Risk management in construction isn't just about ticking boxes for compliance. It’s a practical way of thinking that protects your project’s budget, timeline, and quality from going off the rails. Think of it less as a safety exercise and more as a core business strategy to head off expensive delays and operational headaches before they start.

Why Risk Management Is a Business Necessity

Ignoring risk management in this industry is a surefire way to find yourself in a financial hole. It’s about getting in front of the dozens of things that can derail a project, from sketchy supply chains and labour shortages to wild weather and surprise regulatory changes.

Every project is a massively complex operation. Without a clear plan to manage these variables, you’re basically just gambling with the outcome. And we all know how quickly a small, ignored issue can snowball into a major crisis, triggering rework, disputes, and serious financial pain.

The Real Cost of Poor Planning

The damage from weak risk planning isn't just a theory; it's a harsh reality. The Australian construction industry is filled with examples of projects crippled by a failure to plan.

Mega-projects over $200 million regularly blow their budgets by more than 30%. Even worse, a staggering 77% of them are delayed by over 40%. These aren't just numbers. They represent the real-world impact of failing to get a handle on supply chain snags and regulatory hurdles. Over the last 30 years, these slip-ups have cost the sector around $47 billion in lost opportunities. A national infrastructure risk study lays it all out in grim detail.

Think of a proactive risk management plan as a financial shield for your project. It turns unpredictable threats into variables you can actually manage, putting you back in control of your budget and timeline.

Protecting Your Bottom Line

A practical approach to risk management has a direct, positive impact on your business. Here’s how:

- Prevents Budget Blowouts: When you spot financial risks early, like a jump in material prices or unexpected ground conditions, you can build realistic contingencies into your budget.

- Keeps Schedules on Track: A good plan anticipates delays. Whether it's equipment failure, subcontractor no-shows, or permit hold-ups, you can buffer against the domino effect.

- Reduces Costly Rework: Catching design clashes or buildability issues before the work starts saves a massive amount of time and money that would otherwise be burned on corrections.

- Improves Project Stability: When you systematically tackle potential problems, your project becomes far more predictable and less chaotic to manage from start to finish.

Ultimately, strong risk management is just about making better, more informed decisions. If you want to learn more about the nuts and bolts, our guide on the ISO 31000 risk management framework is a great place to start.

Identifying Critical Risks on Your Construction Site

To get a handle on risk management, you first need a clear picture of what you're up against. Moving from theory to the job site means organizing potential threats into practical categories. This helps you build a mental checklist to spot issues before they blow up.

Risks on a construction site aren't just about hard hats and steel-toed boots; they cover everything that can derail your project's timeline, budget, and legal standing. By breaking them down, you can start tackling them systematically instead of just fighting fires.

To help you see the bigger picture, here’s a quick breakdown of common risks and how they can directly impact your bottom line.

Common Construction Risks and Their Business Impact

| Risk Category | Specific Example | Potential Business Impact |

|---|---|---|

| Financial Risks | Sudden increase in material costs (e.g., timber, steel) | Project budget overruns, reduced profit margins |

| Operational Risks | Breakdown of essential machinery (e.g., crane, excavator) | Significant project delays, increased labour costs |

| Safety Hazards | A serious fall from height incident | Work stoppage, hefty fines, workers' compensation claims, reputational damage |

| Legal/Contractual | Vague scope of work in a subcontractor agreement | Costly disputes, change orders, project delays, potential litigation |

| Environmental Risks | Discovery of contaminated soil on-site | Unforeseen remediation costs, fines from EPA, project suspension |

Thinking about risks in these terms makes it clear that a small oversight in one area can have a massive ripple effect across the entire project.

Financial and Operational Risks

Financial risks are the ones that hit your project's budget directly. Think of a sudden spike in steel prices or a key supplier going bust. If you haven't planned for these curveballs, they can throw your entire cost forecast into chaos.

Operational risks are tied to the daily grind of running the site. This bucket includes everything from a critical equipment breakdown to logistical nightmares and unexpected labour shortages. One key operational risk is ensuring everyone follows the rules for preventing vehicle overloading with heavy machinery; it’s a massive safety and compliance issue.

A project can be perfectly designed and fully funded, but if your primary excavator breaks down for a week, the entire schedule grinds to a halt. Operational risks create a domino effect that impacts every other part of the job.

Critical Safety Hazards

Let's be blunt: construction remains a high-risk game for worker safety in Australia. The industry accounted for 9% of the workforce in 2012–13 but a disproportionate 10% of all workers' compensation claims.

While serious claims dropped by 31% between 2001 and 2012, the rate was still the fourth highest in the country. Tragically, between 2002 and 2014, 417 workers died from job-related injuries. You can dig into the full Safe Work Australia construction industry profile for the hard data.

These aren't just statistics; they represent real people and families devastated by preventable accidents. Spotting these hazards is the first step in making sure they don't happen on your site.

Common safety hazards we see time and again include:

- Falls from height: Working on scaffolding, roofs, or ladders without proper fall protection.

- Moving objects: Incidents involving vehicles, cranes, or falling materials.

- Trench collapses: Excavations without adequate shoring or support systems.

- Electrical shocks: Contact with live overhead or underground power lines.

For more information, check out our guide on common hazards in the workplace.

Legal and Contractual Risks

Finally, there are the legal and contractual risks that can quietly sink a project. These issues often bubble up from poorly written contracts, arguments with subcontractors, or a simple failure to get the right permits.

For instance, a vague scope of work can lead to endless debates and expensive change orders. Likewise, failing to comply with local council rules or environmental protection laws can result in eye-watering fines and stop-work orders, bringing your project to an immediate and costly standstill. These risks are exactly why clear paperwork and diligent oversight aren't just nice-to-haves, they're non-negotiable.

Your Step-by-Step Risk Management Plan

Knowing what the risks are is one thing. Having a practical plan to deal with them is what separates successful projects from chaotic ones. A solid risk management process doesn't need to be complicated. It's about setting up a clear, repeatable system that your entire team, including every single subcontractor, can understand and follow.

Here’s a straightforward, five-step roadmap to build your risk management plan from the ground up. Each step is designed to be actionable, helping you turn theory into daily practice on your job site.

Step 1: Write a Clear Risk Policy

Your risk policy is the foundation of your entire plan. Think of it as a simple, high-level document that states your company's commitment to managing risk and outlines who is responsible for what. It doesn't need to be a 100-page novel.

A good policy clearly defines the why behind your risk management efforts. For example, it should state goals like preventing project delays, protecting the budget, and making sure all workers go home safely. It also assigns accountability, clarifying the roles of project managers, site supervisors, and safety officers in the process.

This document sets the tone for everything else. It makes it clear that managing risk is a core part of the job, not just some afterthought.

Step 2: Build a Comprehensive Risk Register

A risk register is your central tool for tracking and managing threats. Picture it as a live spreadsheet that lists every potential risk, its possible impact, and the plan to handle it. Critically, this isn't a document you create once and file away; it's a dynamic tool for daily decision-making.

Your risk register should be simple and easy for your team to use. At a minimum, it needs to include:

- Risk Description: A clear, simple explanation of the potential issue (e.g., "Unexpected heavy rainfall flooding the main excavation site").

- Likelihood: How likely is this to happen? (A simple Low, Medium, High scale works well).

- Consequence: If it does happen, how bad will it be? (Again, keep the scale simple).

- Risk Rating: A score based on likelihood and consequence to help you prioritize what to tackle first.

- Control Measures: What specific actions will you take to prevent or reduce the impact?

- Person Responsible: Who on your team owns this risk and is responsible for seeing the controls through?

- Status: Is the risk open, being monitored, or closed?

The key here is to keep it practical. A well-maintained risk register gives you a real-time overview of the biggest threats to your project, allowing you to focus your attention where it's needed most.

Step 3: Apply the Hierarchy of Controls

Once you've identified and prioritized your risks, the next step is deciding how to control them. The hierarchy of controls is a proven system that ranks control methods from most effective down to the least. You should always start at the top and work your way down.

- Elimination: The absolute best control is to completely remove the hazard. A great example is designing a building with pre-fabricated components to reduce the amount of high-risk work done at height.

- Substitution: Replace a hazardous material or process with a safer one. This could be as simple as using a less toxic chemical or a different type of machinery that's inherently safer.

- Engineering Controls: Physically change the work environment to isolate people from the hazard. Think of installing guardrails around open edges or using powerful ventilation systems to remove dust from the air.

- Administrative Controls: Change the way people work through new procedures and training. This includes things like job rotation to limit exposure, clear warning signs, and Safe Work Method Statements (SWMS).

- Personal Protective Equipment (PPE): This is your last line of defence. Providing hard hats, gloves, and safety glasses is crucial, but it should only be relied upon after all other, more effective controls have been considered.

By following this hierarchy, you address risks in the most robust way possible. If you find yourself relying solely on PPE, it's often a sign that more effective controls haven't been properly implemented further up the chain.

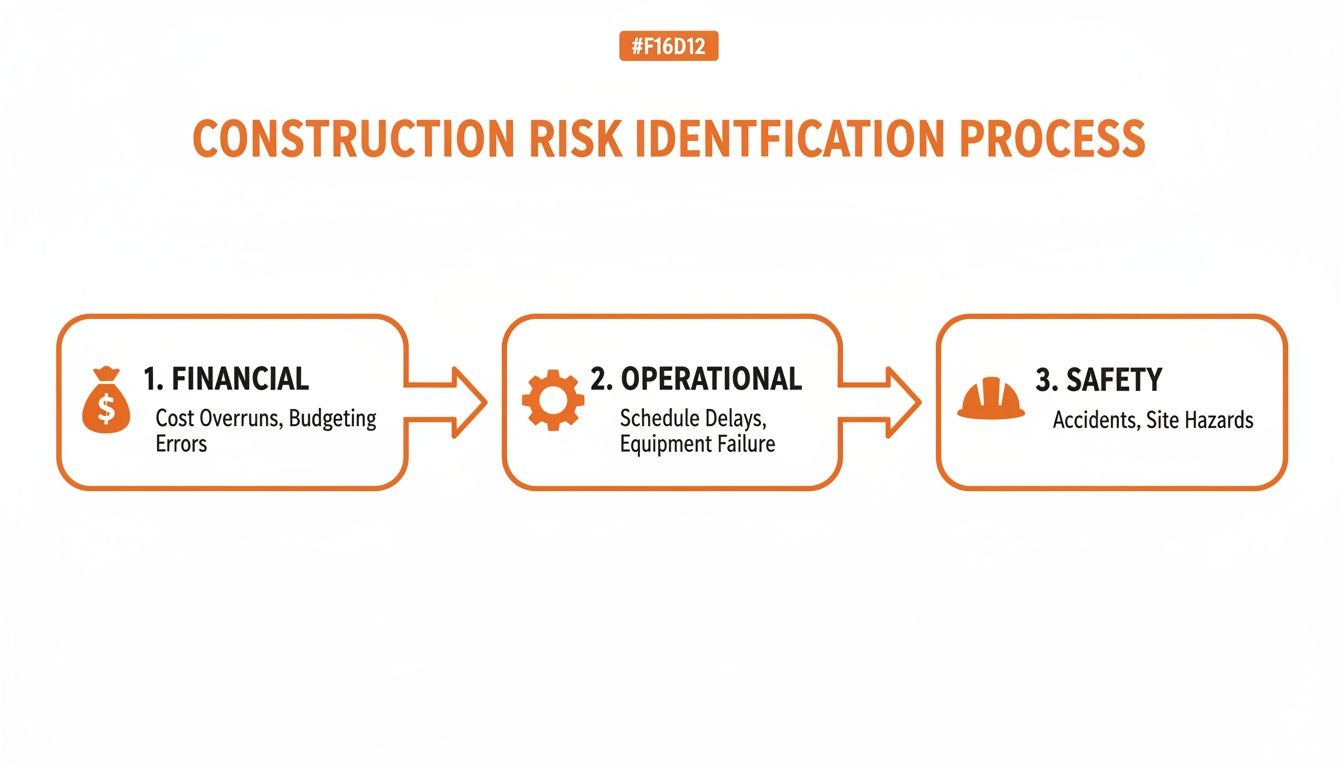

This flowchart shows the common categories risks fall into during the identification phase.

This visual guide helps teams categorize threats into financial, operational, and safety buckets, which forms the basis for a well-structured risk register.

Step 4: Organize Effective Training

Your risk management plan is only as good as the people putting it into practice. Effective training is non-negotiable to make sure your crew and subcontractors understand the risks and know exactly how to apply the controls you've put in place.

Training isn't a one-and-done event. It has to be ongoing and specific to the tasks being performed. This means daily toolbox talks on specific hazards, formal inductions for new starters, and specialized training for high-risk activities like operating cranes or working in confined spaces.

Step 5: Set Up Subcontractor Oversight

Finally, you need a solid system for managing the risks your subcontractors bring onto the site. Your responsibility for site safety and project outcomes doesn't end where their contract begins. You have to make sure their safety systems and on-site actions align with yours.

This involves a few key actions:

- Prequalification: Before they even set foot on site, review their safety record, insurance, and risk management procedures. Don't be afraid to ask tough questions.

- Clear Contracts: Make sure your contracts explicitly outline their safety and risk responsibilities in plain English.

- Onsite Monitoring: Regularly check that their teams are following the agreed-upon procedures and using the correct controls. This is about being visible on-site, not just ticking boxes in the office.

Good subcontractor oversight gets consistency across the entire project, massively reducing the chances of an incident caused by a breakdown in communication or standards. It's an absolutely vital part of a complete risk management plan.

Practical Risk Assessment Methods for the Job Site

So, you’ve got your risk register sorted. That’s a great first step, but now it’s time to assess the risks you’ve listed. This is where we move beyond just identifying problems and start figuring out how serious they really are.

Don’t let the term "risk assessment" intimidate you. At its core, it’s just a practical way to sort the major threats from the minor ones so you know where to focus your energy.

There are two main ways to approach this. Quantitative assessment is the numbers-heavy method, using financial modelling and hard data to put a dollar value on risk. It has its place in high-level corporate planning, but it’s often overkill and far too complex for day-to-day site management.

For the decisions you make on the ground, qualitative assessment is your best friend. This approach relies on descriptive scales, experience, and good judgment to classify risks. It’s fast, simple, and perfectly suited to the fast-paced environment of a construction site. The go-to tool for this is the risk matrix.

Using a Risk Matrix Effectively

A risk matrix is a simple grid that helps you score a risk based on two things: its likelihood (how likely is it to happen?) and its consequence (how bad will it be if it does?). By plotting these two factors, you get a clear risk rating, Low, Medium, High, or Extreme, that points you directly to your biggest problems.

It’s a visual tool that cuts right through the noise. Instead of getting bogged down in complex calculations, your team can see at a glance which hazards demand immediate action and which can be managed with standard procedures. This is why it’s so central to construction safety. It’s easy to teach, easy to understand, and easy to apply.

The real power of a risk matrix is that it turns a subjective feeling about a hazard into a structured, defensible decision. It provides a common language for everyone on site to talk about and prioritize safety issues.

This simple framework also makes your assessment process repeatable. You can apply the same logic to a trip hazard, a potential equipment failure, or a scheduling conflict, which brings consistency to your entire project.

If you want to explore more advanced ways to visualize threats and controls, our article on the BowTie risk assessment method dives into another powerful technique.

To make this even more practical, here’s a simple risk matrix you can adapt for your site.

Simple Risk Matrix for On-Site Use

This 5x5 matrix helps you quickly determine a risk rating. Just find the likelihood of the event happening on the vertical axis and match it with the potential consequence on the horizontal axis. Where they meet is your risk rating.

| Likelihood | Consequence Level 1 (Insignificant) | Consequence Level 2 (Minor) | Consequence Level 3 (Moderate) | Consequence Level 4 (Major) | Consequence Level 5 (Catastrophic) |

|---|---|---|---|---|---|

| 5: Almost Certain | Medium | High | High | Extreme | Extreme |

| 4: Likely | Low | Medium | High | High | Extreme |

| 3: Possible | Low | Medium | Medium | High | High |

| 2: Unlikely | Low | Low | Medium | Medium | High |

| 1: Rare | Low | Low | Low | Medium | Medium |

As you can see, a task with a ‘Catastrophic’ consequence doesn’t need to be ‘Almost Certain’ to warrant an ‘Extreme’ risk rating. This visual guide is invaluable for toolbox talks and pre-start meetings.

A Real-World Example: Working at Heights

Let’s put the matrix to work. Imagine your crew is installing roof trusses on a two-storey house. The risk is obvious: a fall from height.

Here’s how you’d assess it, step by step.

Identify the Hazard: Working on an unguarded roof structure more than two metres above the ground.

Assess the Likelihood: Without any safety controls, workers are near open edges all day. You’d probably rate the likelihood as ‘Likely’ or even ‘Almost Certain’. On a 1-5 scale, let's call it a 4.

Assess the Consequence: If someone falls from that height, the outcome is going to be terrible. A serious injury or fatality is a very real possibility. You'd rate the consequence as ‘Major’ or ‘Catastrophic’. We'll score it a 5.

Determine the Risk Rating: Now, you plot those scores on your matrix. A likelihood of 4 and a consequence of 5 lands you squarely in the ‘Extreme’ risk category. This is a clear stop sign. The work cannot proceed as planned.

Apply Controls and Re-assess: Time to bring in the hierarchy of controls. You install temporary edge protection (an engineering control) and make fall arrest systems mandatory for everyone on the roof (PPE). With these controls in place, you assess the risk again.

The likelihood of a fall is now drastically lower, maybe ‘Unlikely’ (a score of 2). The potential consequence is still catastrophic if both systems somehow fail, but the overall risk rating plummets to ‘Medium’ or even ‘Low’. This simple process proves your controls are working and the task is now safe to proceed.

Navigating Your Legal and Regulatory Duties in Australia

Let's be clear: staying on the right side of Australia's Work Health and Safety (WHS) Act isn't just about ticking boxes. It's the absolute bedrock of risk management in the construction industry. The law spells out your responsibilities to keep people safe, and dropping the ball can lead to crippling penalties, project shutdowns, and a reputation that’s hard to rebuild.

Think of these duties as the first line of defence in your risk management plan. Getting them right is essential. Forgetting them can turn a simple site hazard into a costly legal nightmare.

The PCBU and Your Duty of Care

Under Australian WHS law, the buck stops with the Person Conducting a Business or Undertaking (PCBU). This isn't just a fancy term for the main contractor. It’s a broad definition that can pull in clients, developers, and even key subcontractors. If you're running a construction project in any significant capacity, you're almost certainly a PCBU.

Your core legal obligation as a PCBU is your duty of care. This means you must do everything that is reasonably practicable to protect the health and safety of your workers. And that net is cast wide. It covers your direct employees, your subbies, site visitors, and even the public who might wander past your site.

"Reasonably practicable" is the key phrase here, and it's what gets debated in court. It means you have to weigh up the likelihood and seriousness of a risk against the real-world options to fix it, considering things like cost, time, and available methods. Simply saying a safety measure was "too expensive" is rarely a defence that holds up.

State-Specific Rules: What to Watch for in WA and SA

While the national WHS Act sets the foundation, each state adds its own flavour with specific regulations and codes of practice. If you're working in Western Australia or South Australia, you absolutely have to know the local priorities.

- Western Australia (WA): WorkSafe WA puts a huge emphasis on high-risk activities like crane operations, scaffolding, and mobile plant. They're also increasingly focused on psychosocial hazards, things like workplace bullying and burnout, which are getting a lot more regulatory attention.

- South Australia (SA): In SA, SafeWork SA keeps a close eye on risks like asbestos management, electrical safety, and especially fall prevention. They have incredibly detailed codes of practice for these areas, and they expect PCBUs to know them inside and out.

Ignoring these state-level focuses is a rookie mistake that can cost you dearly. Always jump on the local regulator’s website (WorkSafe WA or SafeWork SA) to get the latest codes and safety alerts for your type of work.

Staying Compliant When Times Get Tough

Let’s be honest, managing all this has become even harder in the current economic climate. The Australian construction sector is navigating a perfect storm of rising insolvencies and sky-high costs.

In the nine months to March 2024, a staggering 27.7% of all company insolvencies were in the construction industry. With project costs jumping over 30% since the pandemic and material prices all over the place, the temptation to cut corners on safety is real. But the legal and financial risks of doing so have never been higher.

You can get a deeper look into these economic pressures by reading the QBE Australian Construction Sector Outlook 2024.

Using Digital Tools to Manage Site Risks Effectively

Let's be honest: relying on paper forms and spreadsheets for risk management is a huge liability on a modern construction site. We’ve all seen it. A completed safety form sitting on the dash of a ute is completely useless to the project manager in the site office.

This old way of working is slow, impossible to track, and creates dangerous information gaps. When data is fragmented across different clipboards and spreadsheets, spotting recurring issues or dangerous trends is just a guessing game. It forces you into a reactive mode, always one step behind the next potential incident.

Moving Beyond Paper and Spreadsheets

This is exactly where centralized safety management platforms come in. By moving all your risk processes into a single digital system, you connect your entire team with one source of truth, from the site supervisor right through to the subcontractors.

This simple shift fixes the biggest weaknesses of manual systems:

- Real-Time Monitoring: Instead of waiting for a pile of paperwork at the end of the day, managers see hazards logged, forms completed, and actions assigned the moment they happen.

- Instant Communication: Information flows freely. A new risk identified on one side of the project can be communicated to every relevant team immediately, not just flagged at tomorrow's toolbox talk.

- Less Admin Drudgery: Digital forms with pre-filled fields and automated workflows slash the time spent on repetitive paperwork. This frees up your team to focus on what actually matters, proactive site management.

How a Digital Platform Works in Practice

Picture this: a supervisor spots an unguarded edge on level three. Instead of scribbling a note (and hoping it doesn't get lost), they pull out their tablet, open an app, and log the hazard. They can snap a photo, tag the exact location, assign a corrective action to the responsible subbie, and set a deadline. The whole process takes less than a minute.

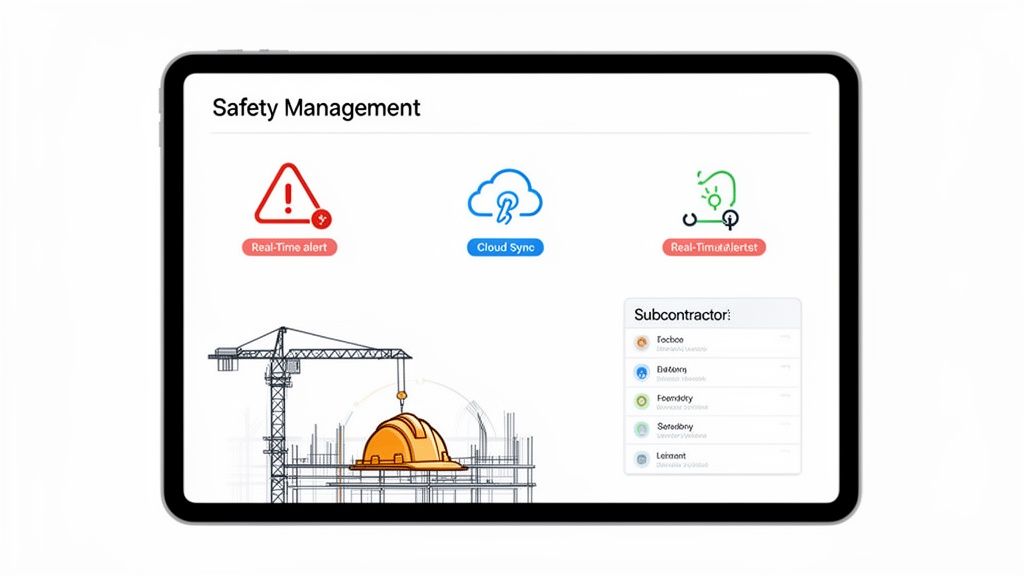

This is what a dedicated platform like Safety Space brings to a project.

The dashboard gives managers an instant, at-a-glance overview of critical safety metrics and open issues, showing them precisely what needs their attention right now.

A huge advantage of going digital is the ability to spot problems early, before they snowball into costly incidents. By tracking data over time, you can identify which subcontractors might have recurring safety issues or which types of hazards are most common on your sites, allowing you to step in with targeted training or support.

It's also worth keeping an eye on how other technologies are changing the game. For instance, understanding drone use in construction shows how aerial surveillance is becoming a standard tool for monitoring site progress and spotting hazards from a safe distance.

Ultimately, bringing digital tools into your workflow is about making risk management an active, integrated part of your daily operations, not a separate, paper-shuffling chore. It gives you the visibility and speed you need to properly manage risk on today's complex construction sites.

Got Questions About Construction Risk Management?

Even with the best-laid plans, things get messy on a busy construction site. Theory is one thing, but practice is another. Here are some straight answers to the questions we hear all the time from site managers and project leads trying to get this right.

Where Do I Even Start With Risk on a New Project?

The very first thing you should do is build a simple risk register. Seriously, before a single boot hits the ground, get your key people in a room and just start brainstorming potential threats.

Don't aim for perfection here. The goal is to just get a list down, anything and everything that could throw your budget, schedule, or safety standards off track. This simple act forces you to think ahead from day one, rather than just reacting when things inevitably go wrong. That initial list is the foundation for everything that follows.

How Often Should We Be Looking at Our Risk Register?

Think of your risk register as a living document, not a "set and forget" exercise you do once. For most projects, running through it in the weekly site meeting is a decent baseline. But honestly, it needs to be updated the moment something changes.

A risk register that’s only reviewed monthly is already a historical document. New hazards pop up, a new subbie arrives on site, the weather forecast shifts, it all matters. The best teams treat it like a daily tool, with supervisors adding notes as they see things happen.

Put it this way: if your crew spots a new, serious hazard during the morning pre-start, it needs to be in the register now, not next week. The pace of your project should dictate how often you’re reviewing your risks.

What’s the Difference Between a Hazard and a Risk, Really?

This is a big one, and it trips a lot of people up, but the distinction is actually pretty simple once you get it.

A hazard is just something with the potential to cause harm. It’s the thing itself. Think of an unguarded edge, a dodgy electrical lead, or a poorly stacked pallet of bricks.

A risk is the likelihood that the hazard will actually hurt someone, combined with how bad the damage could be.

Let's break it down:

- Hazard: An open trench on site.

- Risk: The high likelihood of a worker falling in and suffering a serious injury, especially if there are no barriers up.

Spotting hazards is about keeping your eyes open for dangerous conditions. Managing risk is about figuring out the odds of that condition causing an incident and then doing something meaningful about it. Nailing this difference is fundamental to effective risk management in the construction industry.

Can't We Just Transfer All the Risk to Our Subbies?

In a word? No. While your contracts can and absolutely should outline responsibilities, under WHS law, the principal contractor (the PCBU) almost always holds the ultimate duty of care. You can delegate tasks, but you can't delegate your final legal responsibility for site-wide safety.

Good subcontractor management isn't about offloading blame. It’s about making sure every single person and company on your project is held to the same high standard. You get this with solid pre-qualification, clear contracts, and boots-on-the-ground monitoring, not by hiding behind a clause in a legal document.

Ready to stop juggling spreadsheets and paper forms? Safety Space provides a single, easy-to-use platform to manage all your risk assessments, hazard reporting, and subcontractor compliance in real time. Book a free demo today and see how you can build a safer, more efficient project.

Ready to Transform Your Safety Management?

Discover how Safety Space can help you implement the strategies discussed in this article.

Explore Safety Space FeaturesRelated Topics

Safety Space Features

Explore all the AI-powered features that make Safety Space the complete workplace safety solution.

Articles & Resources

Explore our complete collection of workplace safety articles, tools, and resources.