Keeping your forklifts running properly isn't just about avoiding breakdowns; it’s a key part of your Work Health and Safety (WHS) duties in Australia. A consistent inspection process helps you spot small issues like worn tyres or hydraulic leaks before they cause a major incident or lead to expensive repairs and downtime. The challenge is often finding a practical, reliable method to conduct and record these checks daily. Are paper logbooks still the best option, or should your team be using a digital app or a simple PDF template?

This article provides a detailed forklift inspection checklist broken down into clear, actionable steps. We will cover exactly what your operators need to look for before starting the engine, during operation, and at the end of their shift. To make this process easier to implement, we also round up seven of the best Australian tools, templates, and platforms for managing your forklift checks. We’ll show you options ranging from comprehensive digital solutions to straightforward, regulator-approved guides.

Each review will give you the essential details, highlighting what makes each tool useful for different worksites, from busy warehouses to complex construction projects. We include screenshots and direct links to each resource, so you can quickly find and implement the right system for your business. Our goal is to help you select a practical tool that fits your operational needs, simplifies compliance, and improves the reliability of your equipment.

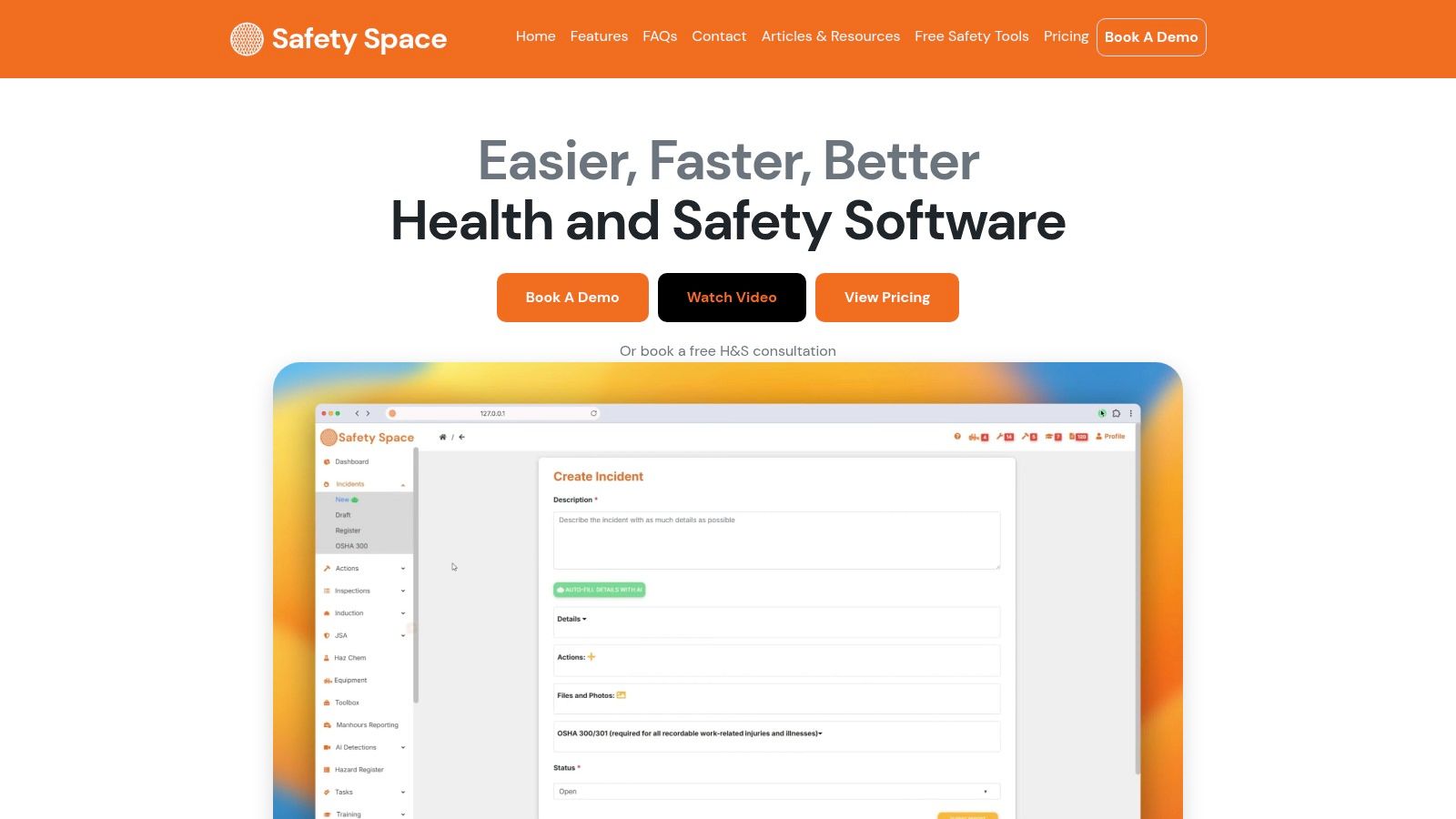

1. Safety Space

Safety Space is an all-in-one Health & Safety management platform designed to move high-risk industries beyond paper checklists and spreadsheets. It offers a powerful, customisable digital environment where creating, distributing, and tracking a forklift inspection checklist is just one part of a larger, integrated safety system. This platform is built for sectors like manufacturing, construction, and mining, where solid compliance and real-time oversight are critical.

What makes Safety Space a solid choice is its focus on deep customisation and automation. Instead of forcing your operations to fit a rigid template, the platform adapts to your existing workflows. This means your digital forklift inspection forms can precisely mirror the specific checks your team already performs, capturing the exact data you need for compliance and operational insight.

Key Features for Forklift Inspection Management

Safety Space provides a suite of tools that directly supports and improves the forklift inspection process. Its features are designed to reduce administrative time, increase accountability, and give managers a clear, immediate view of their fleet's status.

- Fully Customisable Digital Forms: Build your forklift inspection checklist from scratch or adapt existing templates to match your specific models and operational needs. Add fields for photos, signatures, and conditional logic (e.g., if a fault is noted, a "corrective action" field automatically appears).

- AI-Assisted Documentation: A key differentiator is the platform's AI integration. It can instantly generate Job Safety Analyses (JSAs) and Safe Operating Procedures (SOPs) related to forklift operations. This dramatically cuts down the time spent on writing essential safety documents.

- Real-Time Dashboards and Reporting: As soon as an operator completes an inspection on a tablet or phone, the data feeds directly into a live dashboard. Managers can see the status of every forklift across one or multiple sites without chasing paperwork. This allows for immediate action on failed checks.

- Automated Compliance and Auditing: The system is pre-configured to align with major regulatory standards, including SafeWork Australia, WorkSafe NZ, OSHA, and HSE. It automatically logs every inspection, creating a verifiable, audit-ready digital trail that helps you prove compliance and avoid fines.

Practical Application and Use Cases

For a construction site manager overseeing multiple subcontractors, Safety Space provides a single view of all plant and equipment. You can mandate that every subcontractor uses the platform to complete their daily forklift pre-start check, giving you instant visibility and ensuring compliance without being physically present.

In a manufacturing facility, if a forklift fails its daily hydraulic systems check, the system can be configured to automatically notify the maintenance manager via email or SMS. This triggers an immediate work order, documents the fault, and prevents the faulty equipment from being used, directly preventing a potential incident.

Expert Tip: During your onboarding with Safety Space, bring your existing paper forklift checklists. Their team will help you digitise them and can suggest improvements based on regulatory best practices, ensuring your new digital forms are fully compliant from day one.

Pros and Cons

| Pros | Cons |

|---|---|

| Excellent Compliance Automation: Aligns with SafeWork Australia and other key standards, reducing the risk of fines and simplifying audits. | No Public Pricing: Requires completing a verification form to get a quote, which can delay quick budget comparisons. |

| Powerful AI Tools: Instantly generates JSAs and SOPs, saving significant administrative time and effort. | Requires User Adoption: The platform's value is tied to team buy-in. Companies with deep-rooted paper processes may need a change management plan. |

| Complete Visibility: Real-time dashboards provide a single view of all equipment across multiple sites and subcontractors. | |

| Strong Support and Flexible Plans: Offers monthly (cancel anytime) and annual plans with free onboarding and a complimentary H&S consultation. |

To get started, you need to book a free demo or consultation through their website. This allows them to tailor the demonstration to your specific industry and operational challenges and provide an indicative price for your business.

Website: https://safetyspace.co

2. SafetyCulture (iAuditor)

SafetyCulture (iAuditor) is an Australia-founded digital inspection tool offering ready-to-use forklift pre-start and daily check templates. Users can access free templates via mobile or web, capture photos, video clips, digital signatures and maintain time-stamped records with a full audit trail.

Key Features

- Customisable Templates

Free forklift pre-use, pre-shift and operator assessment checklists ready to deploy. - Mobile App and Web Workflows

Capture evidence with photos and video, collect signatures and assign corrective tasks. - Audit Trail and Reports

Automatic time stamps, search function and PDF exports for compliance reviews. - Offline PDF Library

Download printable templates if a device is not available on site.

Why It Stands Out

SafetyCulture offers a broad library of forklift-specific templates suited to multi-site operations needing consistent records. The interface focuses on swift inspections rather than complex menus, so new users find their way around in under an hour. Support is available via email and live chat, which helps with uptime even on remote construction sites.

Pricing and Access

- Free Plan

Access basic forklift checklist templates, mobile app and web dashboard at no cost. - Paid Plans

Scheduling, analytics and multi-user management start from AUD 20 per user per month.

No shipping is required. Sign up with an email to gain immediate access. A video library guides first-time users through setup and first inspections.

Learn more about SafetyCulture (iAuditor) on safetyspace.co

Practical Tips

- Duplicate a template and add your company logo for a professional look.

- Set daily reminders so operators complete pre-start checks before each shift.

- Use photo fields to document tyre wear or fluid leaks instantly.

- Assign corrective tasks to supervisors for prompt follow-up.

Pros and Cons

| Pros | Cons |

|---|---|

| Immediate access without printing | Basic onboarding needed for first users |

| Wide library of ready-made forklift templates | Scheduling and analytics on paid plans |

| Photo, video and signature capture in one flow | Requires a mobile device or web access |

This mix of free tools, digital evidence capture and scalable paid features makes SafetyCulture (iAuditor) a good choice for health and safety managers seeking a practical forklift inspection checklist.

3. Kalamazoo (AU)

Kalamazoo is an Australian supplier providing physical, pre-printed pre-start checklist books specifically for forklifts. Designed for businesses that prefer or require paper records, these A5 books offer a year's worth of duplicate checklists, making them a straightforward tool for maintaining a physical audit trail for each machine.

Key Features

- Duplicate Checklist System

Each book contains 52 duplicate sets (one for each week), allowing operators to keep one copy and submit the other to a supervisor. - Durable and Practical Design

The A5 books are coil-bound with a laminated cover to withstand daily use in industrial environments. Sequential numbering and a fault report log are included. - Australian Made and Customisable

Designed and printed in Australia, Kalamazoo offers custom printing to add company logos or specific checklist items. - All-in-One Record Book

Includes sections for machine details, operator records, and a repair log, keeping all essential information in one place.

Why It Stands Out

Kalamazoo stands out for its simplicity and reliability in non-digital workflows. It offers a tangible, easy-to-use forklift inspection checklist system that requires no training, apps, or internet connectivity. The duplicate copy system provides a clear, physical chain of custody for records, which is useful for direct supervisor sign-offs and for businesses operating in areas with poor network coverage.

Pricing and Access

- Standard Book

The forklift pre-start checklist book is priced at AUD 45.10 (including GST) per book. - Bulk Discounts

Reduced pricing is available for orders of 10 or more books.

Products are shipped directly from their Australian facility. You can order online via their website with standard payment methods.

Learn more about Kalamazoo (AU) on kalamazoo.com.au

Practical Tips

- Assign one book per forklift and label it clearly with the machine’s registration or ID number.

- Establish a daily routine for supervisors to collect and review the duplicate copies from the previous day's shift.

- Use a central filing system to store completed checklist copies chronologically for easy access during safety audits.

- When a fault is logged, ensure the duplicate slip is immediately handed to the maintenance team for action.

Pros and Cons

| Pros | Cons |

|---|---|

| No devices or internet required for use | Manual filing and storage required for all records |

| Duplicate paper copies support supervisor sign-off | Slower to analyse trends compared to digital data |

| Simple, clear pricing and easy to order | No digital evidence like photos or automatic timestamps |

For teams needing a solid, physical record-keeping solution, Kalamazoo's pre-start checklist book is a dependable choice that gets the job done without digital complexity.

4. Adaptalift Store (AAL Store) (AU)

Adaptalift Store offers a practical, paper-based solution for worksites preferring traditional record-keeping. Their A5 pre-start checklist book is designed for LPG and Diesel forklifts, containing duplicate pages for daily checks. This product is a solid choice for companies that already source parts or service from Adaptalift and want a simple, affordable way to manage their forklift inspection checklist process.

Key Features

- Duplicate Page System

Each book includes 48 duplicate sets, creating an instant carbon copy of every daily inspection for office records. - Compact A5 Format

The small booklet size is easy for operators to carry and store inside the forklift cabin without getting in the way. - National Stock Visibility

The online store shows stock availability across Australia, with options for branch pickup or standard freight. - LPG/Diesel Specific

The checklist is tailored specifically for internal combustion forklifts, covering relevant engine and fuel system checks.

Why It Stands Out

Adaptalift Store provides a no-fuss, physical checklist from a trusted Australian forklift supplier. For businesses managing mixed LPG and Diesel fleets, this single book standardises the inspection process. The direct integration with Adaptalift’s national dealer network means you can check local stock online and organise a pickup if you need replacement books urgently, which is a major benefit for site-based operations.

Pricing and Access

- Per-Book Cost

Checklists are sold as individual A5 books at a competitive price point, listed directly on the website. - Shipping and Pickup

Standard freight options are available at checkout, along with a free click-and-collect service from their national branches.

No signup is needed to browse or purchase. The website is a straightforward e-commerce store, allowing for quick and simple transactions.

Learn more about the Forklift Pre-Start Checklist at aalstore.com.au

Practical Tips

- Order multiple books to take advantage of freight costs and ensure you have stock on hand.

- Designate a central filing location for the duplicate carbon copies to maintain a clear audit trail.

- Use the online stock checker to find the nearest branch for a quick pickup if you run out unexpectedly.

- Train operators to press firmly with a ballpoint pen to ensure the duplicate copy is clear and legible.

Pros and Cons

| Pros | Cons |

|---|---|

| Low-cost and simple to implement immediately | Paper format lacks digital search or backups |

| No devices, internet, or batteries required | Does not support photo or video evidence |

| Integrated with a national forklift dealer | Checklist is specific to LPG/Diesel models |

For managers who need a reliable, non-digital forklift inspection checklist, the Adaptalift Store booklet is a cost-effective and dependable option backed by a well-known industry supplier.

5. Easy Guides Australia

Easy Guides Australia is a specialised safety-training publisher offering a physical, A5-sized forklift pre-start checklist book. This solution is designed for organisations that prefer a paper-based system, especially when integrated with hands-on training and durable accessories for heavy-use industrial environments.

Key Features

- Pre-Start Checklist Book

A5-sized book with 7 days of checks per page, providing a full 12-month supply with duplicate carbonless copy pages for record-keeping. - Durable Accessories

Optional protective plastic pockets to shield the book from wear and tear on the workshop floor, plus lock-out danger tags for clear equipment isolation. - Training Integration

As a training-focused supplier, they offer related learning materials and support for safety audits, creating a comprehensive compliance system. - Simple Layout

The checklist is organised with a straightforward design, making it easy for operators to complete checks without confusion.

Why It Stands Out

Easy Guides Australia provides a practical, non-digital solution that directly supports physical lock-out/tag-out procedures. By offering accessories like protective pockets and danger tags, it creates a complete on-the-ground system for forklift inspection and safety. This integrated approach is ideal for businesses that bundle their operational paperwork with formal training and want a robust, tangible record that withstands tough site conditions.

Pricing and Access

- Checklist Book

The forklift pre-start checklist book is available for purchase directly from their online shop. - Accessories

Protective pockets and danger tags are sold separately, allowing businesses to customise their order based on operational needs.

Products are shipped physically from their Australian base. Online ordering is straightforward, with clear pricing for individual items and bundles.

Learn more about Easy Guides Australia on easyguides.com.au

Practical Tips

- Order the protective plastic pockets to extend the life of the checklist book in dusty or wet environments.

- Purchase the lock-out danger tags along with the book to create a unified system for identifying and isolating faulty equipment.

- Store completed duplicate pages in a dedicated binder organised by date for easy access during safety audits.

- Use the supplier's other training resources to ensure operators understand not just how to fill out the checklist, but why each item is important.

Pros and Cons

| Pros | Cons |

|---|---|

| Bundles with training and accessories for a complete system | Still a paper solution requiring manual filing |

| Clear, simple layout designed for easy operator use | Higher price point than some other paper options |

| Durable options suitable for harsh industrial sites | No digital features like analytics or automated alerts |

For companies that value a tactile, paper-based forklift inspection checklist that integrates directly with on-site safety procedures, Easy Guides Australia offers a reliable and well-supported solution.

6. All Trades Safety & Workwear (All Trades Group) (AU)

All Trades Safety & Workwear is an Australian retailer offering a physical checklist book specifically for electric forklifts. This pre-start book is designed for durability, featuring a hard cover and 50 duplicate sets, making it a practical solution for battery-electric fleets often found in warehouses or manufacturing facilities.

Key Features

- Electric-Specific Checklist

The checklist format focuses on items critical to electric models, such as batteries, chargers, and related components. - Duplicate Carbonless Sets

Each book contains 50 sequentially numbered sets, providing an instant copy for office records without needing a printer or scanner. - Durable Construction

A hard cover with fold-in flaps protects the pages from damage in tough on-site environments like warehouses and construction sites. - Phone Support

As an Australian retailer, All Trades Group provides local phone support for enquiries and orders.

Why It Stands Out

This product stands out for its specific focus on electric forklifts, which have different pre-start requirements compared to internal combustion models. The durable, physical format is ideal for operations that prefer paper-based records or operate in areas where digital devices are impractical. Its simple, tangible approach provides a straightforward method for maintaining a consistent forklift inspection checklist.

Pricing and Access

- Per-Book Pricing

The DB54 Electric Forklift Pre-Start Checklist Book is sold individually. Pricing is available upon enquiry. - Availability

The product page indicates 'Order In – Enquire', suggesting it is not always stocked and may have a lead time.

Shipping is required for this physical product. Customers can enquire via the website or phone to confirm availability and place an order.

Learn more about personal protective equipment from safetyspace.co

Practical Tips

- Use the fold-in hard cover flap to protect the current checklist page from grease and dirt.

- Establish a clear process for operators to submit the duplicate copies to a supervisor at the end of each shift.

- Store completed books in a secure, organised filing system for easy access during safety audits.

- Designate a central location near the forklift charging station for the book to ensure it is always accessible.

Pros and Cons

| Pros | Cons |

|---|---|

| Checklist is tailored to battery and charger items for electric fleets | Paper book requires manual filing and retrieval for audits |

| Durable construction suits rough environments and frequent handling | 'Order In' status may mean a variable lead time for availability |

| No need for devices, batteries, or internet connectivity to complete | Does not provide digital evidence like photos or time stamps |

For teams needing a simple, non-digital forklift inspection checklist for their electric fleet, the All Trades Safety & Workwear book offers a purpose-built and resilient solution.

7. WorkSafe Victoria

WorkSafe Victoria is the state's official work health and safety regulator, offering a free and authoritative forklift safety checklist. This resource is designed to help employers manage forklift hazards effectively and align their internal safety procedures with Australian WHS standards. The downloadable PDF serves as a foundational document for developing a comprehensive forklift inspection checklist program.

Key Features

- Regulator-Aligned Template

A free, downloadable PDF checklist that directly reflects the safety expectations of a key Australian regulator. - Broader Safety Guidance

The checklist is part of a wider collection of resources on forklift maintenance, operator training and traffic management. - Audit-Ready Format

Provides a clear, itemised list suitable for internal audits and demonstrating compliance to inspectors. - No Registration Required

The PDF is instantly accessible without needing to create an account or provide personal details.

Why It Stands Out

WorkSafe Victoria’s resource stands out because it comes directly from an official regulatory body, giving it inherent authority. Unlike commercial apps, its purpose is purely compliance and safety, making it a trusted starting point for any business building its safety management system. It is particularly useful for safety managers who need to create or benchmark their own forklift inspection checklist against official standards.

Pricing and Access

- Free Download

The forklift safety checklist PDF and all related guidance materials are available at no cost. - No Paid Tiers

As a government resource, there are no subscriptions or premium features.

No shipping is needed. The checklist can be downloaded directly from the WorkSafe Victoria website as a printable PDF file. It complements broader guidance available for developing thorough workplace inspections.

Learn more about WorkSafe Victoria on safetyspace.co

Practical Tips

- Use the PDF as a master template to create customised checklists for different forklift models in your fleet.

- Incorporate the checklist items into your company’s safety induction for new forklift operators.

- Print and laminate copies for placement in forklift cabins or designated pre-start check areas.

- Reference the checklist during toolbox talks to reinforce key safety inspection points with your team.

Pros and Cons

| Pros | Cons |

|---|---|

| Regulator‑endorsed resource, useful for audits | Not a pre‑printed duplicate book; you must print it |

| No cost and easy to distribute to staff | Lacks digital features like photos or scheduling |

| Good for creating internal WHS policies | Requires manual filing and record-keeping |

For businesses seeking a foundational, compliance-focused tool, WorkSafe Victoria provides an essential and credible forklift inspection checklist without any cost or complexity.

Top 7 Forklift Inspection Checklist Comparison

| Item | Implementation (🔄) | Resource requirements (⚡) | Expected outcomes (📊) | Ideal use cases (💡) | Key advantages (⭐) |

|---|---|---|---|---|---|

| Safety Space | Medium–High: custom setup with dedicated onboarding 🔄 | Cloud subscription, devices, integrations, staff training ⚡ | Automated compliance, multi‑site visibility, reduced admin 📊 | Manufacturing, construction, mining, large multi‑site ops 💡 | ⭐ AI form generation, deep customisation, real‑time dashboards |

| SafetyCulture (iAuditor) | Low–Medium: quick app onboarding; templates ready 🔄 | Mobile/web devices; optional paid plan for advanced features ⚡ | Time‑stamped inspections, photo evidence, corrective workflows 📊 | Operators needing fast digital inspections and audits 💡 | ⭐ Large template library; mobile evidence capture |

| Kalamazoo (AU) | Very low: buy and deploy paper books 🔄 | Physical purchase, manual filing and storage (low tech) ⚡ | Tangible audit trail and supervisor sign‑off; limited analytics 📊 | Sites preferring paper or with limited device access 💡 | ⭐ Clear pricing; duplicate copies for accountability |

| Adaptalift Store (AAL Store) | Very low: purchase and distribute paper books 🔄 | Dealer purchase/pickup or freight; manual filing ⚡ | Affordable physical records; no built‑in digital data 📊 | Dealer customers needing quick replacements; LPG/Diesel fleets 💡 | ⭐ Competitive price; dealer network and stock support |

| Easy Guides Australia | Low: purchase; optional training bundle adds setup 🔄 | Paper books plus optional accessories and training resources ⚡ | Durable records plus strengthened training and lock‑out processes 📊 | Organisations combining checklists with training programs 💡 | ⭐ Bundled training/resources; operator‑friendly layout |

| All Trades Safety & Workwear | Low: purchase; possible lead time for orders 🔄 | Electric‑specific paper book, carbonless sets, manual filing ⚡ | Electric‑focused checks, durable construction for rough use 📊 | Battery‑electric fleets, warehouses, manufacturing 💡 | ⭐ Electric‑specific format; robust build and traceability |

| WorkSafe Victoria | Very low: download and adapt PDF (no setup) 🔄 | Free PDF download; requires printing or digital integration ⚡ | Regulator‑aligned checklist for audits and procedure alignment 📊 | Policy development, audit prep, WHS compliance alignment 💡 | ⭐ Free, authoritative regulator guidance for compliance |

Choosing the Right Inspection System for Your Site

A thorough forklift inspection checklist is not just about compliance; it's a fundamental part of your operational risk management. As we've detailed, the process involves more than simply ticking boxes. It requires a systematic approach covering pre-operation, operational, and post-operation checks to identify and address hazards before they lead to incidents. Moving from a basic checklist to a reliable inspection system is the key to making these checks a consistent and valuable part of your daily routine.

The central decision you face is choosing the right tool for your specific workplace. The options we've covered range from straightforward paper-based logbooks to sophisticated digital platforms. There is no single "best" solution, only the one that fits your operation’s scale, budget, and existing processes.

Paper vs. Digital: Making the Practical Choice

For smaller businesses with only a few forklifts, a paper-based system like those from Kalamazoo or Easy Guides Australia can be a perfectly good choice. They are cost-effective, require no special technology or training, and provide a physical record for compliance purposes. The major drawback is the administrative effort needed to file, retrieve, and analyse these records. Spotting recurring mechanical faults across a fleet becomes a manual, time-consuming task.

Digital tools, such as SafetyCulture (iAuditor), offer a powerful alternative, especially for larger or multi-site operations. They provide real-time data, photo and video evidence, and instant reporting. This allows supervisors to be notified of critical failures immediately, and managers can analyse inspection data to identify trends, such as a specific forklift model experiencing frequent hydraulic leaks. When considering a digital system, exploring smart QR code examples can demonstrate how these tools are effectively used across various industries, including for operational tracking and data linking. However, the move to digital requires an initial investment in devices, software subscriptions, and operator training.

Creating a Connected Safety System

The most effective approach integrates your forklift inspection checklist into your broader Work Health and Safety (WHS) framework. A standalone inspection app is useful, but a comprehensive platform like Safety Space connects these daily checks to the bigger picture.

Imagine an operator finds a fault during a pre-start check. With an integrated system, this failed inspection can automatically:

- Trigger a maintenance request in your asset management system.

- Generate a hazard report for the safety team to investigate.

- Link back to the operator's training records to ensure they are competent to identify such issues.

This level of integration turns a simple compliance activity into a proactive safety tool. It creates a clear, auditable trail of action that not only helps prevent incidents but also provides robust evidence of due diligence. By choosing a system that aligns with your operational needs, you build a dependable inspection routine that protects your people, your equipment, and your business from unnecessary risk.

Ready to move beyond paper checklists and disconnected apps? Safety Space provides an integrated platform that connects your forklift inspections to your entire WHS management system. Manage plant safety, worker training, and incident reporting all in one place. Find out how you can build a stronger, more connected safety process at Safety Space.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.