When you're dealing with high-risk jobs, you can't leave things to chance. That’s where a permit to work system comes in. Think of it as a mandatory safety pause before the real work begins, like a pilot running through a pre-flight checklist. It's not just another piece of paper; it’s a critical communication tool that ensures everyone is on the same page.

Understanding the Permit to Work System

At its heart, a permit to work (PTW) system is a formal, documented process that gives specific people authorisation to carry out a specific job, at a specific time. It clearly outlines the main hazards and lays out the exact precautions needed to get the job done safely.

Crucially, it’s not a substitute for a risk assessment. Instead, it’s the direct result of one, put into action for only the highest-risk tasks.

You can think of it as a formal agreement between the person running the site (the permit issuer) and the team doing the work (the permit receiver). This handshake-on-paper confirms that all known risks have been properly considered and that every protective measure is in place and working.

The Core Purpose of a Work Permit

The number one goal of any permit to work system is to prevent incidents by actively managing risk. It does this by forcing structured planning and clear communication between everyone involved, from the site managers right down to the workers holding the tools. This isn’t about adding red tape; it's about building certainty into complex and hazardous situations.

A solid PTW system provides a clear record that answers the most critical questions before anyone starts work:

- What exactly is being done? This locks in the scope of the job.

- Who is responsible? This assigns clear accountability.

- What are the specific hazards? It forces everyone to identify the real dangers.

- What precautions are in place? This lists the non-negotiable safety controls.

- How long is the work authorised for? It sets a clear, limited timeframe for the permit's validity.

By formalising the answers to these questions, a permit to work system ensures nothing is left to assumption. It takes what might be a quick chat or a vague understanding and turns it into a documented, verifiable plan that everyone can see and agree on before a single tool is lifted.

This structured approach is essential in dynamic environments like construction sites or manufacturing plants where conditions can change in an instant. A permit acts as a stable reference point. It guarantees that even with multiple teams and contractors on-site, high-risk jobs are managed with a consistent, documented level of control from start to finish.

Why Your Business Needs a Permit to Work Process

A permit to work system isn't just a bit of extra paperwork. In many high-risk scenarios, it's a non-negotiable part of meeting your legal duties under Australian Work Health and Safety (WHS) laws. Think of it as a practical, clear method for proving you've done your due diligence when organising dangerous work.

This process creates a formal, auditable record showing you’ve identified the major hazards and put specific controls in place before anyone picks up a tool. It’s a critical defence against both incidents and potential legal action. If something goes wrong, a properly completed permit is tangible evidence that you followed a structured process to manage the risks involved.

The system has grown up alongside Australia’s WHS laws and is now standard practice in industries like construction and mining for a good reason. The data shows that workplaces with strict PTW systems have far better safety outcomes. In fact, sectors with rigorous permit enforcement saw work-related injury rates roughly 30% lower than those with weak or non-existent controls. You can dig deeper into the impact of these formal safety systems in the Future Skills Organisation's 2025 report.

Managing Complex and High-Risk Jobs

On a busy, noisy site, just telling someone what to do isn't good enough. It’s too easy for things to get missed. A permit to work brings much-needed structure, especially when you're managing complex jobs or trying to coordinate multiple contractors working in the same small area. It’s designed to stop dangerous overlaps and make sure one team’s work doesn't create a new, unexpected hazard for another.

A classic example is preventing the accidental start-up of machinery during maintenance. The permit formalises the lockout-tagout procedure, acting as a final check to confirm that the equipment is isolated, de-energised, and verified as safe before a mechanic even touches it.

This level of control isn't optional for certain tasks where the margin for error is zero. In these situations, a permit is standard practice and, in many cases, legally required.

You absolutely need a permit for jobs like these:

- Hot Work: Any task involving welding, cutting, or grinding that could ignite flammable materials. The permit confirms a fire watch is in place and all combustible materials have been cleared.

- Confined Space Entry: Before anyone enters a tank, vessel, or pit, a permit verifies atmospheric testing is complete, rescue plans are ready, and attendants are assigned.

- Electrical Work: For high-voltage jobs, a permit ensures the right circuits are isolated and tested, which is crucial for preventing electrocution.

- Working at Height: When a job requires complex scaffolding or specific fall arrest systems, the permit documents their inspection and correct setup.

A solid permit to work system is the operational backbone for organising dangerous work. It moves safety from a general idea to a specific, actionable plan that is documented, authorised, and checked at every critical step, protecting both your workers and your business.

Common Types of Work Permits on Site

Not all high-risk jobs are created equal, so a single, generic permit to work just won’t cut it. Different tasks carry their own unique hazards, and each one demands specific, targeted controls. Knowing which permit to grab for the job is the critical first step in applying the right safety measures on the ground.

These permits aren't just about ticking boxes; they are purpose-built documents designed to control a specific set of life-threatening risks. You’ll find different types of permits on any major construction or industrial site, and each one serves a very distinct purpose.

Let's get into the most common ones you'll see out in the field and the specific problems they’re designed to solve.

Hot Work Permits

A Hot Work Permit is non-negotiable for any job that generates sparks, open flames, or intense heat. We’re talking about tasks like welding, grinding, soldering, or using a cutting torch. The obvious danger here isn't just the work itself but the very real potential for it to ignite flammable materials in the surrounding area, sparking a fire that can quickly get out of control.

Picture a welder working on a new pipe installation inside a factory. Before they can even strike an arc, a Hot Work Permit forces a thorough check of the entire work zone, typically a 10-metre radius. This ensures all combustible materials like oily rags, wood scraps, or chemicals are cleared out. The permit also confirms a fire extinguisher is right there on hand and a dedicated fire watch is assigned to monitor the area, both during and after the job.

Confined Space Entry Permits

When a worker needs to enter a space that isn't designed for people to be in and has a tricky entry or exit, a Confined Space Entry Permit is mandatory. This could be a storage tank, a large-diameter pipe, a sewer, or a deep excavation. The risks here are severe and often invisible, including toxic gases, a lack of oxygen, and the potential for engulfment by liquids or solids.

Imagine a team is tasked with cleaning the inside of an industrial storage vessel. That entry permit is their lifeline. It verifies that the air inside has been tested for safe oxygen levels and harmful gases before anyone climbs in. Crucially, it also documents the entire rescue plan, spelling out the exact equipment and personnel needed to get someone out fast in an emergency. For a deeper look, check out our guide on managing confined space and working at heights.

The permit acts as a final checkpoint, ensuring every single control, from atmospheric testing to having a standby person, is physically in place before the hatch is opened. It turns a potentially fatal task into a carefully managed procedure.

Electrical Work and Isolation Permits

An Electrical Work Permit, often called an Isolation or Lockout-Tagout (LOTO) Permit, is used for any job on or near energised electrical equipment. Its primary job is simple but vital: to prevent electrocution by making sure the right energy sources have been shut off and locked out.

If an electrician needs to replace a faulty circuit breaker in a large switchboard, this permit is the law. It provides a formal, signed-off record that the correct circuit has been identified, de-energised, physically locked with a personal lock and tag, and then tested to confirm it’s dead. This process is what stops someone else from accidentally flipping the power back on while the work is underway.

While this guide focuses on permits for specific operational tasks, it's worth noting that businesses also navigate other types of formal permissions. For instance, the process of obtaining an occupancy permit is a crucial step before a building can be legally used, ensuring it meets all safety and building codes.

Quick Guide to Common Permit Types

To make it even clearer, here's a quick rundown of the most common permits you'll encounter on a worksite. Each is tailored to a specific set of high-stakes activities.

| Permit Type | Typical Activities | Key Safety Control |

|---|---|---|

| Hot Work | Welding, grinding, torch cutting, soldering | Fire prevention through clearing combustibles, fire watch, extinguisher availability |

| Confined Space | Tank entry, vessel cleaning, sewer access | Atmospheric testing, continuous monitoring, standby person, and a solid rescue plan |

| Electrical/Isolation | Working on circuits, switchboards, machinery | De-energisation, lock-out/tag-out (LOTO), and verification of zero energy |

| Excavation | Trenching, digging foundations, earthworks | Preventing collapse through shoring, sloping, and regular soil inspections |

| Working at Height | Scaffolding, roof work, using EWPs | Fall prevention systems (e.g., harnesses, guardrails) and equipment checks |

This table shows at a glance how each permit system is designed to tackle the unique dangers of a task, forcing teams to pause and verify that the right controls are in place before work begins.

How to Implement a Permit to Work System

Putting a permit to work system in place isn’t about adding layers of bureaucracy for the sake of it. It’s about creating a clear, repeatable process that everyone on site understands and follows. Think of it as building a structured safety checklist for your most dangerous jobs, starting with a solid foundation of clear roles, straightforward procedures, and good training.

The whole process kicks off with a thorough pre-job risk assessment. This is not just a box-ticking exercise; it’s the engine that drives the entire permit system. The assessment identifies the specific hazards of the task, which then tells you exactly what controls and conditions need to be listed on the permit. Without a solid risk assessment, the permit is just an empty form.

Defining Clear Roles and Responsibilities

For any permit system to actually work, everyone needs to know exactly what their part is. There’s simply no room for guessing who is supposed to do what, because ambiguity on a high-risk job site leads to serious mistakes.

You need to clearly define these key roles:

- Permit Issuer: This is typically a site manager or supervisor who has the authority and competence to issue the permit. They’re the ones responsible for confirming the risk assessment is done and that all the required safety precautions are physically in place before signing off.

- Permit Receiver/Holder: This is the person leading the work crew, like a leading hand or contractor supervisor. Their job is to understand every condition on the permit and make sure their team follows them to the letter.

- Affected Workers: These are the team members on the tools. They must be trained to understand the permit, follow its rules, and have the authority to stop the job if conditions change or don’t match what the permit says.

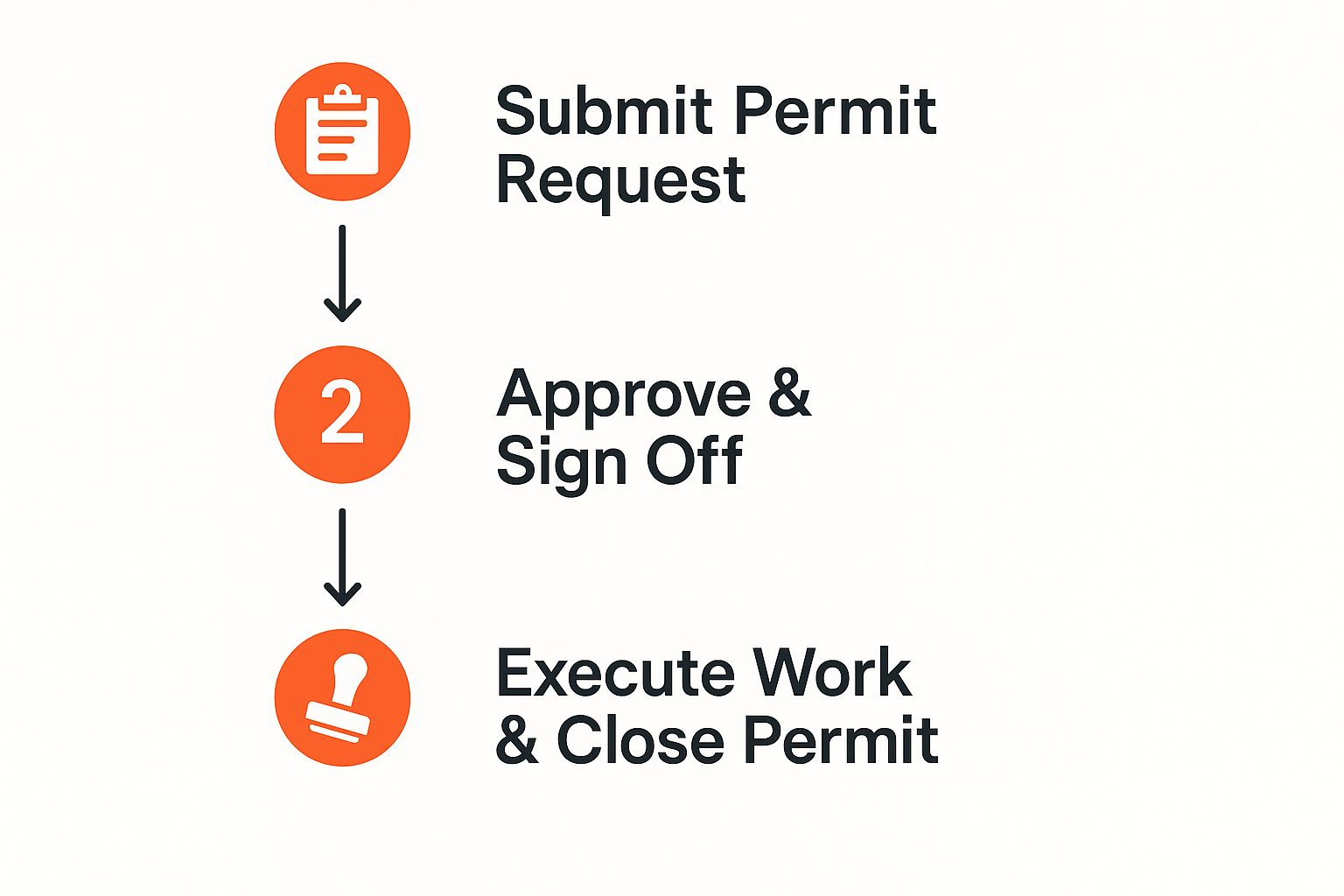

The flowchart below shows how a permit moves from the initial request right through to final closure, highlighting each critical stage.

As the visual shows, the system is a closed loop. It’s designed to ensure work not only starts safely but is also formally completed and the area handed back in a safe state.

Developing Simple and Effective Procedures

Your procedures are the rules of the game. They need to be clear, easy to follow, and written in plain language that everyone on site understands, no matter their background. A successful Permit to Work system hinges on well-defined policies. If you need a hand with that, resources on how to write effective policies can provide some excellent guidance.

Keep your language simple and direct. This is especially vital in Australia, where as of April 2025, the workforce includes around 2.84 million temporary visa holders. With so many of these workers in high-risk industries like construction and manufacturing, clear communication is non-negotiable. Your procedures, much like a good safe work procedure, should leave absolutely no room for misinterpretation.

Your system must have clear rules for shift handovers. What happens when a permit is valid for 12 hours, but the crew changes after 8? The procedure needs to spell out exactly how the outgoing supervisor formally hands over responsibility and communicates the job's status to the incoming one.

Finally, you need a solid process for closing out permits. This means the permit receiver signs off to confirm the work is finished, the area has been left safe, and all tools have been packed up. The permit issuer then does a final inspection before formally closing the permit. This last step is crucial for making sure the area is genuinely safe for normal operations to resume.

Common Permit System Failures and How to Fix Them

Even the most carefully designed permit to work system can fall apart in the real world. The moment the paperwork becomes more important than the on-the-ground safety checks, the system starts to fail. It loses its value and, even worse, creates a dangerous false sense of security.

Spotting these weak points is the first step to fixing them before an incident happens.

One of the most common problems I’ve seen is "pencil-whipping." This is where a supervisor signs off on a permit from their office, without ever setting foot on the worksite to check if the controls are actually in place. This shortcut completely defeats the purpose of the permit, turning a critical safety check into a meaningless box-ticking exercise.

Another major breakdown happens when workers don't truly understand the controls listed on the permit. They might see a line item like "atmospheric testing complete," but do they know what the acceptable gas readings are? Do they know what the alarm on their monitor actually means? The permit is only effective if the people doing the work understand the "why" behind every single precaution.

Spotting and Fixing Common Problems

Let’s be clear: fixing these issues isn’t about creating more paperwork. It’s about practical, on-the-ground actions that ensure the permit reflects reality. You can start by making small but powerful changes to how permits are handled day-to-day.

Here are three direct ways to tackle these problems head-on:

Conduct Regular Field Audits: Don’t just file completed permits away. Get your managers or safety leads to take a live permit out to the job site and check it against what’s actually happening. Is the fire watch where they should be? Is the excavation shoring installed exactly as described? These spot-checks are brilliant for quickly revealing if corners are being cut.

Require Physical Verification: This one is non-negotiable. The permit issuer must physically inspect the work area and verify every single control before they sign the authorisation. This simple step single-handedly crushes the risk of pencil-whipping and guarantees a second set of competent eyes has reviewed the setup.

Implement a Clear "Stop Work" Process: Every single worker needs to know they have the full authority and backing to stop the job if the permit conditions aren’t being met. If a permit requires a standby person for a confined space entry and that person wanders off for a smoke, the crew inside must feel completely confident to call a halt immediately, without fear of getting in trouble. This gives your team the final, crucial check on the system.

When a permit system fails, it's rarely the document itself that's the problem. The failure is almost always in its application. A permit is not a shield; it's a live action plan that must be actively managed from start to finish.

The data confirms just how high the stakes are. According to Safe Work Australia reports, around 20% of serious incidents in mining and construction were linked to failures in the Permit to Work process.

But there's good news. The shift to digital platforms is showing real results, with some sites cutting permit errors by up to 40%. One major WA mining company even reported a 50% drop in lost-time injuries after they moved to a computerised system. You can find out more about how these safety trends are shaping Australian employment outlooks for 2025.

Moving From Paper to Digital Permit Systems

For years, the paper permit on a clipboard has been a familiar sight on worksites. It's the way things have always been done. But anyone who’s ever managed a complex job knows this old-school method is riddled with problems that can bring a project to a grinding halt.

Paper forms get lost, soaked by rain, or buried under a mountain of other documents in the site office. Illegible handwriting can make critical instructions a guessing game, and chasing down the right signatures often leaves skilled teams just standing around, waiting for a simple approval. On a big site, just trying to keep track of all the active paper permits is a full-time headache.

The Problems With Paper-Based Permits

The issues with traditional paper systems go beyond minor annoyances, they create serious operational bottlenecks and dangerous blind spots. A supervisor walking the site has no quick way to get a live overview of all the high-risk work happening at that very moment.

Here are the most common frustrations that come with relying on paper:

- Lost or Damaged Forms: A single permit left on the ute's dashboard or dropped in the mud can stop a high-risk job dead in its tracks.

- Approval Delays: Wasting hours hunting down a site manager for a physical signature is a massive drain on valuable work time.

- Poor Visibility: It’s nearly impossible to get a real-time picture of how many hot work or confined space permits are active across a large facility.

- Difficult Audits: Trying to find a specific permit from three months ago for an incident investigation can mean digging through stacks of disorganised, dusty files.

A digital system transforms this chaotic, manual process into a clear, organised workflow. It gives supervisors the instant access they need to do their jobs properly, right from a tablet or phone.

How Digital Platforms Solve These Problems

Switching to a digital permit to work platform tackles these long-standing issues head-on. Instead of relying on loose sheets of paper, all your information is centralised in one place, ready for anyone who needs it, whenever they need it.

This shift makes the entire process far more efficient and reliable. Approval workflows are automated, pinging notifications directly to the right people for immediate sign-off. That means less downtime for your crews and a much smoother flow of work throughout the day.

For managers, the benefits are huge. A digital dashboard offers a live map of all active permits, showing exactly what high-risk work is happening and where. This gives them the critical oversight needed to manage site-wide risks effectively.

Audits become incredibly simple. Forget the manual search through filing cabinets. You can pull up any permit in seconds, complete with a clear, time-stamped record of every single action and signature. Exploring the range of available workplace safety apps shows just how this technology is being used to solve these long-standing operational headaches for good.

Got Questions About Your Permit System?

Here are some quick answers to the questions we get asked most often about managing a permit to work system on a busy site.

Who Is Responsible for Signing a Work Permit?

Several people have to sign off on a permit, and each signature means something different. The permit issuer, usually a site supervisor or manager, is the one who authorises the work. They sign only after they've been to the work area and physically checked that every safety control is in place.

Next up is the permit holder (or receiver). This is the person leading the crew doing the job. When they sign, they're confirming they understand all the conditions of the permit and are taking responsibility for making sure their team follows them to the letter.

Can a Permit Be Changed After It Is Issued?

Absolutely not. A live permit should never be altered or added to. If the job scope changes, or if site conditions shift, maybe the weather turns or another team starts work nearby, the original permit is immediately invalid. The work has to stop.

The only safe way forward is to suspend the original permit, carry out a completely new risk assessment for the new situation, and then issue a brand new permit to work. This is the only way to guarantee that any new hazards have been properly identified and controlled before work kicks off again.

Think of a permit as a snapshot in time. If the picture changes, you need to take a new one. Trying to just edit a live permit leaves a massive, dangerous gap in your risk management.

How Long Should We Keep Completed Work Permits?

Good record-keeping isn't just about compliance; it's how you learn and improve. Australian WHS regulations are clear that you must keep records related to high-risk work, and completed permits are a critical piece of that puzzle.

As a general rule, you should keep completed permits for the duration of the project as an absolute minimum. But what if there's an incident investigation months or even years later? For this reason, many companies now hold onto them for several years. Digital systems make this a non-issue, letting you archive and pull up any permit instantly without needing boxes of old paper cluttering up the office.

Ready to swap out messy paperwork for a clear, efficient, and compliant digital solution? Safety Space gives you a single place to manage your entire permit to work process, from the first request to the final sign-off. Book a free demo and H&S consultation to see how you can get proper control of your high-risk work.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.