A near miss report is a formal document that records an incident that did not result in injury or damage, but easily could have. Think of it as a warning shot. A heavy box falling from a shelf and landing just inches from a worker is a perfect example of a near miss. Capturing these events is a practical way to find and fix hidden dangers before they cause real harm.

What a Near Miss Report Really Is

Imagine a near miss as a free lesson in workplace safety. It’s a chance to learn what could go wrong without anyone getting hurt or any equipment getting damaged. A near miss report is simply the tool used to document that lesson so you can take action.

These aren't reports about failures or mistakes. Instead, they are valuable pieces of information that highlight weaknesses in your current processes, equipment, or work environment.

Spotting a Near Miss

In busy environments like manufacturing plants or construction sites, near misses happen far more often than people realize. They’re usually dismissed with a sigh of relief, but each one is a signal that a hazard exists.

Here are a few common examples of what a near miss looks like:

- A worker slips on a small oil spill but catches their balance just in time, avoiding a fall.

- An unsecured tool falls from a scaffold, landing in an empty area where someone was working minutes earlier.

- A forklift operator has to brake suddenly to avoid a collision with another worker who stepped out from behind a pallet rack.

A near miss is a clear indicator of a potential future accident. By documenting it with a report, you turn a moment of luck into a practical opportunity for prevention.

Why It's Not Just a Close Call

Calling it "just a close call" downplays the importance of the event. A formal near miss report turns that fleeting observation into useful data. For a deeper dive, you can learn more about what is a near miss and why it matters.

This data helps you spot patterns, identify recurring risks, and make targeted improvements. It’s the difference between hoping an accident doesn’t happen and actively working to make sure it won’t.

Why Near Miss Reporting Is Important

A near miss report isn't just more paperwork. It's one of the most useful tools you have for stopping serious incidents before they happen.

Think of each report as an early warning signal, a red flag pointing directly to a weakness in your system. It’s your chance to be proactive and fix real problems before they lead to an injury, equipment damage, or costly downtime.

Instead of waiting for an accident to reveal where the dangers are, near miss reporting gives you a free lesson. You get to identify a hazard without anyone getting hurt. This simple shift moves your safety approach from being reactive to actively preventive. It's the difference between cleaning up a mess and stopping it from being made in the first place.

A Practical Early Warning System

Every near miss report contains valuable data about what’s really happening in your workplace. When you collect and analyze this information, you start seeing patterns you would have otherwise missed. These are your leading indicators of risk.

For example, one report about a worker nearly slipping on a small coolant leak might seem minor. But what if three similar reports come from that same area in one month? You've just uncovered a significant, recurring hazard. That data lets you dig in and address the root cause, whether it's a faulty machine, a gap in your maintenance schedule, or something else entirely.

By tracking near misses, you get a clear, data-backed view of where your next major incident is most likely to occur. It’s like having a map of your workplace’s hidden dangers.

This proactive approach is the foundation of modern health and safety. In Australia, agencies like Safe Work Australia promote near miss reporting as a vital part of any good incident management system. Spotting these hazards early is absolutely key to preventing costly claims and, most importantly, keeping your people safe.

From Close Calls to Concrete Fixes

There's a direct link between consistent near miss reporting and a drop in actual accidents. It's not magic. When you document a near miss, you are capturing a real-world scenario where your safety measures were tested and almost failed. That information is gold for making targeted, effective improvements.

Here are a few practical ways near miss data leads to genuine fixes:

- Uncovering training gaps: If several reports mention confusion around a specific procedure, it’s a clear signal that your team needs better training or clearer instructions.

- Identifying equipment issues: Multiple near misses involving the same piece of machinery can point straight to a maintenance problem or tell you it’s time for an upgrade.

- Improving workplace design: A few reports of near collisions in a busy warehouse aisle might lead to installing mirrors, painting designated walkways, or changing the flow of traffic.

Each report provides a clear opportunity to strengthen your defenses against accidents. It’s a practical, repeatable process that turns a "lucky break" into a tangible safety improvement, making your worksite safer for everyone involved.

What to Include in a Near Miss Report

A near miss report is only as good as the information inside it. To get real value, you have to capture the right details from the start. A vague or incomplete report makes it impossible to find the root cause, and that means you can't stop it from happening again.

The goal isn't to create a mountain of paperwork. It’s about getting the specific facts down that paint a clear picture of what happened, why it happened, and what could have happened. This is how a simple observation becomes a useful tool for making the workplace safer.

Essential Information for Every Report

Think of a near miss report like an investigator's notebook. The more precise the information, the easier it is to solve the puzzle. Every single report needs to capture a few critical pieces of data to be effective.

These are the non-negotiables:

- Date and Time of the Event: This simple detail helps identify patterns. Are you seeing more near misses towards the end of a long shift? Or maybe during a specific production run? This is how you find out.

- Exact Location: "Warehouse" won't cut it. You need specifics, like "Aisle 3, next to the main loading bay." This pinpoints physical hot spots where hazards might be concentrated.

- People Involved or Witnesses: Getting names isn't about pointing fingers or assigning blame. It’s about knowing who to talk to for follow-up questions to get a complete picture of what went down.

A strong near miss report is all about the details. It answers the key questions: who, what, where, when, and why. Nailing this is the first step toward a real solution.

By gathering these basic facts consistently, you start to build a reliable dataset that helps you spot trends and recurring risks before they turn into incidents. This information is the foundation for any proper investigation that follows.

Describing the Event and Potential Outcomes

Once you have the basics down, it’s time to explain what actually happened. This is the heart of the near miss report. It requires a clear, factual description of the sequence of events, not just a one-line summary.

To make your reports genuinely useful, they need to contain the key information that safety teams can act on. Below is a quick checklist of the essential fields that turn a simple form into a useful safety tool.

Key Information for Your Near Miss Report

| Information Field | Why It's Important | Example |

|---|---|---|

| Clear Description | Provides a step-by-step account of the event so everyone understands the sequence. | "A pallet of boxes being lifted by the forklift became unbalanced and tipped." |

| Potential Consequences | Explains what could have happened, highlighting the severity of the risk. | "The boxes fell in the walkway where a team member had been standing moments before, risking a serious crush injury." |

| Immediate Actions Taken | Shows what was done on the spot to make the area safe and prevent an immediate repeat. | "The area was cordoned off with safety cones, and the damaged pallet was removed from service." |

| Suggestions for Prevention | Captures insights from the person on the ground, who often has the best ideas for a fix. | "Install guarding on the machine." or "Repaint the walkway lines for better visibility." |

This structure moves beyond just flagging a problem and prompts immediate thought about a solution. It gathers all the crucial information needed to understand the risk and start planning a proper fix. It’s about turning a close call into a learning opportunity.

How to Get Your Team to Report Near Misses

So, you've set up a near-miss reporting system, but it’s gathering dust. Sound familiar? This is the most common hurdle. You can have the best system in the world, but it’s useless if your crew doesn’t use it.

Getting people to consistently report near misses isn’t about big announcements or top-down rules. It’s about making the process practical, fast, and free from blame.

The biggest reason workers don't report is that they think it’s not worth the hassle, especially when no one got hurt. They might also be worried about getting themselves or a coworker in trouble. Your job is to remove these barriers and make reporting a normal, helpful part of the workday, not some extra chore.

Make the Process Simple and Fast

If reporting a near miss takes more than two minutes, your team won't do it. Complicated, multi-page forms are a guaranteed way to kill participation. The process needs to feel as easy as sending a text message.

Here are a few practical ways to do that:

- Use a Mobile App: A simple app on a phone or tablet is the fastest method. Workers can snap a photo, add a few quick details, and hit 'submit' right there on the worksite.

- Accessible Paper Forms: If you’re still using paper, don't lock the forms in an office. Keep stacks of simple, one-page forms in common areas like break rooms, tool cribs, and vehicle gloveboxes.

- Keep It Focused: Only ask for what’s absolutely essential. The date, time, location, a quick description of what happened, and maybe a suggestion for a fix is often more than enough to get the ball rolling. You can always follow up for more details later.

The easier you make it to report, the more likely it is to happen. Reducing friction is everything.

Create a No-Blame System

Fear is the single biggest killer of near-miss reporting. Workers will stay quiet if they think a report will lead to punishment for them or their workmates. You have to make it clear that the goal is to fix systems, not to find fault with people.

A near-miss report is about identifying weaknesses in our procedures, equipment, or work environment. It is never about pointing fingers. When a report comes in, the focus has to be on "what went wrong," not "who messed up."

To build this trust, your supervisors and managers have to react constructively every single time. Thank the person for submitting the report. Reinforce that their input is valued. When people see that reporting leads to positive changes instead of disciplinary action, they’ll start to participate. That shift in response is critical for getting honest, consistent feedback from the frontline.

Close the Feedback Loop

People stop contributing when they feel like their input vanishes into a black hole. If a worker takes the time to fill out a near-miss report, they need to see that it leads to something. Closing the feedback loop is non-negotiable.

Here’s how you show your team that their reports matter:

- Acknowledge Every Report: A simple, "Thanks, we got it and are looking into it" is all it takes to show the submission wasn't ignored.

- Share the Actions Taken: Announce improvements during toolbox talks or post updates on a safety board. For example, "Thanks to a near-miss report from last week, we've now installed new anti-slip treads on the main stairs."

- Explain Why If No Action Is Taken: Sometimes a suggestion isn't feasible, and that’s okay. Just explain the reasoning so the worker understands they were heard, even if their idea couldn't be implemented.

When your crew sees their reports directly leading to a safer worksite, they understand the value of their contribution. This creates a positive cycle where more reporting leads to more improvements, which makes everyone safer.

Using Near Miss Data to Make Real Improvements

Collecting a near miss report is just the first step. A stack of reports sitting in an office doesn't stop the next incident. The real value comes from digging into that information and making tangible changes on the worksite.

This means shifting your mindset from simply recording what happened to actively investigating why it happened. A single near miss is a warning. A pattern of them is a roadmap showing you exactly where your biggest risks are.

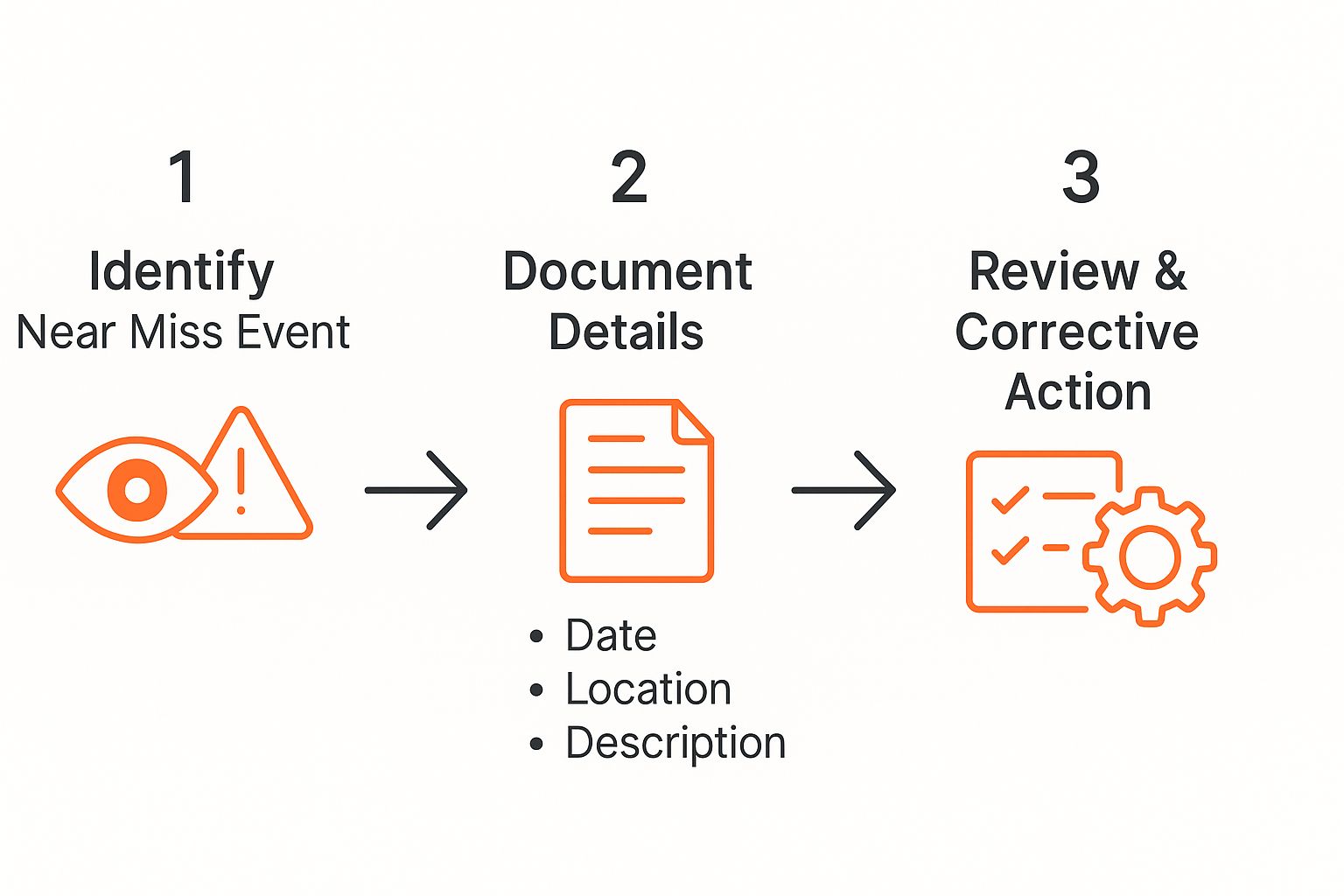

From Report to Resolution

The process of turning a report into a genuine improvement doesn't have to be complicated. It’s a straightforward cycle: identify an issue, get the details down, and then take corrective action to solve it for good.

This simple flow shows how it works.

As you can see, a near miss report isn't the end of the process. It's the trigger for a review that leads to real, practical fixes.

Spotting Trends and Finding Root Causes

The most effective way to use near miss data is to hunt for patterns. Is the same piece of equipment popping up in multiple reports? Are near misses happening more often in a specific area of the factory or during a particular shift? Spotting these trends is crucial.

Once you’ve identified a trend, the next step is to find the root cause. For example:

- Trend: You've had multiple near misses involving forklifts in Warehouse Aisle 4.

- Root Cause Investigation: After a review, you find the aisle has a blind corner with poor visibility and high foot traffic.

- Actionable Fix: The solution isn't just telling drivers to "be more careful." It’s installing a convex mirror on the corner and painting a designated pedestrian walkway.

This approach tackles the core problem, not just the symptom. You can find more detail on documenting these events with a modern incident management system, which helps track reports and resolutions all in one place.

The goal is to make it physically harder for the same near miss to happen again. You do this by changing the work environment, the process, or the tools, not by simply reminding people to be cautious.

Creating a Clear Action Plan

After pinpointing the root cause, you need a clear plan. An effective action plan specifies what needs to be done, who is responsible for doing it, and when it needs to be completed. This creates accountability and ensures the problem gets fixed.

For instance, in the resource and mining sector in New South Wales, this process is a formal requirement. Risks identified from near misses, like equipment failures, are used as leading indicators to refine procedures. It’s a powerful approach that has contributed to a reduction in serious injuries, showing how vital it is to turn reports into immediate action.

For our forklift example, a solid action plan would look like this:

- Task: Purchase and install a 60cm convex safety mirror. Owner: Maintenance Manager. Deadline: Friday.

- Task: Paint a clearly marked pedestrian-only walkway in Aisle 4. Owner: Warehouse Supervisor. Deadline: Next Monday.

By turning every near miss report into a concrete set of actions, you steadily build a safer, more reliable workplace.

Common Questions About Near Miss Reporting

Even with a solid system in place, questions about near-miss reporting always pop up. Getting clear, practical answers helps everyone on the team understand what to do and why it matters.

Here are a few of the most common questions managers and safety officers run into.

How Is a Near Miss Different from an Incident?

A near miss is an event that didn't actually cause an injury or damage, but absolutely could have. An incident, on the other hand, is when that potential is realized and something does go wrong, leading to an injury or property damage, no matter how minor.

A classic example is a box falling off a high shelf. If it lands on the empty floor right next to a worker, that’s a near miss. If that same box hits the worker's foot, it's now a recordable incident.

Both events need to be documented, but the near miss is a "free" lesson. It’s a chance to fix the root cause before someone gets hurt. You can see this distinction clearly when you look through different incident reports samples.

Who Should Fill Out a Near Miss Report?

Simple: anyone who witnesses or is involved in a near miss should report it.

The person closest to the event, whether they're a frontline worker, a contractor, a supervisor, or a visitor on site, is the one with the best view of what happened. They know the details that matter.

The key is making reporting easy and accessible for everyone, not just a task for managers. The more eyes you have looking out for potential hazards, the safer your workplace becomes.

The most effective near-miss systems are the ones where every single person on site feels responsible for flagging risks. It’s a team effort, not just a management function.

What If a Near Miss Seems Trivial?

No near miss is too small to report. A seemingly minor issue, like a small puddle of water on the floor that someone almost slips on, can be a symptom of a much larger problem, like a slow leak, a blocked drain, or a gap in cleaning procedures.

When these "trivial" events are reported, you start to see patterns. One report about a trip hazard might not seem like much on its own. But five similar reports from the same area? That points to a real, fixable hazard that needs attention. It’s the data from these small reports that often prevents the big accidents.

How Often Should We Review Near Miss Reports?

You need a system for both immediate and long-term reviews. It’s a two-speed process.

- Immediate Review: As soon as a report comes in, a supervisor or safety officer should take a look. The goal is to quickly assess if any urgent action is needed to make the area safe right now.

- Regular Review: Your safety committee or management team should then review all reports on a consistent schedule, maybe weekly or monthly. This is where you look for trends, analyze root causes, and track the progress of your corrective actions.

This approach ensures you’re putting out immediate fires while also using the data to strengthen your overall safety system for the long haul.

For example, in Australia’s maritime sector, consistent reporting is a core part of safety management. In 2020, there were 758 marine incidents involving domestic commercial vessels. Many of these started as near misses, providing crucial data that led to proactive safety fixes. You can find out more about how their marine incident reporting works.

Ready to move beyond paper forms and messy spreadsheets? Safety Space provides a simple, all-in-one platform to manage near miss reporting, track corrective actions, and spot trends before they become incidents. See how you can build a safer, more efficient workplace by booking a free demo at https://safetyspace.co.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.