Strategic risk management isn't about creating more paperwork or trying to bubble-wrap the entire business. It’s a forward-looking process for spotting and handling the major risks that could stop your company from hitting its core objectives.

For leaders in construction or manufacturing, this means thinking beyond daily site hazards to see the bigger, strategic picture.

So, What Is Strategic risk management, Really?

Here's a simple way to think about it.

Traditional, day-to-day risk management is like watching your feet to avoid tripping on the factory floor. It’s absolutely essential for immediate safety.

Strategic risk management, on the other hand, is like looking up at the horizon to see if a storm is coming that could flood the entire plant. Both are necessary, but they operate on completely different scales and answer very different questions. This strategic view connects risk directly to your company's long-term goals and survival.

Moving Beyond the Immediate Hazard

Let’s get practical. For a construction site manager, an operational risk is an unsecured ladder. A strategic risk is a critical shortage of skilled tradespeople that could delay projects for the next two years, making you uncompetitive.

For a manufacturing plant director, an operational risk is a machine malfunction. A strategic risk is your single-source supplier for a vital component going out of business, halting your entire production line indefinitely. See the difference?

This shift in perspective is what separates businesses that merely survive from those that do well. It's about proactively managing threats that could impact your:

- Market Position: A competitor quietly develops a new prefabrication method that cuts costs by 30%.

- Reputation: The public turns against you because you weren't prepared for new environmental regulations.

- Financial Stability: A sudden, massive spike in the cost of steel or timber throws all your project budgets out the window.

- Technological Relevance: Failing to adopt new digital tools while the rest of the industry moves on without you.

This proactive approach is gaining serious traction for a reason. In fact, the Australian risk management market was valued at USD 270 million in one year and is projected to climb to USD 782.48 million by 2033. This growth is being pushed by new digital vulnerabilities and ever-tightening regulatory mandates.

Traditional vs Strategic Risk Management A Quick Comparison

To put it plainly, the two approaches have fundamentally different goals and timelines. One is about preventing today's accidents; the other is about making sure the company is still standing in five years.

| Aspect | Traditional Risk Management | Strategic Risk Management |

|---|---|---|

| Focus | Daily operational hazards (e.g., slips, trips, falls). | High-impact risks tied to business goals (e.g., market shifts, supply chain failure). |

| Time Horizon | Immediate, short-term. | Long-term (1-5+ years). |

| Responsibility | H&S teams, site managers. | Executive leadership, board of directors. |

| Goal | Compliance, preventing accidents. | Building resilience, protecting long-term value. |

| Approach | Reactive, rule-based. | Proactive, forward-looking. |

| Example | A worker not wearing a hard hat. | A new technology making your core product obsolete. |

This table shows it’s not about choosing one over the other. A strong organisation needs both. You can’t look at the horizon if you’re constantly tripping over your own feet.

The Core Difference

Strategic risk management isn’t a separate department; it's a way of thinking that needs to be part of every high-level decision. It makes sure that when the leadership team discusses expansion, new product lines, or entering new markets, the big "what ifs" are part of the conversation from day one.

At its core, strategic risk management involves integrating data into all strategic decisions. A powerful example is adopting a data-driven growth strategy to turn information into measurable results and a competitive advantage.

By focusing on these high-impact, low-frequency events, you shift from simply preventing incidents to actively steering the company toward its goals while navigating major obstacles. It's the difference between basic compliance and building a truly resilient, future-proof organisation.

Building Your Strategic Risk Management Framework

Think of a strategic risk management framework like the blueprint for a major construction project. It gives you structure, lays out the materials, and makes it clear who’s responsible for each part of the build. Without one, you’re just putting out fires as they pop up, and that’s a dangerous way to run a business.

The whole process kicks off with a single, crucial question that your leadership team has to answer honestly: how much risk are you actually willing to take on to hit your business goals? This is your risk appetite, and it’s the foundation for every decision that follows.

It’s a bit like setting a speed limit for your company. A high-growth tech startup might set a pretty high speed limit, accepting the chance of a few bumps in the road in exchange for rapid expansion. On the other hand, an established manufacturing firm would likely set a much lower, more cautious limit to protect its hard-won market position and reputation.

Defining Your Risk Appetite

Your risk appetite statement can’t just be some vague corporate slogan. It needs to be a real, practical guide that people can use day-to-day. It’s what connects your big-picture business objectives to the nitty-gritty of how much risk you’ll accept in specific areas.

For a construction company, this might look something like:

- Financial Risk: "We will not take on projects where a single client makes up more than 20% of our annual revenue, so we don’t become over-reliant."

- Technological Risk: "We’ll pilot new building technologies on a maximum of two non-critical projects per year before we even think about a wider rollout."

- Workforce Risk: "We will always maintain a ratio of at least one apprentice for every five senior tradespeople to head off long-term skill shortages."

See how these statements are clear and measurable? They give teams real boundaries to operate within and turn the abstract idea of "risk" into concrete, everyday business rules.

Setting Up Clear Governance

Once you know your limits, the next job is to sort out your governance. This is just a straightforward way of defining who is responsible for what. A solid governance structure makes sure risks are spotted, managed, and communicated properly, from the people on the tools right up to the boardroom.

Governance isn't about creating more red tape. It’s about building clear pathways for information and accountability. It ensures the right people are having the right conversations about the right risks at the right time.

This structure usually has a few key parts.

1. The Board and Senior Leadership

The board’s role is oversight. They’re there to approve the overall risk appetite and make sure the executive team has a robust system in place to manage it. Senior leaders, like the CEO and directors, are the ones who own the strategic risk management framework. Ultimately, the buck stops with them.

2. The Risk Committee

For a lot of organisations, setting up a dedicated risk committee is the most practical move. This group, usually made up of heads from different departments (think Operations, Finance, HR, and H&S), is responsible for the day-to-day running of the framework.

Their job includes:

- Regularly identifying and assessing strategic risks.

- Making sure response plans are actually developed and actioned.

- Keeping an eye on key risk indicators across the business.

- Reporting up to senior leadership on the company's current risk profile.

3. Business Unit Leaders

These are your eyes and ears on the ground. A construction site manager or a manufacturing plant supervisor is in the best possible position to spot emerging risks in their area. Your governance structure has to give them clear channels to flag these concerns, making sure their boots-on-the-ground insights get to the risk committee.

The Construction Company Example

Let's circle back to our construction company. They've defined their risk appetite. Now, they've pulled together a risk committee with the Operations Director, CFO, Head of H&S, and a senior Project Manager.

In their very first meeting, they pinpoint a major strategic risk: the growing shortage of skilled welders is threatening their ability to bid on the large-scale steel-frame projects that are central to their five-year growth plan.

Because their governance is clear, the process is simple. The committee tasks the Operations Director with creating a plan to mitigate this. He gets with HR to launch a new apprenticeship program and starts exploring partnerships with local vocational training centres. He reports back to the committee on progress each quarter, and the committee then gives a summary to the board. Everyone knows their role, accountability is clear, and a critical strategic risk is being actively managed.

If you want to dive deeper into the international standards that underpin these frameworks, our guide on ISO 31000 risk management offers a detailed overview.

How to Implement Your Risk Strategy

Okay, you've got your framework mapped out. Now comes the important part: turning that plan into action. This is where your strategic risk management process stops being a document and starts being a day-to-day tool for making smarter, safer decisions.

Putting your strategy into practice isn't a one-off task. Think of it as a continuous cycle: you identify, assess, respond to, and review risks. It’s a living process.

Let's break it down into four clear, manageable steps. Following these will turn the high-level idea of 'strategic risk' into a concrete plan that actively protects your company's future.

Step 1: Identify Strategic Risks

You can’t manage what you don’t see. The first step is to get a complete picture of the major threats that could throw your business goals off course. This isn't about listing every possible slip, trip, and fall, it's about zooming out and looking at the big picture.

To do this right, you need to look both outside and inside your organisation.

- External Factors (PESTLE Analysis): This is a classic for a reason. It's a simple framework for scanning your environment for risks. Think Political, Economic, Social, Technological, Legal, and Environmental. For a construction company, this could mean flagging new environmental regulations (Legal) or an economic downturn that might dry up new projects (Economic).

- Internal Factors (SWOT Analysis): Now, turn the lens inward. What are your company's Strengths, Weaknesses, Opportunities, and Threats? A manufacturing plant might pinpoint its reliance on a single, ageing piece of machinery as a massive Weakness, a clear strategic risk.

The aim here is to brainstorm a comprehensive list of potential strategic risks, gathering input from different people across the business.

Step 2: Assess and Prioritise Risks

Once your list is ready, you'll see pretty quickly that not all risks are created equal. Some are minor headaches; others are genuine company-killers. You need a simple way to separate the critical threats from the background noise.

This is where a risk matrix comes in handy. It’s a visual tool that helps you score risks based on two simple things:

- Likelihood: How likely is this risk to actually happen?

- Impact: If it does happen, how badly will it hurt the business?

You score each factor, usually on a scale like 1 to 5, and plot them on a grid. Any risk that lands in the "high likelihood, high impact" red zone needs your immediate attention. Something with low likelihood and low impact? You might just decide to keep an eye on it.

This assessment is crucial. It forces you to focus your limited time, money, and energy on the threats that actually matter. It stops your team from chasing down low-priority issues and channels your effort where it will make the biggest difference.

Step 3: Develop Risk Response Plans

For every high-priority risk you've identified, you need an action plan. Just knowing it exists isn't enough. Your response plan spells out exactly what you’re going to do about it.

Generally, you have four main options:

- Mitigate: Take action to reduce the chances of the risk happening or lessen its impact.

- Transfer: Shift the risk (or part of it) to someone else, usually through insurance or by outsourcing.

- Accept: For some risks, the cost of dealing with them is higher than the potential damage. Here, you might consciously decide to accept the risk and have a solid contingency plan ready.

- Avoid: If a risk is just too big to handle, you might decide to stop the activity causing it altogether.

A factory manager who identifies a single-source supplier as a critical risk might choose to mitigate it by spending the next six months finding and onboarding a second supplier. Simple, practical, effective.

Step 4: Monitor and Review the Plan

Strategic risk management is definitely not a "set and forget" exercise. The world changes, and your risks will change with it. That’s why this final step is a continuous loop of monitoring and reviewing your plans.

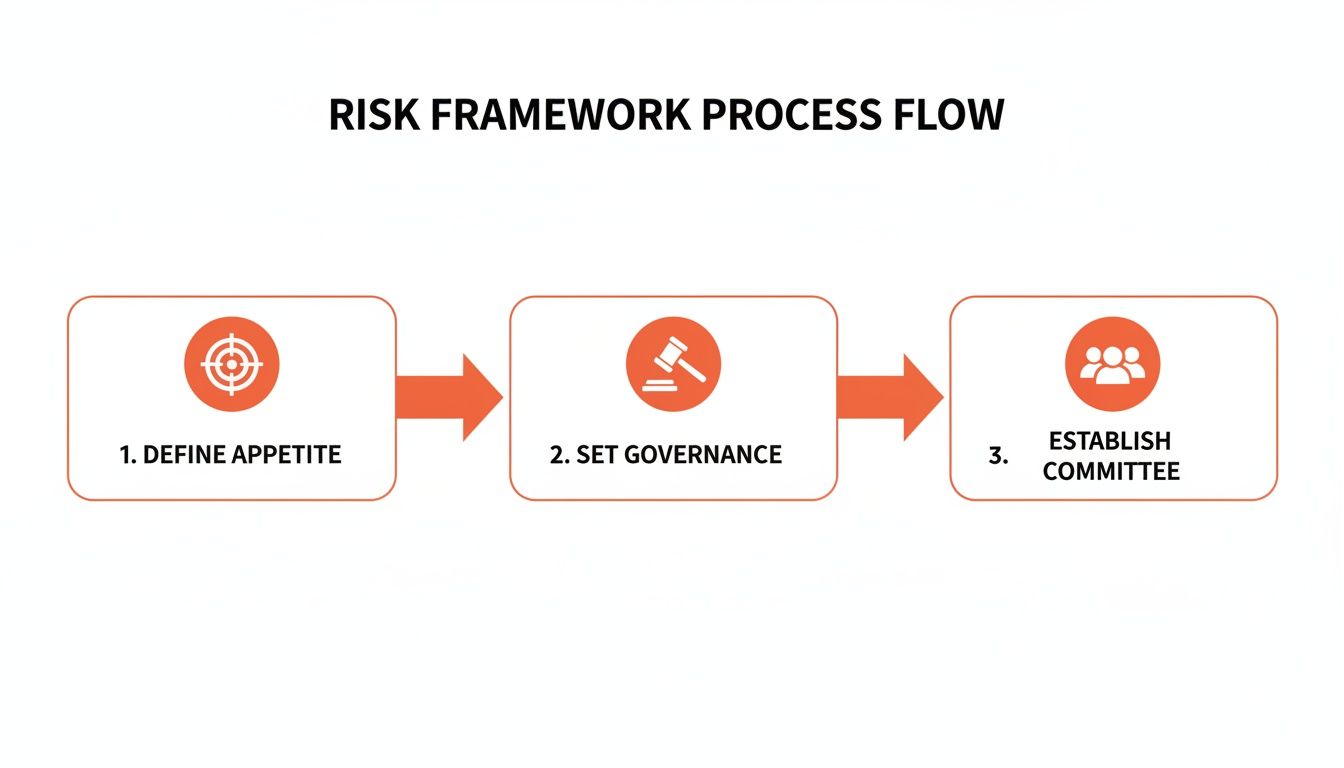

This is all about having a structured process in place, defining your risk appetite, setting the rules of governance, and having a committee to keep things on track.

This ongoing review is essential. Just look at geopolitical risks in Australia's financial system, 70% of stakeholders now see it as a critical concern. In response, regulators brought in new standards to push for more rigorous, forward-looking risk management. The world moves on, and your risk plan has to keep up.

A new competitor could appear, new tech could shake up your industry, or a new regulation could land on your desk. Your risk committee should be meeting regularly (quarterly is a good start) to review the risk register, check progress on your action plans, and scan the horizon for new threats. This keeps your strategy relevant.

A strong implementation process is the foundation for understanding your organisation's complete risk and compliance posture. By systematically working through these four steps, you create a living, breathing system that not only protects your business but also helps you spot opportunities and move forward with confidence.

Measuring Success with Practical KPIs

So, you’ve got a strategic risk management plan. How do you know if it’s actually working? A plan gathering dust in a folder is useless. You need a real-world way to see its impact, and that means looking beyond the usual metrics like incident rates.

Think of it this way: traditional safety metrics, or lagging indicators, are like looking in the rearview mirror. They tell you about accidents that have already happened. For strategic risk management, you need to be looking forward through the windscreen using leading indicators. These are the proactive checks that show your systems are working to head off problems before they even start.

This shift in how you measure is huge. It moves you from just reacting to failures to actively tracking how well you’re building a more resilient organisation.

Moving Beyond Simple Incident Rates

Relying only on lagging indicators like Lost Time Injury Frequency Rates (LTIFR) to measure your strategy is like judging the quality of a building by only counting the number of dropped tools. Sure, it’s information you need to know, but it tells you nothing about whether the foundations are solid.

You need Key Performance Indicators (KPIs) that connect directly to your big-picture goals. These metrics create a feedback loop, showing you what’s working, what isn’t, and where you need to adjust your approach.

A strong set of KPIs turns your strategic risk management from a theoretical exercise into a measurable, performance-driving part of the business. It gives you the data to prove its value and make smart calls on where to put your resources.

And it seems Australian organisations are catching on. Gartner is forecasting that total risk management spending will climb to nearly AU$6.2 billion as companies stare down new cyber, regulatory, and AI-related threats. This isn't just about ticking boxes; it's a major shift toward building proactive, data-driven resilience into the core of how businesses operate. You can learn more about why Australia is spending so much on risk management.

Practical KPIs for Construction and Manufacturing

The best place to start is with metrics that are simple to track but give you powerful insights into the health of your strategy. Here are a few practical examples you can adapt for your own use.

Percentage of Strategic Risks with a Documented Response Plan: This one’s basic but absolutely critical. If you’ve identified your top five strategic risks, what percentage have a clear, actionable plan to deal with them? A low score here is an immediate red flag.

Time to Close Out Mitigation Actions: When you create a response plan, every action needs a deadline. This KPI tracks how long it takes your team to get these critical tasks done. If deadlines are constantly being missed, it points to a problem with either resources or accountability.

Number of Near Misses Related to Strategic Threats: This is a brilliant leading indicator. If your biggest strategic risk is a supply chain failure, tracking how many times a critical delivery was almost late gives you an early warning. It proves your backup plans (like having a secondary supplier) aren't just nice-to-haves, they're essential.

Risk Assessment Completion Rate: Keep an eye on the percentage of key projects or operational areas that have completed their strategic risk assessments on time. This tells you how well the process is actually being adopted across the business.

Creating Your Feedback Loop for Improvement

Tracking these KPIs isn't about producing a pretty report. The whole point is to create a continuous cycle of improvement that keeps your strategy sharp and relevant.

Track Consistently: Use a simple dashboard or even a shared spreadsheet to keep tabs on your KPIs. Make sure the data is updated regularly, weekly or monthly, whatever makes sense for you.

Review Regularly: Your risk committee needs to review these numbers at every meeting. Talk about the trends. Why is it taking longer to close out actions? Why did we have more supply chain near misses this quarter?

Act on Insights: The review has to lead to action. If risk assessments aren't getting done, find out why. Do managers need more training? Is the process a headache to get through? Use the data to fix the root cause, not just the symptom.

By using a mix of these practical KPIs, you can get a real measure of the success of your strategic risk management efforts. This approach gives you the hard evidence you need to show leadership that your plan is protecting the business and helping it hit its long-term goals.

Using Technology in Your Strategic Risk Efforts

Trying to manage a strategic risk plan with spreadsheets and manual check-ins is like trying to build a modern high-rise with hand tools. Sure, it’s possible, but it’s painfully slow, inefficient, and leaves you wide open to things going wrong. Modern tools can change your strategy from a static document into a live, responsive system, making the whole process much less of an administrative headache.

Technology is what connects the dots between your high-level strategy and what’s actually happening on the ground. Instead of waiting for last month's reports to land on your desk, you get a real-time view of your risk landscape. This means you can spot emerging issues early and jump on them before a small problem spirals into a major crisis.

For industries like construction and manufacturing, where site conditions can change by the hour, this ability to see and react quickly is a complete game-changer. It turns risk management into a proactive tool for steering the business forward, not just a reactive box-ticking exercise.

Making Your Strategy Actionable

The right technology is what pulls strategic risk management out of theory and into day-to-day practice. It’s about getting the right information to the right people at the right time so they can make smart decisions.

Here are a few ways specific software features make this happen:

- Real-Time Monitoring: Imagine a construction manager seeing leading indicators from all their sites on a single screen. They can track metrics like the number of near-misses related to a new building material, giving them a crucial early warning of a potential systemic issue.

- AI-Powered Form Completion: One of the biggest hurdles in risk assessment is inconsistent data entry. AI-driven forms standardise the process, using smart prompts and logic to make sure every risk assessment captures the same critical information. This is vital for accurate analysis and spotting meaningful trends.

- Multi-Site Oversight: For leaders overseeing multiple factories or construction projects, getting a high-level view is crucial. A centralised dashboard gives them that birds-eye perspective of risk trends across the whole organisation, helping them make informed, data-backed decisions.

This kind of dashboard view is exactly how technology provides multi-site oversight, allowing leaders to shift from relying on anecdotes to making data-driven strategic decisions.

A Practical Example in Construction

Let’s look at a national construction firm rolling out a new, sustainable building material across dozens of projects. The strategic risk is clear: what if this new material fails under certain climate conditions? That could lead to widespread structural issues and do massive damage to their reputation.

Using a platform with the features we've just talked about, the firm can:

- Standardise Assessments: An AI-guided form ensures every site team assesses the risks of the new material using the exact same criteria, eliminating guesswork.

- Monitor in Real-Time: They can track leading indicators from each site, things like reports of minor cracking or installation difficulties, which are flagged immediately on a central dashboard.

- Gain High-Level Insight: The national H&S director notices an unusual cluster of minor issue reports coming from sites in a specific high-humidity region. This allows them to pause the rollout in that area and investigate before a catastrophic failure occurs.

This proactive approach is only really possible with the right technology in place.

Technology transforms strategic risk management from a periodic review into a continuous, data-driven conversation. It provides the visibility and tools needed to not only identify risks but also to manage them effectively across the entire business.

As you build out your technology stack, it’s also important to protect the data it generates. When thinking about how to use technology for your strategic risk efforts, exploring options like managed network security solutions can be a smart move to protect your organisation's digital assets.

By integrating these kinds of tools, you build a stronger, more responsive strategic risk management process. If you’re exploring how a dedicated platform can help, learn more about what to look for in a modern risk management system. This digital foundation is what makes your strategy more resilient and, ultimately, much more effective.

Getting Started with Strategic Risk Management

Let’s be honest, shifting to a strategic approach to risk can sound like a huge undertaking. The good news? It’s not about flipping a switch overnight. It’s more about building a new discipline, making forward-thinking, risk-based decisions a part of your daily rhythm.

This moves your role beyond just preventing today’s accidents. It’s about protecting the company’s future and proving how vital a proactive safety function is to the bottom line. And getting started is more practical than you might think. You don’t need to overhaul everything at once, just a focused effort on what truly matters.

The goal isn't to eliminate all risk. That's impossible. It’s to understand which risks are worth taking and to have a rock-solid plan for the ones that could genuinely derail your business.

A Simple Three-Step Start

To get this off the ground, you need to turn theory into action. A simple, direct approach builds momentum and shows immediate value without burying everyone in paperwork.

- Get Leadership Buy-In: First things first, you need to speak their language. Frame risk in terms of business objectives. Don't just talk about site incidents; talk about how a major supply chain failure or a shortage of skilled labour directly threatens revenue targets and growth plans.

- Start Small and Focused: Forget trying to identify every possible threat from day one. That’s a recipe for paralysis. Instead, zoom in on the top 3-5 strategic risks, the ones that pose the biggest danger to your company’s core goals.

- Use Technology to Your Advantage: You can’t manage what you can’t measure. Use tools that help you gather consistent data and track how you’re doing. This gives you the hard evidence needed to monitor your action plans and report back to leadership with confidence.

Frequently Asked Questions

Got questions about making the switch from traditional safety to a more strategic approach? You're not alone. Here are a few things we hear all the time from H&S teams in construction and manufacturing.

How Is Strategic Risk Management Different from Daily Safety Audits?

It’s a classic case of seeing the forest for the trees.

Your daily safety audits are all about the trees, spotting trip hazards, checking machine guards, and dealing with the immediate dangers on the floor. That’s operational risk, and it’s absolutely critical.

Strategic risk management is about seeing the whole forest. It asks bigger questions. What if a key supplier of building materials goes under? What if new environmental regulations make our current processes obsolete overnight? What if a major skills shortage brings our projects to a grinding halt?

These are the kinds of threats that could jeopardise the entire business, not just a single task or site. While your daily audits keep people safe today, strategic risk management makes sure the business is still around to keep them safe tomorrow.

Our Team Is Swamped. How Can We Do This Without Drowning in Paperwork?

The last thing anyone needs is another mountain of forms. The key here is to weave strategic thinking into what you’re already doing, not to create a separate, bureaucratic process.

Forget trying to map out every conceivable risk under the sun. Start small. Get your team to pinpoint the top 3-5 threats that would truly hurt the company if they came to pass.

Then, use your existing safety meetings or management catch-ups to talk through those specific risks. What would we do? Who would be in charge? It’s about building simple, practical response plans, not writing a novel.

The goal is smarter work, not more work. It's about shifting some of your efforts from reactive fire-fighting to proactive planning for the big stuff that could seriously derail the company's future.

This is where technology can be a game-changer. A platform that centralises your data can automate a lot of the monitoring and reporting, freeing you up from the admin grind.

Who Should Be in the Room for This Conversation?

While the safety team can definitely steer the ship, this isn't a solo mission. To get this right, you need perspectives from all corners of the business. Senior leadership is non-negotiable, they need to set the company's appetite for risk and sign off on the resources to manage it.

But you’ll also need to bring in other key players:

- Operations Managers: They’re on the ground and know the practical vulnerabilities of your sites and production lines.

- Procurement Teams: They have the inside scoop on supply chain weaknesses and potential disruptions.

- The Finance Department: They can help you run the numbers and understand the real financial hit of different scenarios.

- HR Teams: They’re across workforce risks like skills gaps, high turnover, or an ageing team.

Think of the safety team as the facilitator. Your role is to get the right people talking, provide a framework for the discussion, and help track the plans you all agree on. It’s this combined expertise that gives you a true, 360-degree view of the risks you really face.

Ready to move from spreadsheets to a smarter, more connected system? Safety Space offers an all-in-one platform with real-time monitoring and multi-site oversight to help you put your strategic risk management plan into action. Book a free demo and H&S consultation today.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.