At the heart of workplace safety in Queensland lies the Work Health and Safety Act 2011 (Qld). Think of this as the rulebook that sets the baseline for protecting everyone at work. Its main job is to make sure businesses are actively managing risks to prevent people from getting hurt.

This Act was a big step for Queensland, bringing our state's laws more in line with the rest of Australia. It made life much simpler for companies that work across state borders, creating a more consistent national approach to safety.

Why Queensland WHS Legislation Actually Matters

Let's be clear: getting your head around WHS legislation isn't about memorising paragraphs of legal text. It’s about having a practical roadmap to keep your team safe and your business on the right side of the law. These laws are the foundation for managing real-world risks, whether on a buzzing construction site or a busy factory floor.

For any manager or business owner, getting this right is non-negotiable. It prevents injuries, helps you avoid crippling fines, and protects your hard-earned reputation. This legal framework isn't just a list of 'don'ts'; it's a system for being proactive about safety.

The Key Legal Documents

The legislation isn't just one single document. It's a collection of connected parts that work together, much like a car's operating manual.

Work Health and Safety Act 2011 (WHS Act): This is the engine. It outlines the broad duties and responsibilities, defining exactly who is accountable for safety and spelling out the serious penalties for getting it wrong.

Work Health and Safety Regulation 2011 (WHS Regulation): These are the specific, detailed instructions. The Regulation gives you mandatory rules for handling specific high-risk scenarios, like working with hazardous chemicals, managing noise exposure, or operating certain machinery.

Codes of Practice: Think of these as the practical user guides. While not technically law, they provide step-by-step advice on how to meet the standards set by the Act and Regulation. In a legal dispute, courts often use them as a benchmark to decide if you did everything 'reasonably practicable' to ensure safety.

A Shift to a Modern Approach

Before 2012, Queensland's safety laws were a different beast. The introduction of the WHS Act was part of a national push to harmonise safety legislation across Australia, which simplified things for businesses operating in multiple states.

This change also brought a much stronger focus on proactive risk management and genuine consultation with workers.

The core idea is simple: everyone at a workplace has a role to play in safety. The legislation provides the structure for how those roles and responsibilities fit together to prevent incidents before they happen.

In this guide, we'll break all of this down into practical, actionable steps. We’ll skip the dense legal jargon and focus on what you actually need to do to run a safe and compliant operation in Queensland.

Who is Responsible for What Under QLD WHS Law?

Alright, let’s get down to business. If you’re running a show in Queensland, understanding your duties under the Work Health and Safety (WHS) Act isn’t just good practice, it’s the law. Forget getting bogged down in legal jargon; the first step is figuring out where you fit in.

The legislation moves past simple job titles and introduces broader roles to make sure everyone pulls their weight on safety. The big one? The PCBU.

A PCBU, or a ‘Person Conducting a Business or Undertaking’, isn't just a big corporation. It could be you as a sole trader, a partnership, or any organisation with a business pulse. If you're in charge, you're almost certainly the PCBU, and that means the primary duty of care lands squarely on your shoulders.

So, what does that actually mean? It means you have a fundamental responsibility to ensure the health and safety of your workers and anyone else who could be affected by your work, so far as is reasonably practicable.

What 'Reasonably Practicable' Actually Means

You’ll see the term ‘reasonably practicable’ everywhere in WHS law, and for good reason. It’s the cornerstone of the whole system. Think of it as a balancing act. You need to do everything you can to manage a risk, unless the cost, time, or hassle of doing it is completely over the top compared to the risk itself.

It’s just common sense, really. Installing a guard rail on a mezzanine floor is a no-brainer. The cost is tiny compared to the catastrophic risk of someone falling. On the other hand, demanding every single tool handle be wrapped in bubble wrap? That’s not reasonably practicable. The effort involved is massive for a near-zero safety benefit.

To figure out what’s reasonable for you, you have to weigh up a few things:

- How likely is it that something could go wrong?

- If it does go wrong, how bad could it be?

- What do you know (or what should you know) about the hazard and the fixes available?

- Are there effective and suitable ways to eliminate or minimise the risk?

- What’s the cost of putting those controls in place?

A huge part of this duty involves identifying and controlling hazards. This is non-negotiable. For instance, in many industries, this means getting serious about infection control and conducting comprehensive risk assessments to protect your team and clients.

The Duties of Officers, Workers, and Others

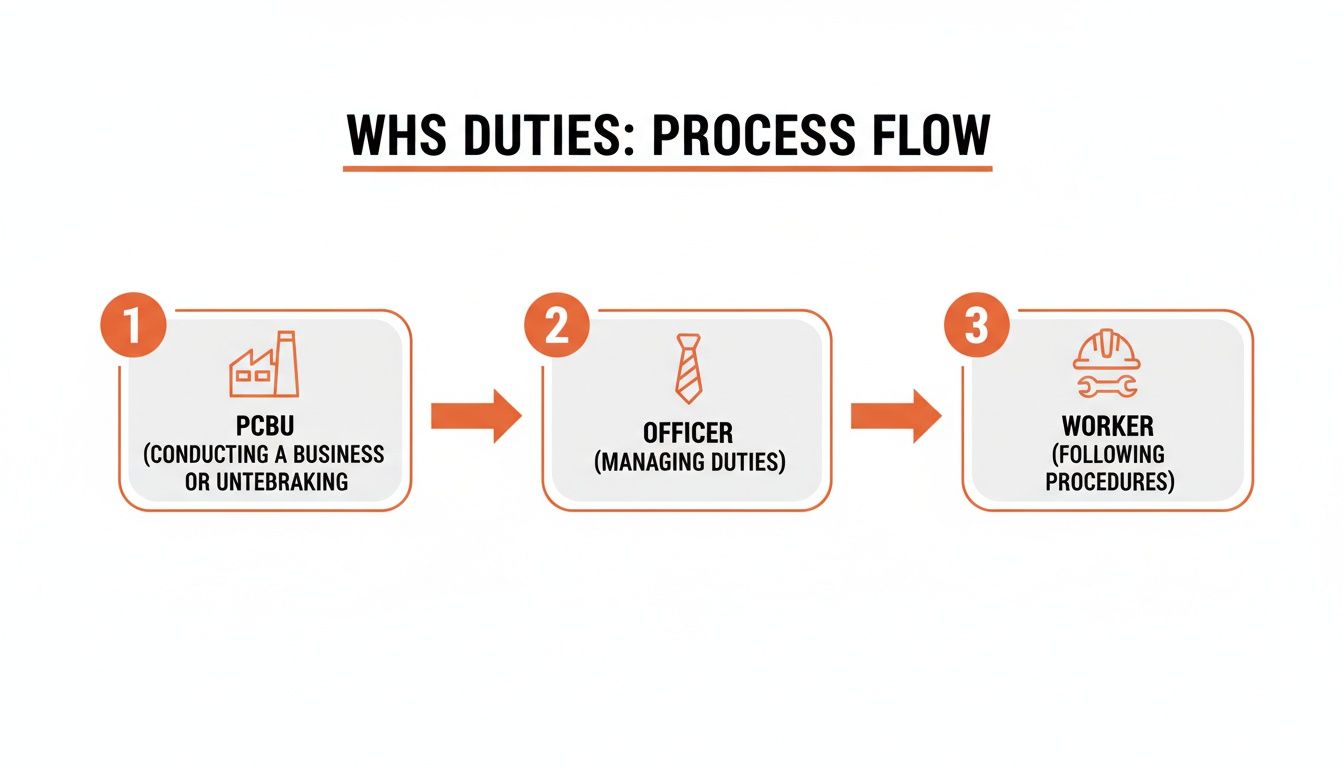

While the PCBU holds the main responsibility, safety is a team sport. The law assigns specific duties to different roles, creating layers of accountability so nothing falls through the cracks.

An Officer is a senior leader who makes decisions affecting a big chunk of the business, think directors and CEOs. Their job is to exercise due diligence, which is a proactive duty to make sure the business is actually meeting its WHS obligations.

This isn't a passive role. Officers have to actively:

- Stay on top of WHS matters.

- Understand the nuts and bolts of the business and its specific hazards.

- Make sure the PCBU has the right resources and processes to manage risks.

- Check that those resources and processes are actually being used.

This graphic shows how the main Act sets the big-picture duties, while the Regulations and Codes of Practice give you the detailed playbook for getting it done right.

Workers have duties, too. They need to take reasonable care of their own safety and make sure their actions don't put others at risk. This means following legitimate safety instructions and cooperating with the company's safety policies and procedures. It’s a two-way street.

Even visitors have a part to play. Anyone on-site must take reasonable care for their own safety and follow any instructions they’re given. This layered approach drives home the point that safety is everyone’s job, not just a task for the boss.

And don't for a second think this is just paperwork. The consequences for getting it wrong are severe. The Work Health and Safety Act 2011 doesn't mess around; a category 1 offence, where reckless conduct puts someone at serious risk, can lead to up to 20 years imprisonment for an individual. For a corporation, fines can rocket past $18 million. You can read more on these penalties over at nortonrosefulbright.com.

How to Handle Notifiable Incidents

When something goes seriously wrong on site, knowing your next steps isn't just good practice, it's the law. Under Queensland's WHS legislation, certain events are classed as 'notifiable incidents' and demand immediate reporting to Workplace Health and Safety Queensland (WHSQ). Get this wrong, and you're facing some serious legal heat.

A notifiable incident isn't just any old accident. We’re talking about specific, serious events that result in a death, a 'serious injury or illness', or a 'dangerous incident' that could have caused major harm. Nailing this distinction is your first step to staying compliant.

The definition is deliberately tight to zero in on the most severe events. This isn't about logging every minor cut and bruise. It's about giving the regulator a heads-up when a situation is critical so it can be properly investigated and, hopefully, prevented from ever happening again.

What Qualifies as a Notifiable Incident?

You have a legal duty to notify WHSQ if an incident fits into one of three buckets:

- The death of a person: This is straightforward and applies to anyone on your site, worker, contractor, or visitor.

- A serious injury or illness: This is more than just a trip to the GP. Think injuries or illnesses needing immediate hospital admission. We're talking amputations, severe head trauma, or exposure to a substance that puts someone in hospital within 48 hours.

- A dangerous incident: This is the high-potential near-miss. It’s an event where someone was lucky to walk away unharmed, like the collapse of a structure, an uncontrolled explosion, or the failure of critical gear like a crane.

The diagram below shows how safety duties flow from the business (PCBU) down through its officers and workers. This is the very framework that underpins your responsibility to manage these risks and have a clear plan for when things go pear-shaped.

This flow makes it clear: the PCBU holds the primary duty to manage risks, and that absolutely includes having a rock-solid plan for notifiable incidents.

The Step-by-Step Notification Process

If you’ve determined an incident is notifiable, you must move fast. The PCBU is legally on the hook to make sure the notification happens without delay.

The process itself is simple, but the clock is ticking:

- Step 1: Immediately Notify WHSQ: Report the incident using the fastest method possible. In almost all cases, this means picking up the phone and calling them on 1300 362 128. Do not wait.

- Step 2: Preserve the Incident Site: This is a big one. It's a serious offence to disturb the site of a notifiable incident until a WHSQ inspector gives the all-clear. You must secure the area and stop anyone from touching or moving anything involved, unless it's to rescue someone or prevent further immediate harm.

- Step 3: Follow Up in Writing: After the initial phone call, you have 48 hours to submit a written notification form.

Preserving an incident scene is non-negotiable. Tampering with evidence, even by accident, can be seen as obstructing an investigation and comes with its own heavy penalties. After ensuring everyone is safe, your first priority is to rope off the area and wait for instructions.

Workplace Health and Safety Queensland actively uses this data to spot risk patterns across the state. They publish detailed reports, like the recent July-December 2023 report, which breaks down fatalities from work activities and gives a sobering look at where the biggest dangers lie. You can dig into these stats and regional safety profiles over at worksafe.qld.gov.au.

Having a clear internal process is vital. Documenting what happened accurately is just as important as reporting it. For a practical guide and template to get this right every time, check out our incident report template for QLD. A well-written report gives clear, objective facts to both the regulator and your own internal review, which is exactly what you need.

Managing High-Risk Construction Work in Queensland

The construction industry simply operates on a different level of risk, and the workplace health and safety legislation in QLD gets that. While the general PCBU duties apply everywhere, some construction jobs are so hazardous they demand extra layers of planning and control.

Getting this wrong doesn't just put people in danger; it guarantees a fast-track to hefty fines and stop-work orders from the regulator.

If you’re a manager or supervisor on a Queensland construction site, understanding these specific rules isn’t optional, it’s a core part of your job. The legislation flags 19 specific activities as ‘high-risk construction work’. The moment any of these show up on your project, the legal requirements immediately escalate.

What Is High-Risk Construction Work?

You don’t get to decide what’s high risk; the WHS Regulation 2011 spells it out for you in black and white. If your team is tackling any of the tasks on that list, you are officially in high-risk territory.

A few of the most common examples include:

- Work where there's a risk of a person falling more than 2 metres.

- Demolishing a load-bearing part of a structure.

- Work in or near a trench or shaft with a depth greater than 1.5 metres.

- Work on or near pressurised gas mains or piping.

- Work in an area with moving powered mobile plant (like excavators or loaders).

- Work on or next to a road, railway, or other traffic corridor in use.

This isn't the full list, but it gives you a clear idea. The second any of these jobs appear on the schedule, your compliance duties change.

To make it clear what this means in practice, here are some common high-risk activities and the primary hazards that trigger the need for a SWMS.

| High-Risk Activity | Primary Hazard Example |

|---|---|

| Work with a risk of falling > 2m | Working on a multi-storey roof without edge protection. |

| Work in a trench > 1.5m deep | Risk of trench collapse or engulfment. |

| Demolition of load-bearing structure | Uncontrolled collapse of the structure. |

| Work near pressurised gas lines | Risk of gas leak, fire, or explosion. |

| Work near powered mobile plant | Being struck by an excavator, truck, or loader. |

| Work adjacent to a live traffic corridor | Workers being struck by public vehicles. |

Each of these scenarios requires a formal, written plan, the SWMS, before any work can begin.

The Role of the Safe Work Method Statement (SWMS)

For high-risk construction work, the single most important document you’ll deal with is the Safe Work Method Statement, or SWMS. It's a mandatory requirement under Queensland’s WHS legislation for every single one of the 19 high-risk activities.

A SWMS is not just another risk assessment. It's a practical, on-the-ground document that breaks down a high-risk job into a sequence of steps. For each step, it identifies the potential hazards and clearly lists the specific control measures you'll use to manage those risks.

A SWMS is your project’s safety playbook. It must be prepared before the work starts, it must be understood by the workers doing the job, and it must be followed on site. It’s a live document, not just paperwork to be filed away.

The PCBU is ultimately responsible for ensuring a SWMS is prepared, implemented, and monitored. If you have multiple contractors on site, you also have to collect, review, and keep an eye on their SWMS for the work they’re doing. Making this process smooth is crucial, and using a compliant SWMS template for QLD can save a huge amount of time and reduce compliance headaches.

Licensing and Training Requirements

On top of the SWMS, Queensland law is very clear that people doing certain high-risk jobs must hold the right qualifications. You can't just put anyone behind the controls of a tower crane or ask them to erect scaffolding above a certain height.

This is managed through a system of high-risk work licences. These are nationally recognised cards that prove a worker has been properly trained and assessed as competent to do that specific work safely.

Examples of work requiring a high-risk work licence include:

- Operating most types of cranes, forklifts, and hoists.

- Scaffolding work where a person could fall more than 4 metres.

- Rigging and dogging operations.

As a manager, it’s your duty to verify that any worker performing these tasks holds a current, valid licence. Just asking isn't enough; you need to see the card and keep a record of it. This applies to your own employees and any subcontractors on your project. Failing to do so is a clear breach of the law, and the responsibility falls squarely on you and your business.

Turning Legal Duties into Practical Action

Right, so you're staring at the WHS Act and wondering how to actually apply it on your site. When you need to get from the broad legal duties to what you physically need to do, Codes of Practice are your best friend.

Think of the WHS Act as the main rulebook, but the Codes of Practice are the detailed instruction manuals for specific high-risk tasks. They translate the legal jargon into practical, actionable steps for your industry.

Now, while a Code of Practice isn't technically law, ignoring it is a massive risk. In a courtroom, an approved Code is admissible as evidence. It essentially sets the benchmark for what’s known about a hazard, the risks involved, and the control measures needed to sort it out.

Put it this way: if you follow an approved Code, you're in a very strong position to prove you’ve done everything 'reasonably practicable' to keep people safe. If you decide to go your own way with a different method, the burden is on you to prove your approach is just as safe, or even safer.

Putting Codes into Action

Let's make this real. A classic high-risk scenario in both construction and manufacturing is working at height. The law says you have to manage the risk of falls, but what does that actually look like on a Tuesday afternoon on site?

This is where you’d grab the ‘Managing the risk of falls at workplaces Code of Practice’. It’s not just a suggestion; it’s a clear, step-by-step game plan.

Instead of a vague instruction like 'prevent falls', the Code lays out a specific hierarchy of controls you must consider in order:

- Work on the ground or a solid construction: The best option. If you’re not up high, you can’t fall. It completely eliminates the risk.

- Use a passive fall prevention device: Think guardrails on scaffolding or installing safety mesh. These controls are 'passive' because they don't require workers to do anything to be effective.

- Use a work positioning system: A good example is a travel restraint system that physically stops a worker from getting close to an unguarded edge.

- Use a fall arrest system: This is your last resort. It’s the harness and lanyard that catches a worker after they've already fallen.

By following this exact order, you’re not just guessing what’s best. You are using a recognised, approved safety standard that will hold up under scrutiny.

A Code of Practice gives you a ready-made, regulator-approved solution for meeting your legal duties. When you adopt its methods, you’re aligning your safety practices with the state's accepted benchmark for what's considered safe.

The Role of Australian Standards

You’ll also bump into Australian Standards (AS/NZS) all the time. Here’s the key difference: Codes of Practice tell you how to manage a risk, while Australian Standards often provide the technical specs for the equipment you use to do it.

Let's stick with our working-at-heights example. The Code of Practice tells you to provide a fall arrest system like a harness. An Australian Standard, such as AS/NZS 1891, then dictates the minimum design, manufacturing, and testing requirements that the harness must meet to be deemed safe for use in Australia.

Making sure your gear complies with the relevant Australian Standards is another critical piece of the puzzle. It proves you’ve selected equipment that has been properly tested and is fit for purpose, which is a massive part of demonstrating you've done everything reasonably practicable.

Your Practical Checklist for QLD WHS Compliance

Knowing the legislation is one thing. Actually turning that knowledge into consistent, daily habits is what keeps your site safe and compliant. This isn't just another list of rules; it's a practical framework for meeting your duties under Queensland’s tough WHS laws.

Think of this as a roadmap built for busy managers in construction and manufacturing. Each point tells you what to do, how to do it, and how the right tools can save you a world of pain.

Foundation Risk Management

Let's get straight to it: the absolute core of all workplace health and safety law in QLD is managing risk. This is where everything starts and ends. It’s the process you’ll come back to time and time again.

Conduct and Document Risk Assessments: You need to be systematically identifying hazards for all work tasks, especially the non-routine ones that often get overlooked. Once you’ve spotted a hazard, assess its risk level and document the controls you’re putting in place. This isn't a "set and forget" job; it's a living, breathing cycle.

- In Safety Space: Our Risk Assessment module lets you create, store, and review assessments in one place. You can assign follow-up actions and set review dates, building a complete, auditable trail that shows you're on top of it.

Manage High-Risk Work Methodically: For any of the 19 high-risk construction activities, a Safe Work Method Statement (SWMS) is non-negotiable. It must be in place before work starts. WHSQ inspectors focus heavily on this, and getting it wrong is a fast track to trouble.

- In Safety Space: Grab one of our compliant SWMS templates. The platform makes it easy to create, distribute, and get digital sign-offs from your crew, ensuring everyone has seen and understood the plan before they even think about picking up a tool.

Worker and Site Management

Real compliance is a team sport. Your systems have to involve every single worker and effectively manage everyone who steps foot on your site.

Consult With Your Workers: The law is black and white on this: you must consult with workers on safety matters that directly affect them. That means actively talking to them about hazards, risks, and any changes to procedures. Documenting these chats is crucial for proving you've met this duty.

- In Safety Space: Log your toolbox talks, pre-start meetings, and safety committee minutes right in the platform. You can record who attended and what was discussed, creating a clear, timestamped record of your consultation efforts.

Verify High-Risk Work Licences: Before anyone operates a crane, drives a forklift, or does any other licensed work, you have to verify they have a current, valid licence. Just taking their word for it isn't going to cut it.

- In Safety Space: Upload and store worker licences and qualifications in their individual profiles. The system even sends you automated reminders when a licence is about to expire, so you never get caught out.

Manage Subcontractor Compliance: Remember, your duty of care extends to your subcontractors. You are responsible for ensuring they're working safely and meeting their own WHS obligations on your site. This requires active supervision, not just collecting a folder of their paperwork at the start of the job.

- In Safety Space: Our contractor management tools give you that crucial oversight. Subbies can upload their SWMS and insurance docs for your review, and you can conduct and record site inspections of their work, all in one system.

Systems and Record Keeping

If an inspector walks on-site tomorrow, you need to be able to show them your systems. Good record-keeping isn’t about bureaucracy; it’s the proof that you’re actively managing safety day in, day out.

A documented safety process is your best defence. If you can't show a record of it, it's almost impossible to prove it ever happened. Your records demonstrate due diligence and a systematic approach to keeping people safe.

Maintain Training Records: Keep an up-to-date register of all worker training, from site inductions to specific task competencies. This shows you're giving your people the knowledge they need to do their jobs safely. For a deeper look at creating solid documentation, check out our guide to building robust WHS policies and procedures.

- In Safety Space: Track all training in a central register. You can link training records directly to worker profiles and set reminders for any necessary refresher courses.

Establish Clear Incident Reporting: You need a dead-simple process for workers to report all incidents and near misses. Your system then needs to trigger the right response, whether that’s a quick internal investigation or a formal notification to WHSQ for the serious stuff.

- In Safety Space: Workers can report an incident instantly from their phones using our mobile app. The platform guides them through capturing the key details and automatically notifies the right managers, so nothing ever falls through the cracks.

Common Questions We Hear About WHS Legislation

Getting your head around workplace health and safety rules in Queensland can throw up a lot of questions. We get it. Here are some straight-shooting answers to the queries we hear most often from managers on the ground in construction and manufacturing.

What Is the Main Difference Between the WHS Act and the WHS Regulation?

The easiest way to think about it is this: the WHS Act 2011 is the big-picture rulebook. It lays down the core principles and the fundamental duties of care for everyone on a worksite. It's the part of the law that establishes who is responsible for safety, like PCBUs, officers, and workers, and outlines the hefty penalties if things go wrong.

The WHS Regulation 2011, on the other hand, is the detailed instruction manual. It gets into the nitty-gritty, providing specific, mandatory instructions for controlling particular hazards. For example, the Act tells you that you must protect workers from harm. The Regulation tells you how you must manage risks from noise exposure, or the exact technical requirements for erecting scaffolding.

Do I Need a Formal Safety Management System?

You won’t find the exact phrase ‘safety management system’ written into the legislation demanding you go out and buy a specific product. But don't let that fool you. The law absolutely requires you to have a clear, repeatable, and organised way of managing risks, consulting with your team, providing training, and reporting incidents.

For any business, particularly in high-risk sectors like construction, a systematic approach is really the only practical way to tick all those boxes consistently. Using a platform like Safety Space creates that reliable framework for you. It gives you documented, dependable processes for critical tasks like risk assessments, inspections, and training records, which is exactly the kind of proof you need to show you’re meeting your obligations.

The law demands a systematic approach to safety. Whether you call it a formal 'system' or not, you must be able to demonstrate you have reliable processes in place to manage your WHS duties.

How Often Should I Review My Safe Work Method Statements?

A Safe Work Method Statement (SWMS) is a living document, not a set-and-forget piece of paper. Under Queensland law, you have to review and update it whenever the high-risk construction work it covers changes, or if an incident shows that your current controls just aren't cutting it.

As a practical rule of thumb, it’s smart to review a SWMS before kicking off any new project or a new phase of work. Most importantly, it's non-negotiable to review it immediately after any incident or near miss related to that task. This ensures the SWMS stays relevant and actually works to control the real-world risks your team is facing on site.

Juggling all these legal requirements can feel like a full-time job, but you don't have to be buried in spreadsheets and binders. Safety Space brings everything into one simple platform to handle your risk assessments, SWMS, incident reports, and training records, making compliance straightforward. See how it works.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.