Before 1984, workplace safety in Western Australia looked very different. The Occupational Safety and Health Act 1984 was the piece of legislation that completely changed the game, moving safety from an afterthought to a core business responsibility.

It marked a shift away from a reactive, blame-focused approach to a proactive one. Instead of just figuring out who was at fault after an accident, businesses were now required to identify and control risks before anyone got hurt.

A New Era of Workplace Responsibility

Before this Act, safety rules were often inconsistent and the legal system was geared towards assigning blame after a tragedy had already occurred. The 1984 Act flipped this on its head by introducing the concept of a primary “duty of care.”

Suddenly, businesses couldn’t just hope for the best. They were now legally required to provide a safe working environment, make sure machinery was properly maintained, and train their people to do their jobs without putting themselves in harm's way. This was a massive change, especially for high-risk industries like construction and manufacturing.

Why Was This Change So Critical?

The push for the 1984 Act didn't come out of nowhere. Workplaces were genuinely dangerous places, and the human cost was simply too high to keep ignoring.

To put it in perspective, in New South Wales during a pivotal year leading up to this era, there were 135 workplace fatalities. On top of that, a staggering 103,927 non-fatal injury claims were filed, revealing just how widespread the problem was. You can dig into these historical figures in this safety report.

These numbers forced a change in the conversation. The focus had to move from blaming individual workers for mistakes to fixing the systems that allowed those mistakes to happen.

The core idea was simple but powerful: the person or business that creates a risk is responsible for managing it. This principle placed the obligation squarely on employers to build safety into their operations from the ground up.

Real-World Changes on the Ground

For a tradie on a building site or an operator in a factory, the Occupational Safety and Health Act 1984 wasn't just legal jargon; it brought real, tangible changes to their daily work.

These new requirements included:

- Mandatory Risk Assessments: Businesses had to start actively looking for hazards. This meant everything from spotting unguarded machinery in a workshop to checking for unsafe scaffolding on a construction site.

- Worker Consultation: For the first time, employers were legally required to talk to their employees about safety. This gave workers a voice to raise concerns without fear of getting in trouble.

- Clearer Duties for Everyone: It wasn't all on the employer. The Act also clarified that workers had a duty to take reasonable care for their own safety and the safety of others by following the rules and procedures.

This legislation set the stage for the next few decades of safety regulation in Western Australia. It established the core principles that our modern WHS laws are still built on today and was the first major step in making proactive safety management a non-negotiable part of doing business.

Understanding Key Duties Under the Act

Before 1984, workplace safety was often a bit vague. The Occupational Safety and Health Act 1984 changed all that, moving away from a general sense of "being careful" to laying down specific, legally binding duties for everyone involved on a worksite.

Think of it like a team sport. For the team to win (and in this case, for everyone to go home safe), every player has a specific role. The Act made it clear that the business owner, the site manager, and the newest apprentice all had a part to play in preventing injuries. It created a solid chain of responsibility where safety became a shared mission.

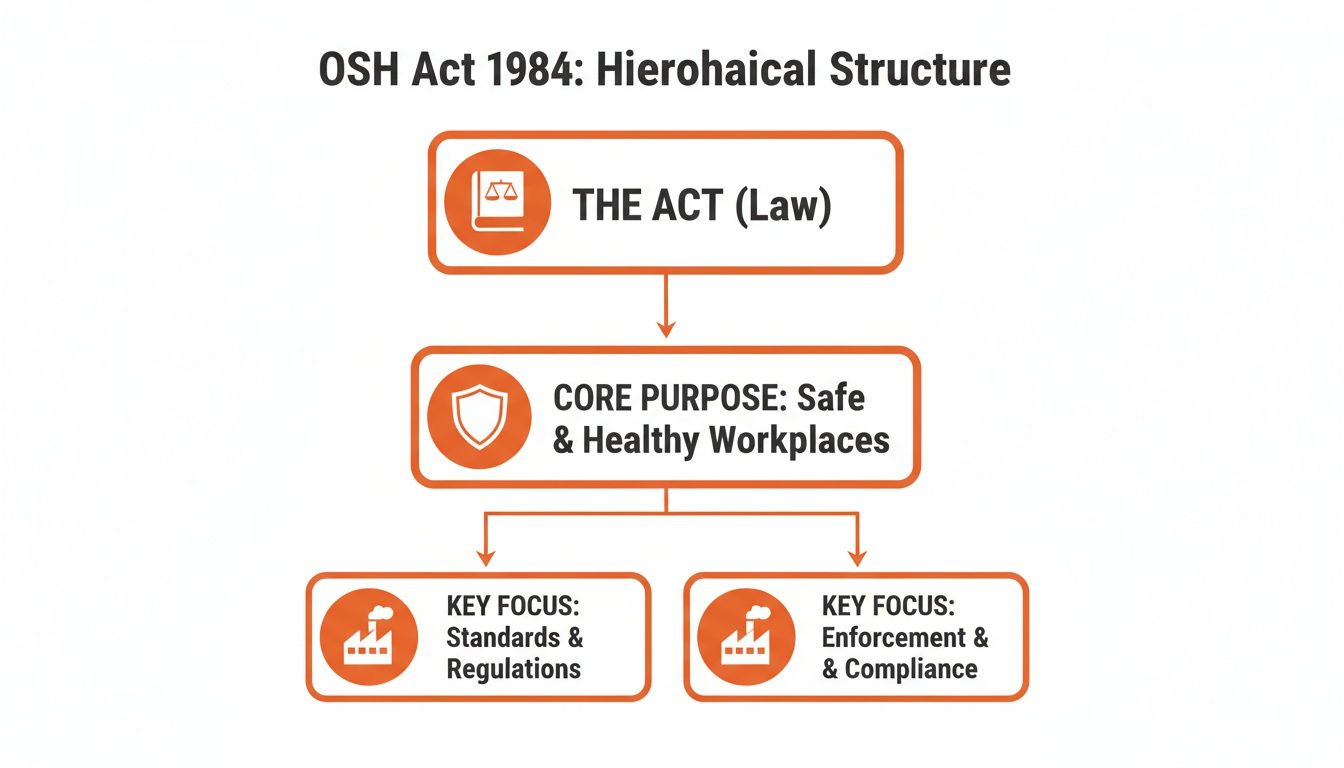

This diagram shows the basic idea behind the Occupational Safety and Health Act 1984, flowing from the law itself down to its core purpose and key focus areas.

As you can see, the legislation's main goal was protection, with a sharp focus on high-risk industries like factories and construction sites where the dangers were most obvious.

The Employer's Duty of Care

The heaviest responsibility landed squarely on the employer. The Act introduced a primary "duty of care," which meant employers had a legal obligation to do everything reasonably practicable to provide and maintain a safe working environment. This wasn't about achieving the impossible; it was about taking practical, sensible steps to manage risks.

This core duty breaks down into a few key areas:

- Safe Plant and Systems of Work: Employers had to make sure all equipment, from a simple power tool to a multi-tonne press, was safe to use and properly looked after. This required having actual systems in place for regular inspections, maintenance, and repairs.

- Safe Use of Substances: If a workshop used chemicals, solvents, or other hazardous materials, the employer was on the hook to ensure they were stored, handled, and used in a way that didn't harm anyone.

- Information, Instruction, and Training: You can’t just point a new worker towards a complex piece of machinery and expect them to be safe. The Act mandated that employers provide the right information, instructions, and training so their team could do their jobs without getting hurt.

- A Safe Workplace: This covered the physical environment itself. It meant things like ensuring clear and safe access to and from the site, good housekeeping to prevent slips and trips, and managing hazards like excessive noise or airborne dust.

Let’s put that into practice. Imagine a manager in a manufacturing plant. Under the 1984 Act, their duty wasn't just to buy a machine that came with a safety guard. It was to ensure that guard was always in place, that workers were trained on why it was there, and that there was a proper lock-out procedure for when the machine needed maintenance.

The Role of Officers

The Act also cast its net wider, looking further up the chain to company "officers" like directors and senior managers. Their job was to ensure the company as a whole was living up to its safety responsibilities. They couldn't just delegate safety to someone else and wash their hands of it.

Officers had to exercise due diligence. This meant they were personally responsible for making sure the company had the right resources, processes, and systems in place to manage safety effectively. A director, for example, had to be confident that there was a proper budget for safety gear and that managers on the ground were actually following the safety procedures.

What About the Workers?

Workers weren't just expected to stand by passively. A crucial part of the Occupational Safety and Health Act 1984 was giving workers their own set of responsibilities. This was a game-changer, as it recognised that a worker's own actions could directly impact the safety of themselves and their workmates.

A worker's key duties included:

- Taking reasonable care for their own health and safety.

- Making sure their actions (or inactions) didn't harm anyone else.

- Following any reasonable instructions from their employer on safety matters.

- Correctly using any personal protective equipment (PPE) the employer provided.

On a construction site, this meant a scaffolder had a duty not only to wear their harness but also to follow the engineered plans when putting up the scaffold. Taking shortcuts wasn't just lazy, it was a breach of their duty that could endanger everyone who set foot on it.

This shared responsibility model was the foundation of the Act. It spelled out that while employers hold the primary duty, creating a genuinely safe workplace needs everyone to be actively involved. It's a system of checks and balances designed to stop incidents long before they happen.

To make it even clearer, here’s a quick summary of who was responsible for what in a typical setting under the Act.

Key Responsibilities Under the OSH Act 1984

| Role | Primary Responsibility | Practical Example |

|---|---|---|

| Employer | Provide and maintain a safe working environment and systems of work, so far as is reasonably practicable. | A factory owner must ensure machinery has functioning guards, provide safety training for its use, and have a regular maintenance schedule. |

| Officer | Exercise due diligence to ensure the company complies with its duties under the Act. | A company director must allocate a sufficient budget for safety initiatives and regularly review safety performance reports. |

| Worker | Take reasonable care for their own safety and health and that of others, and cooperate with the employer. | A construction worker must wear their provided hard hat and steel-toed boots on site and report any identified hazards to their supervisor. |

| Self-Employed Person | Ensure their own safety and the safety of others are not adversely affected by their work. | An independent contractor must ensure their tools are in safe working order and that their work area is kept free of trip hazards. |

Ultimately, this structure ensured that safety wasn't just a policy document sitting in a drawer. It was an active, shared responsibility woven into the daily work of the workplace.

Putting Risk Management and Consultation Into Practice

Beyond just assigning duties on paper, the Occupational Safety and Health Act 1984 brought in two hands-on requirements that changed how work was done: risk management and worker consultation. These were the actions that made the Act’s principles a reality, whether on a noisy factory floor or a busy construction site.

This proactive approach marked a huge shift. Instead of waiting for an accident and reacting to it, businesses were now legally required to actively hunt for potential problems and sort them out before they could hurt someone.

This new way of thinking meant safety was no longer a box to tick. It became a core part of planning and doing the job right.

The Three Steps of Risk Management

At its heart, the Act embedded a simple but effective risk management process into workplace law. Think of it like planning a long road trip: you check your tyres, map the route, and look at the weather forecast to avoid predictable problems. That same common-sense logic was now a requirement for workplace safety.

This process breaks down into three logical steps:

- Identify the Hazard: First up, you have to find what could actually cause harm. A hazard is anything with the potential to hurt someone, from a trailing cable to a noisy machine.

- Assess the Risk: Once you've spotted a hazard, you need to work out the risk. How likely is it that someone will get hurt, and how bad could the injury be?

- Control the Risk: The final step is to take action. This means putting controls in place to either get rid of the hazard completely or, if that’s not possible, reduce the risk as much as you reasonably can.

A great example is an oil spill on a factory floor. The spill itself is a hazard. Assessing the risk means thinking about how many people walk through that area and the chances of someone slipping and suffering a serious injury. The control is simple: clean it up immediately and put up a ‘wet floor’ sign.

This systematic process forced businesses to look at their operations with fresh eyes, moving away from a reactive "clean up the mess" mindset to a preventative one. For a deeper dive, check out this guide on the modern risk assessment process, it’s built on these foundational principles.

The Duty to Consult With Workers

The other game-changer in the Occupational Safety and Health Act 1984 was the duty to consult. For the very first time, employers were legally required to talk with their people about safety, not just talk at them.

This was a massive deal. It was a formal acknowledgement that the people actually doing the work often have the best handle on the real-world risks involved. A machine operator knows the quirks of their equipment better than anyone, and a worker on the ground can spot a potential problem that an office-based manager would never see.

The Act gave this real teeth by setting up formal ways to consult, including:

- Health and Safety Representatives (HSRs): These are workers elected by their colleagues to represent them on safety matters. HSRs were given specific powers to raise issues with management and help find solutions.

- Safety and Health Committees: In larger workplaces, these committees brought management and worker representatives to the same table to discuss safety, review incidents, and develop better procedures together.

This requirement made sure safety wasn't something done to workers, but something done with them. This collaborative spirit is essential for effective risk management, because you can't identify hazards properly without open and honest communication. For workplaces handling specific hazards, like shipping dangerous goods Class 8, these conversations are absolutely critical.

Ultimately, this approach got everyone on the same team, all working toward making the workplace safer.

Enforcement and Penalties for Non-Compliance

Having clear duties on paper is one thing. Making sure they’re followed on a busy worksite is another challenge entirely. The Occupational Safety and Health Act 1984 understood this, giving real teeth to WorkSafe inspectors to get out on-site and check that the rules were being met. This was never about catching people out; it was about stopping accidents before they happened.

Inspectors were the on-the-ground enforcers of the Act. They had the power to walk onto any worksite, often unannounced, to inspect equipment, pull up documents, and talk directly to workers. If they found a problem, they had a specific toolkit to force a business to fix it, ensuring the law had a real-world impact.

Powers of WorkSafe Inspectors

When an inspector spotted a breach, they didn't just write a report and walk away. They could issue legally binding notices that demanded immediate action. This gave them the power to halt dangerous work right there and then or set a hard deadline for a business to sort out a safety issue.

The two main tools in their arsenal were:

- Improvement Notices: An inspector would issue one of these if they found a breach of the Act that needed fixing. It clearly stated the problem and gave the business a specific timeframe to get it sorted. For example, if a factory’s machine guards were missing or inadequate, an improvement notice would require compliant guards to be installed by a set date. Simple as that.

- Prohibition Notices: This was for the serious, immediate risks. If an inspector believed an activity posed a severe, imminent threat to someone's health or safety, they’d issue a prohibition notice. This shut the dangerous work down instantly until the problem was fixed. All activity related to that hazard had to stop until the inspector was satisfied it was safe to continue.

Picture a construction site where an inspector sees workers in a deep trench with no shoring to prevent a collapse. They would issue a Prohibition Notice on the activity immediately, ordering everyone out of that trench. No further work could happen there until proper safety measures were put in place and verified.

The Financial Cost of Getting It Wrong

Getting a notice wasn't the only consequence. The Occupational Safety and Health Act 1984 hit businesses where it hurt: the bottom line. It introduced financial penalties for breaches, directly linking safety failures to financial risk. For their time, these fines were significant enough to make companies sit up and take their duties seriously.

Penalties were tiered based on how bad the breach was. A simple failure, like not providing adequate facilities, might attract a smaller fine. But a breach that led to a worker's death or a serious injury would bring the full weight of the law down on the business. This system made it clear: the greater the potential for harm, the more severe the consequences. Directors and officers weren’t off the hook either; they could be held personally liable and face fines as individuals.

The stats from that era paint a stark picture of why this was all so necessary. During the period shaped by the Act, the national safety landscape was grim. In the 2006–07 period alone, there were 134,105 workers’ compensation claims for serious injuries. Worse, there were 260 compensated work-related deaths that year, hammering home the urgent need for strong laws and real enforcement. You can dig deeper into these historical numbers in this Safe Work Australia report.

These penalties and powers set a crucial precedent. They established that workplace safety was no longer a recommendation but a strict legal requirement with serious financial and operational consequences. While the fines under the 1984 Act might look modest by today's standards, they laid the essential groundwork for the much tougher penalties and industrial manslaughter laws we see in modern WHS legislation.

The Old Guard: The Act's Legacy and Why It Needed to Change

For nearly four decades, the Occupational Safety and Health Act 1984 was the bedrock of workplace safety in Western Australia. It was a groundbreaking piece of legislation for its time, embedding the crucial idea that businesses had to get on the front foot and manage workplace risks proactively. This wasn't just a small tweak; it was a huge shift that saved countless lives and prevented injuries by making safety a non-negotiable part of doing business.

But the world of work doesn't stand still. New industries emerged, technology advanced, and community expectations around what constitutes a 'safe' workplace grew stronger. The old Act, as solid as its foundations were, began to show its age. Its limitations became obvious as serious incidents, unfortunately, kept happening.

Where the 1984 Act Fell Short

By the 2010s, it was clear the old rulebook had some serious gaps. For starters, the penalties for breaking the law simply weren't a big enough stick anymore. A fine that might have seemed hefty in the 1980s barely registered as a cost of doing business for a large company decades later. The deterrent effect had worn off.

Another major blind spot was its narrow focus on physical safety. The Act was great at dealing with tangible hazards like machine guarding or preventing falls from height, but it had very little to say about modern health issues. It was ill-equipped to handle the growing problem of psychological hazards, such as workplace stress, burnout, and bullying.

The Occupational Safety and Health Act 1984 laid a vital foundation, but its effectiveness was fading. Even with the Act in place, the state's fatality rates in high-risk sectors like agriculture, transport, and construction remained stubbornly high. This was a clear signal that a much stronger, more modern legal framework was desperately needed. You can dig into the historical data in this UWA research summary.

A New Era: The WHS Act 2020

To drag workplace safety into the 21st century and bring WA in line with the rest of Australia, the government made a huge move. In 2022, the old Act was officially retired and replaced by the Work Health and Safety (WHS) Act 2020. This wasn't just a fresh coat of paint; it was a complete rebuild from the ground up.

The WHS Act introduced some real game-changers:

- Industrial Manslaughter Laws: For the very first time, a specific criminal offence was created for workplace deaths caused by negligence. This came with the very real threat of jail time for individuals.

- Massively Increased Penalties: The fines were scaled up dramatically. For a corporation, the maximum penalty for the most serious breaches jumped to a staggering $10 million.

- Stronger Officer Duties: The concept of 'due diligence' was beefed up, placing a much heavier burden on directors and senior leaders to be actively involved in safety.

- Focus on Psychosocial Health: The new laws made it clear that managing risks to psychological health is just as important as managing physical safety.

The message from this transition is clear. While the proactive safety principles of the 1984 Act are still there, the consequences for getting it wrong are now in a completely different league. The legal and financial risks for businesses and their leaders have never been higher.

For any business operating today, understanding this history is crucial. Compliance is no longer about ticking boxes from an old manual. It demands a holistic approach that covers every angle of worker health and safety, all under a much tougher and more demanding legal framework. You can explore the specifics in our detailed guide on the Work Health and Safety Act WA.

How to Manage Safety Compliance Today

The principles of the Occupational Safety and Health Act 1984 set the stage, but today’s safety managers are playing a completely different game. The rules have evolved from that original foundation, creating a mountain of paperwork, endless tracking, and constant pressure to prove you're doing the right thing.

For managers in construction and manufacturing, it's a daily battle.

You’re trying to juggle subcontractor pre-qualifications, chase down missing Safe Work Method Statements (SWMS), and manually track who’s done their training and when their tickets expire. It's a huge time drain. This admin pulls you off the worksite where you're actually needed and buries you under a pile of tasks that feel like they never end. With this manual approach, spotting trends or getting ahead of problems is almost impossible.

This is exactly where modern tools come in. Digital safety management platforms aren't just a nice-to-have; they’re designed to solve these specific headaches, replacing messy spreadsheets and overflowing filing cabinets for good.

Moving Beyond Paper and Spreadsheets

Imagine having all your safety information in one place, accessible from your ute, the office, or home. Instead of digging through folders to find a specific SWMS, you could pull up a real-time dashboard showing you exactly what’s happening across all your sites.

That's what centralising your compliance data does. It gives you instant visibility.

- Real-Time Monitoring: See at a glance who has completed their inductions, which subcontractors are compliant, and if any incident reports are still outstanding.

- Automated Workflows: Set up automatic reminders for expiring licences or upcoming training. The system does the chasing for you, cutting down on all those follow-up calls and emails.

- A Clear Audit Trail: Every single action, from a toolbox talk sign-off to a completed risk assessment, is automatically recorded and timestamped. This creates an unbreakable record of your safety activities, which is vital for proving due diligence if something goes wrong.

With a digital system, you’re no longer just reacting to safety issues. You finally have the data to spot patterns and address risks before they turn into incidents. It lets you manage safety from the front foot.

The Practical Benefits of a Digital Approach

Making the switch from paper to a platform like Safety Space delivers immediate, tangible results. It drastically cuts down the administrative load, freeing up your safety managers to spend more time on the floor, actually talking with workers and improving safety practices where it counts.

For those looking to deepen their expertise, there are plenty of great Occupational Health and Safety courses available to upskill your team. Combining the right skills with the right tools is what makes modern compliance work.

A solid first step is simply getting your core documents in order. You can start today by downloading a free Occupational Health and Safety Management Plan template to give your safety approach some real structure.

Your OSH Act Questions Answered

When it comes to workplace safety laws, things can get confusing, especially with the recent shift in legislation. Let's tackle some of the most common questions we hear about the old Occupational Safety and Health Act 1984 and what it all means for businesses today.

Is the Occupational Safety and Health Act 1984 Still in Force in WA?

In short, no. The Occupational Safety and Health Act 1984 was officially replaced by the Work Health and Safety Act 2020 (WHS Act). The new laws came into effect across Western Australia on 31 March 2022.

But that doesn't mean the old Act is irrelevant. Its core ideas are all over the current WHS rules. Think of it as the foundation upon which the much tougher, more modern legislation was built. Understanding where we've come from helps make sense of why today's safety landscape looks the way it does.

What’s the Biggest Difference Between the Old OSH Act and the New WHS Act?

The game really changed with two things: the introduction of industrial manslaughter as a specific crime and a massive hike in penalties. These changes seriously raised the stakes for getting safety wrong.

Fines under the new WHS Act are on another level, with the most serious breaches now costing a company up to $10 million. The new laws also brought in a much stronger, more personal responsibility for company directors and officers to be actively involved in safety, a duty known as 'due diligence'.

On top of that, the definition of 'health' was officially expanded to explicitly include psychological health. This wasn't just a suggestion; it made managing mental wellbeing at work a non-negotiable legal duty.

The core shift is all about consequences. While the old Act was focused on having the right systems on paper, the new WHS Act is laser-focused on the severe legal and financial pain for businesses and individuals if those systems fail to keep people safe.

If My Business Complied with the 1984 Act, Am I Compliant with the New WHS Act?

Not necessarily. If you were compliant with the old Act, you’ve got a good head start, but it’s definitely not a guarantee you're meeting the new WHS standards. The 2020 laws brought in fresh duties and demand a much more proactive approach to managing safety.

Take the 'due diligence' duty, for example. It requires company officers to personally take reasonable steps to ensure the business is following the law. This is a far more hands-on role than what was expected under the old Occupational Safety and Health Act 1984.

It’s time for a health check on your entire safety management system. You'll need to hold it up against the WHS Act 2020 requirements and hunt for any gaps. Pay special attention to these areas:

- Officer Due Diligence: Do your senior leaders have clear processes to stay across safety issues and make informed decisions about resources?

- Psychological Risk Management: Are you actively identifying and controlling hazards to mental health, like workplace bullying, stress, or burnout, in your risk assessments?

- Consultation Mechanisms: Have you reviewed how you consult with your workers? Your processes need to be solid and cover all the requirements of the new legislation.

Running through this checklist is the first practical step to making sure your business is properly aligned with today's laws.

Bringing your safety systems up to modern standards can feel like a huge task, but the right tools make it manageable. Safety Space cuts through the clutter of old-school paperwork and messy spreadsheets. It gives you a single, straightforward platform to see what’s happening across your entire safety system in real-time. From managing subcontractors to reporting incidents, it provides the solid structure you need to protect your people and prove your compliance.

See how it works by booking a free demo at https://safetyspace.co.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.