It’s easy to get the terms risk assessment and risk rating mixed up, but the difference is pretty straightforward once you break it down. Think of it this way: the risk assessment is the process of finding hazards, while the risk rating is the score you give each one, like low, medium, or high, to decide what needs fixing first.

Clarifying Risk Assessment vs Risk Rating

Let's use an analogy. A risk assessment is like a full vehicle inspection before a long road trip. You or a mechanic would check everything: tyre pressure, brake fluid, engine oil, windscreen wipers. The point is to find anything that could go wrong and create a list of potential problems.

A risk rating, on the other hand, is the mechanic's final verdict on each item. This is the step that turns a list into an action plan. For example, "low tyre pressure" is a hazard you’ve identified. The rating tells you how urgent it is. A slightly low tyre might be a "Low" risk, but completely worn-out brake pads? That’s an "Extreme" risk that needs immediate attention.

The Core Difference

The key takeaway is that one is a process, and the other is a result. You perform a risk assessment to find the hazards. Then, you apply a risk rating to measure and rank them.

This distinction is vital. Without a rating, a long list of potential problems is just overwhelming. It doesn't tell your team on a busy manufacturing floor or construction site what to fix first. To see how this fits into the bigger picture, it helps to understand what is risk in risk management in more detail.

The rating process also brings objectivity and consistency to the table, making sure everyone from the site supervisor to the plant manager is on the same page about what counts as a severe danger.

A risk assessment finds the problems. A risk rating tells you which ones could shut you down tomorrow. It turns a simple checklist into a practical tool for prioritisation.

This systematic approach helps you direct limited resources, like your team's time and your budget, to the most critical issues first.

Risk Assessment vs Risk Rating At a Glance

To make it even clearer, here’s a simple side-by-side comparison. This table shows their distinct roles in keeping a workplace safe and compliant.

| Aspect | Risk Assessment | Risk Rating |

|---|---|---|

| Purpose | To identify and document all potential workplace hazards and who might be harmed. | To evaluate the severity and likelihood of each identified hazard to determine its priority. |

| Output | A comprehensive list of hazards (e.g., a risk register). | A specific score or level (e.g., a numerical value, Low/Medium/High, a colour code). |

| Analogy | A complete vehicle inspection to find all potential faults. | The mechanic's priority list of what needs fixing immediately versus what can wait. |

| Action | This is the "finding" step in the overall process. | This is the "ranking" step that drives subsequent actions and control measures. |

Ultimately, you can't have an effective rating without a thorough assessment, and an assessment without a rating is just a list of problems with no clear path to solving them. They are two sides of the same safety coin.

How to Calculate Ratings with a Risk Matrix

So, you've identified the hazards. What's next? The real trick is figuring out which ones to tackle first. This is where a risk matrix becomes your best friend. It’s a simple but useful tool used everywhere, from construction sites to factory floors, to give each hazard a score. Suddenly, that long, overwhelming list of problems turns into a clear, prioritised action plan.

A risk matrix works by looking at two key factors: how likely something is to go wrong (Likelihood) and how bad the fallout will be if it does (Consequence). By plotting these two on a grid, you get a risk rating that tells you exactly how urgently you need to act.

This isn't just about ticking boxes. In high-stakes industries like Australian construction and manufacturing, getting this right has been a game-changer for saving lives. Data from Safe Work Australia shows a dramatic drop in worker fatalities over the last two decades. The rate has fallen from 2.7 deaths per 100,000 workers to a record low of 0.9, a testament to taking risk assessment seriously.

Breaking Down the 5x5 Matrix

The most common tool for this job is the 5x5 risk matrix. It hits the sweet spot: detailed enough to be meaningful, but not so complex that it becomes a headache to use.

Let's look at the two sides of the matrix.

Likelihood is just a simple way of asking, "What are the chances of this actually happening?" On a 5x5 grid, the scale typically looks like this:

- 1 - Rare: Might happen once every 5-10 years. Think of a catastrophic failure of major, permanently installed factory equipment.

- 2 - Unlikely: Could happen once every couple of years. Maybe a spill from a fully bunded chemical storage area.

- 3 - Possible: Something that might pop up about once a year, like a worker straining their back from occasional manual lifting.

- 4 - Likely: Could happen several times a year. Minor cuts from handling materials without the right gloves are a classic example.

- 5 - Almost Certain: This happens all the time, daily or weekly. That trip hazard in a busy walkway that everyone knows about but no one has fixed? That's a 5.

Consequence measures how severe the damage will be if the incident occurs. Here's a typical breakdown:

- 1 - Insignificant: No real injury. Maybe a band-aid and a quick laugh. No damage to gear.

- 2 - Minor: First aid is needed. Perhaps some minor equipment damage that's easily fixed.

- 3 - Moderate: The person needs proper medical treatment. This usually means lost time and some moderate equipment damage.

- 4 - Major: A serious injury that requires a hospital stay. You're also looking at significant equipment damage and production downtime.

- 5 - Catastrophic: The worst-case scenario. A fatality, permanent disability, or a complete plant shutdown.

This simple flow chart shows how identifying hazards, rating them, and then taking action all fit together in a continuous loop.

As you can see, getting the risk rating is the critical middle step. It's the bridge between knowing about a problem and actually doing something about it.

Putting It into Practice with an Example

Alright, let's run through a real-world calculation. To get this right, you first need to understand how to prioritise risks in a risk register, which is all about scoring hazards based on their likelihood and potential severity.

The Hazard: An A-frame ladder is left unsecured in a busy walkway on a construction site. We've all seen it.

Figure out the Likelihood: The ladder is used daily by different tradies and is constantly left in a high-traffic spot. Based on our scale, the chance of someone bumping it and knocking it over is pretty high. We’ll give that a Likelihood Score of 4 (Likely).

Figure out the Consequence: If that ladder falls, it could easily strike a worker, causing a serious injury like a concussion or broken bones. That's a trip to the hospital. Let's call that a Consequence Score of 4 (Major).

Calculate the Risk Rating: Now for the simple maths. Just multiply the two scores.

Likelihood (4) x Consequence (4) = Risk Rating (16)

A score of 16 on a standard 5x5 matrix puts this hazard squarely in the "High Risk" zone. That's your cue. It signals that you need to take immediate action to control this hazard, whether that’s creating a strict procedure for ladder storage or setting up a designated, barriered-off area for their use.

To get a clearer picture of how these scores come together, here's a standard 5x5 matrix.

Example 5x5 Risk Matrix

| Likelihood | Consequence: Insignificant (1) | Consequence: Minor (2) | Consequence: Moderate (3) | Consequence: Major (4) | Consequence: Catastrophic (5) |

|---|---|---|---|---|---|

| Almost Certain (5) | 5 (Low) | 10 (Medium) | 15 (High) | 20 (Extreme) | 25 (Extreme) |

| Likely (4) | 4 (Low) | 8 (Medium) | 12 (High) | 16 (High) | 20 (Extreme) |

| Possible (3) | 3 (Low) | 6 (Medium) | 9 (Medium) | 12 (High) | 15 (High) |

| Unlikely (2) | 2 (Low) | 4 (Low) | 6 (Medium) | 8 (Medium) | 10 (Medium) |

| Rare (1) | 1 (Low) | 2 (Low) | 3 (Low) | 4 (Low) | 5 (Low) |

Our ladder example landed right on 16, clearly showing it as a high-priority issue. You can explore our guide to learn more about creating and using a risk management matrix that’s tailored to your specific workplace.

Applying Risk Ratings in Your Industry

Moving from theory to practice is where a solid risk rating system really proves its worth. It’s one thing to understand the matrix, but another to apply it when you’re looking at a real-world hazard on a busy worksite. Let's walk through how these ratings work in construction and manufacturing, turning abstract scores into clear, practical actions.

These examples show how a simple calculation can directly lead to specific safety controls. This makes the whole process tangible for supervisors, plant managers, and anyone responsible for safety on the ground.

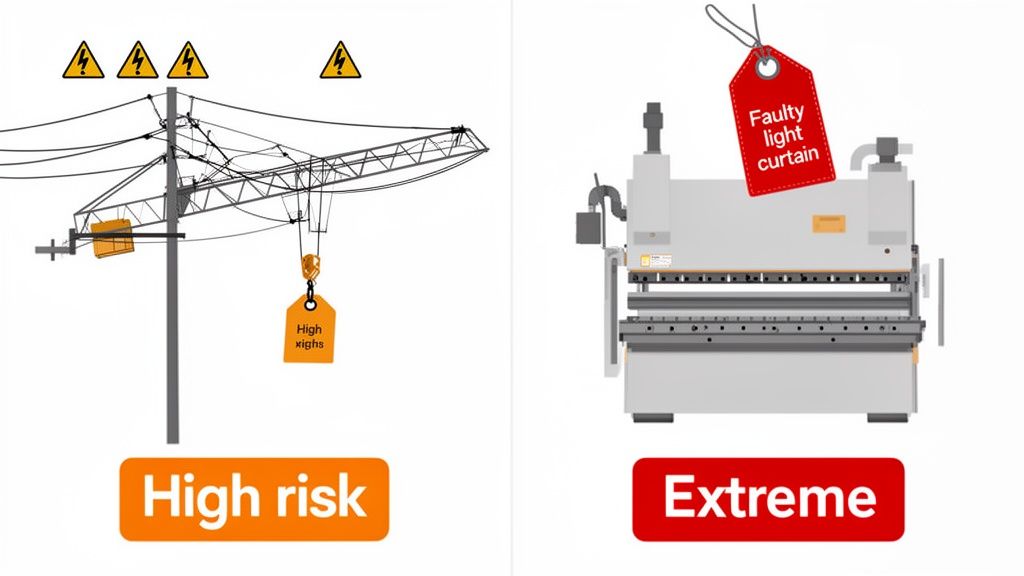

Construction Site Crane Lift

Picture a common but high-stakes scenario on a construction site. A crane is set to lift a heavy steel beam, but the lift path is uncomfortably close to overhead power lines. This is a classic high-risk task that requires a proper risk rating before anyone even thinks about starting.

1. Identify the Hazards The most obvious hazards here aren't just a single issue, but a cluster of critical ones:

- Electrocution: The crane boom or load line could easily make contact with the power lines.

- Dropped Load: A sudden electrical arc could cause the crane to fail, dropping a multi-tonne beam onto the site below.

- Arc Flash: Even without direct contact, getting too close can trigger a dangerous arc flash, severely burning anyone nearby.

2. Rate the Risk Now, let's apply scores from our 5x5 matrix to the primary hazard, electrocution.

- Likelihood: The lift is complex, requiring precise maneuvering near live wires. Without exceptional controls in place, the chance of something going wrong is significant. We'll rate this a 4 (Likely).

- Consequence: Contact with high-voltage power lines would almost certainly be fatal for the crane operator and riggers. This is a clear 5 (Catastrophic).

3. Calculate and Act The calculation is straightforward, but the result is serious.

Likelihood (4) x Consequence (5) = Risk Rating (20)

A score of 20 puts this task squarely in the "Extreme Risk" category. This rating isn't just a number; it’s a non-negotiable demand for action. Work simply cannot proceed until robust controls are in place.

This high rating means standard procedures are not enough. It forces the team to implement higher-order controls.

- Mandatory Controls: A clearly marked exclusion zone must be established. A dedicated, trained spotter, whose only job is to watch the distance between the crane and the power lines, is required.

- Additional Steps: The power authority may need to be contacted to de-energise the lines for the duration of the lift. If that’s not possible, insulated barriers ("tiger tails") must be installed on the lines by qualified professionals.

This process turns a vague concern like "be careful near the power lines" into a specific, actionable safety plan driven by an objective risk rating.

Manufacturing Plant Press Brake

Let's shift gears to a manufacturing plant. A metal press brake is used every day to bend sheet metal. An operator reports that the light curtain, a safety device that stops the machine if a hand enters the danger zone, has been intermittently faulty.

1. Identify the Hazards The primary hazard is clear, severe, and all too common.

- Amputation/Crushing Injury: If that light curtain fails at the wrong moment, an operator's hands or arms could be crushed by the press brake's ram. We're talking about a life-changing injury.

2. Rate the Risk The fact that this machine is part of the daily production workflow heavily influences its risk rating.

- Likelihood: The machine is used constantly through every shift, and the safety device is known to be unreliable. The chance of it failing at the exact moment an operator reaches in is incredibly high. This is an easy 5 (Almost Certain).

- Consequence: The outcome of such a failure would be catastrophic, leading to a permanent disability. We rate this as a 5 (Catastrophic).

3. Calculate and Act The final risk score paints a grim, undeniable picture.

Likelihood (5) x Consequence (5) = Risk Rating (25)

A score of 25 is the highest possible on a 5x5 matrix. It lands firmly in the "Extreme Risk" category, demanding an immediate stop-work response. There is no acceptable reason for this machine to continue operating.

The action isn't optional; it has to be immediate and decisive. The press brake must be isolated, locked out, and tagged out of service instantly. It cannot be used again until the faulty light curtain is repaired or replaced by a qualified technician and fully tested.

This is a perfect example of how a risk rating provides an objective, data-driven justification for halting production to prevent a tragedy.

Common Mistakes in Risk Rating to Avoid

A risk rating system is only as good as the people using it. Even with a perfect matrix, simple mistakes can render the entire process useless, leaving your team exposed and your business vulnerable.

Getting the rating wrong isn't just a paperwork error. It leads to misplaced priorities, wasted resources, and, worst of all, preventable incidents.

Here are some of the most common pitfalls teams fall into and, more importantly, how to sidestep them.

Overlooking Worker Input

One of the biggest mistakes is conducting a risk assessment from an office, completely disconnected from the factory floor or construction site. While managers have a critical perspective, they don’t perform the tasks every single day.

It’s the workers who actually operate the machinery or perform the high-risk jobs who have invaluable, hands-on knowledge. They know the informal workarounds, the equipment's quirks, and the near misses that never get reported. Ignoring their input means you’re working with incomplete and often inaccurate information.

The Fix: Make consultation a mandatory step. Don't just send out a survey; have genuine conversations with the people doing the work. Involve them directly in the risk assessment process, ask them to review your ratings, and listen when they tell you a 'low' risk feels much higher in reality.

Letting Subjectivity Creep In

What one supervisor considers a 'Medium' risk, another might label 'High'. This is a classic sign of vague definitions for likelihood and consequence. Without clear, agreed-upon standards, risk ratings become a matter of opinion, which completely undermines the goal of having an objective system.

This inconsistency leads to confusion and means the most serious hazards might be underrated simply because the person assessing them has a higher tolerance for risk. This kind of subjectivity is a major weak point in any risk assessment risk rating process.

A risk matrix without clear definitions is just a colourful chart. The definitions give it power and consistency, ensuring everyone speaks the same language of risk.

The Fix: Standardise your risk matrix across the entire company. Define exactly what each level of likelihood and consequence means in practical, tangible terms.

- Likelihood 4 (Likely): Don't just say 'likely'. Define it as "an event expected to occur several times per year at a specific site."

- Consequence 4 (Major): Don't leave it open to interpretation. Define it as "a single serious injury requiring hospitalisation or significant, non-repairable equipment damage."

When everyone uses the same ruler to measure risk, your ratings become consistent and far more reliable.

Suffering from Hazard Blindness

This is a subtle but dangerous trap. When a team works around a hazard every day, like a noisy compressor in a workshop or a cluttered walkway, they get used to it. This familiarity makes them underestimate its true risk.

"We've always done it this way" or "No one's been hurt yet" are classic warning signs of hazard blindness. The danger doesn't decrease just because people have become accustomed to it. This complacency often leads to the hazard being consistently underrated, leaving a serious accident waiting to happen.

The importance of objective, data-driven ratings is backed by broader analysis. Post-event analysis across various sectors shows that communities with index-based risk ratings saw 35% lower property losses in major events. Similarly, in a year with 12 major fire events in Western Australia, rated industrial sites reported zero worker fatalities from secondary hazards. You can find more data on how incidents are tracked by exploring the latest Australian Bureau of Statistics information on causes of death.

Getting Bogged Down in Paperwork

The final common mistake is treating the risk rating as the end goal. It's easy to spend weeks creating beautiful, detailed risk registers and matrices, only for them to sit in a folder on a shelf.

But the purpose of a risk assessment risk rating isn't to produce a document; it's to produce action.

If your 'Extreme' and 'High' risk items don't have immediate, assigned control measures with deadlines and responsible people, the exercise was a waste of time.

The Fix: Make the 'Action Plan' column of your risk register the most important one. For every significant risk identified, immediately assign a corrective action, a person responsible for seeing it through, and a clear due date. This turns your risk assessment from a passive report into an active management tool that drives real change.

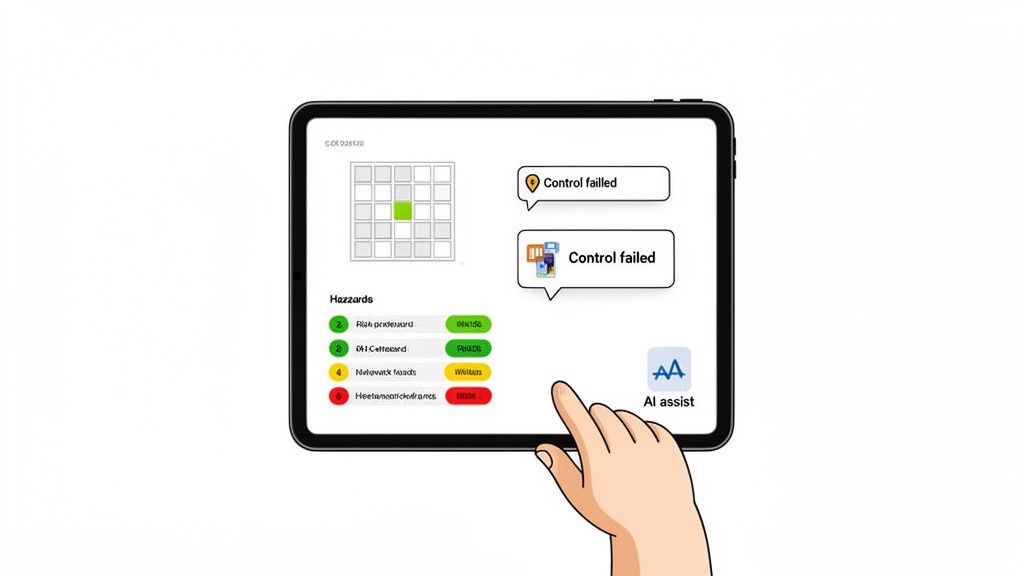

How Digital Tools Improve Risk Ratings

Let's be honest. Wrestling with paper forms or clunky spreadsheets often creates the very problems that make risk ratings unreliable in the first place. When different teams use their own templates or supervisors apply their own subjective judgement, consistency goes right out the window.

Digital tools cut through this chaos by moving your entire risk assessment risk rating process into a single, centralised system that everyone can actually use.

Instead of a dozen different spreadsheets floating around, everyone on your team, from the site office to the factory floor, uses the same digital risk matrix. This small change has a huge impact. It instantly standardises how likelihood and consequence are defined and applied, getting rid of the guesswork and "gut feel" ratings that cause so many headaches.

This shift moves your safety management from a static, paperwork-heavy exercise to a live, responsive system.

The image above shows a supervisor updating a risk rating directly from their tablet on site, a simple action that once required a trip back to the office to fill out a form. This real-time capability is one of the biggest advantages of modern health and safety platforms.

Real-Time Updates and Instant Notifications

One of the most powerful features of digital safety platforms is their ability to deliver real-time information. This is a game-changer for dynamic environments like construction sites and manufacturing plants where conditions can change in an instant.

Imagine a critical control measure fails on a construction site, say, a temporary guardrail is removed from an edge. A supervisor can update the task's risk rating from "Medium" to "Extreme" on their tablet, right there and then.

That simple action can automatically trigger notifications to the project manager and safety officer, ensuring the right people know about the increased risk immediately. This instant communication loop closes the gap between spotting a new hazard and taking action to control it, preventing incidents before they happen. For businesses managing complex projects, learning more about enterprise risk assessment software can highlight how these features work at scale.

With a digital system, a risk assessment is no longer a document that gets filed away and forgotten. It becomes a live dashboard that reflects the true state of your worksite at any given moment.

This live data feed allows managers to focus their attention and resources exactly where they are needed most, rather than waiting for a weekly safety meeting to find out about problems.

AI Assistance and Data-Driven Insights

Modern platforms also incorporate smart features that simplify the assessment process itself. Think of AI-powered form completion that can suggest common hazards and controls based on the task being assessed. This speeds up the initial data entry without sacrificing quality.

This allows your team to complete thorough assessments faster, freeing them up to focus on implementing controls rather than getting bogged down in paperwork.

Better yet, digital systems collect vast amounts of data that can be turned into practical insights. A dashboard can give a manager a live, visual overview of the highest risks across multiple sites, all in one place.

- Identify Trends: Are certain types of high-risk activities clustering at one particular site? This might point to a need for targeted training or new equipment.

- Track Control Effectiveness: You can monitor how quickly high-risk items are being closed out, giving you a clear measure of your team's responsiveness.

- Improve Accuracy: For industries like construction, where project variables are endless, specialised digital platforms such as an Exayard AI construction estimating platform can provide data accuracy that underpins sound financial risk assessments.

By collecting and organising this data, digital tools help you move from a reactive "put out the fire" approach to a proactive one. You can spot patterns and address underlying issues before they lead to an incident, making your entire risk management program far more effective and efficient.

Answering Your Questions About Risk Ratings

Even with a clear process, a few practical questions always pop up when you start applying a risk assessment risk rating system on the ground. We get it. Moving from theory to practice can be tricky.

This final section tackles some of the most common queries we hear from managers and supervisors in construction and manufacturing. Think of it as a quick guide to handling those real-world situations after you've done your initial assessments.

How Often Should We Review Our Risk Ratings?

Risk ratings aren't a "set and forget" exercise. They need to be live documents. Under Australian WHS laws, you’re legally required to conduct a formal review whenever a significant change happens. This isn't just good practice; it’s a core part of your compliance duties.

So, what triggers a mandatory review?

- A new hazard is identified: A new piece of machinery arrives on the factory floor, or a new chemical is introduced on site. You need to rate the new risks immediately.

- An incident or near-miss occurs: Any event, even one that doesn't cause an injury, is a massive red flag. It’s telling you that your controls and ratings might not be working as well as you thought.

- A control measure is not working: A guardrail is found to be flimsy, or you notice workers are consistently ignoring a specific procedure. The risk rating has to be revisited.

- Major changes to the work environment: This could be anything from bringing on a night shift to a major extension of your site.

For high-risk industries like construction and manufacturing, we strongly recommend scheduling proactive reviews at least once a year, even if none of these triggers pop up. Digital platforms are great for this, as they can automate review reminders so nothing important gets missed.

What Is the Difference Between a Hazard and a Risk?

This is one of the most fundamental concepts in safety, but it's amazing how often people get them mixed up. Getting the distinction right is crucial for an effective risk assessment risk rating because it helps your team focus on the actual danger, not just the source of it.

Here’s a simple way to think about it: a hazard is anything with the potential to cause harm. It’s the thing itself. A risk is the likelihood that the hazard will actually hurt someone, combined with how severe that harm would be.

Let's look at a couple of real-world examples:

- An unguarded machine press is the hazard. The high risk is the chance of amputation for an operator in a busy factory.

- A slippery, wet floor is the hazard. It presents a high risk of a serious fall in a main walkway, but a very low risk in a locked storage closet that nobody ever enters.

Your assessment identifies the hazards, but your rating evaluates the actual risk they create in their specific context. That’s why the same hazard can have completely different risk ratings depending on the situation.

A hazard is the loaded gun. The risk is the chance it will actually go off and the damage it will do when it does. Focusing on risk helps you prioritise which hazards need to be made safe first.

Can a Low Risk Rating Ever Be Unacceptable?

Absolutely. A 'low' rating doesn't mean 'no action required'. This is a trap that's easy to fall into. The guiding principle in Australian workplace safety is to eliminate or reduce risks 'so far as is reasonably practicable'. This is a critical legal and ethical standard.

A risk that you've rated as 'low' might still be unacceptable if there’s a simple, cheap, and easy control measure available to get rid of it completely. The rating helps you prioritise, but it doesn't give you a pass on your fundamental duties.

For example, imagine a slightly raised edge on a concrete path. You might rate it as a 'low' risk trip hazard. But if it can be ground down and fixed in five minutes by a worker who already has the right tool, it’s not 'reasonably practicable' to just leave it there.

Always come back to the hierarchy of controls. If you have a straightforward opportunity to eliminate a hazard entirely, you should take it, no matter how low its initial risk rating might be.

Who Is Responsible for Conducting the Risk Assessment?

In Australia, the legal responsibility lands squarely on the 'Person Conducting a Business or Undertaking' (PCBU). This is the business entity itself, the company. Ultimately, the buck stops with the business leadership.

However, the process of actually doing the assessment has to be a team effort. A manager filling out forms in an office will never have the full picture. For a risk assessment risk rating to be accurate and truly effective, it must be done in consultation with the people who are directly exposed to the risks every day.

A solid assessment team should always include:

- Workers: They have the hands-on, practical knowledge of the tasks and what really happens on the floor.

- Health and Safety Representatives (HSRs): They are the elected voice for workers on safety matters and are a vital link.

- Supervisors and Managers: They bring operational oversight and are responsible for putting the controls into action.

Using a simple, accessible system, especially a digital one, makes it much easier for everyone to have their say. This collaborative approach ensures your final risk ratings are based on reality, not just assumptions made from a distance.

Ready to move beyond spreadsheets and paperwork? Safety Space offers an all-in-one platform that makes managing your risk assessments simple, consistent, and effective. See how you can protect your team and your business by booking a free demo at https://safetyspace.co.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.