Grabbing a workplace safety policy template off the internet is a good first step. But it's just that: a first step. I’ve seen it time and time again: a business downloads a generic document, puts their logo on it, and thinks they’re covered. This is a big mistake that leaves your team exposed and your business on the wrong side of the law.

Why a Generic Safety Policy Just Won't Cut It

Your safety policy isn't just paperwork to keep regulators happy. It’s a hands-on guide that should direct your day-to-day operations and actively protect your people. It’s your public commitment to safety, spelling out exactly who is responsible for what.

A generic, off-the-shelf document almost always falls short of Australian Work Health and Safety (WHS) laws because it can't possibly account for the real-world, specific risks your crew faces every single day.

Think about it. A policy for a construction company needs to cover working from heights, silica dust, and operating heavy machinery. For a manufacturing plant, the focus shifts to machine guarding, lockout/tagout procedures, and handling chemicals. A one-size-fits-all approach completely misses these critical details, making it pretty much useless in a real situation.

An effective safety policy is a living document. It has to reflect the actual hazards in your workplace, from the factory floor to the construction site, and give your team clear instructions on how to get the job done safely.

The Real Cost of a Box-Ticking Policy

Failing to build a specific, functional policy can have serious consequences. The stats from Safe Work Australia paint a grim picture. Over the last decade, more than 1,850 Australian workers have died from work-related injuries, and over 1.14 million serious workers' compensation claims were lodged. These aren't just numbers; they're a stark reminder of why solid, customised safety planning is so important. You can look into these workplace safety statistics to get the full national picture.

Turning Paperwork into a Practical Tool

Your real mission is to turn that template from a piece of paper into a practical, everyday tool. A generic policy might have a line like, "Workers must use appropriate Personal Protective Equipment (PPE)." That’s so vague it’s not helpful.

Let’s see what that looks like when it’s done right. A customised policy for a metal fabrication workshop would get straight to the point:

- For welding tasks: You need a P2 respirator, leather gloves, and a welding helmet with a specific shade rating. No exceptions.

- When grinding: Safety glasses, hearing protection, and a face shield are mandatory.

- Just to be in the workshop: Steel-capped boots are required at all times.

See the difference? That level of detail is what makes a policy actually work. It’s how you move beyond being a compliance checkbox and start building a genuinely safe work environment. Your workplace safety policy template is the blueprint, but you’re the builder. It’s your job to make it strong enough to protect your team.

How to Customise Your Safety Policy Template

Let's be clear: a downloadable workplace safety policy template is your starting point, not the finish line. Just finding and replacing your company name isn't going to cut it. That won't create a document that actually keeps people safe.

The real work is in tailoring each section to reflect the specific risks and realities of your industry. Whether you're in manufacturing, logistics, or construction, the details matter.

Your first move should be to hunt down and replace all the generic placeholders with information specific to your business. This goes way beyond just the company name and address. You need to clearly define who is in charge of safety on a day-to-day basis. Is it the site supervisor? The warehouse manager? The business owner? Put their roles in writing and spell out their exact safety duties.

Here’s a look at the first page of our template. Notice the clear placeholders for your company details and the opening policy statement.

This first section sets the tone for the entire policy. It's your chance to make the commitment to safety feel genuine and specific to your operations, right from the first sentence.

Make the Policy Relevant to Your Site

The most critical part of this whole process is the hazard identification section. This is where a generic policy completely falls flat. Your policy has to detail the actual risks your team faces every single day.

A construction site policy, for example, has to tackle high-risk activities head-on. It’s not enough to just say "manage hazards." You need to get specific.

- Working at Heights: Your policy must outline mandatory fall prevention systems. Think guardrails or fall arrest harnesses for any work above 1.8 metres.

- Silica Dust Exposure: It should demand on-tool dust extraction and specify the exact type of respiratory protection (like P2 masks) needed during cutting or grinding.

- Trenching and Excavation: The policy needs to state that trench shields or battering is required for any dig deeper than 1.5 metres.

A warehouse policy, on the other hand, would zero in on a completely different set of risks.

- Forklift Operation: Detail the requirement for a current high-risk work licence, daily pre-start checks, and clearly marked pedestrian exclusion zones.

- Manual Handling: Specify safe lifting limits and make the use of mechanical aids like pallet jacks mandatory for any load over 20 kg.

The whole point is to create a document that a worker can pick up and immediately see how it applies to their specific job. Vague statements don't prevent accidents; clear, direct instructions do.

Define Roles and Reporting Procedures

Once you've nailed down the risks, you have to clearly outline who is responsible for what. Every effective workplace safety policy template needs a detailed "Roles and Responsibilities" section. Be direct.

For instance:

- Site Supervisors are responsible for conducting daily pre-start safety briefings.

- All Workers are responsible for reporting any hazard or near-miss immediately, using the company’s reporting app or designated form.

- Management is responsible for investigating all reported incidents within 24 hours.

This level of detail gets rid of any confusion. It makes sure everyone knows their exact role in keeping the site safe, turning the policy from a piece of paper in a folder into a functional, everyday tool. By taking the time to customise these key areas, you turn a generic template into a powerful safety asset for your business.

Building Your Policy with Essential Components

Alright, once you've tailored the basics of the template, it's time to get into the real substance of your safety policy. These next parts are non-negotiable; they’re the backbone of the entire document and give your team practical, clear guidance. This is where we move past high-level statements and into the specific instructions that make sense on a busy factory floor or a noisy construction site.

A solid policy needs a clear statement of intent, defined roles, practical procedures for hazards, and straightforward emergency plans. Each part has to be written with your specific operations, your people, and your site in mind.

Defining Roles and Responsibilities

One of the quickest ways for a safety policy to fail is by being vague about who is responsible for what. I’ve seen it a hundred times: phrases like "management is responsible for safety." That's completely useless. Your policy has to assign specific safety duties to specific roles. No ambiguity.

Think about a normal day in your business. Who does what? Write it down. Be direct and leave no room for anyone to say, "I didn't know that was my job."

Here’s how you can break it down:

- Site Supervisor: Responsible for conducting and documenting daily pre-start safety checks and toolbox talks.

- All Workers: Must report any identified hazard or near-miss immediately using the designated mobile form before continuing work.

- Maintenance Team: Accountable for completing scheduled machinery servicing and lock-out/tag-out procedures as per the maintenance log.

This kind of clarity makes sure everyone knows exactly what part they play in keeping the workplace safe. For a deeper look into how these responsibilities fit into a bigger picture, it's worth understanding the 9 key elements of a health and safety management system.

The Policy Statement: A Clear Commitment

This is the first thing people will read, so it needs to have an impact. Your policy statement is your public declaration of commitment to workplace health and safety. A weak one is full of corporate fluff; a strong one sets a decisive, no-nonsense tone for the rest of the document.

Let's look at the difference. A weak statement is generic and non-committal, while a strong one is active, specific, and ties safety directly to how you do business.

You've probably seen a few policies that miss the mark. A proper policy statement leaves no doubt about your commitment. Below is a breakdown of what to include in the core sections to make sure your policy is solid and effective.

Essential Components of Your WHS Policy

| Policy Section | What to Include (Be Specific) | Example for a Manufacturing Business |

|---|---|---|

| Policy Statement | A clear, active commitment to safety. Mention specific legislation (e.g., WHS Act 2020) and state that safety is a condition of employment. | "[Company Name] will actively identify and control all workplace hazards to prevent injury. We will meet and exceed the WHS Act 2020. Safe work is a condition of employment." |

| Roles & Responsibilities | Assign specific, daily safety tasks to job titles. Avoid generalisations. Think: "Who does what?" | Supervisor: Daily pre-start checks. Forklift Operator: Pre-use forklift inspection checklist. All Staff: Report hazards immediately via the QR code system. |

| Hazard Management | Outline your step-by-step process: how to identify (e.g., site walks), assess (e.g., risk matrix), and control (e.g., hierarchy of controls) hazards. | Identify hazards via daily walk-arounds. Assess risk using our 3x3 matrix. Controls must follow the hierarchy (e.g., install machine guarding before issuing PPE). |

| Emergency Procedures | Detail evacuation routes, assembly points, location of first aid kits/fire extinguishers, and list trained first aid officers/fire wardens by name and contact info. | Evacuation map posted at workshop entrance. Assembly point is the north car park. First Aid Officer: Jane Doe (contact number). Fire Warden: John Smith (contact number). |

Getting these sections right turns your policy from a piece of paper into a practical tool that people actually use.

Your policy statement shouldn’t just be words on a page. It should be a direct reflection of your operational standards, showing that safety is integral to how you do business, not just an administrative task.

Hazard and Emergency Procedures

Now we get to the most practical part of your policy. This section needs to outline the actual, step-by-step processes your team will follow to manage risks and handle things when they go wrong.

Your hazard management section should detail:

- How to Identify Hazards: Explain your methods: daily site walks, pre-start checks, formal risk assessments for new tasks.

- How to Assess Risk: Describe how you determine severity. For example, using a risk matrix to prioritise what gets fixed first.

- How to Control Hazards: List the specific control measures for your biggest risks, always following the hierarchy of controls (e.g., machine guarding comes before relying on PPE).

Your emergency procedures need to be just as specific. Clearly state the evacuation routes from the workshop floor, pinpoint the location of fire extinguishers and first aid kits, and list the names and contact details of trained first aid officers and fire wardens. Make it so simple anyone could follow it under pressure.

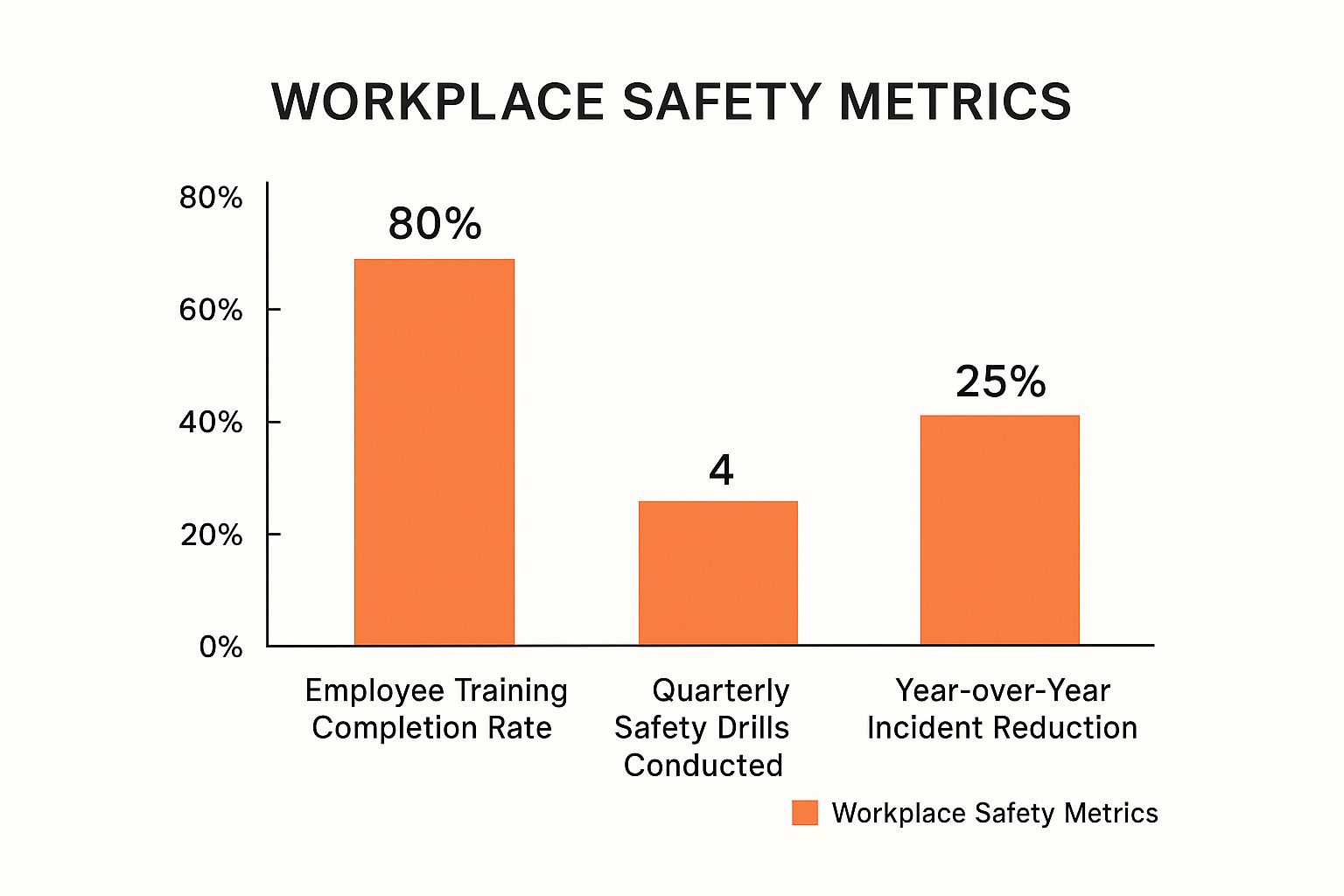

The data above shows key indicators that a well-constructed policy can directly influence, like improving training completion and driving down incident rates. At the end of the day, a clear, practical policy leads to measurable safety outcomes.

Addressing Modern Workplace Safety Risks

Let's be honest, a safety policy that only covers slips, trips, and falls is hopelessly out of date. Today’s safety landscape is much broader and includes risks that aren't always visible, like work-related stress, bullying, and harassment.

These psychosocial hazards can be just as damaging as any physical injury. Your policy needs to tackle them head-on.

Ignoring these issues isn't just bad practice; it's a real business risk. Here in Australia, the legal goalposts have shifted. Regulators now expect businesses to actively manage these complex risks. A policy stuck in the past, focusing only on traditional physical safety, is incomplete and leaves you exposed.

The trick is to build clear, preventative statements and procedures directly into your policy. This isn't about vague promises or feel-good statements. It’s about creating practical ground rules that guide how people interact and how work is organised.

Writing Practical Psychosocial Hazard Clauses

Weaving psychosocial safety into your policy requires specific, actionable language. You need to give managers and workers clear directions on what to do and what not to do. This is a critical step in making your policy relevant to the real challenges people face at work today.

Here are a few real-world examples of what you can include:

- Workload Management: Add a simple statement that managers must make sure workloads are reasonable and achievable within standard work hours. This one clause gives workers a solid foundation to raise concerns about being overloaded.

- Clear Reporting Channels: Your policy has to spell out a confidential process for reporting stress, bullying, or harassment without any fear of comeback. Name the specific person or role they should report to.

- Zero-Tolerance Statement: Don't beat around the bush. Include a direct statement that bullying, harassment, and discrimination will not be tolerated. Then, define these terms in simple language so there’s no confusion.

Taking this approach turns your policy from a document about physical hazards into a practical guide for building a respectful and mentally healthy workplace. It's much easier to prioritise these risks when you can properly identify and assess them first; check out our guide on using a risk management matrix for some practical steps.

Meeting Evolving Australian Legal Standards

It's not just a trend; it's the law. Regulatory bodies across Australia are putting a much stronger emphasis on managing psychosocial risks. Recent legislative changes and new codes of practice mean businesses are now expected to have explicit, preventative measures in place.

For instance, the Australian Government's Work Health and Safety (Sexual Gender-based Harassment) Code of Practice gives businesses clear guidance on identifying and reducing these specific risks. It signals a clear shift: comprehensive psychosocial hazard management is no longer optional for your workplace safety policy template.

By proactively addressing psychosocial hazards in your policy, you aren't just ticking a box. You are establishing a clear standard for how people are treated and supported, which is fundamental to creating a safe workplace.

Common Mistakes to Avoid in Your Safety Policy

A policy document is only useful if it actually works in the real world. I’ve reviewed hundreds of policies over the years, and the same simple mistakes pop up again and again. These slip-ups can turn a potentially powerful tool into a document that just gathers dust on a shelf.

Avoiding these common pitfalls should be the final quality check before you roll out your safety policy.

One of the biggest errors I see is a policy written in complicated, corporate jargon. If a worker on the factory floor can't understand it, it’s useless. Legal terms and overly formal language just create a barrier, making the policy seem disconnected from day-to-day work.

The fix is simple: write in plain English. Use short sentences, bullet points, and clear headings. Once you have a draft, grab one of your workers and ask them to read it. If they can explain it back to you in their own words, you’ve got it right.

The "Set and Forget" Problem

Another major mistake is treating the policy as a one-and-done task. A safety policy isn't something you create once and then file away forever. Your workplace is constantly changing: new equipment comes in, procedures get updated, and teams evolve. A policy that isn’t reviewed regularly becomes irrelevant and, frankly, dangerous.

Even with the best intentions, many Australian workplaces struggle to apply their safety policies effectively. A key reason is inadequate risk assessments. Too many organisations only conduct them annually or without the right expertise, completely missing new hazards that creep in with technological or procedural updates. You can read more about common workplace safety mistakes in Australia.

To avoid this trap, schedule a formal review of your policy at least once a year. On top of that, you must update it whenever:

- A significant incident or near-miss occurs.

- New machinery or a new work process is introduced.

- Workplace Health and Safety legislation changes.

A safety policy is a living document that must evolve with your business. An outdated policy doesn't just fail to protect your workers; it fails to protect your business from non-compliance.

Forgetting to Involve Your Team

Finally, a critical oversight is creating the policy in a bubble. Managers and business owners don't always see the day-to-day realities of a job. When you write a policy without consulting the people who actually do the work, you’re guaranteed to miss crucial insights and practical hazards.

Involving your workers in the process does two things. First, it makes the policy far more accurate and realistic. They know the shortcuts people take and the real-world challenges of a task. Second, it gives them a sense of ownership, making them much more likely to follow the procedures they helped create.

This collaborative approach is especially vital for getting incident reporting right. To really understand why this matters, it helps to know what a near-miss is and why your team reporting them is so important for preventing future accidents.

Got Questions About Your Workplace Safety Policy?

Getting your safety policy down on paper is a massive win. But as anyone who's been through the process knows, that's often when the real-world questions start popping up. We get it. Here are some straight answers to the most common queries we hear from Aussie businesses.

How Often Should I Be Reviewing My Safety Policy?

Think of your safety policy as a living document, not something you write once and shove in a drawer. In Australia, the rule of thumb is to give it a thorough review at least once a year.

But that's just the baseline. You must dust it off for an immediate review whenever something changes. This could be after a serious incident on site, when you bring in new equipment or processes, or if the WHS laws get an update. Even a valid concern raised by one of your workers is a trigger. Keeping it current is the only way to make sure it actually protects your team from the risks they face today.

An outdated policy isn’t just a compliance headache; it’s a failure to protect your people. It’s only effective if it mirrors what’s actually happening on the ground in your business right now.

What’s the Difference Between a Safety Policy and a SWMS?

It's a common point of confusion, but they play two very different roles.

Your safety policy is the big picture, the ‘why’ and ‘who’ of your company's entire approach to safety. It’s a high-level document that states your commitment and outlines everyone's general responsibilities, from the CEO down to the newest apprentice.

A Safe Work Method Statement (SWMS), on the other hand, is all about the ‘how’ for a specific, high-risk job. It's a detailed, step-by-step guide for a single task, like operating a crane or working in a trench. It pinpoints the hazards for that one job and details the controls needed to do it safely.

Basically, you need one safety policy for the whole business, but you only need a SWMS for specific high-risk construction activities.

Do I Legally Need a Written Safety Policy in Australia?

This is where things can feel a bit grey. The WHS Act doesn't have a line that says, "Every business must have a document called a workplace safety policy." However, it does legally require every Person Conducting a Business or Undertaking (PCBU) to ensure the health and safety of their workers.

So, how do you prove you're doing that?

A written policy is the clearest, most direct way to show you're meeting that fundamental duty of care. It's documented proof of your safety systems, your commitment, and your processes. If a regulator from SafeWork NSW or WorkSafe Victoria ever comes knocking, especially after an incident, that piece of paper becomes critical.

Ready to build a safety system that's simple, smart, and fully compliant? Safety Space replaces outdated paperwork with a single, easy-to-use platform that gives you real-time oversight and control. Book your free demo and consultation and see how we can help protect your people and your profits.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.