A workplace health and safety management system is a structured framework of policies, procedures, and processes designed to manage risks and prevent injuries. It's not just a set of documents; think of it as the central operating system for safety in your business. This system is crucial for high-risk industries like manufacturing and construction.

What Is a Workplace Health and Safety Management System

Let's cut through the jargon. A Workplace Health and Safety (WHS) management system, often called a WHSMS, is simply your business's formal plan to find and fix hazards before they cause harm. It’s the complete framework that organises how you handle safety, from the factory floor to the main office.

Instead of reacting to incidents after they happen, a good system gives you a repeatable method for preventing them in the first place. For a construction site or manufacturing plant, this isn't optional—it's the foundation of a safe, compliant, and productive operation.

A Practical Blueprint for Safety

The system provides clear instructions and assigns specific responsibilities, making sure everyone knows exactly what they need to do to keep themselves and their workmates safe. It moves safety from being an abstract idea to a set of daily, practical actions.

A well-designed workplace health and safety management system helps with:

- Identifying Risks: Pinpointing potential hazards like unguarded machinery, unsafe electrical setups, or chemical exposure risks before they become a problem.

- Controlling Hazards: Putting practical fixes in place, such as machine guards, lockout/tagout procedures, or providing the correct personal protective equipment (PPE).

- Ensuring Compliance: Meeting your legal duties under Australian WHS laws and regulations, which helps avoid significant fines and legal issues.

- Maintaining Operations: Keeping projects on schedule by reducing the downtime caused by accidents, injuries, and investigations.

A WHS management system isn't about creating more paperwork. It's about building a clear, logical, and repeatable process to manage real-world risks, protecting your people and your business at the same time.

Why It's More Than Just a Binder on a Shelf

For a system to actually work, it has to be part of your company’s daily rhythm. A dusty binder full of policies that no one ever reads is completely useless.

A functional WHS system is active, visible, and used by everyone, from the newest apprentice to the CEO. It provides the structure you need to protect your team, satisfy your legal obligations, and keep the business running smoothly. Understanding the different terms used can be helpful, and you can learn more about the specifics of OHS and WHS definitions in our detailed guide.

This guide will walk you through building a practical system that your people will actually use.

The Building Blocks of an Effective WHS System

A solid workplace health and safety (WHS) management system is built from several core parts all working together. Think of it like an engine; every component has a critical job, and if one is missing or faulty, the whole thing can grind to a halt. These building blocks give you a practical framework to figure out what could go wrong and establish clear, repeatable steps to stop it from happening.

They’re what turns safety from a vague idea into a defined set of actions for your construction site or manufacturing floor. The aim is to create a logical structure that everyone, from a new hire to a senior manager, can understand and follow. Ultimately, these elements are the foundation for protecting your people, making sure you meet your legal duties, and keeping your business running without costly interruptions.

This diagram shows how the main goals of a WHS system all feed into one another.

As you can see, the central goal branches into three critical outcomes that support each other. Protecting people is always the priority, which in turn helps maintain business continuity and satisfy your compliance obligations. It's all connected.

To give you a clearer picture of how these pieces fit together, let's look at the essential parts of a WHS system.

Core Components of a WHS Management System

| Component | Its Practical Function | Example in a Manufacturing Plant |

|---|---|---|

| WHS Policy | A formal statement from the top, showing commitment and setting safety expectations for everyone. | A one-page document signed by the CEO, displayed in the lunchroom, stating the company's goal of zero harm. |

| Risk Assessment | The process of proactively finding hazards, figuring out how serious they are, and planning how to manage them. | A supervisor walks the factory floor, identifying that an old grinding machine has a loose guard and rates it as a high risk. |

| Control Measures | The actual fixes you put in place to eliminate or reduce risk, following the hierarchy of controls. | Instead of just giving workers gloves (PPE), the company replaces the old grinder with a new, fully enclosed model (Elimination/Engineering). |

| Safe Work Procedures | Step-by-step instructions that tell workers exactly how to do a high-risk job safely. | A clear, laminated guide next to the new grinder showing the pre-start checks, correct operation, and shutdown sequence. |

| Training & Competence | Making sure every worker has the knowledge and skills to do their job without getting hurt. | New machine operators must complete a practical training session and be signed off as competent before using the grinder unsupervised. |

| Incident Reporting | A simple system for staff to report accidents and near misses, so the business can learn from them. | An online form where a worker can quickly report that a near miss occurred when the old grinder guard almost fell off. |

These components form a continuous loop. An incident report might trigger a new risk assessment, which leads to better controls and updated procedures, showing how a living safety system constantly gets better.

Let's break down each of these components in a bit more detail.

The WHS Policy: Your Foundation Statement

The WHS Policy is the starting point for your entire system. It’s a formal statement from senior management that spells out the company's commitment to providing a safe workplace. This isn’t just a poster for the break room; it’s the document that sets the tone and expectations for everyone.

A good policy is simple, direct, and signed by the highest level of management. It needs to clearly state the organisation's safety goals and confirm its dedication to complying with all relevant WHS legislation. This document gives your managers the authority to enforce safety rules and gives workers confidence that safety is taken seriously at the very top.

Practical Risk Assessment Processes

With a clear policy in place, the next job is to actively hunt for hazards. This is done through risk assessment, a systematic process of identifying what could harm people and deciding on reasonable steps to prevent that harm. It’s about being proactive, not waiting for an accident to show you where the problems are.

For example, on a factory floor, a risk assessment would involve:

- Identifying hazards: Looking for things like unguarded machinery, tripping hazards from cables, or exposure to loud noise.

- Assessing the risk: Figuring out how likely it is that someone could be hurt and how severe that injury might be.

- Recording findings: Documenting the identified risks so you can track and manage them properly.

This has to be a practical process. It means walking the site, talking to the people who actually do the work, and watching tasks as they happen.

A risk assessment isn't a one-time event. It should be reviewed regularly, especially when new equipment is introduced, work processes change, or after an incident occurs.

Control Measures: The Real-World Fixes

Once you've found the risks, you need to control them. Control measures are the actions you take to eliminate or reduce the likelihood of someone getting hurt. The smartest way to do this is to follow the "hierarchy of controls," which prioritises the most reliable and effective fixes first.

The hierarchy, from most to least effective, includes:

- Elimination: Completely removing the hazard. For instance, designing a process so workers no longer need to work at height.

- Substitution: Replacing the hazard with a safer alternative, like using a less toxic chemical.

- Engineering Controls: Isolating people from the hazard, such as installing guard rails or ventilation systems.

- Administrative Controls: Changing the way people work, like implementing job rotation or safe work procedures.

- Personal Protective Equipment (PPE): Providing workers with equipment like hard hats or gloves. PPE is always the last line of defence.

Safe Work Procedures: Clear Instructions

Safe Work Procedures (SWPs) or Safe Work Method Statements (SWMS) provide step-by-step instructions on how to perform a task safely. They break a job down into its basic steps, identify the hazards at each stage, and describe the control measures needed to stay safe.

For a welder in a fabrication shop, an SWP would detail the requirements for ventilation, the correct use of PPE, and emergency procedures for fires. These documents are practical tools designed for the person doing the job, so they must be clear, concise, and easy to follow. You can learn more about the 9 key elements of a health and safety management system in our comprehensive guide.

Effective Training and Competence

Having policies and procedures is pointless if your team doesn't know about them. Effective training makes sure every worker understands the hazards of their job and knows how to follow the safety procedures you've put in place.

This covers initial induction for new starters, ongoing refresher training, and specific training for high-risk tasks like operating a forklift or working in a confined space. The goal of training isn't just to tick a box; it's to confirm that workers are genuinely competent to do their jobs safely.

Straightforward Incident Reporting

No system is perfect, and incidents or near misses will still happen. An incident reporting system provides a structured way to report, investigate, and learn from these events. When the reporting process is simple and non-punitive, it encourages workers to speak up about minor issues before they escalate into major accidents.

When an incident is reported, the investigation should focus on finding the root cause, the real "why" behind what happened, rather than just blaming an individual. The findings from these investigations are gold; you use them to improve your risk assessments, procedures, and training, making the entire workplace health and safety management system stronger.

The Legal and Financial Case for a WHS System

It’s easy to get bogged down in policies and procedures, but let's be clear: a workplace health and safety (WHS) management system is one of your most critical business assets. It has a direct, measurable impact on both your legal standing and your financial health.

In Australia, ignoring WHS isn't just a bad idea; it’s a violation of the law. The consequences are severe and can ripple through your entire business, from the site office right up to the boardroom. Thinking about these duties isn't just about avoiding trouble. It's about seeing a structured WHS system for what it is—a smart investment in your people, your productivity, and your bottom line.

Your Legal Duty of Care Under Australian Law

Under Australia’s model Work Health and Safety (WHS) laws, every business has a primary duty of care. This is a non-negotiable legal requirement that means you must do everything reasonably practicable to keep your workers safe. It applies to every single construction site, factory, and workshop in the country.

And this duty doesn't just stop with your direct employees. It covers contractors, subcontractors, labour-hire staff, and even visitors to your site. The law is crystal clear: if someone is doing work for your business, you have a responsibility to protect them.

Failing to meet this duty comes with a heavy price:

- Heavy Fines: Companies can be hit with fines well into the millions of dollars for serious breaches.

- Individual Liability: Directors and company officers aren't shielded. They can be held personally liable and face their own huge fines or even jail time for not doing their due diligence.

- Work Stoppages: Regulators can issue improvement or prohibition notices, forcing you to fix safety issues on the spot or shut down work entirely until a hazard is controlled. Think major project delays.

A WHS management system is your documented proof that you are actively meeting your duty of care. It’s the evidence that shows you have a logical, organised process for managing risk—exactly what a regulator wants to see.

The Direct Financial Benefits of a WHS System

While avoiding legal drama is a huge motivator, the financial argument for a WHS system is just as strong. Good safety management isn't a cost centre; it's a direct contributor to your profitability. A well-oiled system cuts both the obvious and the hidden costs that come with workplace incidents.

Think about the immediate financial hit from an injury. The most obvious cost is workers' compensation claims, which drive up your insurance premiums. A poor safety record means you simply pay more. In Canada, for example, understanding the mandatory scheme is crucial, and a comprehensive guide on WSIB insurance in Ontario shows just how detailed these duties can be. The principle is the same here in Australia.

But the costs don't stop at insurance. You also have to factor in:

- Lost Productivity: When a worker gets hurt, work stops. This can bring an entire production line or construction crew to a standstill, leading to blown deadlines and unhappy clients.

- Equipment Damage: Incidents that injure people often damage expensive machinery or materials at the same time, hitting you with unexpected repair or replacement bills.

- Investigation Costs: A proper incident investigation takes time and people, pulling managers and supervisors away from their real jobs.

The Real Cost of Workplace Incidents

The numbers tell a sobering story. In Australia, 188 worker fatalities were recorded from traumatic injuries, with a fatality rate of 1.3 deaths per 100,000 workers. While this is a 24% decline since 2014, it's a stark reminder that serious risks are still very much present.

For businesses in southern Australia and WA, the higher rates in states like Queensland (53 fatalities) and Western Australia (1.9 per 100,000 workers) highlight the very real, localised dangers your teams face every day. Every single incident, fatal or not, carries a massive cost.

Investing in a robust WHS system isn’t about ticking boxes. It’s about making a smart financial decision to protect your business from predictable, preventable losses. When you systematically manage risk, you’re safeguarding your most valuable assets: your people, your equipment, and your company’s future.

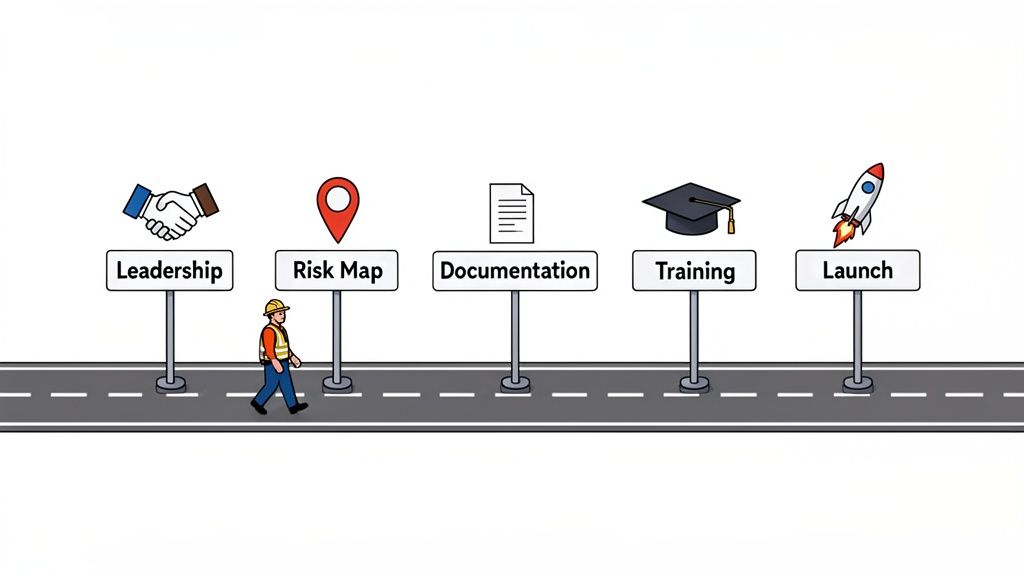

A Step-by-Step Roadmap to Implement Your WHS System

Setting up a workplace health and safety management system can feel like a mountain to climb, but it doesn't have to be. The best approach is a structured, step-by-step plan that builds momentum and gets everyone on board from day one.

Think of it less like writing a giant, dusty rulebook and more like building a practical toolkit that your team will actually want to use. The goal here is to move methodically from the big-picture ideas right down to the daily habits on the ground. By following a clear sequence, you'll build a system that not only ticks the legal boxes but becomes a genuine part of how your business operates.

Here’s a practical, five-step roadmap that cuts through the complexity.

Step 1: Secure Commitment from Leadership

Before you draft a single procedure, your first job is to get genuine buy-in from the top. Let’s be blunt: a WHS system driven solely by the safety manager is doomed to fail. It needs visible, active support from directors and senior leaders to have any real authority.

This means more than just a signature on a policy document. Leadership needs to put their money where their mouth is by allocating the necessary resources: time, people, and a realistic budget. When your crew sees the boss actively leading a safety talk or participating in an inspection, it sends a powerful message. It says safety is a core business priority, not just another box-ticking exercise.

To get this commitment, you need to build a solid business case. Show them how a functional workplace health and safety management system is a direct shield against legal penalties, costly downtime, and rising insurance premiums. Frame it as what it is: a critical investment in the company’s stability and future.

Step 2: Map Your Specific Risks

With leadership on board, it's time to get your hands dirty and understand the real-world hazards your workers face. This is a risk mapping exercise, and it’s much more than a simple checklist. You need to get out on the floor, walk the site, and see the work as it actually happens.

The absolute best way to do this? Involve your workers. They’re the true experts in their own tasks and often know exactly where the hidden dangers lie.

- Consult with your team: Run toolbox talks or workshops and just ask them: "What part of your job worries you the most?" or "What's the most likely thing to cause an injury around here?" The answers might surprise you.

- Walk the floor: Watch how tasks are actually performed. Look for the shortcuts people take, because those often point directly to an impractical procedure or an uncontrolled hazard.

- Review past incidents: Your incident reports and near-miss logs are a goldmine. They reveal recurring problems and the weak spots in your current setup.

This whole process is about prioritisation. You can’t fix everything at once, so focus first on the hazards that have the potential to cause serious injury or death.

Step 3: Develop Clear and Usable Documentation

Now that you know your risks, you can start building the paperwork. The key word here is practical. Your goal is to create documents that people will actually read and use, not complex manuals that gather dust on a shelf.

Your core documentation should include:

- A simple WHS Policy: This should be a one-page statement of commitment from leadership. Nothing more.

- Risk Register: A central list of all identified hazards, their risk levels, and the controls you have in place.

- Safe Work Procedures (SWPs): Clear, step-by-step instructions for your highest-risk tasks. Use photos and plain English. Ditch the technical jargon.

A 50-page procedure that no one reads is useless. A one-page visual guide taped to the machine it relates to? That’s effective. Focus on clarity and accessibility, not complexity.

Step 4: Roll Out Practical Training

A system is only as good as the people using it, and that comes down to training. Your training has to be practical and directly relevant to each person's role. A generic PowerPoint presentation just won't cut it.

Good training is hands-on. Instead of just talking about lockout/tagout, get your team to physically walk through the process on the actual machinery they use every day. Make sure everyone, including contractors and temp staff, understands their specific safety responsibilities.

And remember to document it all. A simple training register that tracks who was trained, on what, and when is essential for proving competence and meeting your legal duties.

Step 5: Launch and Monitor the System

The final step is to go live. Formally launch the system and make sure everyone in the company knows the "go-live" date, understands the new procedures, and knows where to find everything. This launch isn't the finish line; it’s the starting pistol for a process of continuous improvement.

Once the system is live, you need to keep a close eye on how it’s working. This means regular checks to make sure procedures are being followed and, more importantly, that they are actually effective at controlling risks. Regular site inspections and internal audits are your best friends here, helping you spot gaps and find areas to improve.

This constant monitoring is the feedback loop that turns a static set of documents into a living, breathing system, one that adapts, improves, and ultimately builds a genuinely safer workplace for everyone.

How Technology Makes WHS Management Simpler

Moving from a manual, paper-based safety system to a modern digital platform is like swapping an old street directory for a live GPS. The old way can get you there eventually, but it’s slow, often out of date, and takes a whole lot of manual effort. Technology completely changes how you manage safety, replacing messy spreadsheets and overflowing filing cabinets with a single, reliable source of truth.

This shift isn't just about convenience; it’s about making your entire safety framework more effective. It’s about freeing up your team’s time for what really matters. Instead of being stuck behind a desk drowning in administrative tasks, your safety managers can be out on the floor, actively identifying and controlling risks where the work is actually happening.

The focus moves from managing paperwork to truly managing safety.

Gain Real-Time Visibility of Site Risks

With a paper-based system, information is always delayed. A safety inspection form filled out on a construction site might not make it back to the office for days. By then, a serious hazard could have already caused an incident.

Technology gives you a live look across all your sites at once. A manager in head office can see instantly that a critical machine guard inspection is overdue at a manufacturing plant across the country. A project manager on a large construction site can get an immediate alert on their phone that a worker has just identified a new, high-risk hazard on the other side of the project.

This instant visibility allows you to spot problems before they escalate. It changes safety management from a reactive exercise, where you analyse what went wrong, to a proactive one, where you prevent things from going wrong in the first place.

Reduce the Administrative Burden

Let’s be honest, creating Safe Work Method Statements (SWMS), incident reports, and risk assessments involves a huge amount of admin. It's repetitive, time-consuming, and prone to human error. Modern platforms use smart tools to lighten this load.

AI-assisted features can help pre-fill standard templates for common tasks, cutting the time it takes to create a compliant SWMS from an hour down to just minutes. When an incident is reported through a mobile app, the system can automatically notify the right people, assign corrective actions, and log all the necessary details for compliance without anyone lifting a pen.

This automation means:

- Less Paperwork: Digital forms replace stacks of paper, making storage and retrieval simple.

- More Consistency: Standardised templates make sure all your documentation is complete and consistent across the board.

- Faster Turnaround: Corrective actions are assigned and tracked immediately, closing the loop on hazards much, much faster.

Get a Clear View of Subcontractor Compliance

Managing subcontractor compliance is a major headache, especially in construction. Keeping track of their insurance certificates, licences, and safety documentation can feel like a full-time job in itself. A single missed expiry date can expose your business to significant legal and financial risk.

A digital platform acts as a central hub for all your subcontractor management. You can set up a portal where subcontractors upload their required documents, and the system automatically tracks expiry dates and sends reminders when renewals are due. This gives you a clear, at-a-glance dashboard of who is compliant and who isn’t.

You end up with a clear and defensible record of your due diligence. You can instantly confirm that every contractor walking onto your site has met your safety requirements, which is a critical part of your workplace health and safety management system. For businesses looking to make this switch, exploring dedicated health and safety management software can provide a practical roadmap.

Measuring Performance and Improving Your System

A workplace health and safety management system is never really “finished.” Think of it less like a project you complete and more like a living part of your business that has to grow and adapt as your work changes. To make sure it’s actually working, you need practical ways to check its performance and find opportunities to make it better. This isn't about drowning in complex reports; it's about getting a clear, honest look at how well you're really managing risk.

The old way of thinking was just to count injuries. But that’s like trying to drive by only looking in the rearview mirror, it only tells you about the crashes you’ve already had. An effective system focuses on proactive metrics that show you whether your safety processes are working before someone gets hurt. These are your Key Performance Indicators, or KPIs.

Setting Meaningful Safety KPIs

Good KPIs give you data you can actually use. They help you spot weaknesses in your WHS system and give you solid evidence of what’s working well, which is vital for proving its value to leadership.

You want to track metrics that measure your safety activities, not just the outcomes. Some practical examples we see make a real difference include:

- Inspection Completion Rate: What percentage of scheduled site inspections were actually completed on time? A high number, say 95% or more, suggests your supervisors are actively on the lookout for hazards.

- Near-Miss Reporting: How many near misses were reported this month? A sudden increase here is often a good sign. It shows that workers feel safe enough to report issues and trust the system to fix problems without blame.

- Corrective Action Closure Time: When a hazard is identified, how long does it take to fix it? A short timeframe, like under 7 days on average, shows you’re jumping on problems quickly.

Using Audits and Reviews for Improvement

The data from your KPIs is the fuel for a much larger improvement cycle, one driven by regular audits and reviews. Conducting a regular workplace health and safety audit is a crucial part of this. Think of it as a deep check-up on your entire system to make sure you’re following your own procedures and meeting your legal duties.

Management reviews are just as important. These aren't just tick-box meetings; they are scheduled sessions where leadership sits down to look at the performance data, audit findings, and any incident reports. The goal is simple: make decisions that will make the workplace safer.

This proactive approach has to include emerging risks, especially psychosocial hazards. Mental health claims now account for 12% of all 146,700 serious workers’ compensation claims, a massive 161% increase over the past decade. In industries like manufacturing and construction, operational pressures and tight deadlines crank up the stress, making mental health a key safety issue right alongside physical hazards. You can read the full report on these statistics from Safe Work Australia to understand the growing impact.

A good workplace health and safety management system learns from experience. It uses data from near misses, inspections, and audits not to assign blame, but to make the system smarter and stronger. This constant feedback loop is what drives real, lasting improvement.

Got Questions About WHS Systems? We've Got Answers.

When it comes to setting up a workplace health and safety system, managers and business owners often have the same practical questions. Let’s cut through the noise and give you the clear answers you need to move forward.

How Long Does It Realistically Take to Set Up?

This really depends on the size and complexity of your business. If you’re a small or medium-sized company starting from square one, you could be looking at three to six months to get a solid foundation in place.

For larger, multi-site organisations in high-risk industries like construction or manufacturing, it’s often a bigger job, more like a 12-month project. But using a digital platform can seriously speed things up. Because the framework is already built, you can often get set up and running in a matter of weeks, not months.

What's the Biggest Mistake People Make?

The most common trap is creating a system that looks great on paper but never leaves the shelf. We call it "shelf-ware", beautifully written, complex documents that no one on the factory floor or construction site ever reads, let alone follows.

An effective system isn’t just stored in a binder; it's woven into your daily operations. It needs everyone to be involved, leaders to visibly champion it, and simple, practical procedures that your workers can actually use on the job.

Do I Really Need to Hire a Full-Time Safety Manager?

Not necessarily, especially if you run a smaller business. The legal requirement is to have a competent person managing health and safety, not a dedicated manager.

For many SMEs, this role can be handled by an owner or an operations manager. This is especially true if you’re using a platform that automates many of the admin tasks that come with a WHS system. For bigger or higher-risk operations, however, having a dedicated safety professional is usually essential to properly manage the system day-to-day.

Managing your workplace health and safety management system shouldn't feel like a burden. Safety Space replaces the mountain of paperwork with a simple, all-in-one platform that makes compliance easier. That way, you can focus on what really matters: protecting your people and your business.

Book a free demo to see how it works.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.