A Job Safety Analysis, or JSA, is a useful tool for finding and controlling worksite hazards before they cause an incident. While the concept is straightforward, finding practical examples that are genuinely useful can be a challenge. Many templates available online are either too generic to apply to specific high-risk tasks or so complicated they create more administrative work than actual safety improvement.

This article is different. We are going to break down six specific job safety analysis examples from high-risk industries, including construction, manufacturing, and electrical work. We're moving beyond theory to give you a clear, direct look at how a JSA is structured for real-world tasks. For each example, we will look at the job steps, potential hazards, and the specific control measures you can implement.

Forget abstract concepts and vague advice. The goal here is to provide actionable insights you can take and apply directly to your own safety procedures. You will see how to identify critical risks in tasks like crane operation, machine maintenance, and forklift driving, and learn the practical controls that make a real difference in preventing injuries. Let's get started.

1. Construction Site Crane Operation JSA

Crane operations are among the most high-risk activities on any construction site. A Job Safety Analysis (JSA) for this task is non-negotiable, breaking down the entire process from setup to dismantling into distinct steps. This detailed approach is needed for identifying and controlling severe hazards like electrocution from overhead power lines, structural failure, dropped loads, and ground instability. By creating a specific plan for each lift, teams can proactively manage these risks.

The core function of a crane operation JSA is to provide a clear, documented procedure that everyone involved, from the operator to the riggers and spotters, must follow. It makes sure that critical safety checks are completed before, during, and after each lift. This JSA is a vital tool for meeting standards set by organisations like OSHA and NIOSH and is a fundamental part of a site's overall safety management system.

Strategic Breakdown and Insights

Leading construction firms show how an effective JSA moves beyond a simple checklist. For instance, Skanska USA integrated comprehensive JSAs into their daily workflow, which contributed to a reported 45% reduction in crane-related incidents. This wasn't just about having the document; it was about its active use.

Turner Construction takes a modern approach by using digital JSA platforms. This allows for real-time monitoring and instant updates, making sure that any changes in site conditions, like weather or new ground disturbances, are immediately reflected in the safety plan. Bechtel Corporation’s JSA program goes even further by integrating automated systems, such as weather monitors that trigger automatic shutdowns when wind speeds exceed safe operating limits.

Key Takeaway: A crane operation JSA is most effective when it is a live, active document. Integrating technology for real-time updates and automated safety protocols transforms the JSA from a static form into a dynamic risk management tool.

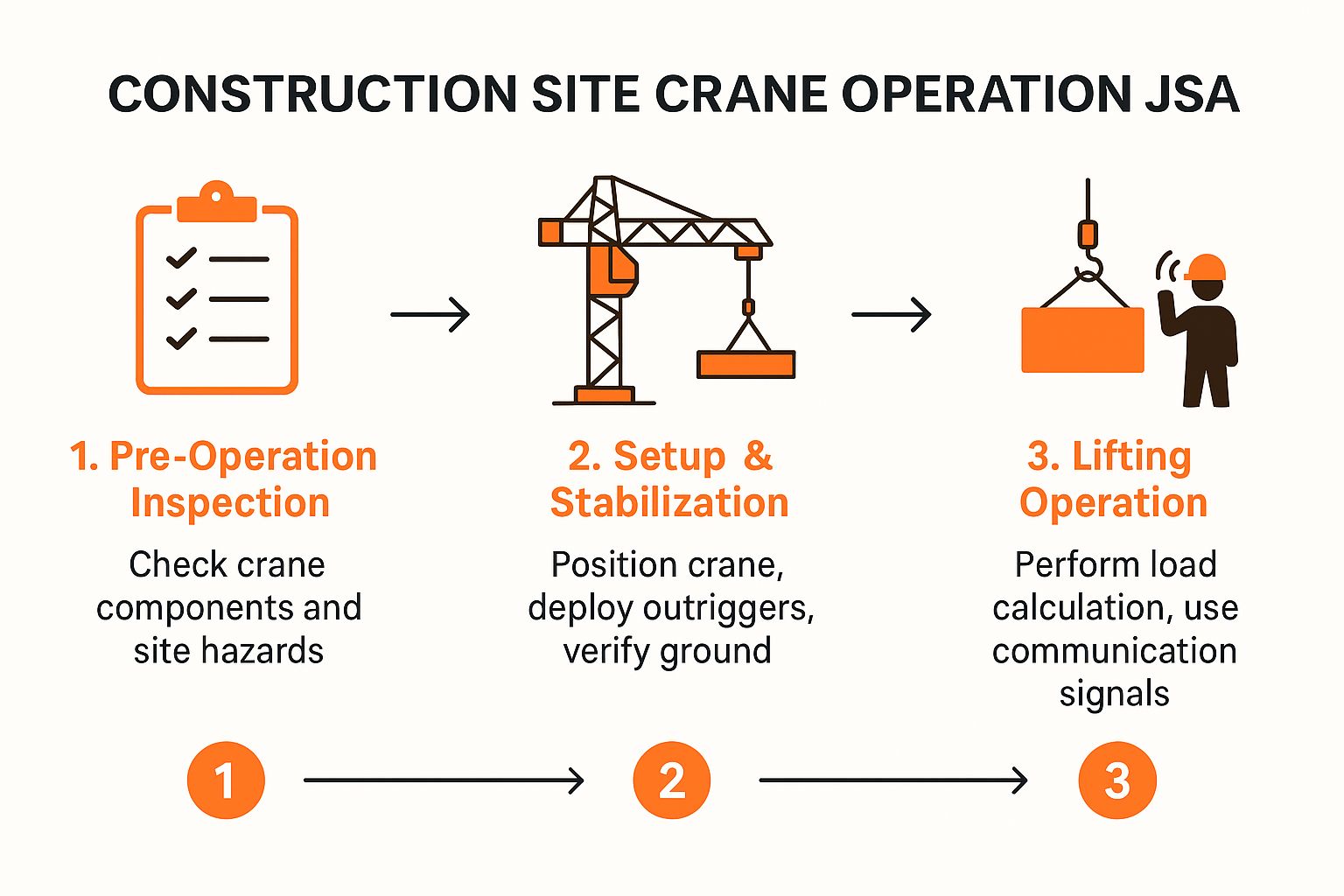

Visualising the Crane JSA Process

The following infographic illustrates the three critical phases of a safe crane operation as outlined in a JSA.

This visual process flow highlights how each phase builds upon the last, showing that a safe lift is the result of a systematic and structured preparation process.

Practical and Actionable Tips

To get the most out of your crane operation JSA, consider these practical steps:

- Daily Pre-Start Meetings: Before any lift, gather the entire crew (operator, riggers, dogman, supervisors) to review the JSA for that day's specific tasks.

- Use Visual Aids: Don't rely on text alone. Use diagrams to map out the crane's position, swing radius, and exclusion zones for personnel.

- Implement a Permit System: Require a formal "Permit to Lift" that cannot be issued until the JSA has been completed, reviewed, and signed off by a competent person. For a deeper analysis of potential failure points, a Bowtie risk assessment can be a valuable complementary tool. Find out more about how these methods work together by exploring the bowtie risk assessment methodology.

2. Manufacturing Machine Maintenance JSA

Maintenance activities on manufacturing equipment are full of risk, involving direct interaction with powerful machinery. A Job Safety Analysis (JSA) for machine maintenance is essential for controlling hazards like unexpected start-ups, hazardous energy release, and chemical exposure. It breaks down complex repair or servicing tasks into manageable steps, focusing heavily on critical safety procedures like lockout/tagout (LOTO) and confined space entry.

The main purpose of a machine maintenance JSA is to create a standardised, safe work procedure for every piece of equipment. This ensures that every technician, regardless of experience, follows a proven process to isolate energy sources and secure the machine before work begins. This document is a cornerstone of compliance with safety regulations and a key part of any effective plant safety program, directly preventing severe injuries and fatalities associated with machinery.

Strategic Breakdown and Insights

Leading manufacturers have shown how deeply integrating JSAs into maintenance workflows can produce significant safety improvements. For example, General Electric's manufacturing facilities implemented digital JSA systems, a move that contributed to a reported 60% reduction in maintenance-related injuries. This digitisation allows for easier access and consistent application across all shifts.

The Toyota Production System incorporates the JSA concept directly into its Total Productive Maintenance (TPM) program, making safety analysis a core part of equipment care rather than a separate process. At 3M manufacturing plants, QR codes are placed on equipment, which technicians can scan to instantly pull up the specific JSA for that machine on a mobile device. This provides immediate access to correct procedures, diagrams, and energy isolation points right at the job location.

Key Takeaway: The most effective machine maintenance JSAs are equipment-specific and easily accessible at the point of work. Using technology like QR codes or digital platforms transforms the JSA from a document filed in an office into an interactive tool used directly on the plant floor.

Visualising the Machine Maintenance JSA Process

The following infographic illustrates the core phases of a safe maintenance task as detailed in a JSA, from preparation to completion.

This visual guide shows how a safe maintenance outcome depends on a strict, sequential process of isolating energy, performing the work, and carefully returning the machine to service.

Practical and Actionable Tips

To make your machine maintenance JSAs more effective, consider these practical actions:

- Create Equipment-Specific JSAs: Develop a unique JSA for each major piece of machinery, including detailed diagrams that clearly mark all energy isolation points (electrical, hydraulic, pneumatic, etc.).

- Use Mobile Devices: Equip maintenance teams with tablets or ruggedised phones to access JSAs directly at the machine. This eliminates guesswork and makes sure the correct procedure is always used.

- Implement a "Buddy System": For high-risk tasks, require two qualified workers to verify that LOTO has been applied correctly before any work starts. One person applies the lock, the other confirms it.

- Conduct Monthly JSA Reviews: Hold regular meetings with the maintenance team to go over existing JSAs. Use their hands-on feedback to update and improve the procedures based on real-world experience. A Fault Tree Analysis can also be a useful tool to complement the JSA by investigating potential failure scenarios in greater detail.

3. Chemical Plant Hot Work JSA

Hot work, which includes welding, cutting, or grinding, is a high-risk activity in any setting, but it becomes critically dangerous inside a chemical plant. A Job Safety Analysis (JSA) for this task is essential, as it must account for flammable vapours, toxic chemicals, and complex process piping. This JSA breaks down each step to manage the severe hazards of explosions, fires, and toxic gas releases.

The primary purpose of a hot work JSA in a chemical environment is to create a rigid, documented control system. It makes sure that atmospheric testing, isolation of energy sources, and fire prevention measures are completed and verified before any spark-producing work begins. This document is a cornerstone for compliance with standards from organisations like the American Petroleum Institute (API) and is a non-negotiable part of the plant’s permit-to-work system.

Strategic Breakdown and Insights

Leading chemical companies show how a JSA becomes part of a larger, integrated safety system. For example, ExxonMobil refineries utilise integrated JSA and permit-to-work systems, which have reportedly reduced hot work incidents by 75%. This system makes sure the JSA isn't just a pre-work check but a live permit condition.

Dow Chemical uses a smart JSA platform that incorporates real-time data from atmospheric monitors. If a gas detector senses a change in conditions, it can trigger an alert directly within the digital JSA, stopping work immediately. BASF has implemented digital hot work JSAs with automatic emergency response integration, meaning a confirmed emergency from the JSA system can directly activate site alarms and notify response teams.

Key Takeaway: A chemical plant hot work JSA is most effective when connected to live data and site-wide systems. Integrating real-time atmospheric monitoring and automated emergency notifications turns the JSA into a dynamic control measure that actively responds to changing hazards.

Visualising the Hot Work JSA Process

The following infographic illustrates the four critical stages for safely conducting hot work as detailed in a JSA.

This visual guide shows that safe execution is the result of systematic preparation, continuous monitoring, and thorough post-work verification.

Practical and Actionable Tips

To get the most out of your chemical plant hot work JSA, consider these practical steps:

- Mandate Continuous Gas Monitoring: Use portable gas detectors with real-time monitoring and alarms for the entire duration of the work, not just as a pre-check.

- Establish Clear Communication Protocols: Make sure the fire watch, work crew, and control room operators have a dedicated communication channel and pre-agreed hand signals for emergency stops.

- Conduct Thorough Pre-Work Inspections: Check that all drains are covered, process lines are positively isolated (e.g., with blind flanges), and adequate ventilation is in place.

- Maintain Detailed Records: Keep a log of all atmospheric readings, permit conditions, and personnel involved. This data is vital for incident investigation and process improvement. For assessing long-term risks, you can find helpful tools to calculate potential exposure by exploring how to use a chemical exposure calculator.

4. Healthcare Patient Handling JSA

Musculoskeletal injuries from handling patients are a leading cause of harm for healthcare workers. A Job Safety Analysis (JSA) for patient handling is a critical tool to address this, breaking down tasks like lifting, transferring, and repositioning patients into manageable steps. This structured approach helps identify risks such as awkward postures, excessive force, and repetitive motions that lead to sprains, strains, and chronic pain. By planning each interaction, care teams can reduce these dangers before they cause an injury.

The main purpose of a patient handling JSA is to standardise safe work procedures for a highly variable task. It makes sure that every team member, from nurses to support staff, uses the correct techniques and equipment for each patient's specific needs. This documented process is fundamental for compliance with safe patient handling and mobility (SPHM) programs and is a cornerstone of a healthcare facility's overall safety management system, protecting both staff and patients.

Strategic Breakdown and Insights

Leading healthcare organisations show how a well-implemented JSA can produce significant results. For example, Kaiser Permanente's comprehensive Safe Patient Handling program, which relies on JSA principles, led to a reported 70% reduction in lifting injuries system-wide. Their success came from making the JSA a standard part of patient assessment, not an optional extra.

The Mayo Clinic integrates patient-specific JSAs directly into electronic health records. This allows for real-time updates based on a patient's changing mobility status, making sure caregivers always have the most current safety plan. Similarly, Veterans Affairs hospitals implemented standardised JSAs across all facilities, leading to a 50% drop in patient handling injuries by removing procedural guesswork and ensuring consistency.

Key Takeaway: A patient handling JSA is most effective when it is dynamic and patient-specific. Integrating the JSA into daily care routines and electronic health records transforms it from a generic policy into a practical tool used at the point of care.

Visualising the Patient Handling JSA Process

The process for a patient handling JSA follows a clear, logical flow to ensure safety at every stage.

- Patient Assessment: The first step is to evaluate the patient's mobility, weight, and cognitive status to determine the level of assistance required.

- Equipment Selection: Based on the assessment, the correct mechanical lift, slide sheet, or other aid is chosen. The equipment is checked for functionality before use.

- Safe Transfer Execution: The team, often consisting of two or more staff members, follows the planned procedure to move the patient, using proper body mechanics and clear communication.

This three-step process shows how a safe patient transfer is the outcome of careful planning and preparation, not just physical effort.

Practical and Actionable Tips

To get the most out of your patient handling JSA, consider these practical steps:

- Assess Every Patient: Before any transfer, evaluate the patient's specific needs, mobility level, and cooperation ability to select the right equipment and technique.

- Use a Team Approach: Always use two-person teams or more for patients over specified weight limits or for those who are uncooperative.

- Prepare the Environment: Position mechanical lifts, wheelchairs, or beds and clear any obstacles before you begin the patient transfer.

- Conduct Regular Equipment Checks: Implement a schedule for inspecting and maintaining all patient handling equipment to ensure it is safe and in good working order. For more information on safe lifting procedures, you can explore detailed manual handling techniques.

5. Warehouse Forklift Operation JSA

Forklift operations are a daily activity in warehouses and distribution centres, but their routine nature can mask significant risks. A Job Safety Analysis (JSA) for this task is essential for systematically managing hazards such as collisions with pedestrians, dropped loads, tip-overs, and unsafe battery charging procedures. This JSA breaks down every phase of forklift use, from pre-start checks to parking and shutdown.

The primary purpose of a forklift JSA is to create a standardised, safe operating procedure that minimises the potential for human error and equipment failure. It provides a clear reference for operators, supervisors, and pedestrian workers, making sure everyone understands their role in maintaining a safe environment. This document is crucial for meeting regulatory requirements and is a cornerstone of any effective safety management system in the material handling industry.

Strategic Breakdown and Insights

Leading logistics and retail companies provide excellent job safety analysis examples that show how a JSA can become part of daily operations. For instance, Amazon's fulfilment centres use digital JSAs integrated with automated forklift monitoring systems. These systems track speed, impacts, and maintenance needs, feeding real-time data back into the safety process to identify and correct risky driving.

FedEx Ground facilities implement JSA-based operator certification programs that go beyond basic licensing. Operators must demonstrate proficiency in the specific tasks and hazards identified in the JSA for their work area. Similarly, Home Depot distribution centres have reported a 40% reduction in forklift incidents after implementing comprehensive JSA programs that are reviewed and updated after any near-miss or accident.

Key Takeaway: A forklift JSA is most powerful when it is supported by technology and data. Integrating telematics and real-time monitoring transforms the JSA from a static compliance document into a proactive tool for continuously improving operator performance and warehouse safety.

Practical and Actionable Tips

To get the most value from your warehouse forklift operation JSA, consider these practical steps:

- Use Visual Management: Reinforce JSA controls with clear floor markings for pedestrian walkways and forklift-only zones, along with highly visible signs at intersections and blind corners.

- Implement a Near-Miss System: Encourage operators to report near-misses without fear of blame. Use this information to identify weaknesses in your JSA and make immediate improvements before an incident occurs.

- Conduct Regular Safety Meetings: Dedicate monthly meetings to discussing the forklift JSA. Cover recent incidents or near-misses, review specific procedures, and introduce any updates or changes.

- Supplement with Technology: Use additional safety controls like blue spot warning lights, backup alarms, and pedestrian detection systems. These technologies don't replace the JSA but act as additional layers of protection to support its protocols.

6. Electrical Work High Voltage JSA

Working with high voltage systems presents some of the most severe electrical hazards in any industry, including arc flash, electrocution, and thermal burns. A Job Safety Analysis (JSA) for this work is a critical control measure that methodically breaks down tasks performed on systems over 1000V, such as substation maintenance or work on industrial power distribution networks. It ensures every step is checked for potential dangers. This document provides a systematic approach to identifying these hazards and implementing controls in line with standards like NFPA 70E.

The primary goal of a high voltage JSA is to create a documented, repeatable procedure for de-energising, locking out, testing, and performing work safely. It serves as a vital communication tool for the entire electrical team, from qualified electricians to safety observers, making sure everyone understands the risks and the exact safety protocols required. This JSA is foundational for creating a safe work environment when interacting with lethal energy levels and is a key part of any serious electrical safety program.

Strategic Breakdown and Insights

Leading organisations in the power sector show how a detailed JSA can significantly reduce electrical incidents. For instance, the Tennessee Valley Authority drove an 80% reduction in electrical injuries after implementing a comprehensive JSA program that mandated detailed pre-job briefings for all high-voltage tasks. The focus was on active participation rather than just signing a form.

Pacific Gas & Electric (PG&E) has modernised its approach by using digital JSAs that incorporate real-time arc flash calculators. Before starting work, crews can input equipment specifics and get immediate calculations for incident energy, making sure they select the correct personal protective equipment (PPE). Similarly, General Electric's power division developed JSAs that became industry benchmarks for turbine generator maintenance, standardising safety procedures across complex, high-energy equipment.

Key Takeaway: For high voltage electrical work, the JSA must be more than a procedural checklist. It becomes a critical risk calculation tool when integrated with live data like incident energy analysis, transforming it from a static document into an active defence against catastrophic failure.

Practical and Actionable Tips

To improve the effectiveness of your high voltage electrical work JSAs, consider these specific actions:

- Verify Before You Trust: Always use properly rated and tested equipment to verify that a circuit is de-energised before any work begins. This "live-dead-live" test sequence is non-negotiable.

- Use Current Arc Flash Data: Select arc flash PPE based on up-to-date incident energy calculations for the specific equipment being worked on. Relying on outdated studies or generic labels is a recipe for disaster.

- Respect Approach Boundaries: Strictly maintain minimum approach distances as defined by regulations, even when you believe equipment is de-energised. Unforeseen back-feeds or induction can still pose a lethal threat.

- Plan for the Worst: Ensure that an emergency response plan is in place and that medical assistance is immediately available during any live or potentially live high voltage work. Every second counts in the event of an electrical incident.

Job Safety Analysis Examples Comparison

| Job Safety Analysis Title | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Construction Site Crane Operation JSA | High: Multi-phase, detailed steps, extensive training | High: PPE, communication systems, load calculation tools | Significant reduction in crane incidents and fatalities | Construction, Manufacturing, Ports | Standardizes safety, improves communication, OSHA compliance |

| Manufacturing Machine Maintenance JSA | High: Complex LOTO and confined space protocols | High: Specialized training, equipment-specific JSAs | Dramatic decrease in maintenance injuries, audit-ready | Manufacturing, Automotive, Food Processing | Makes sure equipment is reliable, strengthens safety procedures |

| Chemical Plant Hot Work JSA | Very High: Complex permits, atmospheric monitoring | Very High: Fire watch, monitoring devices, specialized PPE | Major prevention of fire/explosion incidents | Chemical Processing, Oil & Gas, Petrochemicals | Manages high-risk hot work, process safety compliance |

| Healthcare Patient Handling JSA | Moderate: Equipment use and body mechanics training | Moderate to High: Mechanical lifts, ongoing training | Significant reduction in musculoskeletal injuries | Hospitals, Nursing Homes, Rehabilitation | Reduces worker injury, improves patient dignity |

| Warehouse Forklift Operation JSA | Moderate: Daily inspections, certification requirements | Moderate: Training, inspection tools, safety tech | Lower forklift accidents, improved efficiency | Warehousing, Distribution, Retail | Improves operator competency, reduces property damage |

| Electrical Work High Voltage JSA | Very High: Specialized calculations, strict protocols | Very High: Arc flash PPE, test equipment, certifications | Large reduction in electrical fatalities and arc flash injuries | Utilities, Manufacturing, Data Centers | Ensures compliance with NFPA 70E, systematic hazard control |

Putting These JSA Examples into Practice

The diverse range of job safety analysis examples we’ve explored, from crane operations in construction to forklift use in a warehouse, all point to a single, critical idea: a JSA is only as good as its practical application. Simply filling out a template is not enough. The true value comes from treating it as a dynamic tool for risk identification and control, tailored specifically to the task at hand.

Across all the examples, from high-voltage electrical work to patient handling in healthcare, a few core principles proved consistently effective. First, the most insightful JSAs are built with direct input from the workers performing the task. Their on-the-ground experience provides details that a manager or safety officer might miss from a distance. Second, specificity is non-negotiable. Vague steps like "check equipment" are far less useful than "inspect forklift tines for cracks and hydraulic hoses for leaks before ignition".

Key Takeaways for Your Next JSA

Reflecting on the breakdowns of each JSA, here are the most important, actionable takeaways to apply immediately:

- Break Down Tasks Granularly: As seen in the machine maintenance JSA, don't lump complex actions into one step. Deconstructing a job into its smallest sequential parts reveals hidden hazards you might otherwise overlook.

- Identify Specific Hazards: The chemical plant hot work example underscored the need to move beyond generic risks like "fire". A better JSA identifies specific ignition sources (e.g., sparks from grinding) and specific flammable materials (e.g., residual vapours in a pipeline).

- Define Concrete Control Measures: Vague controls are ineffective. Instead of "use PPE," specify exactly what is required, such as "wear Class 5 hearing protection, arc-rated face shield, and insulated gloves rated for 1000V". This leaves no room for misinterpretation.

Making Your JSAs Work in the Real World

The ultimate goal of studying these job safety analysis examples is to build better, more effective safety procedures for your own operations. The common thread is moving from a compliance-focused mindset to a practical, preventative one. A JSA isn't just paperwork to be filed; it’s a plan to keep people from getting hurt. It’s a communication tool that gets everyone, from the apprentice to the seasoned supervisor, on the same page about how to do a job safely.

The power of a well-crafted JSA lies in its ability to transform abstract safety policies into clear, step-by-step instructions that workers can follow on-site. By adopting the detailed, practical approach shown in these examples, you can create documents that actively prevent incidents rather than just documenting risks after the fact. This focus on clear, actionable steps is what separates a useful JSA from one that just sits in a folder.

Tired of chasing paper and managing outdated documents? Safety Space centralises all your JSAs and other safety forms into one easy-to-use digital platform. Get your team completing job safety analysis examples on-site, in real-time, and make your safety management simple and effective. Learn more at Safety Space.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.