A generic health and safety management plan template is little more than a starting point. Just slapping your company name on a downloaded document might feel like you've ticked a box, but it creates a false sense of security. It does nothing to address the unique risks your team faces every single day.

Frankly, it's a paper-shuffling exercise that leaves dangerous gaps in your safety system.

Why a Generic Safety Template Fails

A one-size-fits-all approach to safety is a massive gamble, especially in high-stakes industries like construction and manufacturing. Every single worksite has its own unique fingerprint of hazards, from the layout of the factory floor to the specific machinery in use. A generic template can't possibly account for these critical variables.

For instance, a standard plan might have a line item for "forklift safety," but it won't address your site's narrow aisles, blind corners, or specific pedestrian traffic patterns. These are the details that actually prevent incidents. Relying on a generic document means you're not actively identifying and controlling the real dangers your crew confronts daily.

The Real Cost of a Copy-Paste Plan

This lack of customisation is where things go wrong. Think about a construction site using a boilerplate template with a basic entry for "working at heights." It’s highly unlikely to specify the project's unique risks, like working near unprotected edges on the third floor or the precise anchor points needed for harnesses on that particular structure.

This is precisely where generic plans fall flat. They don't force the critical thinking required to make a safety plan truly effective. Instead of being a practical tool used on the ground, the document becomes a compliance piece filed away in an office, gathering dust.

Meeting Australian Standards

In Australia, the entire purpose of a safety plan is to systematically reduce workplace incidents. And while there’s been progress, the numbers show we still have a long way to go. According to Safe Work Australia, 188 Australian workers died from traumatic injuries at work in a recent year, a fatality rate of 1.3 deaths per 100,000 workers. A properly customised plan is a vital tool for bringing that number down.

A truly effective health and safety plan is built from the ground up, reflecting the real-world conditions of your specific workplace. It should be a living document, not a static file.

To be compliant, and more importantly, effective, your plan must be tailored. This involves a thorough, hands-on assessment of your specific operational risks. It also means clearly documenting your WHS policies and procedures for everyone to see and follow.

This customisation process ensures the plan is relevant to the people who need it most. It transforms the document from a liability into a useful, practical guide for day-to-day work, helping everyone understand their role in keeping the site safe.

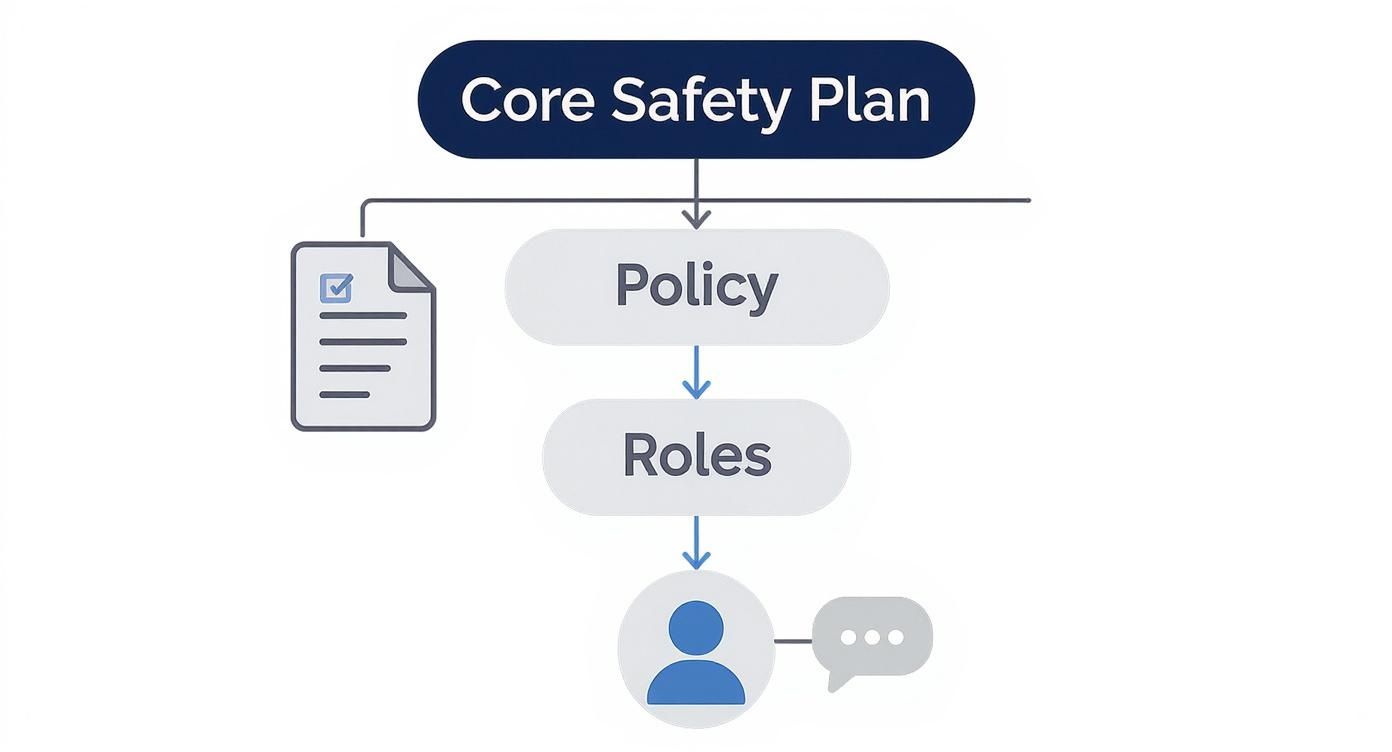

The Building Blocks of a Strong Safety Plan

Every rock-solid health and safety management plan template is built on the same foundational pillars. Think of these as the non-negotiables that give your document structure and purpose. Without them, you’ve just got a collection of good intentions, not a system that actually works in the real world.

The whole point is to create a framework that's clear, direct, and easy for everyone on site to follow. Forget complicated corporate jargon; this is about practical action. Let’s break down the three absolute must-haves for any plan that’s worth the paper it’s written on.

1. Safety Policy and Objectives

Your safety policy is your line in the sand. It’s a short, sharp declaration from management that safety is a top priority, period. This isn't the place for vague, fluffy statements; it needs to be direct and actually mean something to the people reading it.

A policy for a manufacturing plant, for instance, could be as simple as: "Our goal is to ensure every team member goes home safely at the end of their shift. We are committed to providing the right equipment, training, and procedures to prevent injuries."

That’s the what. Next, you need the how. That’s where objectives come in. These are the specific, measurable goals that bring your policy to life.

- Objective Example 1: Cut machine-related incidents by 15% in the next 12 months by installing new guarding and rolling out updated operator training.

- Objective Example 2: Hit a 100% completion rate for mandatory manual handling training for all new hires within their first week.

- Objective Example 3: Conduct weekly site safety inspections and ensure all hazards are actioned and closed out within 48 hours.

These objectives give you a target to aim for and a clear way to see if your plan is actually making a difference.

2. Roles and Responsibilities

This is where you kill the guesswork. This section clearly maps out who is responsible for what, from the managing director right down to the newest person on the tools. Ambiguity is a massive risk in safety management; this part ensures everyone knows exactly what they need to do.

When you're defining roles, be specific. Don’t just list job titles, spell out the actual duties.

Example for a Construction Site Supervisor:

- Lead daily pre-start safety briefings (toolbox talks).

- Ensure every worker on site has completed the required inductions.

- Verify Safe Work Method Statements (SWMS) are in place and being followed for all high-risk work.

- Has the authority to stop any work that is being performed unsafely.

- Lead incident investigations for any near misses or injuries in their area.

A well-defined roles and responsibilities section is your secret weapon. It creates clear lines of accountability and stops critical safety tasks from falling through the cracks because someone thought it was "someone else's job."

This level of detail leaves no room for confusion. Anyone can look at the plan and see exactly what’s expected of them, creating a system of personal accountability.

3. Consultation and Communication

Safety isn't a lecture; it's a conversation. Your plan absolutely must detail how you’ll communicate with and consult your workers. This isn’t just about pushing information down from the top. It’s about creating genuine channels for feedback to flow back up.

You need a system for listening.

Practical Ways to Make it Happen:

- Toolbox Talks: Brief, regular meetings held on-site to discuss hazards relevant to the day's work.

- Safety Meetings: Scheduled monthly or quarterly catch-ups with worker reps to review incidents, talk about upcoming work, and get honest feedback.

- Notice Boards: A designated, highly visible spot for posting safety alerts, inspection results, and meeting minutes.

- Reporting Systems: A dead-simple way for workers to report hazards or suggest improvements without any fear of comeback.

By documenting these methods, you're building a formal structure for safety conversations. It makes it crystal clear that worker input isn't just welcome, it's an essential part of keeping everyone safe.

Before you finalise your plan, it's a good idea to run through a quick checklist to make sure you've covered all the non-negotiable components. These are the core sections that regulators, clients, and your own team will expect to see.

Essential Plan Components Checklist

Here’s a simple table to help you double-check that your plan’s foundation is solid.

| Component | What It Covers | Example Action |

|---|---|---|

| Safety Policy | The organisation's high-level commitment to health and safety. | Draft a clear, one-paragraph statement signed by senior management. |

| Objectives & Targets | Specific, measurable goals to improve safety performance. | Set a goal to reduce slips, trips, and falls by 20% this year. |

| Roles & Responsibilities | Who is accountable for specific safety tasks, from management to workers. | Create a clear chart listing key roles and their primary safety duties. |

| Hazard Management | The process for identifying, assessing, and controlling workplace hazards. | Implement a simple hazard reporting form (digital or paper) accessible to all staff. |

| Consultation | How you will involve workers in safety decisions and communications. | Schedule and minute monthly toolbox talks and quarterly safety committee meetings. |

| Incident Management | Procedures for reporting, investigating, and learning from incidents and near misses. | Develop a flowchart for incident reporting and investigation protocol. |

| Emergency Procedures | Plans for responding to emergencies like fire, medical events, or chemical spills. | Post clear evacuation maps and conduct a fire drill every six months. |

| Training & Competency | How you ensure workers are trained and competent for their tasks. | Maintain a training matrix that tracks required certifications and refreshers. |

| Plan Review | The schedule and process for reviewing and updating the safety plan. | Set an annual review date in the calendar to update the plan and objectives. |

Using this checklist ensures you don't miss any of the fundamentals. These three core components, Policy, Roles, and Consultation, form the backbone of your plan, but fleshing it out with the other essentials turns it into a truly effective system.

Identifying and Managing On-Site Risks

Alright, you’ve got the skeleton of your plan sorted. Now it's time to add the muscle, the stuff that actually keeps people safe on the ground. This is where we shift from paperwork to the practical, gritty work of finding the real-world hazards your team faces and figuring out exactly how to manage them.

Honestly, this part is the absolute heart of a useful health and safety management plan template. Without a proper risk assessment, you just have a document gathering dust. With one, it becomes a living guide that helps you stop incidents before they even have a chance to happen.

To keep this real, let's walk through the process using a busy manufacturing plant as our example.

Finding the Hazards That Matter

First things first: you need to walk the site with a critical eye. This isn't just a casual stroll; you're actively hunting for anything that could hurt someone. Don't just look for the obvious stuff like unguarded machines. Pay attention to how the work actually gets done, day in and day out.

During a walkthrough of our example manufacturing plant, we might spot a few serious issues:

- Machinery: An old hydraulic press is running with a dodgy, makeshift guard that doesn't actually stop anyone from reaching the danger zone.

- Chemicals: Drums of highly flammable solvent are being stored right next to a welding station. That’s a massive fire risk waiting to happen.

- Traffic: Forklifts and people on foot are using the same main aisle, creating a chaotic and dangerous mix, especially during shift changes.

Just listing these isn't enough. Your plan needs specifics to be effective. Don't just write "forklift risk." Instead, document it like this: "High risk of collision between forklifts and pedestrians at the intersection of Aisle 3 and the main workshop door between 7-8 AM and 4-5 PM." See the difference? That level of detail makes your plan genuinely useful.

This infographic shows how the core parts of your safety plan, like your policy and defined roles, are the foundation for managing these risks.

As the diagram illustrates, having a solid policy and clear roles in place gives you the structure you need to communicate effectively about the specific hazards on your site.

Assessing the Risks Practically

Once you’ve identified the hazards, you need to figure out which ones to tackle first. You don't need a complicated scientific formula for this. A simple, practical approach is usually best. Just think about two things: the likelihood of something going wrong, and how severe the injury would be if it did.

A simple high, medium, or low rating system works perfectly. Let's apply it to our plant:

| Hazard | Likelihood | Severity | Risk Level |

|---|---|---|---|

| Unguarded Press | High | High | High |

| Chemical Storage | Medium | High | High |

| Forklift Traffic | High | Medium | High |

This quick analysis immediately tells you where your priorities should be. In our example, all three hazards are high-risk and need immediate attention. Overlooking these kinds of specific, documented risks is where many safety plans fall flat. A tailored plan is vital, especially when you consider that vehicle incidents accounted for 42% of fatalities and falls from height for 13% in Australian workplaces. Detailing your controls is a key part of meeting your legal duties.

Putting Effective Controls in Place

Now for the most important step: deciding what you’re going to do about these risks. The best way to think about this is by using the hierarchy of controls. It’s a framework that ranks control methods from most effective to least effective. You should always try to use controls from as high up the list as you can.

Let's apply it to our manufacturing plant hazards:

- Elimination: Can we get rid of the hazard completely? For the chemical storage, maybe we could switch to a non-flammable solvent. If that's possible, the risk is gone. Problem solved.

- Substitution: Similar to elimination, can we replace the hazard with something safer?

- Isolation & Engineering: Can we physically separate people from the hazard? For the unguarded press, the best fix is an engineering control: installing a proper, compliant fixed guard. For the forklift traffic, we could install physical barriers to create separate pedestrian walkways, an isolation control.

- Administrative Controls: Can we change how people work? For the forklift issue, we could implement a site-wide speed limit, put up clear warning signs, and schedule pallet movements for times when foot traffic is low.

- Personal Protective Equipment (PPE): This is your last line of defence. For handling the chemicals, this would mean gloves and safety glasses. PPE is crucial, but it should never be your only control measure.

The goal is to choose controls that are reliable and don't just depend on someone remembering to do the right thing every single time. A physical barrier is always more effective than a sign telling people to be careful.

By documenting these specific fixes in your health and safety management plan template, you’re creating a clear action plan. Our internal guide has more detail on how to choose the right control measures for risks in your specific workplace. This approach turns your plan from a compliance document into a genuine roadmap for making your site safer.

Building an Effective Incident Response Plan

Let's be realistic: no matter how well you identify and control your risks, incidents can still happen. When they do, panic and confusion are your worst enemies. A clear, actionable incident response section within your health and safety management plan template is what separates a controlled situation from a chaotic one.

This isn't just about sticking a list of phone numbers on the wall. It’s a pre-planned playbook that tells people exactly what to do when things go sideways. A good plan gives your team the confidence to act, helps reduce the severity of an incident, and gets your operations back on track much faster.

Moving Beyond Basic Emergency Contacts

A generic "in case of fire" instruction just doesn't cut it. Your plan has to be tailored to the specific emergencies you could actually face on your site. Think about your specific work environment, whether it's a factory floor, a high-rise construction site, or a quiet office, and map out simple, step-by-step procedures for those scenarios.

For example, the procedure for a chemical spill in a manufacturing facility is worlds apart from handling a medical emergency on a multi-level construction site. You've got to get specific.

- Medical Emergency: Who is the designated first aider on this shift? Where is the first aid kit? Critically, what is the exact site address and best access point for the ambulance to use?

- Fire: Where are the extinguishers, and what type are they? Who is responsible for hitting the alarm? Are there specific shutdown procedures for nearby machinery that need to happen immediately?

- Chemical Spill: Where's the spill kit? Who is trained to use it? What are the immediate first aid actions for someone exposed to the specific chemicals you have on site?

Having clear, scenario-specific procedures means people don't have to think under pressure; they just have to act. This is the single most important function of an effective incident response plan.

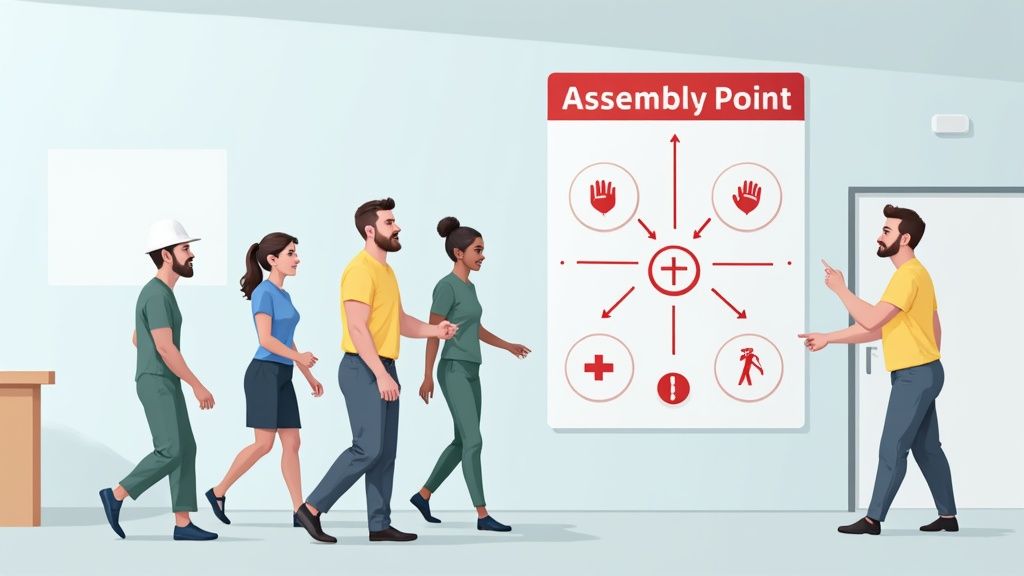

Mapping Out a Clear Response

Visuals are a game-changer here. Your plan should include a simple, easy-to-read map of the worksite. We’re not talking about a complex architectural drawing; this is a practical safety tool.

On the map, use clear symbols to mark evacuation routes, emergency exits, and first aid stations. Most importantly, clearly show the emergency assembly points. These are the safe, open areas away from the building or work zone where everyone gathers after an evacuation. This is non-negotiable for doing a quick and accurate headcount to make sure everyone is safe.

Just as important as the map is assigning clear roles. Your plan needs to name the people responsible for specific actions during an emergency. This removes any doubt or hesitation about who is in charge.

Key Response Roles:

- Emergency Coordinator/Chief Warden: This person takes charge of the overall response. They’re the one communicating with emergency services and making the final call to evacuate.

- First Aiders: These are your trained personnel responsible for providing immediate medical assistance until the pros arrive.

- Fire Wardens: Their job is to clear their designated area, do a final check to ensure everyone has evacuated, and report back to the coordinator at the assembly point.

To make this all run smoothly, especially in the heat of the moment, specialised software can be a huge help. Digital tools, like some of Resgrid's incident management features, can help with communication and help manage personnel and track resources during a critical event.

Simple Incident Reporting and Investigation

The response doesn't stop when the immediate danger is over. What you do next is absolutely crucial for preventing the same thing from happening again. Your plan must include a straightforward process for reporting and investigating every single incident, and that includes near misses.

The goal here is simplicity. If you make people fill out a complicated, multi-page form, they just won't bother reporting things. A simple form, whether it's digital or on paper, should capture the essentials: what happened, where and when, who was involved, and any immediate actions taken.

Once an incident is logged, the investigation needs to focus on finding the root cause, not on blaming people. Ask "why" it happened, not "who" caused it. Was it a failed piece of equipment? A gap in a procedure? A training issue? The findings from this investigation must then be used to update your risk assessments and control measures. This is how you turn every incident, no matter how small, into a valuable lesson.

For more guidance on this, our detailed emergency response plan template can help you structure this critical section of your safety plan.

Including Psychological Health in Your Plan

Safety isn't just about hard hats and high-vis vests anymore. A truly effective health and safety management plan template has to account for the total well-being of your people, and that absolutely includes their psychological health.

Ignoring mental well-being is a massive oversight. It leaves your team exposed to risks just as serious and costly as any physical hazard. We're talking about moving beyond the obvious, visible dangers and addressing the stressors that can tank your team's focus, morale, and overall safety on the job. This isn't a vague, feel-good exercise; it's a critical part of modern risk management that has a real, tangible impact.

Identifying Workplace Stressors

First things first, you need to pinpoint the psychological hazards lurking in your specific work environment. These are often less obvious than an unguarded machine but can be just as damaging. Take a hard look at the daily pressures your team is under.

In high-pressure settings like manufacturing or construction, common stressors often include:

- High Workloads: Unrealistic deadlines, crazy long hours, and being constantly understaffed are a recipe for burnout and mistakes.

- Low Job Control: When workers have little to no say in how their work gets done, they can feel powerless and completely disengaged.

- Workplace Conflict: Ongoing friction between team members or with management creates a tense, unproductive atmosphere that grinds everyone down.

- Isolation: This is a huge risk for lone workers or those on remote sites who don't have that regular interaction and support network.

And this isn't some minor issue. The focus on psychological health in Aussie work health and safety plans is growing for a very good reason. Recent data from Safe Work Australia showed that mental health disorders now account for a staggering 12% of all serious workers' compensation claims. That's a 161% increase over the last decade alone.

Turning Awareness into Action

Once you've got a handle on the potential stressors, the next step is building concrete actions into your safety plan to manage them. This is how you show a real commitment to supporting your team, turning your plan from just another document into a practical, everyday tool. When thinking about a comprehensive health and safety management plan, it's vital to address the mental well-being of employees. For practical advice on managing workplace stress and relationships, external resources can offer valuable insights.

These actions don't need to be complex. They just need to be clear, consistent, and properly documented right there in your plan.

Your plan should treat psychological hazards with the same structured approach as physical ones. Identify the risk, assess its impact, and implement clear, practical control measures.

Start with simple initiatives that give you the biggest bang for your buck.

Here are a few practical steps you can build into your plan:

- Implement Supportive Check-in Policies: Train your supervisors to have regular, informal check-ins with their teams. These aren't performance reviews; they're genuine opportunities to ask, "How are you going?" and actually listen to the answer.

- Provide Access to Support Services: Make sure your plan includes clear, easy-to-find information about your Employee Assistance Program (EAP), if you have one. Everyone needs to know what it is, that it’s confidential, and exactly how to use it.

- Train Managers to Spot Signs of Distress: Give your leaders the skills to recognise changes in behaviour that might signal someone is struggling, things like increased irritability, withdrawal, or a sudden drop in work quality.

- Promote a Fair and Respectful Workplace: Your plan should clearly spell out your policy on bullying and harassment, along with a simple, confidential way for people to report any issues.

Documenting Psychological Safety in Your Template

So, what does this actually look like in your health and safety management plan template? It's about adding a specific section dedicated to psychological well-being, just like you would for hazard management or incident response.

Here’s a simple way you could structure this section in a table:

| Plan Component | Description of Action | Responsibility |

|---|---|---|

| Psychological Hazard ID | Conduct confidential worker surveys every six months to identify key workplace stressors (e.g., workload, conflict). | H&S Manager |

| Manager Training | All supervisors to complete mental health awareness training within three months of starting in their role. | HR Department |

| Supportive Communication | Promote EAP services in monthly toolbox talks and on-site notice boards to reduce stigma. | Site Supervisor |

| Workload Management | Implement a formal review process for project deadlines to ensure they are realistic and achievable. | Project Manager |

By documenting these actions and assigning clear responsibilities, you create a system of accountability. It ensures that supporting psychological health becomes an active, managed part of your safety system, not just an afterthought. This approach helps you build a more resilient, focused, and ultimately safer team.

Making Your Safety Plan a Living Document

A health and safety management plan is completely useless if it’s just a document that gets signed, filed, and forgotten. Its real value comes when it’s treated as a living document, one that’s actively used on the workshop floor or construction site every single day.

A plan gathering dust on a shelf doesn't prevent injuries; it just creates a false sense of security. The goal is to weave your safety plan into the fabric of your daily operations, not just tick a box for a compliance check.

It has to be a practical tool that adapts to your changing workplace and genuinely guides how your team works safely. This means building a simple system for keeping it current and making sure everyone on the crew actually knows what's in it.

Regular Reviews and Updates

Your worksite is never static. New machinery gets installed, project scopes shift, and new people join the team. Your safety plan has to keep pace. A plan that's even a year out of date could completely miss a new, significant hazard that's been introduced.

Scheduling regular reviews is the first, most basic step. At an absolute minimum, your entire plan should get a formal review once a year. But some events should trigger an immediate review and update, no questions asked.

Triggers for an Immediate Plan Review:

- After an Incident or Near Miss: This is your most critical learning opportunity. The investigation has to identify the root causes, and your plan must be updated with new controls to stop it from happening again.

- When New Equipment is Introduced: A new press, vehicle, or piece of scaffolding brings new risks. Your plan needs to be updated with safe operating procedures and specific training requirements before it’s even switched on.

- Changes in Work Processes: If you change the layout of your factory floor or adopt a new construction method, your original risk assessments are no longer valid. The plan has to reflect the new way of working.

- Feedback from the Team: If workers are consistently reporting a specific hazard or raising concerns, that’s a clear signal that a part of your plan isn't working in practice and needs another look.

A safety plan should never be considered "finished." Think of it more like a service manual for your workplace; you have to update it whenever you make changes to the machine.

This constant cycle of review and improvement ensures the document remains relevant and useful. It becomes a reliable source of information that reflects the reality of the work being done, not just an idealised version from months ago.

Communicating the Plan Effectively

Creating a brilliant, up-to-date plan is only half the job. If your team doesn't know what's in it or how to use it, it’s all for nothing. Effective communication is about getting the right information to the right people in a way they can easily understand and apply.

This process starts on day one. Every new hire, whether they're a permanent employee or a short-term contractor, must be taken through the key parts of the safety plan during their site induction. This sets the expectation from the very beginning that safety is non-negotiable.

Beyond the initial induction, you need regular, ongoing communication to keep the plan front of mind. This is where toolbox talks are absolutely essential.

Making Toolbox Talks Practical:

- Keep them short and focused. Pick one specific topic from your safety plan, like the procedure for working near mobile equipment or the emergency response for a chemical spill. Don't try to cover everything at once.

- Make it relevant to the day's work. If the crew is doing roof work, the toolbox talk should be about fall prevention, referencing the specific controls outlined in your plan.

- Encourage discussion. Don't just lecture. Ask questions. Get the team to share their own experiences or point out potential hazards they've seen. This turns it into a two-way conversation.

By embedding the plan into these daily and weekly routines, you transform it from a document into a shared understanding of how to work safely on your site. Everyone knows the rules, understands why they exist, and has a clear process for suggesting improvements. It becomes a tool that truly works.

Got Questions About Your Safety Management Plan?

When you're putting together a health and safety management plan, a few questions always seem to pop up. Here are the answers to some of the most common ones we hear from people in the field.

How Often Should I Review My Safety Management Plan?

The official answer is at least once a year. But honestly, thinking of it as an annual task is a mistake.

You absolutely need to review it the moment anything significant changes on site. That could be bringing in new machinery, introducing a different work process, or, and this is the big one, after any incident or near-miss.

A safety plan that sits on a shelf gathering dust is just a historical document. An immediate update after an incident or change is what keeps it a practical, useful tool for preventing the next one.

Treat it as a living document. This constant review cycle is the only way to make sure the plan actually reflects the work being done and keeps your people safe.

What's the Difference Between a Risk Assessment and a Safety Plan?

This one trips a lot of people up, but it's pretty simple when you break it down.

A risk assessment is a specific tool you use to zoom in on a particular task or hazard. Think of a Job Safety Analysis (JSA) or a Safe Work Method Statement (SWMS). You're identifying what could go wrong with a specific job and figuring out how to control it.

The health and safety management plan is the big picture. It’s the entire framework that holds everything together. It lays out your company's safety policies, who's responsible for what, and all your procedures. Your risk assessments feed into this larger plan, but they aren't the plan itself.

Who Is Actually Responsible for Implementing the Plan on Site?

While the buck stops with senior management, making a plan work on the ground is a team sport. Your site supervisors and managers are on the front line, responsible for the day-to-day enforcement and making sure everyone knows what's expected of them.

But here’s the crucial part: every single person on site has a part to play. Each worker is responsible for following the procedures and, just as importantly, for speaking up and reporting any hazards they spot.

That's why having crystal-clear roles and responsibilities defined in your plan is non-negotiable. When everyone knows their role, the whole system works.

Still juggling paper, spreadsheets, and endless follow-ups? Safety Space is the all-in-one platform that makes managing health and safety simple. From real-time monitoring to AI-powered form completion, we help you focus on what really matters.

See how it works by booking a free demo and consultation.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.