In the world of risk management, risk is simply the chance that something unexpected could throw a spanner in the works, whether that affects your project's timeline, budget, or day-to-day operations. It's the real-world effect of uncertainty on whatever you’re trying to achieve.

What Is Risk In a Practical Management Context

Forget the textbook definitions. Think of risk management as a hands-on tool for staying in control. It's all about looking ahead, spotting potential roadblocks, and making smart, proactive decisions to stop nasty surprises from derailing your work. It’s the shift from reacting to fires to preventing them in the first place.

Here’s a simple analogy from a construction site. Let's say you've got a massive concrete pour scheduled for tomorrow. The risk isn't just that it might rain. The real risk is the combination of an unpredictable weather forecast and the massive consequences if it does pour down: a ruined foundation, expensive delays, and a whole lot of wasted concrete.

Beyond Just Major Accidents

When we talk about risk in a management sense, it’s important to look beyond just the big, dramatic accidents. While keeping people safe is always the number one priority, risk also covers a much wider spectrum of potential issues that can hit a business.

These different types of risk are often tangled together. A critical equipment failure on a production line doesn't just halt work. It can lead to serious financial losses from downtime and even damage your company's reputation if you suddenly can't deliver on your orders. Taking this broader view helps protect the entire operation, not just one part of it.

To help break it down, here’s a quick summary of the core ideas.

Key Risk Concepts at a Glance

| Concept | Simple Explanation | Industrial Example |

|---|---|---|

| Hazard | The thing that has the potential to cause harm. | A chemical spill on a factory floor. |

| Likelihood | How probable it is that the hazard will actually cause harm. | The floor is slippery, and workers frequently walk through that area. |

| Consequence | The severity of the harm if it occurs. | A worker slips, resulting in a serious injury and lost work time. |

| Risk | The combined effect of likelihood and consequence. | The high probability of a slip combined with the severe injury potential. |

This table shows how these elements come together to define the overall risk you need to manage.

A Framework for Making Decisions

At its core, understanding risk gives you a structured way to make decisions when you don't have all the answers. It’s not about having a crystal ball to predict the future perfectly. It’s about methodically identifying what could go wrong and putting sensible controls in place to handle the fallout.

Risk management is fundamentally about gaining control over uncertainty. It's the process of identifying what you don't know and creating a plan to manage it before it manages you.

This systematic approach is essential across every part of an organisation. For instance, understanding how to handle risks brought in by external vendors is a huge piece of the puzzle for many businesses. For anyone focused on that area, you can Delve into the specifics of Third-Party Risk Management (TPRM) to see these principles in action. Adopting this mindset is what keeps projects on track and businesses resilient.

The Three Core Components of Workplace Risk

To really get your head around risk in a practical way, you need to break it down into its moving parts. Just thinking about "danger" is too vague and doesn't give you a clear path forward. Instead, a structured approach looks at three distinct elements that come together to define any risk you might face, whether it’s on a construction site or a factory floor. This method gives you a repeatable framework for seeing things clearly.

This process is what takes you from having a gut feeling about a problem to having a logical way of understanding and dealing with it. By separating these components, you can analyse any situation, from operating heavy machinery to working with hazardous chemicals, in a consistent and objective way.

1. The Hazard

First up, you have the hazard. Put simply, this is the thing or situation that has the potential to cause harm. It’s the source of the danger.

Think of it this way: a hazard on its own isn't a risk just yet. It’s more like a loaded gun waiting for a trigger.

Consider an unguarded saw blade in a workshop. That blade is the hazard. It has the clear potential to cause a severe injury, but at this point, nothing has actually happened.

Here are a few more real-world examples:

- An unmarked wet floor in a busy hallway.

- A pallet of heavy materials stored incorrectly on a high shelf.

- Faulty electrical wiring on a piece of equipment.

Identifying the hazard is always the first step. You can't manage a problem you haven’t seen.

2. The Likelihood

Next, we need to think about likelihood. This is all about the probability or chance that someone will actually be harmed by the hazard. It answers the crucial question, "How likely is this to actually happen?"

Let's go back to our saw blade example. If that machine is in a locked room that no one ever enters, the likelihood of an incident is extremely low. But if it’s an active machine used daily by multiple operators, the likelihood suddenly becomes much higher.

The likelihood component forces you to consider the context of the hazard. A hazard in isolation is a theoretical problem; likelihood makes it a practical one by adding factors like frequency of exposure, number of people involved, and existing controls.

3. The Consequence

Finally, you have to assess the consequence. This is the severity of the outcome if the event actually occurs. It asks, "If this does happen, how bad will it be?" Consequences can range from a minor first-aid issue right through to a catastrophic failure.

For the unguarded saw, the consequence is obviously severe: amputation, life-changing injury, or even death. For the wet floor, the consequence might range from a minor bruise to a broken bone. A single risk can have multiple consequences, affecting people, equipment, and even project timelines.

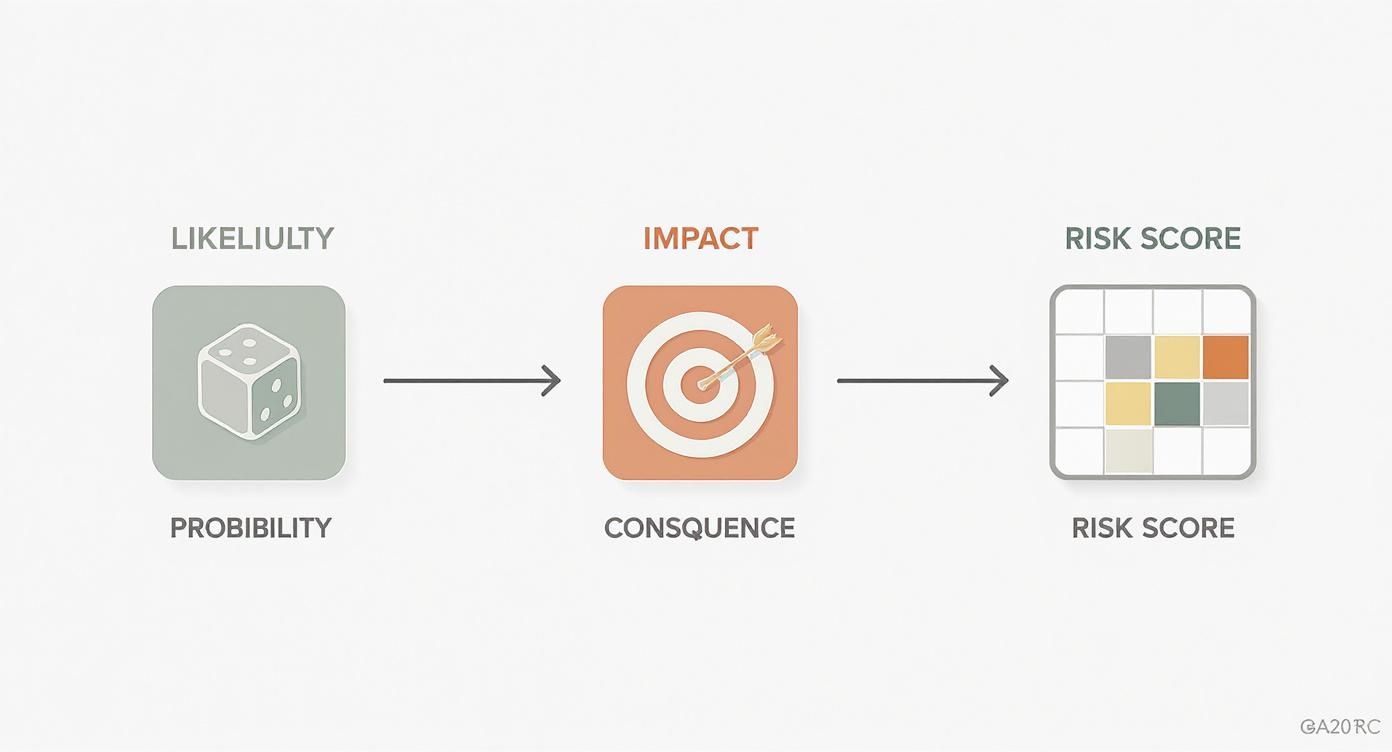

By combining these three components, Hazard, Likelihood, and Consequence, you get the full picture of the risk. A high-risk situation isn't just one with a dangerous hazard; it's one where a hazard has a high likelihood of causing a severe consequence. This simple formula is the foundation of every practical risk assessment you'll ever do.

Common Types of Risk in Industrial Operations

Understanding risk in theory is one thing, but seeing how it plays out on a busy worksite or factory floor is where the rubber really hits the road. In industrial and construction settings, risks aren't just abstract ideas; they're daily realities that can derail everything from worker safety to project deadlines.

To get a proper handle on them, it helps to break them down into practical categories.

Thinking about risk in buckets like operational, financial, and compliance helps you see the whole picture. It shifts the conversation from just "what could hurt someone?" to "what could stop this project or damage the business?" This bigger-picture view is essential for building a truly solid risk management plan.

Operational Risks

Operational risks are the most hands-on, immediate threats you face day-to-day. These are the risks tied directly to your processes, your gear, and your people. When something goes wrong here, it can bring an entire operation to a grinding halt.

Think about these classic examples:

- Equipment Failure: A critical piece of machinery, like a crane on a construction site or a press in a factory, gives up without warning.

- Supply Chain Delays: A key supplier fails to deliver essential materials on time, leaving your crews with nothing to do and production lines sitting idle.

- Human Error: An employee makes a simple mistake during a complex task, leading to rework, wasted materials, or even worse, a safety incident.

These aren't just one-off problems. A single crane failure doesn't just stop one lift; it kicks off a domino effect that can ripple across the entire project.

Financial and Compliance Risks

The fallout from an operational breakdown rarely stays in its lane. It almost always spills over, creating new headaches. The most obvious are financial risks, which hit the project's budget and the company's bottom line directly.

Let's go back to that broken crane, an operational risk. It immediately triggers financial consequences. Now you’re dealing with project delays, the cost of emergency repairs, and maybe even penalty clauses for missing deadlines. All of a sudden, an operational issue has become a massive financial headache. A recent KPMG report backs this up, highlighting that economic uncertainty and regulatory pressures are top concerns for Australian businesses, showing just how tangled these issues are. You can find more details in the full report on top risks for Australian businesses.

A key part of understanding risk is seeing how one problem creates another. The initial event is rarely the end of the story; it's the chain reaction that often causes the most damage.

Finally, you have compliance risks. These are all about failing to meet legal, regulatory, or industry standards. If that crane failed because someone skipped the required inspections, your business could be staring down the barrel of heavy fines from regulators and a badly damaged reputation.

This is a perfect example of how a single hazard can trigger operational, financial, and compliance risks all at once. For a deeper look into this, check out our guide on the different types of risks in the workplace.

Using a Risk Matrix to Prioritise Your Actions

So, you've identified a list of potential risks. Great. Now for the big question: where on earth do you start? You can’t tackle everything at once, and frankly, you shouldn't have to.

This is where a risk matrix becomes your most practical tool. It’s a simple visual grid designed to cut through the noise, helping you stop guessing and start making logical decisions about what needs your attention right now.

The whole point of the matrix is to take that gut feeling you have about a risk and turn it into something more concrete. It does this by plotting the two key elements we've already covered: likelihood against consequence. This simple act gives you a clear, colour-coded priority list, showing which risks demand immediate action and which can be managed with less urgency.

How to Plot Risks on the Matrix

Getting started with a risk matrix is surprisingly straightforward. For each hazard you've identified, you just need to ask two simple questions:

- How likely is this to happen? You'll rate this on a scale, usually from something like "Rare" up to "Almost Certain."

- If it does happen, how bad will it be? Again, this gets rated on a scale, from "Insignificant" to "Catastrophic."

You then take those two ratings and find where they intersect on the grid, where the likelihood axis (often the vertical one) meets the consequence axis (the horizontal one). The box where they meet gives you a risk score, typically colour-coded as low (green), medium (yellow), or high (red).

A risk matrix isn't just for scoring things; it's a decision-making tool. Its real purpose is to create a clear, visual plan that tells you exactly where your focus needs to be. Anything in the red zone is a non-negotiable priority.

Making Practical Decisions on Site

Let's put this into a real-world context. Imagine a construction site manager has two different risks on their mind:

- Risk A: A large excavation pit is protected by temporary fencing, but workers keep pushing it aside to take a shortcut. The likelihood of someone falling in is rated as "Possible." The consequence, however, would be catastrophic: a serious or fatal injury.

- Risk B: Workers are occasionally leaving hand tools on walkways at the end of the day. The likelihood of someone tripping is "Likely." The consequence, though, would probably be a minor injury, like a sprain or a few bruises.

When plotted on the matrix, Risk A (Possible likelihood, Catastrophic consequence) lands squarely in the high-risk, or red, zone. Meanwhile, Risk B (Likely likelihood, Minor consequence) would probably fall into the medium-risk, or yellow, zone.

Even though a trip-up (Risk B) is more likely to happen, the sheer severity of a fall into the pit makes Risk A the absolute top priority. The site manager knows they need to install proper, secure fencing immediately. For a deeper dive on building and using this tool effectively, check out our complete guide to the risk management matrix and how to apply it.

This process strips away the emotion and guesswork. It gives you a defensible, logical reason for putting your resources, your time, your money, and your people, towards the problems that pose the biggest threat. It’s the critical link between identifying a risk and actually doing something meaningful about it.

The Four Practical Steps of Risk Management

Knowing what risk is and how to score it is only half the battle. The real value comes from a straightforward, repeatable process to actually manage it. Forget complicated theories; this is about a practical, four-step loop you can apply on any worksite or factory floor to get a handle on uncertainty.

This process gives you a clear framework for action. It moves you from simply worrying about what might go wrong to systematically controlling it. Each step builds on the last, creating a cycle of continuous improvement, not just a one-time, tick-box exercise.

Step 1: Identify the Hazards

You can't manage a risk you haven't seen. The first step is all about proactively spotting potential hazards before they cause a problem. This is a hands-on task. It means getting out from behind the desk and looking at how work actually gets done.

A few practical ways to do this include:

- Regular Site Walkthroughs: Physically walk the job site or factory floor with the sole purpose of spotting potential issues. Look for things like unguarded machinery, unsafe storage, or blocked walkways.

- Team Brainstorming Sessions: Your crew is your best asset here. They’re the ones doing the work day in, day out, and they often have the best insight into what feels unsafe or just doesn't work.

- Reviewing Past Incidents: Dig into old incident reports and near-miss logs. They can reveal recurring problems that were never properly fixed.

Step 2: Assess the Risk

Once you have a list of hazards, you need to figure out which ones demand your attention first. This is where you bring back the risk matrix we talked about earlier. For each hazard, you'll assess its potential likelihood and consequence to calculate a risk score.

This simple process transforms a long, overwhelming list of problems into a clear, prioritised action plan. It helps you focus your limited time and resources on the issues that pose the greatest threat to your people and your project.

Visualising the process like this lets you quickly categorise hazards and decide what to tackle first. It’s a simple but powerful way to bring clarity to chaos.

Step 3: Control the Risk

After assessing the risk, it's time to act. The next step is to implement controls to either eliminate the hazard or reduce its risk to an acceptable level. The most effective way to approach this is by following the Hierarchy of Controls, which prioritises the most robust and reliable solutions first.

- Elimination: The best-case scenario. Completely remove the hazard. For example, instead of having people work at height, prefabricate structures on the ground and lift them into place.

- Substitution: Can't eliminate it? Replace it with something safer. A great example is swapping out a toxic chemical for a less hazardous one for a cleaning task.

- Engineering Controls: Isolate people from the hazard. This could involve installing guardrails on machinery, putting up acoustic barriers, or fitting ventilation systems to remove harmful fumes from the air.

Step 4: Monitor and Review

Risk management is never "set and forget." The final step, and one that never really ends, is to continuously monitor your controls to make sure they're working as intended. You also need to review your risk assessments regularly. Situations change, new equipment is introduced, and procedures evolve. Your understanding of risk has to keep up.

Effective risk management isn't just about reacting to problems; it's about proactive measures. For instance, considering how to approach emergency water damage prevention and restoration is a key part of property risk management long before a leak ever happens.

This ongoing cycle of identifying, assessing, controlling, and monitoring is the backbone of any strong safety management system. Many organisations follow established frameworks to guide this process, and you can learn more about how this works by reading our detailed breakdown of the ISO 31000 risk management standard.

Let's be honest, trying to manage risk with paper forms and spreadsheets is a recipe for disaster. It’s slow, clunky, and creates information silos where serious problems can fester unseen. If you're still shuffling paper, you're stuck in a reactive loop. Switching to a modern digital platform is about more than just convenience; it’s about making a fundamental shift from putting out fires to preventing them in the first place.

Digital tools pull your entire risk management process into one place. Instead of hunting through filing cabinets or chasing down different versions of a spreadsheet, you get a single, live risk register that everyone in the team can see and use. That means no more outdated information floating around, causing confusion and costly mistakes.

Get a Clear Line of Sight Across Your Projects

One of the biggest wins you'll get is real-time visibility. It's a total game-changer. With good software, you can automate parts of the risk assessment workflow, pin control actions on specific team members, and see the moment they’re completed. Guesswork gets replaced with genuine accountability.

What does this actually look like on the ground?

- True oversight through clear dashboards and reports that build themselves.

- Fewer human errors because you're using standardised templates and workflows.

- One source of truth for all risk information, right across the business.

Digital risk management gives you a clear line of sight from the hazard a worker spots on the floor to the control action being tracked by a manager. That kind of transparency is what lets you make faster, smarter decisions when it really counts.

Make Better Decisions with Real Data

For anyone in a management role, this level of clarity is gold. You can easily get a snapshot of risk levels across an entire project, or even multiple sites, without drowning in paperwork. And this isn't just about the physical hazards on site anymore.

The threat from digital risks, for instance, is exploding here in Australia. We saw 1,113 data breaches reported in a single year alone. That’s a staggering number, and it’s why Australian organisations are projected to spend over AUD 7.3 billion on information security and risk management. You can get more insight into the expanding risk management market on hbs.edu. Using the right digital tools gives you the structure needed to tackle both physical and digital threats properly, ensuring nothing slips through the cracks.

A Few Common Questions About Risk

When you start putting risk management theory into practice on-site, a few practical questions always seem to pop up. Here are some clear, no-nonsense answers.

What’s the Difference Between a Risk and an Issue?

This is a classic one, and the distinction is simple but critical. A risk is a potential problem, something that hasn't happened yet but could. An issue, on the other hand, is a problem that’s happening right now.

- Risk: We've got a concrete pour scheduled for next week, but there's a risk that the heavy rain in the forecast could delay it.

- Issue: The concrete truck just broke down and is blocking the site entrance. That's an issue that needs to be sorted immediately.

Good risk management is all about getting ahead of the game, identifying and controlling risks before they blow up into full-blown issues.

How Often Should We Review Our Risk Assessments?

There isn’t a one-size-fits-all answer here, but a good rule of thumb is to review your assessments at regular intervals and whenever something changes.

You should definitely pull them out and have a look:

- At least once a year, just as a general health check.

- Whenever a significant change happens, think new machinery, a different work process, or a new crew coming on board.

- Immediately after an incident or a near-miss. This is a non-negotiable learning opportunity.

For really high-risk jobs, you might need to review them far more often, maybe even before every single shift. Your risk assessment should be a living document, not a piece of paper you file and forget.

The key is that a risk assessment must reflect the reality of the work being done today, not six months ago. An outdated assessment can be almost as dangerous as having none at all.

Can a Risk Ever Be a Good Thing?

Technically, yes, though it’s not how we usually talk about it in workplace safety. In formal project management, a positive risk is often called an ‘opportunity’. The official definition of risk covers any uncertainty that could affect your goals, for better or worse. For example, a new piece of tech might carry the risk of failure, but also the opportunity for massive efficiency gains if it works out.

However, in the day-to-day reality of a construction site or a factory floor, the term ‘risk’ almost always refers to the bad stuff: the potential for harm, damage, or delays.

Stop chasing paperwork and start preventing problems. Safety Space gives you a single platform to identify, assess, and control risks in real-time, helping you build a safer, more efficient workplace. See how it works with a free demo and consultation today.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.