards and known control measures.

- The availability of solutions. Are there proven ways to eliminate or minimize the risk, like machine guards or safer chemicals?

- The cost of those solutions. Cost can only be a reason for not acting if it is grossly disproportionate to the risk. You can't skip a $500 guardrail to prevent a fatal fall.

Connecting Legal Duties to Daily Operations

Your legal duties shouldn't live in a dusty folder. They should be the blueprint for your daily operations. Every policy, safe work method statement (SWMS), and emergency plan you write is a direct answer to that primary duty of care.

A company’s operational policies are the practical, on-the-ground expression of its legal safety obligations. They turn the broad requirements of the law into specific, actionable instructions for your team.

This link is crucial. It shows that safety isn’t some separate department or an annoying checkbox exercise, it's woven into the very fabric of how you get the job done right. When your procedures are clearly tied to your legal duties, they carry more weight and make more sense to everyone on the ground.

This is also where many businesses stumble. When compliance feels clunky and disconnected from operations, it slows everything down. A recent PwC survey found that a staggering 93% of Australian executives said compliance challenges hurt their tech initiatives, and 56% saw a negative impact on growth drivers like innovation. It’s a powerful reminder of how important it is to get this connection right from day one. You can dig into the full survey findings on PwC's website to see how compliance impacts business growth.

Ultimately, a clear grasp of your legal obligations and what's reasonably practicable allows you to build an operational framework that not only keeps people safe but also helps your business run smoothly.

A 5-Step Process for Managing Workplace Risks

A systematic approach is always the most reliable way to handle workplace risks and stay compliant. Instead of just reacting when things go wrong, you can build a solid, repeatable process that finds and fixes problems before they cause harm.

Think of it as a continuous loop, not a one-off task. This five-step method gives you a clear framework for managing safety that works in just about any setting, from a busy construction site to a manufacturing floor. It really just boils down to identifying what can go wrong, figuring out how serious it is, deciding on a fix, putting it in place, and then checking to make sure it actually worked.

Step 1: Identify Hazards

First things first: you need to find what could cause harm. This means getting out on the floor, walking through the worksite, and most importantly, talking to the people who do the work every day. They’re the ones who know the real-world hazards they face, and their insights are invaluable.

Keep an eye out for potential issues in these common areas:

- Physical Hazards: Things like unguarded machinery, noisy equipment, working at heights, or simple slip and trip dangers.

- Chemical Hazards: This could be anything from unlabelled containers and poor ventilation where solvents are used, to incorrect storage of flammable liquids.

- Ergonomic Hazards: Look for repetitive tasks, poor workstation setups, or heavy lifting that could lead to strain injuries over time.

A crucial first step in any risk management process is conducting a thorough assessment. Even a cybersecurity risk assessment template can provide a useful structure for thinking methodically about non-digital risks. The key is to be systematic and document everything you find.

Step 2: Assess Risks

Once you have a list of hazards, you need to figure out the level of risk each one presents. This isn't guesswork. It involves looking at two key factors: the likelihood of something happening and the potential severity of the harm it could cause.

For example, a frayed electrical cord on a machine that’s rarely used is a hazard. But if that same cord is on a primary power tool used daily by multiple workers, the likelihood of an incident shoots way up, making it a much higher risk. Assessing risks this way helps you prioritise what needs fixing right now.

Step 3: Control Risks

With a clear picture of your biggest risks, it's time to decide how to control them. The best way to approach this is by following the Hierarchy of Controls, a model that ranks risk control methods from most effective to least effective.

The Hierarchy of Controls prioritizes actions that permanently remove hazards over those that simply rely on people to work safely. The goal is to choose the most effective, reliable control that is reasonably practicable for your situation.

The hierarchy looks like this, starting with the best option at the top:

- Elimination: Completely remove the hazard. A classic example is getting rid of a toxic chemical and finding a safer alternative.

- Substitution: Replace the hazard with something safer, like using a water-based paint instead of a solvent-based one.

- Isolation: Separate people from the hazard. This could mean putting noisy machinery in a soundproof room.

- Engineering Controls: Make physical changes to the workplace, like installing guard rails on a machine or improving the ventilation system.

- Administrative Controls: Change the way people work. This involves new procedures, more training, or rotating jobs to limit exposure to a hazard.

- Personal Protective Equipment (PPE): This is your last line of defence. Providing gear like safety glasses, gloves, or hard hats only protects the individual and does nothing to remove the hazard itself.

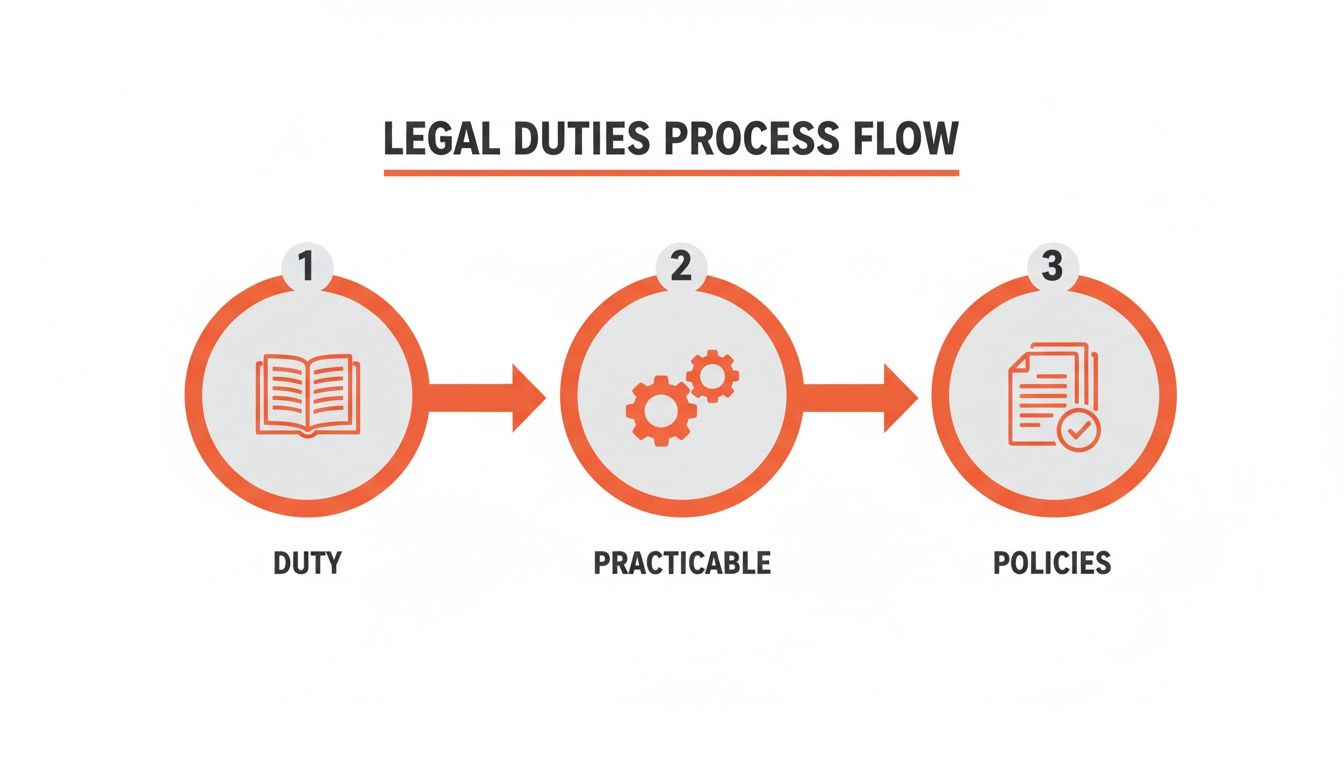

This infographic shows how your legal duty connects directly to the policies and controls you put in place.

The flow from duty to practical application really highlights why choosing the right control is a core part of meeting your compliance obligations.

Step 4: Implement Controls

A plan on paper doesn't protect anyone. This is the step where you put your plan into action: installing the guards, updating procedures, running the training sessions, and buying the necessary equipment you decided on.

Clear communication is absolutely vital here. Everyone affected needs to understand what the new control is, why it's being introduced, and how to use it correctly.

Step 5: Review Controls

Finally, managing risk and compliance is an ongoing cycle. It’s not "set and forget." You have to regularly review your controls to make sure they’re working as intended and haven't created any new, unforeseen problems.

Ask yourself: Has the control actually reduced the risk? Are workers using it correctly? Have circumstances on site changed since it was implemented? This review process is what keeps your safety system relevant and effective over the long haul.

How to Build and Monitor a Compliance Program

Knowing how to handle individual risks is a good start, but a truly strong safety approach comes from building a complete program around risks and compliance. This isn't about creating a hefty folder of documents destined to gather dust on a shelf. It’s about setting up a living, breathing system that actively keeps an eye on performance, flags issues before they get worse, and keeps your entire safety effort on the right track.

A solid compliance program weaves all your safety activities, from daily toolbox talks to annual reviews, into a single, coherent framework. It’s the difference between reacting to incidents and proactively managing safety across the entire business.

Key Components of a Working Program

To build a program that genuinely works, you need a few core components that talk to each other. Think of these as the engines driving your day-to-day safety management.

- Regular Site Inspections: Scheduled walk-throughs are your first line of defence for catching hazards before they cause harm. These aren't just about spotting faults; they’re an opportunity to see if your safety controls are actually being used correctly in the real world.

- A Clear Incident Reporting Process: Everyone on your team needs to know exactly how to report an incident or a near miss. More importantly, they need to feel confident doing so without fear of blame. This process is your single best source of data for finding the weak spots in your system.

- Up-to-Date Training Records: Compliance isn’t just about having the right procedures; it’s about proving your team is competent to follow them. Keeping accurate records of who has been trained on what, and when they need a refresher, is a non-negotiable part of your legal duty of care.

This image shows someone reviewing documents and plans, a core activity in monitoring any compliance program.

Careful review of safety data and reports is how you find trends and measure whether your program is actually making a difference.

Tracking Performance with Practical KPIs

You can't manage what you don't measure. Key Performance Indicators (KPIs) are what turn your compliance goals from vague aspirations into hard numbers. They tell you, without ambiguity, how you're tracking and where you need to focus your attention.

The trick is to avoid vanity metrics. Good KPIs are practical and directly tied to what’s happening on the ground.

- Percentage of Corrective Actions Closed on Time: This simple metric tracks how quickly you fix the problems you find. If the percentage is low, it might be a sign that you don’t have enough resources allocated or that accountability isn't clear enough.

- Number of Days Since a Lost-Time Injury (LTI): It's a classic for a reason. This powerful metric gives everyone on site a shared, visible goal to work towards every single day.

- Completion Rate of Scheduled Inspections: This KPI reveals whether your program is being followed consistently. If inspections are regularly being missed, you need to dig in and find out why.

These simple metrics give you a real-time snapshot of your program's health, allowing you to make decisions based on data, not just gut feelings.

A well-structured compliance program relies on consistent monitoring and clear metrics. It creates a rhythm of checks and balances that makes safety a predictable and manageable part of daily operations, rather than a series of disconnected reactions.

Creating a Simple Audit Cadence

Consistency is everything. A regular schedule of safety activities keeps everyone engaged and ensures nothing important falls through the cracks. This rhythm of review is the very heartbeat of a strong program.

To get started, here is a straightforward schedule you can adapt to fit your workplace. It’s a great way to build a routine and make sure all the key bases are covered.

Example Audit and Review Schedule

| Activity | Frequency | Purpose |

|---|---|---|

| Toolbox Talks | Weekly | Discuss immediate site hazards and reinforce safe work procedures with front-line workers. |

| Site Inspections | Monthly | Conduct a formal walk-through to check controls, identify new hazards, and document findings. |

| Management Review | Quarterly | Analyze KPI data, review incident reports, and adjust the program based on performance trends. |

This regular cadence ensures continuous oversight and helps embed safety into your weekly, monthly, and quarterly routines.

Digital tools can be a huge help here, especially when it comes to keeping everything organised and on schedule. Our guide on audits and compliance offers more detail on how platforms can support this rhythm: https://safetyspace.co/audits-and-compliance.

Unfortunately, many businesses are still stuck wrestling with the manual effort this requires. Salesforce's State of IT survey found that a staggering 85% of ANZ organisations still don't have fully automated processes, which inevitably leads to errors in tracking compliance. With only 61% of leaders feeling their teams are 'AI-ready', there's a clear gap where technology could step in to make monitoring far more effective. You can find more details about these technology gaps by reading the full report on Salesforce's website. This really highlights the need for a system that makes monitoring simple, reliable, and almost automatic.

Common Compliance Pitfalls and How to Sidestep Them

Even the best-laid plans for managing risk and compliance can run into trouble. Knowing the common tripwires ahead of time is the best way to keep your program on track and dodge the simple mistakes that often snowball into major problems.

Most of these pitfalls aren’t about complex legal theory; they’re about everyday operational gaps that are surprisingly easy to overlook, but just as easy to fix.

One of the biggest culprits is messy or incomplete record-keeping. When an inspector shows up asking for a specific training record or SWMS, "I'm sure it's around here somewhere" is the last thing you want to be saying. This kind of disorganization doesn't just make audits a nightmare; it signals a casual, and therefore risky, approach to safety management.

It’s about more than just paperwork. It’s about having proof that you're doing what you say you're doing. A sloppy system makes it almost impossible to spot trends, track whether fixes have been implemented, or demonstrate due diligence when it really counts.

The 'Set and Forget' Mindset

Another classic blunder is the ‘set and forget’ attitude towards risk assessments. A risk assessment isn't a trophy to be mounted on the wall; it's a living snapshot of the hazards and controls present on the day it was written.

Workplaces are always in flux. New gear arrives, project scopes change, and people come and go. A risk assessment you did six months ago might be dangerously out of date today. Treating these documents as a one-off box-ticking exercise is a surefire way to have an incident.

True compliance is an active, ongoing process, not a passive one. Risk assessments should be live documents, reviewed regularly and updated any time something significant changes on site. This is how you ensure your safety controls actually match your real-world risks.

Sticking with outdated assessments creates a false sense of security. You think you're covered, but in reality, your team could be exposed to unmanaged risks.

Forgetting to Ask the People Doing the Work

Consultation isn't just a nice-to-have; it's a critical, and legally required, part of managing risks and compliance. Let's be honest, managers can't see everything. The workers on the tools are the ones who have an intimate understanding of the day-to-day hazards of their jobs.

Ignoring their input is a massive mistake. You don’t just miss out on priceless insights from the front line; you end up creating a system that the people on the ground have no ownership of. When workers aren’t involved in building the safety solutions, they’re far less likely to follow them.

It's not hard to get this right. Simple steps include:

- Bring them into risk assessments: Get your experienced operators to walk through the process with you.

- Talk about changes at toolbox talks: Use these quick meetings to get real-time feedback on new procedures or equipment.

- Make reporting dead simple: Give them a straightforward, friction-free way to raise a concern.

The Headaches of Subcontractors and Multi-Site Operations

Keeping things consistent is one of the biggest challenges when you’re dealing with subcontractors or juggling multiple locations. A system that works perfectly at one site can completely fall apart at another if standards aren’t applied across the board.

With subcontractors, the solution starts with a rock-solid, standardized induction process. Every single contractor who sets foot on your site must understand your specific rules, emergency plans, and reporting requirements before they start work. This sets a clear, non-negotiable baseline for everyone.

For businesses with multiple sites, a centralized system is non-negotiable. Without it, each location becomes its own little island, with different processes, standards, and levels of compliance. This fragmentation makes it impossible to get a clear picture of your company's overall risk profile and opens up huge compliance gaps. A recent State of Data Readiness in ANZ report found over a third of businesses struggle with conflicting regulations across borders, a problem that mirrors the chaos of managing multiple sites without a single source of truth. You can get more insights on how centralized systems address these challenges on Commvault's website.

Using Digital Tools to Manage Risks and Compliance

Let's be honest. Trying to wrangle health and safety compliance with a mountain of spreadsheets, paper forms, and overflowing filing cabinets is a recipe for disaster. Important details get lost, reports are out of date the second you print them, and getting a clear, real-time picture of what’s happening across your sites is next to impossible. This is where the right digital tools can completely change the game.

Instead of chasing paperwork, a dedicated platform brings your entire safety system into one central hub. Every risk assessment, inspection report, training record, and corrective action lives in one accessible place. Right away, this solves the messy record-keeping pitfall that trips up so many businesses come audit time.

Centralizing Information for Clear Oversight

Moving away from scattered documents creates a single source of truth for your entire operation. This isn't just a nice-to-have; it's critical for businesses managing multiple locations or relying on subcontractors, as it ensures everyone is working from the same playbook.

A centralized system allows you to:

- Assign clear accountability: When someone identifies a hazard, you can assign a corrective action to a specific person with a firm due date. The system keeps track of it until it’s closed out, so nothing ever slips through the cracks.

- Automate reporting: Forget manually crunching numbers from different spreadsheets. You can get instant access to performance data and see your leading and lagging indicators at a glance.

- Standardize processes: Ensure that every site is using the exact same inspection checklist and risk assessment template, creating much-needed consistency across the board.

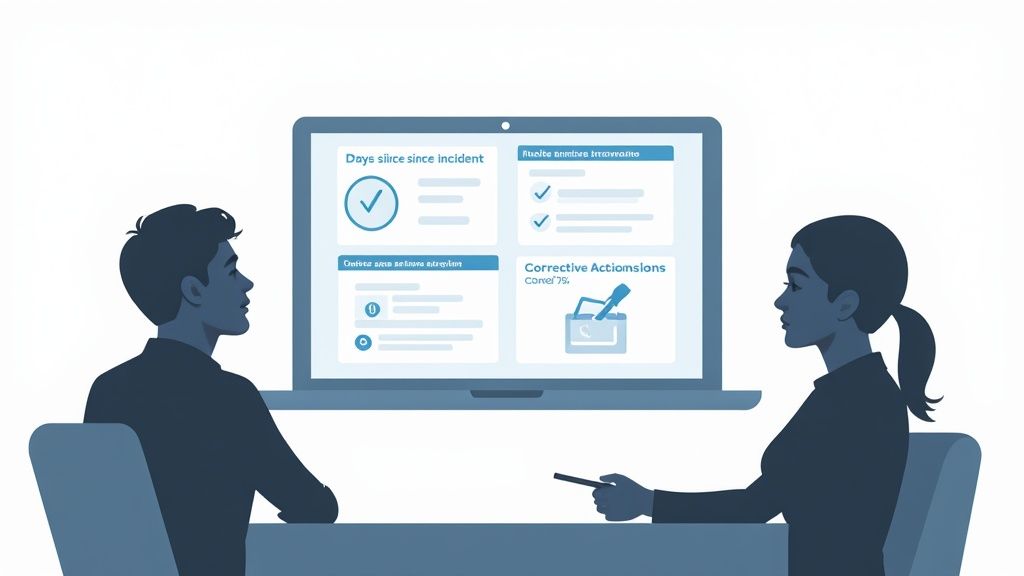

This dashboard gives you an idea of how a digital system can present key safety metrics in a simple, easy-to-digest format.

Having this kind of real-time data means you can spot negative trends early and jump on problem areas before they escalate into an incident.

Turning Compliance into a Proactive Function

A good digital platform shifts safety management from a reactive, box-ticking chore into a proactive business function. It gives you the visibility needed to make sharp decisions based on hard data, not just guesswork. To stay on top of regulatory changes, businesses can explore top compliance management solutions to find a system that fits their specific needs.

By moving your risk and compliance processes into a digital system, you create an active, auditable record of your safety efforts. It proves you are not just talking about safety, but actively managing it every single day.

This digital paper trail is invaluable. When an inspector walks in, you can instantly pull up any record they ask for, demonstrating a robust and well-managed system. Platforms like a dedicated health and safety compliance software make this happen, giving you the tools to build a truly resilient program.

The goal is simple: spend less time buried in administration and more time on the actions that actually keep your people safe.

Common Questions We Hear About Risks and Compliance

Even with the best safety plan in place, a few common questions always pop up when you're trying to manage risks and compliance on the ground. Here are some straight-shooting answers to the things we hear most often from managers in the thick of it.

How Often Should We Review a Risk Assessment?

There's no single magic number, but a good rule of thumb is to review your risk assessments at least once a year. The real answer, though, is that you must review them the moment anything significant changes.

That means pulling it out and updating it when:

- New machinery or equipment shows up on site.

- You change a process or a core part of the workflow.

- An incident or even a near miss happens.

Think of a risk assessment as a living document. If it's just sitting in a folder gathering dust and doesn't reflect what's actually happening on your worksite today, it's not doing its job.

What Should I Do If a Worker Ignores a Safety Rule?

If you see a worker deliberately ignoring a safety rule, you have to act immediately. The first step is simple: stop the work and have a conversation. You need to understand why they aren't following the procedure.

Sometimes, the rule might be impractical in a real-world scenario, or maybe they just weren't trained on it properly. Get to the root cause. But if it's a clear case of someone knowing the rule and choosing to ignore it, you have to follow your company's disciplinary procedure. Consistency is everything here; it shows everyone that safety rules are non-negotiable.

Turning a blind eye to a breach sends a dangerous message to the whole team: that safety rules are optional. A firm, fair, and consistent response is the only way to protect the integrity of your entire compliance program.

How Can I Prove Compliance During an Audit?

When an auditor walks in, they want to see cold, hard evidence, not just hear promises. The best way to demonstrate your commitment to risks and compliance is with organized, easily accessible records. This isn't just paperwork; it's your proof of due diligence.

An auditor will almost certainly ask to see things like:

- Completed Records: Your stack of inspection forms, risk assessments, and incident reports.

- Training and Competency Records: Proof that your team is actually qualified for the jobs they're doing.

- Corrective Action Logs: Evidence that you don't just find problems, you fix them methodically.

- Consultation Records: Minutes from safety meetings or toolbox talks that show you’re involving your workers in the process.

Having all this information ready to go in a central system shows you're running a managed, active safety program, not just scrambling to find a folder of old, forgotten documents.

Ready to ditch the messy spreadsheets and get real-time control over your safety management? At Safety Space, we built a simple, all-in-one platform to centralize your records, automate reporting, and make sure your business stays compliant. Book a free demo to see how it works.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.