Safe work modules are practical, task-specific safety plans that your teams use directly on the job. They are a complete instruction kit for performing a high-risk task safely, bundling everything from the risk assessment to the emergency plan into one clear guide. This isn't about theory; it's about giving your crew step-by-step instructions to manage real-world dangers.

What Are Safe Work Modules and Why Use Them?

Think of a safe work module as a blueprint for a specific hazardous job, like operating a press brake in a factory or working in a confined space on a construction site. It replaces that thick, generic safety binder sitting on an office shelf with a targeted guide a worker can actually reference for that particular task.

The point is to move beyond just ticking a compliance box. A well-designed module is a tool for getting the job done both safely and efficiently. It translates complex safety regulations into a practical format that people on the ground can follow.

The Core Components of a Module

Any strong safe work module pulls together a few key pieces of information. When combined, they give a complete picture of the task and its associated risks.

- Task Breakdown: A clean, step-by-step sequence of how to complete the job from start to finish.

- Hazard Identification: Pinpointing the specific dangers that pop up at each stage of the task.

- Risk Controls: Practical and specific actions to either eliminate or reduce those identified hazards.

- Required PPE: An exact list of the personal protective equipment needed for the job, with no ambiguity.

- Emergency Procedures: Simple, clear instructions on what to do if something goes wrong.

This structure ensures nothing is left to guesswork. When a team starts a high-risk job, they have a single source of truth that outlines the agreed-upon safe method.

Practical Benefits for Your Team

Bringing safe work modules into your high-risk environments delivers some very real advantages. The most obvious one is a drop in workplace incidents. When procedures are clear and controls are well-defined, the odds of errors and injuries go down.

For example, warehouse workers face injury rates nearly double the average across all industries, according to the Bureau of Labor Statistics. This is exactly the kind of environment where focused safety plans can make a huge difference.

A module forces you to think through a task completely before work begins. It bridges the gap between knowing a job is dangerous and knowing exactly how to make it safer. It's a proactive tool, not a reactive document you only look at after an incident.

Modules also make compliance much simpler. Instead of juggling multiple documents, a single module can contain everything needed to meet regulatory standards for a specific task, like a Safe Work Method Statement (SWMS). This clarity helps both workers and supervisors stay aligned. For a deeper dive into how these documents fit together, you can find more detail on how to develop a safe work procedure for your team.

Ultimately, these modules are about creating a more predictable and controlled work environment. And if you're looking for a good approach to developing training that prevents incidents, there’s some great guidance on creating a high-impact health safety course.

Breaking Down Tasks for Your First Module

So, where do you start when creating your first safe work module? It all kicks off with one simple but vital step: breaking a complex job down into its individual tasks.

This isn't about making things more complicated. It’s about looking at a high-risk job, like erecting scaffolding or operating a press brake, the way your experienced workers already do. They see it as a sequence of smaller, more manageable actions, and that's the perspective you need to capture.

The goal is to map out the entire process, from the moment the job starts to the final clean-up. A task that looks like a single activity on paper is rarely that simple in reality. Take scaffolding. It involves inspecting components, laying sole boards, erecting the first lift, and installing handrails. Each of these phases brings its own unique set of risks to the table.

This detailed breakdown becomes the foundation of an effective module. It lets you connect specific hazards to specific actions, which is the only way to assign practical controls that actually make sense on the ground.

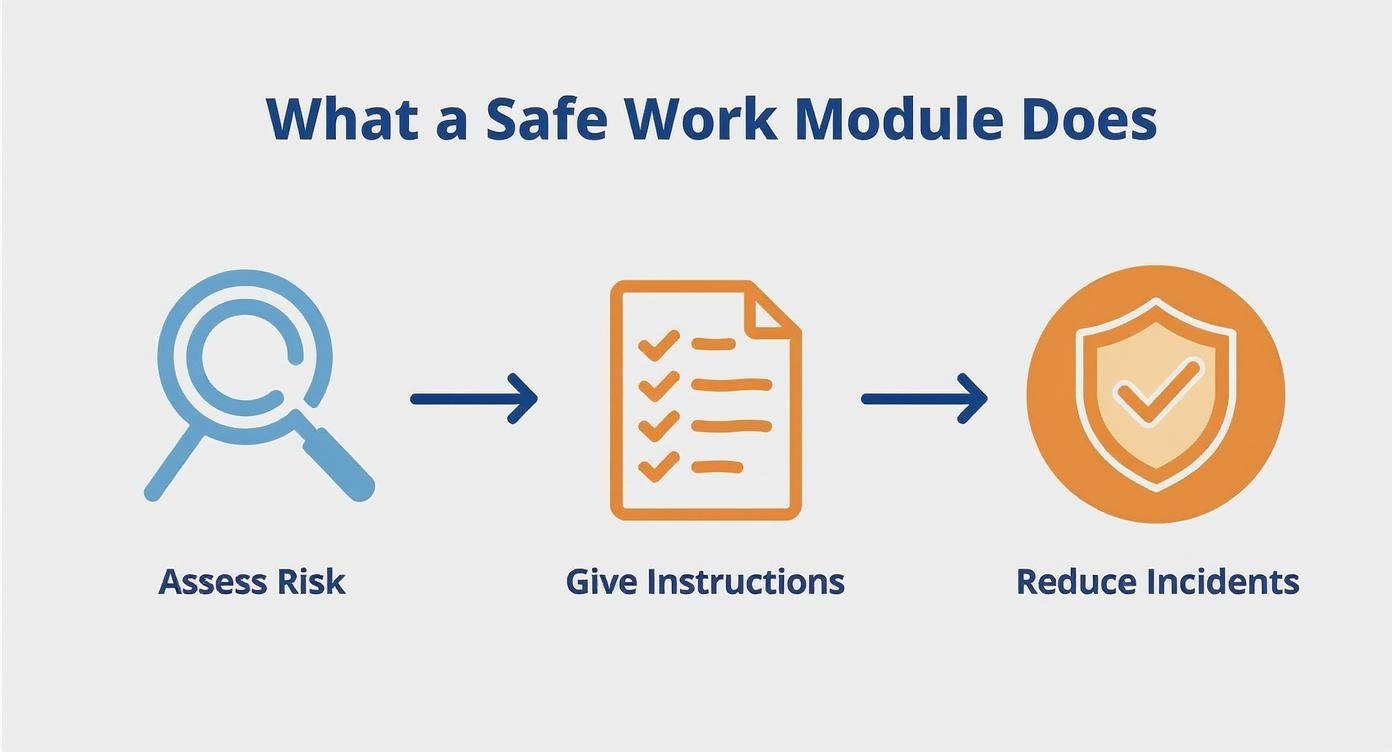

The infographic below shows this simple flow: assess the risk, provide clear instructions, and ultimately, reduce incidents.

As you can see, the module is a proactive tool. It’s designed to arm your workers with the right information at the right time, preventing incidents before they even have a chance to happen.

Get Your Team Involved from Day One

The biggest mistake you can make is trying to build a safe work module from an office, completely detached from the action. Your people on the tools hold the most valuable knowledge. Their experience is what will make this document practical and accurate, not just another piece of paper.

Sit down with your experienced operators or leading hands. Ask them to walk you through the job, step by step. Get them to explain not just what they do, but why they do it a certain way. You’ll be surprised at the informal safety checks and clever workarounds they’ve developed over the years, which are valuable pieces of information you can formalize in your module.

When your team helps build the module, they own it. They are far more likely to follow a procedure they had a hand in creating because it reflects the reality of their work, not just a theoretical process from a manual.

This collaborative approach is non-negotiable if you want a module that addresses the real hazards workers face. A document created in isolation is just compliance fluff. One created with the team is a functional, life-saving tool. This process is very similar to building a Job Safety Analysis (JSA), and you can check out some useful JSA examples here to see how those tasks are broken down.

From Task Steps to Hazard Identification

Once you have your list of task steps, it’s time to put on your critical thinking hat and attach potential hazards to each one. For every single step you’ve listed, you need to ask, "What could go wrong here?"

Think broadly and consider every type of hazard:

- Gravity: Could something fall from a height?

- Mechanical: Are there moving parts that could crush, cut, or entangle someone?

- Electrical: Is there any risk of contact with live wires or faulty equipment?

- Environmental: Will workers be exposed to extreme heat, excessive noise, or hazardous substances?

Let's take a common manufacturing task: operating a press brake. A seemingly simple step like "loading material into the machine" is packed with potential hazards. The metal sheet could have razor-sharp edges (laceration hazard), it might be heavy (musculoskeletal hazard), and the machine's clamp presents a serious crush hazard. Getting this detailed is key.

Linking Hazards to Practical Controls

Now for the final and most important piece of the puzzle: connecting each hazard to a specific, actionable control measure. This is where your module provides the clear, direct instructions your team will follow to stay safe.

Forget vague advice like "be careful." Your controls need to be direct commands describing a precise action.

Using our press brake example, the controls would look something like this:

- Hazard: Sharp edges on metal. Control: Wear Level 5 cut-resistant gloves when handling all materials.

- Hazard: Heavy material causing strain. Control: Use the overhead crane for any workpiece weighing over 15 kg.

- Hazard: Hand crush from machine clamp. Control: Keep hands clear of the die area and use the two-hand controls to operate the machine.

Here's a look at how you might structure this for a construction task like erecting scaffolding.

Task Breakdown for Scaffolding Erection

This table shows how to break down a complex job into manageable steps, identify hazards at each stage, and assign practical control measures.

| Task Step | Potential Hazard | Control Measure |

|---|---|---|

| Inspect components | Damaged or faulty parts, sharp edges | Visually inspect all components before use; wear cut-resistant gloves. |

| Lay sole boards/base plates | Uneven ground, trip hazards | Ensure ground is level and compacted; maintain clear access around the base. |

| Erect first lift | Manual handling strain, falling components | Use correct lifting techniques; work in pairs; secure standards immediately. |

| Install planks and handrails | Falls from height, dropped objects | Use a fall arrest system; establish an exclusion zone below; secure tools. |

By breaking down the task, involving your team, spotting the hazards, and assigning concrete controls, you create a safe work module that is logical, easy to follow, and genuinely useful on the workshop floor or construction site. It's not just about ticking a box; it's about building a safer way to work.

Writing a SWMS People Will Actually Read

A Safe Work Method Statement, or SWMS, is meant to be the backbone of your safe work module for any high-risk job. But let's be honest. It's often just a document that gets a signature without a second glance, then gets tucked away in a folder until something goes wrong. A SWMS stuffed with legal jargon and generic warnings doesn't help anyone holding the tools.

The real test of a good SWMS isn't its length; it's whether a worker can quickly look at it and know exactly what they need to do to stay safe. It has to be a practical, on-the-job guide, not a dense legal text. Making that shift is easier than you might think.

Use Simple Language and Visuals

First rule: write for the people doing the work, not for a lawyer. Ditch the overly formal language and tangled sentences. Use direct, clear instructions that are impossible to misinterpret.

Instead of writing, "Personnel must ensure appropriate manual handling techniques are utilised to mitigate musculoskeletal risks," just say it plainly: "Always use the trolley to move boxes over 10 kg." One is vague corporate-speak; the other is a clear, direct, and actionable instruction.

Visuals are your best friend here. A single photo or a simple diagram can explain a complex setup far better than a whole paragraph of text ever could.

- Include photos of the actual equipment and the specific work area.

- Use simple diagrams to show the correct setup, like where to place guards on a machine.

- Add icons to grab attention for specific hazards like electrical risks or chemicals.

A visual SWMS is much quicker to scan and understand, which is a massive help for workers who might have English as a second language or simply learn better visually.

Focus on Critical Risks

A classic mistake is trying to list every single potential hazard, no matter how minor. This just creates noise and buries the information that could actually save a life. A SWMS that lists "paper cuts" as a risk right next to "falls from height" has completely lost its focus.

Your SWMS should zero in on the high-risk activities, the tasks that could lead to serious injury or death. These are the steps that absolutely must have controls. By concentrating on what truly matters, you make the document more impactful and much easier for workers to remember.

A SWMS is not a general safety manual for the entire site. It is a specific plan for a specific high-risk task. If it’s stretching past two pages, you’re probably including details that belong somewhere else.

This focused approach keeps the document short and to the point, which dramatically increases the chance it'll actually get used before the job starts.

Structure for Quick Reference

Think of your SWMS layout more like a quick-reference chart than a traditional document. A clean, scannable format is essential for people on site who need information fast.

A simple table is one of the most effective ways to structure it. Use clear, simple headings to organize the information logically.

| Task Step | Potential Hazards (What can go wrong?) | Control Measures (What will we do?) | Person Responsible |

|---|---|---|---|

| Unload steel beams from truck | Uncontrolled movement, crush injuries | Use a crane with certified slings; establish a 3-metre exclusion zone | Crane Operator & Spotter |

| Position beams on structure | Dropped load, falls from height | Connect to a fall arrest system before moving into position; double-check rigging | Rigger & Dogman |

This format makes it incredibly easy for a supervisor to run through the plan with their team during a pre-start meeting. Everyone can see the job broken down, understand the specific risks, and confirm the controls that need to be in place.

Practical SWMS Review Checklist

Before you finalize any SWMS, run it past this simple checklist. The goal is to make sure it’s a practical tool, not just a tick-box compliance document.

- Is the language simple and direct? (Could a new worker understand it without asking questions?)

- Does it focus only on the high-risk tasks? (Have you cut out all the low-risk filler?)

- Are the controls specific and actionable? (Does it say what to do, not just "be careful"?)

- Are there visuals to help explain key steps? (Could a photo make this instruction clearer?)

- Is the format clean and easy to scan? (Can someone find what they need in 30 seconds?)

- Have the workers who actually do this job reviewed it? (This is the single most important step for checking if it’s practical).

If you can confidently say yes to all of these, you've created more than just a piece of paper. You've built a useful communication tool that forms the core of a truly effective safe work module.

Deploying Modules for Subcontractors and Multiple Sites

Managing safety across multiple construction sites or manufacturing plants brings a unique set of headaches. Throw subcontractors into the mix, and things get even more complicated. The secret to keeping everyone safe and on the same page isn't creating dozens of different safety plans; it's about standardizing your core safe work modules and then adapting them for each specific situation.

A common mistake is letting each site or team reinvent the wheel. This creates dangerous inconsistencies, wastes a ton of time, and opens the door for critical risks to be missed. A much smarter approach is to build a master module for a high-risk task and then treat it as a template that can be adjusted for site-specific conditions.

This method ensures your fundamental safety standards, the non-negotiables, remain locked in everywhere, while still allowing for the flexibility needed to address local hazards on the ground.

Adapting a Core Module for Different Sites

Let's say you have a core safe work module for "Working at Heights." It covers all the universal rules: fall arrest system requirements, equipment inspection protocols, and emergency rescue procedures. These are your company's baseline standards, no exceptions.

Now, when you deploy this module to a new site, you don't start from scratch. Instead, you create a simple, site-specific addendum. This smaller document just details the local variations.

- Access Points: How are workers getting up there? Is it scaffolding, a mobile elevated work platform (MEWP), or fixed ladders at this particular location?

- Environmental Factors: Is this site exposed to high winds, extreme heat, or torrential rain that could change the situation?

- Anchor Points: What are the approved anchor points on this specific structure? Photos and diagrams are perfect here.

This approach keeps your core safety principles consistent while making the module relevant and practical for the team doing the work. It’s faster, more reliable, and much easier to manage than juggling entirely separate documents for every single site.

Inducting Subcontractors Effectively

Bringing subcontractors onto a site is a critical control point. You simply can't assume their safety procedures align with yours. Using your safe work modules as the foundation for their induction is the most direct and practical way to get everyone on the same page, fast.

Forget those generic site inductions that workers forget by lunchtime. Focus the process on the specific high-risk tasks they will actually be performing.

Don't just hand them a document to sign. Walk them through the relevant module for their scope of work. Point out the specific hazards on your site and explain the control measures you require. This is about active communication, not passive paperwork.

This simple act shows them you take safety seriously and establishes clear expectations from day one. It also gives them a chance to ask questions and clarify anything that might be different from how they usually operate. A robust contractor management system can be a huge help here, tracking who has completed which module induction and creating a clear record of compliance.

The Power of a Central Digital Platform

Trying to manage this process with paper documents, spreadsheets, or emails across multiple sites and dozens of subcontractors is a recipe for failure. A central digital platform, like Safety Space, is pretty much essential for deploying and managing safe work modules at scale.

Using a digital system provides a single source of truth. Everyone, from the project manager in the office to the subcontractor on the tools, has access to the most current version of the module. There’s no risk of someone working off an outdated printed copy they found in the back of their truck.

A digital platform also makes distribution and tracking incredibly simple. You can assign modules to specific teams or individuals and see exactly who has viewed and acknowledged them. This creates built-in accountability without the endless chasing.

Here are the key advantages of a digital approach:

- Instant Updates: When you update a core module, the changes are pushed out to all relevant sites and personnel immediately. No lag time.

- Access Anywhere: Workers can pull up modules on a tablet or phone right at the worksite, where they actually need the information.

- Clear Records: You have a clean, auditable trail of who has been inducted into which procedures and when.

- Version Control: You completely eliminate the confusion of multiple document versions floating around, ensuring everyone follows the correct, approved procedure.

This digital approach moves your safe work modules from being static documents filed away in a cabinet to active, manageable tools that genuinely help people work safely. It ensures that your safety standards are applied consistently, whether you're managing two sites or twenty, and whether the work is done by your own crew or a team of trusted subcontractors.

Monitoring and Improving Your Safe Work Modules

Creating a safe work module is a great first step, but it’s definitely not a "set and forget" task. Let's be real, the workplace is always in flux. You get new equipment, site conditions change, and your team's experience evolves. If your modules don't keep up, they quickly become irrelevant decorations for a folder somewhere.

The most effective safe work modules are living documents. They need to be reviewed, tweaked, and improved over time to reflect what's actually happening on the ground. This creates a cycle where your safety procedures get sharper and more practical, not just filed away and forgotten.

Setting a Simple Review Schedule

As a baseline, it's good practice to schedule a formal review of all your modules at least once every 12 months. This ensures nothing important gets missed.

But a fixed schedule isn't enough. You have to be ready to react when things change. Certain events should automatically trigger an immediate review of a module. Don't wait for the annual check-in if something significant happens.

Key triggers for an immediate update include:

- After any incident or near miss: This one's non-negotiable. The module clearly missed something, and you need to find out what it was and fix it, fast.

- When new equipment is introduced: A new press brake, crane, or even a different type of scaffolding brings its own risks and operating steps. Your module needs to reflect that.

- If a work process changes: Even a seemingly small tweak in how a task is done can introduce new, unforeseen hazards.

- Following feedback from the team: If your workers tell you a procedure is clunky, impractical, or just plain confusing, listen. They're your best source of truth.

This reactive approach keeps your modules accurate and genuinely useful day-to-day.

Gathering Feedback from the Ground

The most valuable insights for improving your safe work modules will come from the people using them every single day. The crew on the tools know what works in theory versus what’s practical in reality. You just need a simple way to capture their feedback.

Don't overcomplicate it. You can get great input through informal chats during pre-start meetings, by adding a simple feedback section to digital forms, or by holding brief toolbox talks focused on a specific task. Ask direct questions like, "Is there a step in this module that doesn't make sense?" or "Did we miss any hazards you've run into out here?"

Your team's feedback is the ultimate reality check for your safety procedures. If they can't follow a control measure in the real world, it's not an effective control, no matter how good it looks on paper.

This feedback loop is what turns your team from people just following rules into active participants in making the workplace safer for everyone.

Making Meaningful Improvements

Once you've gathered feedback or a review has been triggered, the goal is to make meaningful changes. This isn't just about correcting typos; it's about digging into the root of the problem.

If a control measure is consistently ignored, don't just blame the workers. Ask why it's being ignored. Is it impractical? Is the required equipment always unavailable? Is there a faster, but more dangerous, way they've figured out?

For anyone managing these systems, pursuing a comprehensive qualification like a Cert IV in Workplace Health Safety can give you the deeper knowledge needed to drive this kind of continuous improvement.

Making modules more relevant also means tailoring them to specific risks. Workplace injury data shows huge differences from one region to another. For instance, Victoria not only has a high claim rate per worker but also the highest average cost per claim, pointing to more severe injuries. This data shows why a one-size-fits-all approach just doesn't work and why your modules must address the specific risks of your industry and location.

By constantly monitoring, listening to feedback, and making practical adjustments, your safe work modules become powerful, dynamic tools that actually protect your team and adapt to the real-world challenges of your worksites.

Got Questions About Safe Work Modules? We've Got Answers

Even with the best intentions, questions always pop up when you're putting safety procedures together. Getting straight, practical answers is the only way to build safe work modules that your team will actually pick up and use.

Here are a few of the most common questions we hear from businesses, especially in construction and manufacturing.

Are Safe Work Modules the Same as a SWMS?

Not quite, but they're very closely linked and should work hand-in-hand.

A Safe Work Method Statement (SWMS) is a specific legal document you must have for high-risk construction work here in Australia. Its job is laser-focused: identify the high-risk hazards and spell out the controls for those specific tasks.

A safe work module, on the other hand, is the whole package. Think of it as the complete, user-friendly instruction manual for getting a job done safely. A solid module will almost always have a SWMS tucked inside as its core risk assessment. But it doesn't stop there.

It also includes other essential bits and pieces, like:

- Pre-start checklists for the gear you're using.

- Key operating instructions or snippets from the manual.

- Site-specific emergency contacts and procedures.

- Diagrams showing things like exclusion zones or the right way to set up equipment.

So, while the SWMS handles the critical risk management, the module pulls everything together. It ensures a worker has all the info they need in one spot, right when they need it.

How Often Should We Be Reviewing Our Modules?

As a bare minimum, you should give your modules a once-over at least annually. But honestly, waiting a full year is often way too long in the real world. The best approach is to treat your modules like living documents, they should be updated whenever something changes.

Certain events should trigger an immediate review, no questions asked.

If your team has an incident or even a near-miss while following a module, that’s a massive red flag. The procedure failed. You need to stop, figure out what went wrong, and update the module straight away to make sure it never happens again.

Other triggers that demand a review include:

- New plant or machinery shows up: A different model of excavator or a new press brake brings its own unique set of risks.

- The work process changes: Even a seemingly small tweak in how a job is done can introduce brand-new, unexpected hazards.

- You get feedback from the crew: If workers tell you a procedure is confusing, impractical, or just plain wrong, listen to them. That’s your cue to revise it.

Treating your modules this way keeps them relevant and useful for the people on the tools every single day.

What's the Best Way to Get Workers to Actually Use the Modules?

It all comes down to two things: involvement and accessibility. Get these right, and you're golden. It’s that simple.

First, you have to involve the people doing the work in creating and reviewing the modules. They are the true experts. They know the shortcuts people take, the real-world frustrations, and what’s practical versus what just looks good on paper. When your team helps build the safety plan, they own it.

Second, make the modules ridiculously easy to get to and understand. A 30-page document locked in a filing cabinet in the site office? Useless. A two-page visual guide on a tablet or phone right there at the job? Now that's a tool people will actually use.

Keep the language simple, use photos of your actual equipment, and make the format clean and easy to scan.

Can We Just Use a Generic Template?

A template can be a fantastic starting point to give your module some structure, but it's never a finished product. One of the most common, and dangerous, mistakes we see is a business downloading a generic template and using it "as is."

That template you found online knows nothing about:

- Your specific site conditions, like the sloping ground or the overhead power lines.

- The exact make and model of the equipment your team is using.

- The experience and skill level of your actual workers.

- The other work happening nearby that could create a new hazard.

All these factors can completely change the risk profile of a task. Always use a template as a guide to jog your thinking, but the heart of the module, the risk assessment and the control measures, has to be based on the actual task, in the actual environment, with the actual people doing the work.

Ready to stop juggling paper, spreadsheets, and outdated documents? Safety Space gives you a single, easy-to-use platform to create, share, and track your safe work modules across every site and team.

Book a free demo today and see how you can simplify compliance and build a genuinely safer workplace.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.