Reporting near misses is one of the most practical ways to stop serious injuries before they even have a chance to happen. It's all about documenting those unplanned events that didn't cause any harm but absolutely had the potential to. Think of a tool falling from scaffolding and landing just centimetres from a worker.

The whole point is to use these 'close calls' as real-world data to fix the underlying problems before your luck runs out.

Why Reporting Near Misses Actually Matters

Let's cut to the chase. Every single major workplace incident is foreshadowed by smaller warnings. Reporting near misses is one of the best ways to spot these warnings and act on them before someone gets seriously hurt.

This isn't about filling out paperwork to tick a compliance box. It’s about gathering important information from the factory floor or the construction site to genuinely make the workplace safer for everyone.

A simple report about a frayed electrical cable, a patch of spilled oil, or a wobbly bit of scaffolding isn't just a complaint. It's a data point flagging a failure in a system, a process, or a piece of equipment. When these "small" issues are ignored, they almost always become the direct cause of a future injury.

From Close Calls to Concrete Fixes

Think of it this way: a near miss is a free lesson. It gives you all the insight of an actual accident, but without the awful consequences.

For instance, a report about a forklift turning a blind corner too quickly can lead to installing mirrors or painting designated walkways. That simple, low-cost fix, prompted by a close call, can prevent a horrific collision down the line.

The true value in reporting near misses comes from this proactive mindset. It shifts the focus from reacting to injuries to actively preventing them. This is just a smarter, more effective way to manage workplace safety. To really get the fundamentals, you can learn more about what is a near miss in our detailed guide.

A common mistake is thinking that if no one got hurt, it's not a big deal. The reality is that a near miss is a clear signal that a hazard exists and will almost certainly cause harm if left unchecked.

Overcoming On-Site Scepticism

Let's be honest, many workers, and even some managers, are sceptical about reporting. They might see it as a waste of time or, worse, fear they’ll get someone in trouble. This is a massive roadblock.

The key to breaking down this barrier is to show that every single report leads to a real outcome. When people see that their report about a loose guard rail actually gets it fixed, they start to believe the process works.

This isn't about pointing fingers. A proper near-miss system focuses on figuring out the why behind the event.

- Why was that floor slippery?

- Why was that piece of equipment left in a walkway?

- Why did the safety gate malfunction?

By asking these questions, you move beyond blame and start fixing the root causes. When a near miss is reported, investigated, and closed out, it proves a genuine commitment to everyone's safety. It shows that it’s a smart tool, not just another box-ticking exercise.

How to Build a Simple Near Miss Reporting System

Let's be honest. A reporting system is only as good as the number of people who actually use it. If reporting a near miss feels like a mission, hunting down a supervisor, digging up the right paper form, then losing 15 minutes to paperwork, it’s just not going to happen.

The goal here is to build something so quick and painless that there’s no reason not to use it. The secret is to remove every single point of friction.

Think about how your team uses their phones. Everything is quick, mobile, and intuitive. Your near-miss system needs to feel the same. The whole process, from spotting the hazard to hitting 'submit', should take less than two minutes.

A really effective way to do this is with QR codes. Stick a weatherproof QR code on the side of a key piece of machinery, at site entry points, or in the lunchroom. A worker scans it, and it takes them straight to a simple, mobile-friendly form. No logins, no clunky menus, just a direct line to report what they saw.

Make Reporting Accessible and Fast

The accessibility of your reporting tool is the single biggest factor in its success. When a worker spots a potential hazard, the window to capture that information is tiny. They're busy, they have a job to do, and they won't stop what they're doing for something that feels like a hassle.

This is where a digital approach becomes a must-have. Here in Australia, underreporting is a massive blind spot for many companies. Some estimates suggest that a staggering 31% of all safety incidents, including near misses, are never reported. That’s a huge gap in safety information, especially when you consider that close to 500,000 work-related injuries happen each year. A huge driver for this is the sheer effort involved.

The core principle is simple: make it easier to report a near miss than to ignore it. A 90-second scan-and-report process will always beat a 10-minute paper chase.

What to Include on Your Near Miss Form

Once you’ve made reporting easy, the next job is to make sure you’re collecting the right information. Your form needs to find that sweet spot between gathering enough detail for an investigation and not overwhelming the person reporting. Stick to the absolute essentials.

A bloated form with a dozen fields will kill participation just as fast as a hard-to-find paper version. Focus only on what you need for the initial review.

Essential Fields for Your Near Miss Report Form

Here’s a practical checklist of what to include on your form. The idea is to gather useful data without making the reporter feel like they're writing an essay.

| Field Name | What to Ask | Why It's Important |

|---|---|---|

| Location | Where did this happen? (e.g., Workshop Bay 3, Level 2 Scaffolding) | Pinpoints the exact area for immediate inspection and risk assessment. |

| Date & Time | When did the near miss occur? | Helps establish context, like time of day or shift, which can be a critical factor. |

| Description | What happened? Be specific. | This is the core data. It tells the story of the event for the review team. |

| Photo/Video Upload | Can you add a photo or video? | A picture is worth a thousand words. It provides undeniable proof and context. |

| Immediate Actions | Did you take any immediate action? (e.g., moved the trip hazard) | Shows initiative and helps determine if the immediate risk has been controlled. |

Keeping the form this lean makes it incredibly fast to complete on a mobile device, right there on the spot. You can always gather more detail during the follow-up investigation. A modern incident management system can automate this data collection and kick off the next steps without anyone lifting a finger.

The Post-Report Workflow: What Happens Next Matters Most

Submitting the report is just the start. What happens next is what truly builds trust and makes the entire system work. A clear, transparent follow-up process shows your team that their reports are taken seriously and lead to real, tangible action.

This workflow doesn't need to be complicated. It just needs to be consistent and well-communicated.

Immediate Notification: The moment a report is submitted, key people should get an automatic alert. This could be the site supervisor, the Health and Safety Manager, and maybe an area manager. Real-time alerts mean risks can be assessed almost instantly.

Initial Triage and Review: The designated person (often the H&S Manager) should review the report within a set timeframe, like 24 hours. Their first job is to assess the severity. Is this a critical risk that requires an immediate shutdown, or something that can be scheduled for a fix?

Communicate Back to the Reporter: This step is crucial. Acknowledge the report. A simple automated email or notification saying, "Thanks, we've received your report and are looking into it," makes a world of difference. It closes the loop and validates their effort. Integrating the ability to electronically sign documents can also improve any approvals or formal acknowledgements in your workflow.

Action and Closure: Finally, the issue is investigated, a corrective action is implemented, and the loop is closed with the original reporter. Letting them know what was done because of their report is the single most powerful way to encourage them, and their colleagues, to report again in the future.

From Report to Resolution: The Investigation Workflow

A near-miss report that just sits in an inbox is pointless. Its real value comes from what you do next. The process of turning that initial report into a concrete fix is where you actually start preventing future injuries.

This isn't about launching a massive, formal investigation for every single report. It's about having a practical, repeatable workflow that moves a report from acknowledgement to resolution without getting bogged down. The goal is simple: find out why something happened and fix it for good, not find someone to blame.

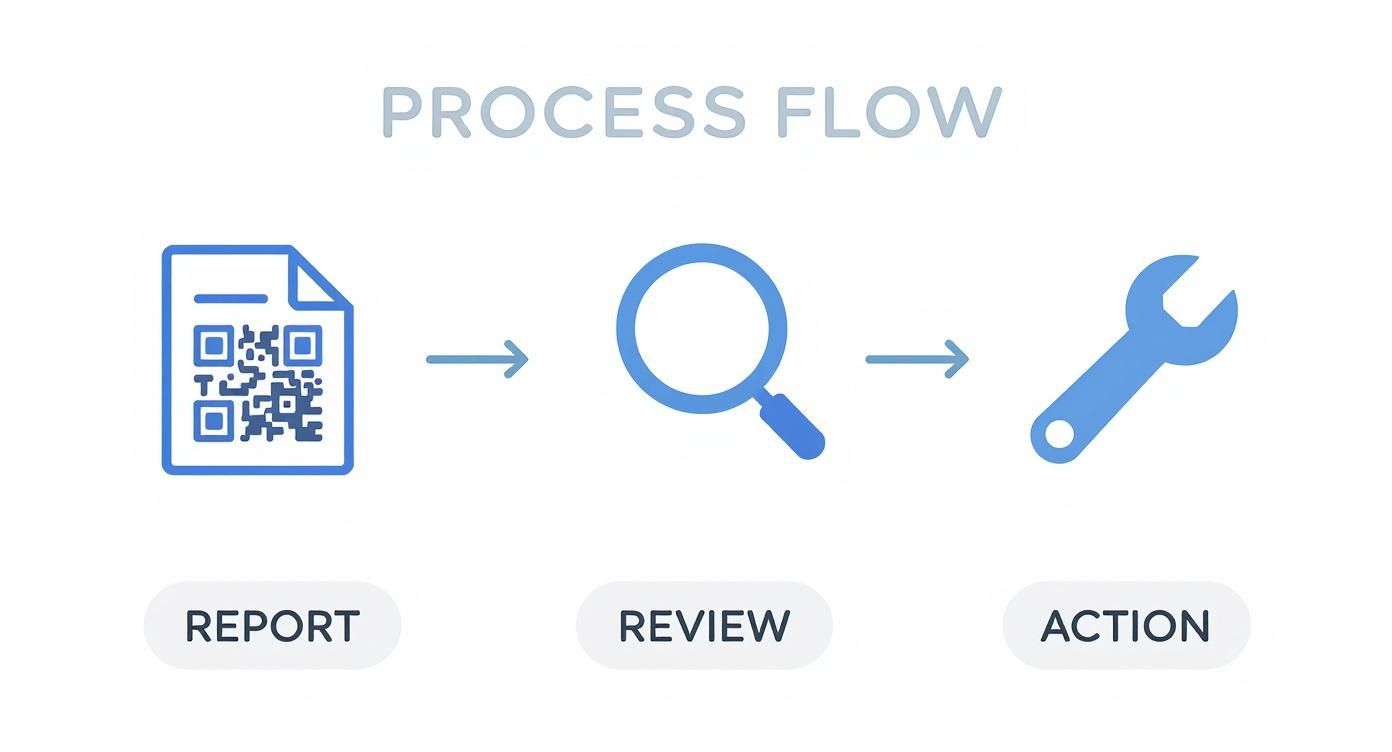

This workflow breaks down the core steps from a new report to a closed-out action.

This visualises how a report travels from submission through to a meaningful corrective action that actually closes the loop.

Assembling the Right Review Team

You don't need a huge committee for most near misses. In fact, a small, focused team is far more effective. The key is getting the right perspectives in the room to understand the full picture.

For a typical near miss, your review team should probably include:

- The Area Supervisor: They know the specific work area, the crew, and the daily processes better than anyone.

- A Worker Representative: Pull in someone who does the actual job. They bring a ground-level view of how tasks are really done, which is often different from the official procedure.

- The Safety Manager: They're there to guide the process, ensure proper documentation, and help spot any underlying system failures.

This trio brings together operational knowledge, practical experience, and safety expertise, a balanced and effective combination.

Fact Finding, Not Fault Finding

This is the most important rule of any near-miss investigation: focus on the "what" and "why," not the "who." The moment the process feels like an interrogation, people will clam up and stop reporting. Your entire focus should be on understanding the sequence of events and the contributing factors.

The goal is to uncover system weaknesses, not to assign blame to an individual. An effective investigation concludes by identifying root causes like inadequate training, a faulty piece of equipment, or a flawed work procedure.

Start by asking open-ended questions to piece together what happened.

- "Can you walk me through what was happening right before this?"

- "What gear was being used at the time?"

- "Was there anything unusual about the conditions for that task?"

These questions encourage a story, not just a "yes" or "no." The aim is to get the full context. If you need more guidance on structuring these investigations, you can find a helpful incident reporting sample that shows how to document your findings clearly.

Developing Practical Corrective Actions

Once you've figured out the root causes, the next job is to come up with corrective actions that actually fix the problem. This is where so many processes fall apart. A vague instruction like "be more careful" is completely useless, it’s not a real corrective action.

Good corrective actions are specific, measurable, and assigned to a person with a deadline. They need to directly address the root causes you found.

| Root Cause Example | Weak Corrective Action | Strong Corrective Action |

|---|---|---|

| Trip Hazard | Clean the area. | Install a permanent bin for offcuts in Bay 3. John S. to complete by Friday. |

| Poor Visibility | Tell drivers to go slow. | Install a convex mirror on the corner of Aisle 4. Maintenance Team to complete by 25/11. |

| Machine Guard Missing | Remind staff about guards. | Fabricate and install a new guard for the lathe. Lock out machine until complete. Pete W. to complete by EOD. |

The difference is night and day. Strong actions are tangible tasks that permanently remove or control the hazard.

Closing the Loop and Communicating Outcomes

The final, and most critical, step is closing the loop. This means not only completing the corrective actions but also communicating the outcome back to the person who submitted the report and the wider team.

When workers see that their report about a forklift speeding through a doorway led directly to new traffic management rules and floor markings, it proves the system works. It shows them that reporting near misses is a vital part of keeping everyone safe, not just a box-ticking exercise. This builds trust and encourages everyone to keep their eyes open for the next potential hazard.

Tracking What Matters: Near-Miss KPIs and Metrics

Collecting near-miss reports is only half the job. Honestly, if the data just piles up in a folder somewhere, you're missing the entire point. The real value comes from using that information to spot patterns, identify emerging risks, and make smart, proactive decisions about where to focus your safety efforts.

This means moving beyond simply counting reports and starting to track what really matters.

This isn't about getting lost in complex spreadsheets or drowning in numbers. It's about picking a handful of key performance indicators (KPIs) that give you a clear, honest look at how your reporting system is working and what it's telling you about your worksite.

Moving Beyond Vanity Metrics

The most common mistake is teams focusing only on the total number of reports. Sure, a high volume can be a good sign of an engaged workforce, but it doesn't tell the whole story. A much better approach is to track metrics that measure the effectiveness and efficiency of your entire process, from the moment a report is submitted to when the issue is resolved.

Here are a few practical KPIs that are genuinely useful on Australian job sites:

- Number of Reports per Team or Area: This is a simple way to pinpoint hotspots. Is Workshop B reporting twice as many near misses as Workshop A? That could signal anything from a specific equipment issue to a need for more targeted training in that area. It gives you a place to start digging.

- Average Time to Close an Investigation: This one is huge. It measures how quickly you're acting on the information you receive. If reports are left sitting open for weeks, it sends a clear message that the process is broken, and people will quickly lose faith in it.

- Percentage of Reports Resulting in Corrective Action: This KPI shows whether your system is actually driving change. If the percentage is low, it might mean you're getting poor-quality reports, or perhaps your investigation process isn't getting to the root cause effectively.

The goal isn't just to track numbers for the sake of it. It's to use these metrics to ask better questions. Why is our time-to-close metric creeping up? What's driving the sudden spike in reports from the night shift?

Analysing the Data to Spot Trends

Once you start tracking these KPIs, you can begin looking for trends. This is where your near-miss data transforms into a powerful tool for predicting and preventing future incidents. By regularly reviewing the information, you can identify recurring issues long before they escalate into something serious.

We can learn a lot from industries like aviation, which has logged over 500,000 confidential near-miss reports over three decades in Australia alone. This data has shown that near misses happen 3 to 300 times more often than actual accidents, providing a massive pool of information to identify small failures before they become catastrophes. This kind of data is invaluable for predictive safety analysis. For a deeper look, you can discover more insights about predictive safety analysis on PMC.

Common trends to watch for on your own site include:

- Recurring Equipment Issues: Seeing multiple reports about the same forklift or a particular piece of machinery? That's a clear red flag pointing to a maintenance or replacement need.

- Specific Task-Related Risks: If several reports mention close calls during a specific task, like loading trucks or working at height, it’s a strong sign that the safe work procedure itself needs to be reviewed.

- Time-of-Day Patterns: Noticing a cluster of near misses towards the end of a long shift might indicate that fatigue is a bigger contributing factor than you realised.

Presenting Data for Decision Making

The final piece of the puzzle is presenting this information in a way that’s easy for management to understand and, more importantly, act upon. A simple, visual dashboard is far more effective than a dense, multi-page report that no one has time to read.

Use simple charts and graphs to display your key metrics. A line graph showing the "average time to close" over the last six months can instantly highlight if things are improving or getting worse. A bar chart comparing the number of reports by location quickly shows where the biggest risks are concentrated.

This is where a platform like Safety Space automates the entire process. It captures the data and presents it in real-time dashboards, turning your near-miss reports into a live, interactive tool for safety management. This lets you stop spending hours building reports and start focusing on making smart, data-driven decisions that genuinely improve safety on site.

Common Reporting Barriers and How to Fix Them

Even with a simple system in place, getting your crew to consistently report near misses can feel like an uphill battle. It's a common frustration. You know the data is valuable, but real-world barriers get in the way, causing even the most well-intentioned programs to fizzle out.

Understanding these roadblocks is the first step. The problems aren’t usually complex; they almost always boil down to human factors. Things like fear, scepticism, or just feeling like it’s too much hassle for zero reward.

Let's break down these issues and look at some practical ways to fix a reporting system that’s struggling to get traction.

The Fear of Blame

This is the number one killer of any reporting program. Full stop. If workers think reporting a near miss will land them, or a mate, in hot water, they’ll keep their mouths shut. Every single time. This fear isn't just about getting formally written up; it can be as simple as being blamed in a toolbox talk or getting a reputation as a troublemaker.

The only way to stamp this out is with a strict, well-communicated no-blame policy.

Your team has to believe, without a shadow of a doubt, that the focus is on fixing the system, not finding a person to pin it on. This message needs to come straight from the top and be hammered home by supervisors in every single conversation about a report.

When an investigation kicks off, it has to be a fact-finding mission, not a fault-finding one. That’s how you build the trust needed for people to feel safe speaking up.

"Nothing Will Change Anyway"

Scepticism is another huge hurdle. Many workers have been around the block and believe reporting is just a box-ticking exercise. They’re convinced their report will vanish into a black hole of paperwork, never to be seen or heard from again. And honestly, they're often right.

To fight this, you have to make the results impossible to ignore.

- Share the Wins: Regularly talk about the positive changes that have come directly from reports. Use team meetings or site notice boards to say something like, "Thanks to a report about slippery stairs near the site office, we've installed new grip treads." Be specific.

- Close the Loop Directly: This one is massive. Always follow up with the person who lodged the report. Let them know what action was taken because of their input. That personal feedback is incredibly powerful and shows their contribution was actually valued.

The Process Is Too Complicated

If reporting a near miss takes more than a couple of minutes, people won't do it. Simple as that. A clunky, multi-step process is a massive turn-off for a busy crew. Anything that feels like bureaucratic nonsense will be ignored.

The solution here is radical simplicity. Make it easier to report it than to ignore it. A QR code slapped on a toolbox that links straight to a three-field mobile form is a brilliant example. If someone can report a hazard from their phone in under 90 seconds, they're far more likely to actually do it.

Just as identifying and reporting near misses is crucial for physical safety, understanding how to prevent data breaches through strategic controls is vital for digital security. Both rely on clear processes and proactive measures.

Not Knowing What to Report

Sometimes, workers just don't have a clear picture of what actually counts as a near miss. They might think it needs to be a dramatic, life-threatening event. This confusion leads to the underreporting of all the small, everyday hazards that often precede a serious injury.

Clear communication and practical, relatable examples are your best tools here.

- Provide Simple Definitions: Use toolbox talks to explain what a near miss is, using real examples from your own workplace. "A box falling off a shelf and landing where someone was standing two seconds earlier, that's a perfect example of a near miss we need to know about."

- Use Visual Aids: Don't just talk about it, show it. Post photos of what to look for, frayed electrical cords, blocked fire exits, improperly stacked materials. This makes the concept of reporting near misses tangible and easy for everyone on site to grasp.

Your WHS Legal and Compliance Duties in Australia

In Australia, the rules around workplace safety aren’t just a set of nice-to-have guidelines, they're legal obligations. Under the Work Health and Safety (WHS) laws, your business has a primary duty of care to protect the health and safety of your workers.

This isn’t about just reacting when something goes wrong. It means you must actively hunt down and manage risks. A solid near-miss reporting system is one of the most practical ways to prove you’re taking that duty seriously.

Notifiable Incidents vs. Near Misses

It’s crucial to know the difference between a near miss and a 'notifiable incident'. A notifiable incident is the serious stuff, a fatality, a severe injury, or a dangerous event that must be reported immediately to your state regulator, whether that's SafeWork NSW, WorkSafe VIC, or another equivalent body.

A near miss, on the other hand, is an event that could have caused harm but thankfully didn't. You don’t have to call the regulator for every near miss, but you absolutely have to manage the risks they bring to light. Consistently documenting and acting on these reports is clear proof you're proactively managing safety on your site.

The Legal Duty to Manage Risks

WHS regulations don't just ask you to try; they legally require you to eliminate or minimise risks so far as is reasonably practicable. Every near-miss report you receive is a direct input into that process. Think of each one as a flag, highlighting a potential crack in your safety systems.

Ignoring this information isn’t just bad practice; it could easily be seen as failing to meet your legal obligations.

Proper record-keeping is a massive part of this. You need to be able to show a regulator, at a moment's notice, that you have processes for finding hazards and taking action. A well-maintained log of near-miss reports, investigations, and the corrective actions you took is a powerful record of your safety diligence.

If a WHS inspector visits your site after an incident, one of the first things they'll ask for is evidence of your risk management processes. A detailed history of near-miss reporting and resolution is one of the best ways to demonstrate you're on top of it.

This proactive mindset is a major reason for Australia’s comparatively strong safety record. The data shows Australia's workplace fatality rate is roughly half of New Zealand's, with Australian construction seeing approximately 2.93 fatalities per 100,000 workers. This difference is often put down to Australia’s emphasis on identifying risks early through methods like structured near-miss reporting. You can dig into the numbers by reading the full analysis of workplace safety rates on HazardCo.

Common Questions About Near-Miss Reporting

We get a lot of questions about the specifics of reporting near misses. Here are some straight answers to the most common ones we hear from teams on the ground.

What’s the Difference Between a Near Miss and an Incident?

This one trips people up all the time, but it’s pretty simple. A near miss is an unplanned event that could have caused an injury or damage but, by pure luck, didn’t. Think of a dropped hammer landing just a metre away from someone’s foot.

An incident, on the other hand, is when that luck runs out and the event does result in actual harm or damage. The hammer hits the foot.

The reason we obsess over near misses is that they're free lessons. They give you a chance to fix the underlying issue before it turns into a recordable injury.

Can I Report a Near Miss Anonymously?

Absolutely. In fact, many of the best reporting systems allow for it. The goal is to get the information, and if anonymity helps people feel comfortable speaking up without fear of blame, then it’s a massive win for everyone.

That said, providing a name can be helpful if the investigation team needs a few more details to solve the puzzle. A good system and management approach will always protect reporters from any kind of blowback, whether their name is attached to the report or not.

How Long Should It Take to Report a Near Miss?

It needs to be fast. Ridiculously fast. With a simple, mobile-friendly form, a worker should be able to flag the essentials in under two minutes.

If the process is clunky, complicated, or takes too long, people just won't do it. The goal is to make reporting a near miss easier than ignoring it and walking away.

Ready to make near-miss reporting simple and effective on your site? Safety Space replaces clunky paperwork with a fast, mobile-first platform that helps you capture, track, and resolve hazards in real-time. Book a free demo today to see how it works.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you build a safer, more compliant workplace with our comprehensive safety management platform.

Book a Free DemoRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.