A workplace hazard is anything with the potential to cause harm. Think of it as any condition, object, or substance in your work environment that could lead to an injury or illness.

Getting a handle on what is a hazard is the first step. It's the foundation for building a workplace that’s safe for everyone.

What is a Workplace Hazard, Really?

A good way to think about a hazard is as a sleeping risk. An oily patch on the factory floor is the hazard. It only turns into a real risk the moment someone walks near it. The goal is to spot these hazards before they cause an incident.

This means you have to start looking at your work environment with a critical eye. It’s not just about obvious things like exposed wiring or unguarded machinery. Hazards can be less obvious, like repetitive tasks that lead to strain injuries over months, or poor lighting in a stairwell that eventually causes a fall.

To make this process easier, it helps to group hazards into categories. Knowing these categories gives you a mental checklist, allowing you to scan your workplace and spot potential problems that might otherwise be missed.

The Main Categories of Hazards

Most hazards you’ll find fall into a few distinct groups. Understanding these categories helps you organize your safety inspections and make sure all bases are covered. A chemical spill requires a different response to an electrical fault, but both are serious hazards that need attention.

To help you get started, here are the main categories of workplace hazards, with practical examples you’d find on a construction site or in a manufacturing plant.

Common Workplace Hazard Categories

| Hazard Category | Description | Example (Construction/Manufacturing) |

|---|---|---|

| Safety Hazards | Unsafe conditions that can cause immediate injury. These are often the easiest to spot. | Slips on wet floors, trips over cables, falls from height, getting caught in machinery. |

| Physical Hazards | Environmental factors that can cause harm without direct contact. | Excessive noise from machinery, extreme heat or cold, radiation from welding, vibrations from power tools. |

| Ergonomic Hazards | Physical stressors on the body related to workplace design and tasks. | Poorly designed workstations, repetitive movements on an assembly line, improper manual handling techniques. |

| Chemical Hazards | Exposure to any chemical substance, whether it's a liquid, gas, or solid. | Inhaling fumes from solvents or paints, skin contact with cleaning products, exposure to flammable materials. |

| Biological Hazards | Organic substances that pose a threat to health. | Bacteria or mould from contaminated water sources, viruses, insect bites on an outdoor site. |

Having these categories helps you be more methodical. Instead of just wandering around looking for "danger," you can actively hunt for specific types of hazards.

Identifying these specific types of hazards is the foundation of any effective safety management process. It allows you to move from reacting to incidents to proactively preventing them.

Australia's Most Common Workplace Dangers

It’s one thing to know the different categories of hazards, but another to know which ones are actually causing the most harm. By looking at national data, we can pinpoint the specific hazards in the workplace that lead to the most serious outcomes across Australia.

This isn’t about guesswork; it's about focusing attention where it’s needed most.

The statistics from 2024 show Australia recorded 188 work-related traumatic injury fatalities. While that number is a slight drop from the five-year average, it's a stark reminder of the real risks people face at work.

These incidents aren't random. The data shows they follow predictable patterns, often concentrated in specific industries and situations. You can see more on these trends in the 2024 Australian work health and safety statistics.

The Biggest Culprits: Vehicle Incidents and Falls

When you break down the numbers, two clear dangers stand out. Vehicle incidents are the leading cause of workplace deaths, responsible for 42% of all fatal injuries.

This is a massive category, covering everything from truck collisions on highways to incidents with forklifts, excavators, and other mobile machinery on a worksite. The constant interaction between people and moving vehicles creates a high-stakes environment that demands tight management.

Coming in second are falls from a height, accounting for 13% of fatalities. This highlights a persistent and critical risk, especially in industries like construction where working high up is part of the job. Together, these two categories are responsible for well over half of all workplace deaths, making them a top priority for any safety plan.

The data is clear: managing interactions with moving vehicles and preventing falls from height are two of the most critical actions any business can take to reduce the risk of a fatality in their workplace.

High-Risk Industries and Occupations

It’s no surprise that some lines of work are more dangerous than others. The statistics back this up, showing that 80% of all fatalities happened in just six sectors. These are the industries on the front line:

- Agriculture, forestry, and fishing

- Transport, postal, and warehousing

- Construction

- Manufacturing

- Public administration and safety

- Health care and social assistance

This concentration proves that the nature of the work itself is a huge factor. Jobs that involve heavy machinery, a lot of travel, or intense physical labour carry a higher burden of risk. If you want to see which specific roles have the highest incident rates, check out our guide on the most dangerous jobs in Australia.

Drilling down further, machinery operators and drivers face the highest fatality rate at 6.7 deaths per 100,000 workers, more than five times the national average. This really hammers home the dangers that come with operating heavy equipment and vehicles for a living.

The Human Element

The data also reveals a massive gender imbalance, with men accounting for 96% of all workplace fatalities. This is because they are disproportionately represented in the high-risk industries and roles just mentioned.

It shows that the risk is fundamentally tied to the task at hand. Physically demanding jobs or those involving heavy machinery are still predominantly filled by men, which directly exposes them to serious hazards far more often.

Geography plays a role, too. While Queensland recorded the highest raw number of deaths at 53, the Northern Territory had the highest fatality rate, at 2.8 per 100,000 workers. This suggests that working in more remote areas can bring its own set of risks, likely due to factors like longer travel times and slower emergency response.

These aren't just abstract figures; they show the real-world, human cost of unmanaged hazards in the workplace.

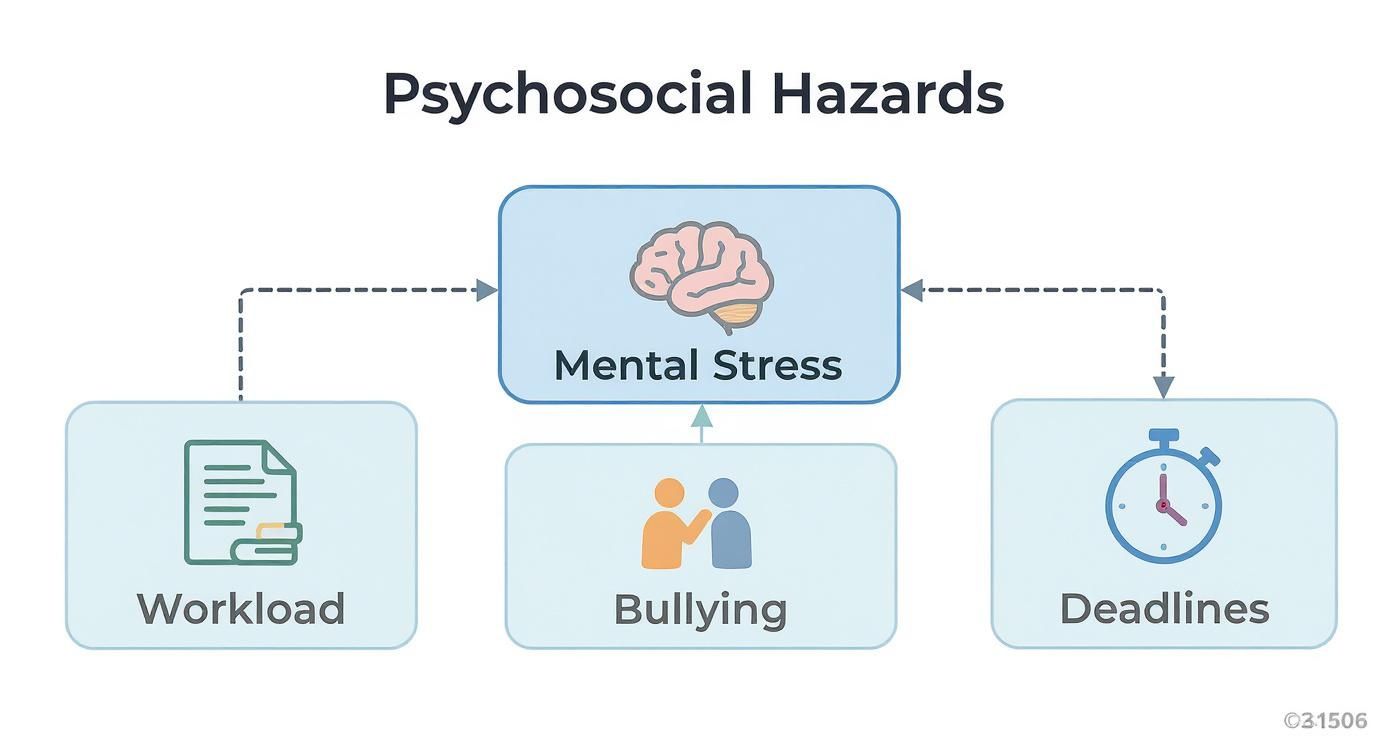

Understanding Psychosocial Hazards

Not all hazards in the workplace are things you can trip over or touch. Some of the most damaging risks are invisible, affecting the mental and emotional wellbeing of your team.

We're talking about psychosocial hazards. These come from poor work design, badly organized jobs, and negative workplace relationships.

Think of things like crushing workloads, impossible deadlines, workplace bullying, or a lack of clarity around what someone is supposed to be doing. You can't see them like a chemical spill, but their impact is just as real. These factors create mental stress, which, over time, can lead to serious physical and psychological health problems.

Ignoring these hazards isn't an option. The data is clear: mental health challenges are a major driver of serious workers' compensation claims.

The Growing Impact on Worker Health

The link between work-related stress and poor health is undeniable. Constant pressure from psychosocial hazards can lead to burnout, anxiety, and depression. It also shows up physically as headaches, high blood pressure, and sleep problems, all of which affect a worker's ability to do their job safely.

For example, imagine a factory worker under immense pressure to hit unrealistic production targets. They might start rushing, skipping safety checks, or become so fatigued they can't operate machinery properly. A psychosocial hazard has created a very real physical safety risk. Recognizing this connection is critical if you want to build a safe workplace.

Protecting workers' mental health is just as important as preventing physical injuries. A complete approach to workplace safety must address both visible and invisible hazards.

The sharp rise in mental health claims proves this point. Mental stress now accounts for 11.5% of serious workers' compensation claims in Australia. Historically, safety stats were all about physical injuries, but we now know that mental health issues are a major cause of lost work time. As the Australian Institute of Health & Safety notes, workplace fatalities are falling while mental health claims are rising, a trend that demands attention.

Common Examples of Psychosocial Hazards

So what do these hazards actually look like day-to-day? They often hide in plain sight, embedded in everyday work processes and team interactions.

Here are some of the most common culprits:

- High Workload: The constant pressure to do too much in too little time, leading to chronic stress and exhaustion.

- Lack of Control: When workers have little or no say over how their work gets done, it creates feelings of helplessness.

- Poor Support: A lack of backup from managers or colleagues, leaving people feeling isolated and exposed.

- Workplace Bullying: Repeated, unreasonable behaviour directed towards a worker or a group of workers.

- Job Insecurity: The constant worry about whether your job is stable, creating a significant source of background stress.

These factors are draining and are a fast track to burnout. One of the most common outcomes of unchecked psychosocial hazards is extreme tiredness. We cover this in more detail in our article on creating a fatigue risk management system.

For more ideas on how to soften the impact of these factors, especially for a diverse team, check out these 10 Effective Workplace Stress Management Strategies for Neurodivergent Employees. Dealing with these hazards means actively looking for them and putting controls in place, just as you would for any physical risk.

A Practical Process for Risk Assessment

Once you know how to spot the different hazards in your workplace, what comes next? It's not enough to just see a problem; you need a structured, repeatable process for figuring out how serious it is and what you’re going to do about it. This is where risk assessment comes in.

A solid risk assessment process doesn't need to be complicated. It boils down to three simple, practical steps.

- Find the hazard: This is the identification stage, actively looking for anything with the potential to cause harm.

- Assess the risk: Once you've found a hazard, you need to work out how likely it is to cause harm and how severe that harm could be.

- Control the risk: Finally, you have to implement measures to either get rid of the hazard completely or reduce the risk to an acceptable level.

This simple three-step loop of find, assess, and control is the engine of any effective safety management system. It turns safety from a guessing game into a logical, reliable process.

Introducing the Hierarchy of Controls

When it comes to the third step, controlling the risk, there's a tried-and-tested framework called the Hierarchy of Controls. Think of it as a ladder of solutions. The most effective, permanent fixes are at the top, and the least effective are at the bottom. The goal is always to start at the top and only move down when the higher-level options aren't feasible.

This model forces you to think beyond the quick fix. It’s easy to put up a warning sign, but that relies on people noticing it and doing the right thing. Getting rid of the hazard altogether is a far more reliable solution.

The hierarchy gives you a clear roadmap for making your workplace safer, pushing you to prioritize actions that have the biggest and most lasting impact.

Breaking Down the Levels of Control

The Hierarchy of Controls has five distinct levels, each offering a different way to tackle a risk. Let's walk through them with practical examples from construction and manufacturing.

Elimination: This is the top of the ladder and the best option. It means physically removing the hazard from the workplace completely. If the hazard isn't there, it can't cause harm.

- Construction Example: Instead of having workers operate at height, prefabricate wall sections on the ground and then lift them into place with a crane. The risk of falling from that height is now gone.

- Manufacturing Example: Replace a toxic solvent used for cleaning machine parts with a non-toxic, water-based alternative. The chemical hazard has been eliminated.

Substitution: If you can't eliminate the hazard, the next best thing is to replace it with something less dangerous.

- Construction Example: Use a smaller, battery-powered saw instead of a large, petrol-powered one to reduce both noise levels and fume exposure.

- Manufacturing Example: Swap out a noisy metal-on-metal conveyor system for a quieter, belt-driven one to lower the risk of hearing damage.

Engineering Controls: These are physical changes to the workplace, equipment, or process that put a barrier between people and the hazard. They are designed to work without anyone needing to actively do something.

- Construction Example: Installing guardrails around an open excavation to physically prevent falls.

- Manufacturing Example: Placing a fixed guard around the moving parts of a machine to stop workers from getting their hands or clothing caught.

Administrative Controls: These controls rely on people’s actions. These are changes to the way people work, like procedures, training, and warning signs.

- Construction Example: Implementing a safe work procedure for operating a forklift, which includes things like speed limits and designated travel paths.

- Manufacturing Example: Providing mandatory training on correct manual handling techniques for lifting heavy items to prevent back injuries.

Personal Protective Equipment (PPE): This is your last line of defence. PPE includes things like hard hats, safety glasses, gloves, and respirators. It doesn't remove the hazard; it just puts a final barrier between the worker and that hazard.

PPE should always be your last resort, only used when all other controls are not practical. Its effectiveness relies completely on the worker using it correctly, every single time, which makes it the least reliable control.

Applying the Controls to Psychosocial Hazards

The Hierarchy of Controls isn't just for physical dangers like open pits or noisy machines. It’s just as powerful for managing psychosocial hazards, the risks that affect a worker's mental health. Things like extreme workload, tight deadlines, and workplace bullying require the same structured thinking.

This diagram shows how different factors can contribute to mental stress. Just like a physical hazard, you can apply the hierarchy to control them. For example, redesigning job roles to make workloads manageable (elimination) is far more effective than just offering stress management training (an administrative control).

For those interested in more advanced methods, you can learn more about the bowtie risk assessment methodology, which provides a visual way to understand and manage more complex risks.

Managing Hazards with Safety Space

Knowing how to spot, assess, and control hazards is one thing. Doing it day in and day out on a hectic construction site or a busy factory floor is another. This is where having a proper tool for the job can make all the difference, helping you ditch paper checklists and spreadsheets for a system that works in real-time.

Using a platform like Safety Space lets you put all the principles we’ve talked about into practice. It gives you one central place to log every hazard, manage risk assessments, and get corrective actions to the right people. It turns a messy process into a series of clear, manageable steps.

A Central Hub for Hazard Tracking

The first big win is visibility. Instead of reports getting buried in emails or put in a filing cabinet, every hazard is logged in one spot. This creates a live, accessible record of what’s happening on your site.

For example, a site supervisor can log a new hazard straight from their phone, complete with photos and notes. That report is instantly visible to the safety manager back at the office, who can kick off the risk assessment process without delay. This closes the gap between spotting a problem and starting to fix it.

Having a clear, time-stamped record of every safety activity is good practice and a powerful tool for accountability and compliance. It shows exactly what was done, by whom, and when.

From Identification to Action

Finding hazards is just the start. The real work is in getting effective controls in place and making sure they get done. This is where software adds needed structure.

Once a risk assessment is done, you can assign specific actions to individuals or teams. These aren't just vague suggestions; they are trackable tasks with clear deadlines.

- Assign Responsibility: A job like "Install guardrail on Level 3" can be assigned directly to the site foreman.

- Set Deadlines: The system can automatically set a due date and send reminders so the task doesn’t get forgotten.

- Track Progress: Managers get a view of all open actions on a single dashboard, watching them move from "To Do" to "In Progress" and "Completed."

This brings a level of accountability that’s almost impossible with paper trails. Everyone knows what they’re responsible for, and management has a clear view of whether controls are being implemented on schedule.

Verifying That Controls Are Working

Just because a control is in place doesn't mean the risk has vanished. You need to circle back and check that the solution is doing its job. A digital system helps you build this critical verification step into your workflow.

After a corrective action is marked as complete, you can schedule a follow-up inspection. For instance, after a new ventilation system is installed to manage chemical fumes (an engineering control), an air quality test can be scheduled and the results logged right in the system.

This creates a closed-loop process. You find the hazard, you control it, and then you verify that the control worked. This systematic approach ensures that hazards in the workplace aren't just patched up, but properly managed from start to finish.

Your Legal Duties for Workplace Safety in Australia

Managing hazards in the workplace isn’t just a good idea, it’s the law in Australia. Under the Work Health and Safety (WHS) framework, every business has a primary duty of care to protect its workers, as far as is reasonably practicable. This isn't a passive role; it means you have to actively eliminate or minimize risks.

This responsibility falls on the Person Conducting a Business or Undertaking, or PCBU. This term is broad and covers sole traders, large corporations, and even volunteer groups with workers. If you run the business, you’re responsible for making it safe.

Your core duty is to provide a work environment that is free from health and safety risks. This is a wide-reaching obligation, covering everything from the physical layout of your site to the machinery your team uses every day.

So, What Does "Primary Duty of Care" Actually Mean?

The concept of "reasonably practicable" is the heart of WHS law. It’s a balancing act that requires you to do what’s reasonable and possible in your specific situation to ensure safety. It’s not about achieving the impossible, but it is about being proactive.

To figure out what's "reasonably practicable," you need to weigh up a few things:

- How likely is it to happen? What are the chances of the hazard actually causing harm?

- How bad could it be? If someone does get hurt, is it a minor cut or a life-changing injury?

- What's the common knowledge? What do you know about the hazard and the ways to control it?

- Are there solutions available? What are the options for controlling the risk, and are they suitable for your workplace?

- What's the cost? Cost is a factor, but it can never be the only reason for ignoring a risk, especially a serious one. Safety has to come first.

This framework forces you to be proactive. You can't just wait for an incident to occur; you have to actively hunt for potential hazards in the workplace and do what’s reasonable to get them under control.

Key Obligations for PCBUs

Beyond this main duty, the law outlines specific actions every PCBU must take. Think of these as the practical, non-negotiable foundations of your safety management system.

Here are your key obligations:

- Provide and maintain a safe work environment.

- Make sure all machinery, structures, and substances are used, handled, and stored safely.

- Provide clean and accessible welfare facilities for workers (like toilets and drinking water).

- Give your team the right information, training, instruction, and supervision to do their jobs without getting hurt.

- Monitor your workers' health and the workplace conditions to prevent illness or injury.

A critical piece of the puzzle is the legal requirement to consult with your workers. You must talk to them about WHS matters that affect them, listen to what they have to say, and factor their feedback into your decisions.

Failing in these duties has serious consequences. In 2023-24 alone, 146,700 serious workers' compensation claims were lodged in Australia. Body stressing and falls were the biggest culprits.

Industries like healthcare, construction, and manufacturing consistently top the charts for these claims, highlighting where the risks are most concentrated. For a full breakdown, you can read the new data on Australia's serious injury claims. And while rules differ by region, looking at how other jurisdictions handle WSIB insurance and employer duties can offer valuable perspective on worker compensation systems.

Got Questions About Workplace Hazards? We’ve Got Answers.

When you're trying to get a handle on workplace hazards, a few common questions always seem to pop up. Let's get straight to the practical answers you need.

Hazard vs. Risk: What's the Real Difference?

This is a common point of confusion, but the distinction is simple.

A hazard is anything with the potential to cause harm. Think of it as a dormant threat. A puddle of oil on a factory floor is a classic example. It's just sitting there, but it has the potential to hurt someone.

A risk is the likelihood of that hazard actually causing harm, combined with how bad that harm could be. The risk only comes into play when a worker walks near that oily patch. The hazard is the source of the danger; the risk is the chance of that danger affecting someone.

Who Is Actually Responsible for Workplace Safety?

Under Australian WHS laws, the responsibility ultimately lies with the Person Conducting a Business or Undertaking (PCBU). That’s the official term for the employer, and they have a primary "duty of care" to ensure the workplace is safe, so far as is reasonably practicable.

But it’s not a one-way street. Every worker also has a duty to take reasonable care of their own health and safety, and to make sure their actions don’t put others at risk. This means using safety gear correctly, following procedures, and speaking up when you see something wrong.

Workplace safety is a team effort. While the employer holds the primary legal responsibility to provide a safe work environment, everyone on site has a role in spotting and managing hazards.

What Should I Do If I Spot a Hazard?

If you see a potential hazard, the worst thing you can do is assume someone else will handle it. Acting immediately is key.

Here’s a simple, practical process to follow:

- Assess the immediate threat. If it’s something like an exposed live wire that poses a serious, immediate danger, the first priority is to clear the area and warn others.

- Report it. Fast. Find your supervisor, manager, or health and safety rep and tell them straight away. Give them the specifics: what it is and exactly where it is.

- Log it officially. If your workplace has a reporting system (like an app or a form), use it. This creates a record and ensures the hazard is tracked until it's resolved.

Unless you are trained and authorized to fix a specific problem, don't try to fix it yourself. Your most important job is to report the hazard clearly and quickly so the right people can control it safely.

Ready to stop chasing paperwork and start preventing incidents? Safety Space gives you a single, straightforward platform to identify, track, and control hazards in real-time. Find out how you can build a safer, more compliant workplace by booking a free demo at https://safetyspace.co.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.