A Safety Compliance Officer is the person responsible for making sure a company follows all relevant Work Health and Safety (WHS) laws. Their main job is not just reacting to problems; it's about building and managing the practical systems that prevent workplace injuries from happening.

What a Safety Compliance Officer Actually Does

Think of a Safety Compliance Officer as the person who sets up a worksite’s safety framework, not its police force. In high-risk industries like construction and manufacturing in Australia, their role is essential to keep operations running both safely and legally. They are the link between dense WHS regulations and what actually happens on the ground.

Their work is about proactive system management. This means they are constantly checking, documenting, and adjusting safety procedures to make sure they work and are being followed by the team.

Core On-Site Responsibilities

The daily life of a Safety Compliance Officer is hands-on and varied. A big part of their role is translating complex legal jargon into simple, actionable steps that protect workers on site.

To give you a clearer picture, here’s a quick rundown of their key responsibilities.

Safety Compliance Officer Core Responsibilities at a Glance

| Responsibility Area | Key Tasks |

|---|---|

| Site Inspections & Audits | Regularly walking the site to spot potential hazards like unguarded machinery, unsafe scaffolding, or poorly stored materials. These checks are the backbone of effective audits and compliance management. |

| Documentation & Records | Making sure all necessary paperwork, like Safe Work Method Statements (SWMS), risk assessments, and incident reports, is accurate, complete, and up to date. |

| Procedure Checks | Verifying that workers are using the correct personal protective equipment (PPE), following critical lockout/tagout procedures, and sticking to established safety rules. |

| Incident Response | Leading or assisting in the investigation of accidents and near misses. The goal is to find the root cause and implement corrective actions to stop it from happening again. |

These tasks form the foundation of a proactive safety system, moving a company from simply reacting to incidents to actively preventing them.

A key duty involves putting regulatory compliance training into practice to make sure the entire workforce understands and follows safety laws and policies. This training bridges the gap between written rules and real-world application.

This systematic focus has had a real, measurable impact. Australia’s workplace safety performance has improved, with fatality rates dropping by 24% since 2014 to just 1.3 deaths per 100,000 workers. These numbers show the direct value of having a dedicated professional managing a worksite’s risks day-to-day.

A Day in the Life of a Safety Officer

To get a feel for what a safety compliance officer does, you have to walk a mile in their steel-toed boots. Forget the stereotype of a box-ticker with a clipboard. This role is a hands-on, dynamic blend of being on the ground, spotting risks, and handling the critical admin that keeps a project safe and compliant.

Let’s step onto a busy construction site and follow an officer through their typical day.

The Early Start: Before the Action Kicks Off

The day always starts early, well before the chorus of power tools begins.

6:30 AM: The Pre-Start Meeting

First up is the pre-start meeting, or what most of us call a toolbox talk. The safety officer joins the site foreman to run through the day’s main jobs with the crew. They’re not just reading from a script; they’re pointing out the real-world risks for the tasks ahead, whether that’s working at heights or operating near heavy machinery.

Today, for example, the focus is on a newly erected scaffolding section. The officer makes sure everyone knows the go with fall arrest systems and does a quick visual check that the team has the right harnesses. It’s less of a lecture and more of a practical chat to get everyone switched on before work starts.

Morning: Walking the Site

With the pre-start done, it's time to walk the site. This isn't just a casual wander; it's a systematic inspection to catch any hazards that might have popped up overnight or any signs of non-compliance.

During this walk, they're looking for specifics:

- Verifying Scaffold Tags: Are all scaffolds showing a current, green "safe for use" tag? If a tag is missing or out of date, that scaffold is a no-go zone until it’s been properly re-inspected and signed off.

- Checking Machine Guards: They’ll check equipment like angle grinders and concrete saws to make sure the guards are fitted correctly and haven't been messed with. It’s a common shortcut, but a dangerous one.

- Inspecting Excavations: Any open trenches or pits need proper shoring and barriers. A bit of overnight rain can turn stable ground into a serious collapse risk, so this is a non-negotiable check.

This proactive part of the job is all about prevention. It’s about maintaining the standards, not just writing them down somewhere.

10:00 AM: Incident Response and Documentation

A call comes through on the radio about a minor incident. A worker tripped over a loose cable and scraped their knee. Nothing serious, thankfully. The safety officer heads straight there, not to point fingers, but to manage the situation correctly.

First, they make sure the worker gets first aid. Then, they secure the area and figure out what happened. They'll document everything with photos of the cable, a chat with the worker, and any witness accounts. This all goes into an incident report, which is valuable for spotting trends and stopping a similar, maybe far more serious, accident from happening down the track.

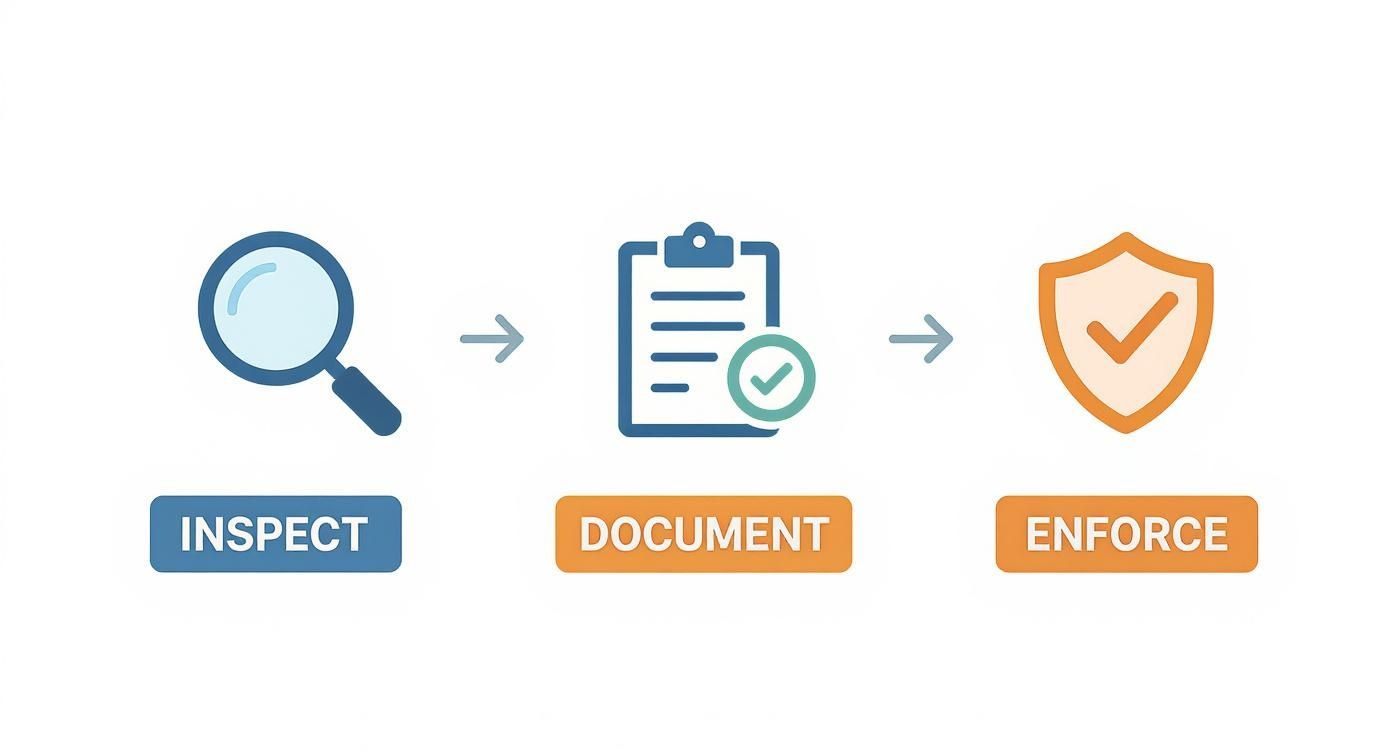

The heart of compliance isn't complicated. It's a simple, repeatable cycle: inspect the work area, document everything you find, and check that the safety rules are being followed. This loop makes sure nothing gets missed.

This simple workflow is the backbone of effective site safety.

As you can see, each step feeds directly into the next, creating a continuous cycle of improvement that actively manages risk on site.

Afternoon: The Admin Grind

The afternoon often means heading to the site office to tackle the paperwork. This side of the job is just as vital as the on-site inspections for keeping the project legally sound.

A few typical afternoon tasks might include:

- Reviewing a SWMS: A subcontractor has sent over a new Safe Work Method Statement (SWMS) for steel erection. The officer will go through it line-by-line, checking that it covers all the risks and meets the standards in the relevant Code of Practice.

- Checking PPE Stock: A quick inventory check of the personal protective equipment (PPE) shows they’re getting low on safety glasses. Time to put an order in before they run out completely.

- Writing Reports: Finally, they’ll pull together notes from the day's inspections and the incident investigation into a weekly compliance summary for the project manager. This report gives management a clear, honest snapshot of the site’s safety performance and flags any hotspots that need immediate attention.

The Right Qualifications and Skills for the Job

Becoming a good safety compliance officer is about more than just memorising a rulebook. It’s about a specific blend of formal qualifications and practical, on-the-ground skills that let you turn dense regulations into simple actions that keep people safe. Without that foundation, you just can't be effective.

In Australia, the path into this career is pretty well-defined. You don’t just walk onto a high-risk construction site or factory floor and start managing compliance. Employers need to see proof that you understand the legal and practical frameworks of workplace safety.

This isn’t a niche demand, either. There's a growing talent gap, with 34% of organisations expecting a shortage of specialist compliance skills in the next year. This just goes to show how much demand there is for people with the right qualifications.

Essential Formal Qualifications

To get your foot in the door, you’ll need some nationally recognised training. These qualifications prove you have a solid grasp of the principles behind Work Health and Safety (WHS).

Certificate IV in Work Health and Safety (WHS): This is the usual starting point. It gives you the core knowledge for roles with WHS responsibilities, teaching you how to spot hazards, assess risks, and play your part in a WHS management system.

Diploma of Work Health and Safety (WHS): Think of this as the next level up from the Certificate IV. It’s built for people who will have a more hands-on, influential role in managing WHS, like developing entire policies and procedures. This qualification is often a non-negotiable for a dedicated safety compliance officer role.

These aren’t just pieces of paper. They’re the building blocks that teach you the why behind the rules, giving you the confidence to apply them correctly on site. For those looking to build similar foundational skills in regulated fields, a specialised diploma like an Access to Higher Education Diploma in Public Sector Services and Policing can also be a valuable step.

Key Practical Skills

Of course, qualifications are only half the battle. The best officers combine their book smarts with a set of real-world skills that make them effective communicators and problem-solvers.

Deep Understanding of WHS Legislation

You need to know the model WHS Act inside and out. But what really matters is your ability to apply the specific Codes of Practice for your industry, whether that’s for scaffolding, electrical work, or machine guarding. It’s all about turning legal jargon into a simple checklist a worker can actually follow.

Sharp Attention to Detail

Compliance lives and dies in the details. You have to be the person who notices an out-of-date tag on a fire extinguisher, an incorrect entry in an incident log, or a missing guard on a conveyor belt. This focus is what stops small oversights from becoming major incidents.

The most effective safety compliance officers are good at observation. They see the small things that others miss and understand how those details connect to the bigger picture of worksite safety.

Strong Communication Abilities

One minute you're training workers, the next you're explaining procedures to managers or writing up detailed reports. You have to communicate complex ideas clearly and confidently to everyone, from a brand-new apprentice to the company director. This isn't about barking orders; it's about helping people understand the reasoning behind the rules. There are plenty of risk management and compliance courses available that can help you sharpen these crucial skills.

Good Problem-Solving Skills

When you find a compliance issue, your job is to help fix it. This calls for a practical, solutions-first mindset. It might mean figuring out a better way to store chemicals or working with a supervisor to redesign a workflow to eliminate a trip hazard.

How Performance is Measured in a Safety Role

So, how can you tell if a safety compliance officer is actually making a difference? It’s not about how many times they walk the site or how many reports they write. Real performance is measured with solid, objective data that paints a clear picture of a worksite’s safety status.

To get this picture, we rely on two main types of Key Performance Indicators (KPIs): lagging indicators and leading indicators. You need to understand both to get a full view of how well safety is being managed on the ground.

Lagging Indicators: What Has Already Happened

Lagging indicators are the classic safety metrics everyone knows. They measure outcomes and incidents that have already happened, giving you a historical view of performance. Think of them as looking in the rearview mirror; they tell you where you’ve been, which is essential for understanding past failures.

The most common lagging indicator in Australia is the Lost Time Injury Frequency Rate (LTIFR). This metric calculates the number of injuries serious enough to stop an employee from working their next full shift, measured against the total hours worked. A lower LTIFR is obviously better, as it signals fewer serious incidents.

Another key one is the Total Recordable Injury Rate (TRIR). This is a broader measure that includes any work-related injury or illness needing medical treatment beyond basic first aid, not just those causing lost time. While these metrics are useful, they only tell half the story because they are reactive; they measure failure after it’s already happened. You can get a feel for the numbers by using an accident frequency rate calculator to see how these figures are derived.

Leading Indicators: What Is Happening Now

This is where a modern safety compliance officer really shows their value. Leading indicators are proactive measurements that track safety activities and processes. They are designed to predict and prevent incidents before they happen.

These metrics focus on inputs rather than outputs. They give you real-time insight into whether your safety systems are actually working as intended. It’s like looking at the road ahead instead of just staring into the rearview mirror.

A strong focus on leading indicators is the difference between a safety program that just documents accidents and one that actively stops them. It shifts the focus from reaction to prevention.

Effective leading indicators are all about tracking positive actions. Instead of just counting injuries, you track the things that stop injuries from happening in the first place.

Leading vs Lagging Safety Indicators

To make this crystal clear, let's look at the two types of indicators side-by-side. They aren't in competition; a good safety program uses both to get the complete story.

| Indicator Type | Definition | Example KPI |

|---|---|---|

| Lagging | Measures outcomes and events that have already happened (reactive). | Number of Lost Time Injuries (LTIs) per million hours worked. |

| Leading | Measures proactive safety activities and processes (preventative). | 95% completion rate of scheduled monthly safety inspections. |

| Lagging | Provides data on past failures and shortcomings. | Total cost of workers' compensation claims in a quarter. |

| Leading | Provides data on current safety efforts and compliance. | Average time taken to close out identified hazards (e.g., <48 hours). |

By tracking both, a company gets a balanced scorecard. Lagging indicators confirm that your overall strategy is reducing incidents over the long haul, while leading indicators show that your team is doing the day-to-day work required to keep people safe right now. A successful safety compliance officer knows how to drive improvement across both categories.

Your Career Path and Salary Expectations

So, you're wondering what a career in safety actually looks like. Let's get practical.

First, we’ll break down a no-nonsense job description template. This is exactly the kind of thing you’ll see advertised for a Safety Compliance Officer in Australian construction or manufacturing. Then, we’ll map out the typical career journey, from your first day on site to a senior leadership role, and talk about the money you can expect to earn at each stage.

This isn’t just another job. It’s a proper career with clear steps for moving up and solid earning potential. Knowing the path ahead helps you see exactly where you can go and what you need to do to get there.

Sample Safety Compliance Officer Job Description

Here’s a straightforward template that cuts straight to the essentials.

Job Title: Safety Compliance Officer

Industry: Construction / Manufacturing

Location: [e.g., Western Sydney, NSW]

Reporting to: Safety Manager / Project Manager

Position Summary:

We’re looking for a dedicated Safety Compliance Officer to join our team. Your job will be to monitor our worksite to make sure all activities comply with current Work Health and Safety (WHS) legislation and our own company policies. You'll be the person on the ground, playing a key role in putting our safety management system into action day-to-day.

Key Responsibilities:

- Conduct daily site inspections and safety audits to spot and fix hazards.

- Review and help develop Safe Work Method Statements (SWMS) and risk assessments.

- Keep accurate records of safety inspections, incident reports, and training.

- Help with incident investigations to figure out what went wrong and put corrective actions in place.

- Check that all workers and subcontractors are following safety rules, including wearing their Personal Protective Equipment (PPE) correctly.

Qualifications and Skills:

- A Certificate IV in Work Health and Safety (WHS) is a must.

- A Diploma of WHS is a big plus.

- Proven experience in a safety role within construction or manufacturing.

- Solid working knowledge of the WHS Act, Regulations, and relevant Codes of Practice.

- Great communication skills and a sharp eye for detail.

A Typical Career Progression

A career in safety compliance usually follows a pretty logical path. Each step builds on the last, and it's a field where what you learn on the ground is just as valuable as any certificate on your wall.

The pathway gives you the chance to move from hands-on site roles to more strategic, big-picture leadership positions.

The journey from a junior safety role to a senior leadership position is a marathon, not a sprint. It's built on a foundation of consistent on-site experience, continuous learning, and a proven ability to manage risk effectively.

Each stage brings more responsibility and, of course, a better paycheque. Here’s what that journey typically looks like in Australia.

Salary Expectations at Each Career Stage

Salaries can shift depending on your location, the size of the project, and the specific industry, but this should give you a realistic idea of what to expect.

Safety Administrator / Assistant (Entry-Level): This is the starting line for many. The work is mostly admin-based, helping with paperwork, scheduling training, and keeping safety records organised.

- Typical Salary: $65,000 - $80,000 per year.

Safety Compliance Officer / Advisor: Once you’ve got some experience and a Cert IV or Diploma under your belt, you’ll step into this core role. Now you’re on-site doing inspections, audits, and managing compliance directly.

- Typical Salary: $90,000 - $125,000 per year.

Safety Manager: With a good few years of experience, you can move up to Safety Manager. This role is more strategic. You’re designing safety systems, managing a team of officers, and reporting to the higher-ups.

- Typical Salary: $130,000 - $170,000+ per year.

Head of WHS / National Safety Manager (Senior Leadership): At the top of the ladder, you’re overseeing the entire safety strategy for the organisation, often across multiple sites or the whole country. This requires deep industry knowledge and serious leadership skills.

- Typical Salary: $180,000+ per year, often with significant bonuses.

As you can see, the path for a safety compliance officer offers real growth, both in terms of your career and your bank account.

Common Challenges and How to Solve Them

Even the most seasoned safety compliance officer hits a few walls now and then. The role isn't just about knowing the rules; it's about making them work on a busy site where deadlines and budgets are always screaming for attention. Getting a handle on these common hurdles is the first step to clearing them.

The day-to-day reality of the job means navigating pushback, managing mountains of paperwork, and keeping up with a legal landscape that never sits still. Each of these challenges needs a practical, no-nonsense solution.

Getting Pushback from the Team

One of the toughest jobs is dealing with resistance from workers or even supervisors. People often see safety rules as a hassle that just slows the job down, which can lead them to take shortcuts. It’s rarely malicious; it’s usually just a desire to get the work done faster.

The trick is to connect the rule directly to a real-world consequence. Instead of just saying, "You need to wear your safety glasses," explain the specific risk. Try something like, "We're grinding steel today, and a hot metal splinter can cause permanent eye damage. The glasses stop that."

By explaining the ‘why’ behind the rule, you stop being an enforcer and start providing context. It helps workers understand the very real dangers a procedure is designed to prevent.

The most effective safety compliance officers are translators. They take dense regulations and turn them into simple, logical reasons for working a certain way, making safety a practical part of the job, not an obstacle.

This simple shift changes the conversation from a top-down order to a shared goal: making sure everyone goes home in one piece at the end of the day.

Drowning in Paperwork

Another massive headache is the sheer volume of documentation. Between Safe Work Method Statements (SWMS), risk assessments, inspection records, and incident reports, the paperwork can quickly become a monster. When documents are a mess or out of date, it’s not just an admin problem; it’s a serious compliance risk.

A manual, paper-based system is almost always the culprit. It's slow, full of potential errors, and makes it nearly impossible to get a clear, real-time picture of what’s actually happening on site.

The most direct solution is to ditch the paper and spreadsheets. Using a digital compliance platform centralises all your safety documentation so it works for you, not against you.

- Real-Time Access: All your docs are in one place, ready to go on a tablet or phone right there on site.

- Automated Reminders: Get alerts for expiring certifications or inspections that are overdue. No more chasing things up.

- Clearer Oversight: Dashboards can show you in a glance which tasks are done and which are falling behind.

This approach turns documentation from a burden into a genuinely useful tool for managing site safety.

Keeping Up with Changing Laws

Work Health and Safety (WHS) legislation and Codes of Practice are not set in stone. They get updated to reflect new tech, emerging risks, and learnings from major incident investigations. For a safety compliance officer, staying current isn't just a good idea; it's a core part of the job.

If you fall behind, you're not just exposing your company to massive fines; you're putting your workers at risk.

To solve this, you need a system for staying informed.

- Subscribe to Official Updates: Sign up for the newsletters from Safe Work Australia and your state’s WHS regulator. They'll land right in your inbox.

- Join Industry Groups: Get involved in forums or associations like the Australian Institute of Health & Safety (AIHS). It’s a great way to hear what’s happening on the ground.

- Schedule Regular Reviews: Block out time each month to go over any legislative changes and update your company’s policies and procedures to match.

Being proactive about staying informed means your safety systems will never be left gathering dust.

Got Questions? We've Got Answers

Stepping into the world of safety compliance always brings up a few questions. Let's clear up some of the most common ones you're likely to have.

Safety Officer vs Safety Manager: What’s the Difference?

It’s easy to get these two mixed up, but they play very different roles. The simplest way to think about it is hands-on versus big-picture.

A Safety Officer is your person on the ground. Their work is all about the day-to-day: walking the site, running inspections, making sure safety procedures are actually being followed, and dealing with incident reports as they come in. They are the frontline presence making sure the site is compliant right now.

A Safety Manager, on the other hand, works at a more strategic level. They’re the ones designing the entire safety management system, digging into incident data to spot trends, setting the safety KPIs, and answering to senior leadership. The officer checks the rules, but the manager wrote the rulebook.

How Do I Land a Safety Job with No Experience?

Breaking into the safety field without a track record might seem daunting, but there’s a well-trodden path to get you there. It boils down to getting the right ticket to the game and then finding a way onto the field.

First things first, you need to get qualified. A Certificate IV in Work Health and Safety (WHS) is the absolute minimum. It’s the qualification that tells employers you know the basics and are serious about a career in safety. Without it, your CV probably won’t even get a look-in.

With your certificate in hand, start looking for roles that put you on a worksite, even if they aren't dedicated safety jobs. Think Safety Assistant or Site Administrator on a major project. These are perfect stepping stones. You’ll soak up how a site really operates and learn directly from the seasoned pros around you.

Don't sleep on the power of networking. Joining an organisation like the Australian Institute of Health & Safety (AIHS) gets you in the room with people who can offer solid advice and maybe even point you towards your first opportunity.

What Are the Key WHS Regulations in Australia?

The world of WHS law is massive, but a great safety compliance officer knows exactly which parts matter most for their workplace. You need to have a rock-solid grasp of the core legislation and the specific rules for your industry.

The foundation for everything is the model Work Health and Safety (WHS) Act. Most states and territories have built their laws on this framework, so understanding its core principles, duties of care, risk management, and consultation, is non-negotiable, wherever you are in Australia.

But the Act is just the starting point. You also need to know the specific Codes of Practice for your industry inside and out. These are the practical playbooks that tell you how to meet the standards set by the WHS Act.

- Working in construction? You'll live and breathe the codes for scaffolding, excavation work, and preventing falls.

- Based in a manufacturing plant? Your focus will be squarely on the codes for machine guarding, storing hazardous chemicals, and managing electrical risks.

Knowing these practical guides is what separates someone who just knows the theory from a safety officer who genuinely makes a difference on site.

Ready to stop drowning in paperwork and start managing safety effectively? Safety Space provides an all-in-one platform to centralise your documentation, automate reminders, and get a clear view of compliance across your entire operation. Book a free demo to see how you can simplify your safety systems today.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.